Apparatus and method for supplying foils

A kind of equipment and foil technology, which is applied in the field of foil supply equipment, can solve the problems of foil tension change, pull-out force is not constant, etc., and achieve the effect of constant tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

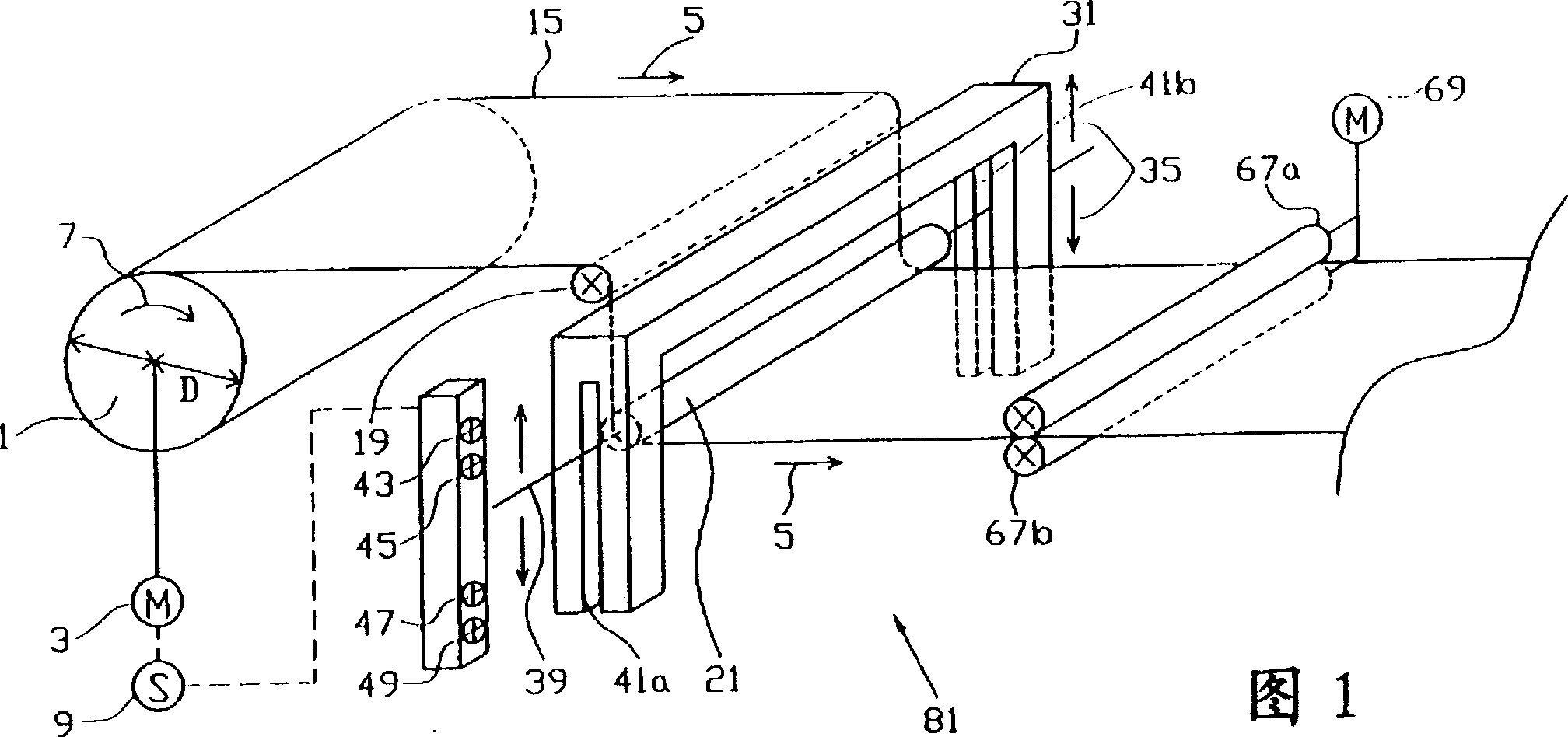

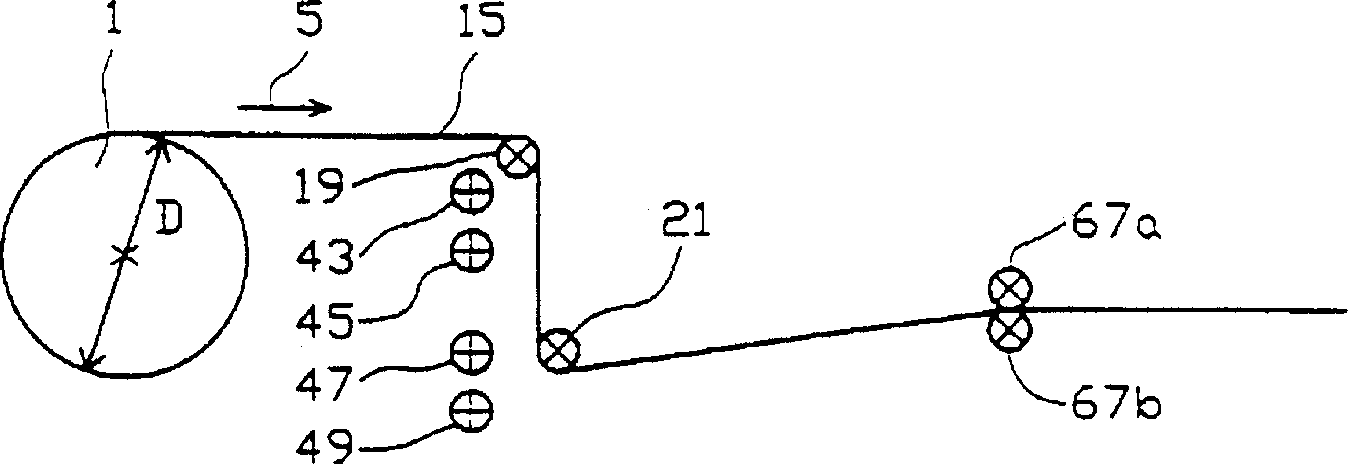

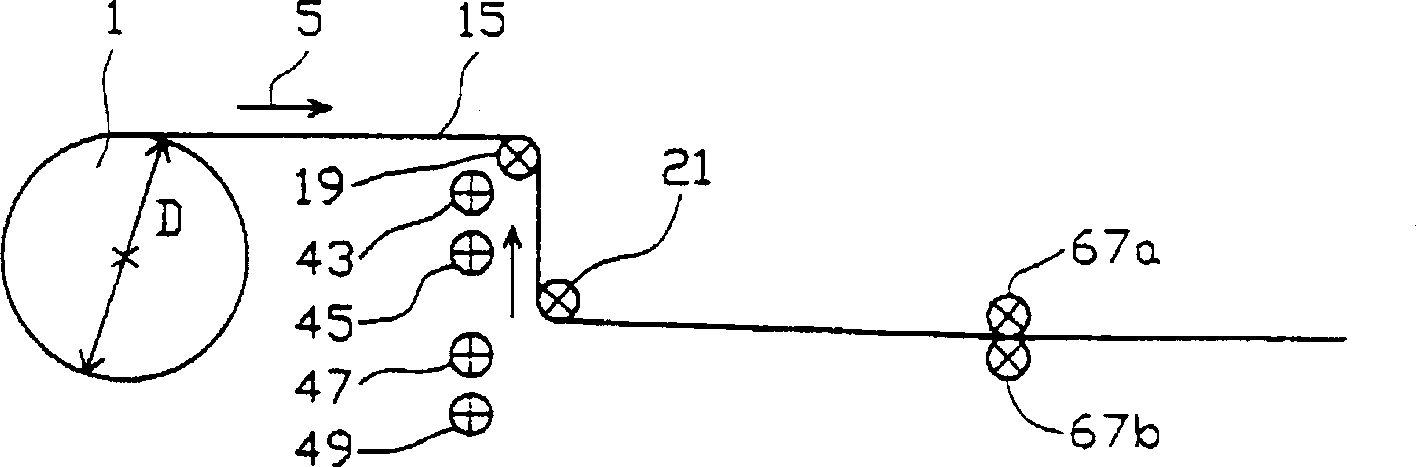

[0029] 1 and 2 show a first embodiment of the device according to the invention. 1 denotes a supply roll whose diameter D gradually decreases as the unwinding operation proceeds. The foil 15 is unwound from the supply roll 1 and guided in the consumption sensor 81 to move around the fixed deflection roll 19 and the movable sensor roll 21 . 67a and 67b schematically show pulling means, such as rollers connected to the foil by friction grippers and running at a speed and rate corresponding to further processing operations. The actual design of the respective electric motors 3 and 69 of the supply roller 1 and of the pull-off devices 67 a and 67 b is not relevant here, so the electric motors are only shown schematically. The movement of the foil is indicated by arrow 5 . The sensor roller 21 is supported in guides 41 a and 41 b vertically provided in the guide frame 31 . A trigger 39 is provided on the extension line of the rotation axis of the sensor roller, and the trigger 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com