Tension control device and tension regulation method of automatic winder

An automatic winding machine and tension control technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of poor consistency and large tension value difference, and achieve good reliability and stability , The yarn tension remains constant and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

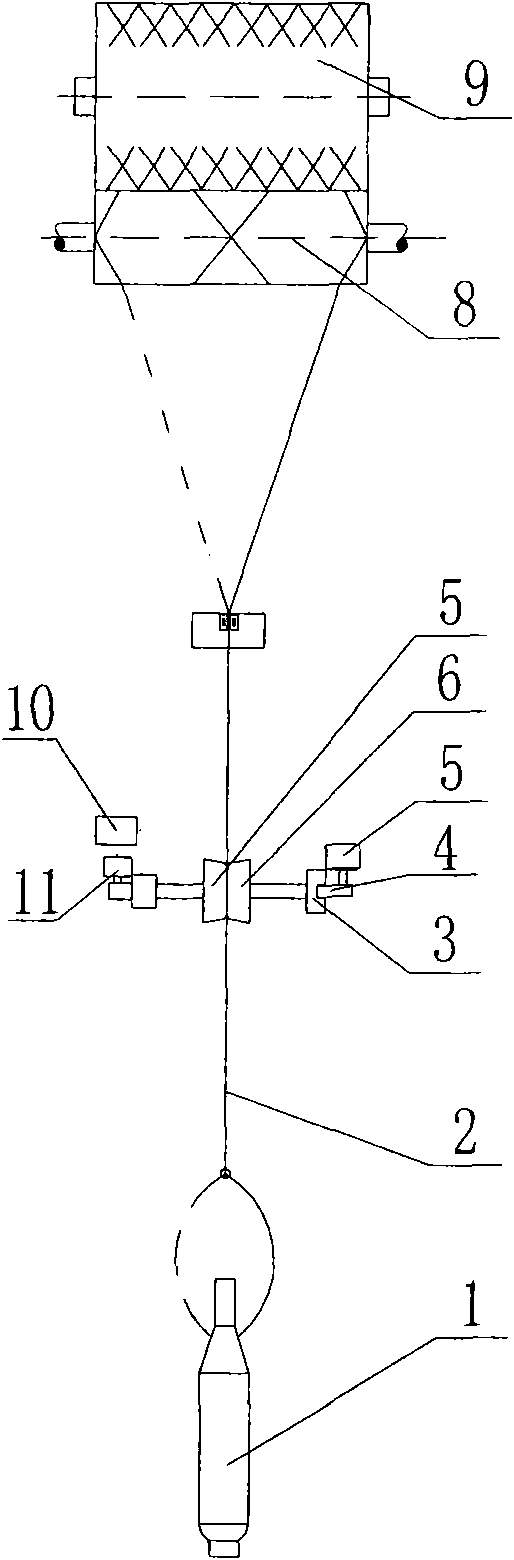

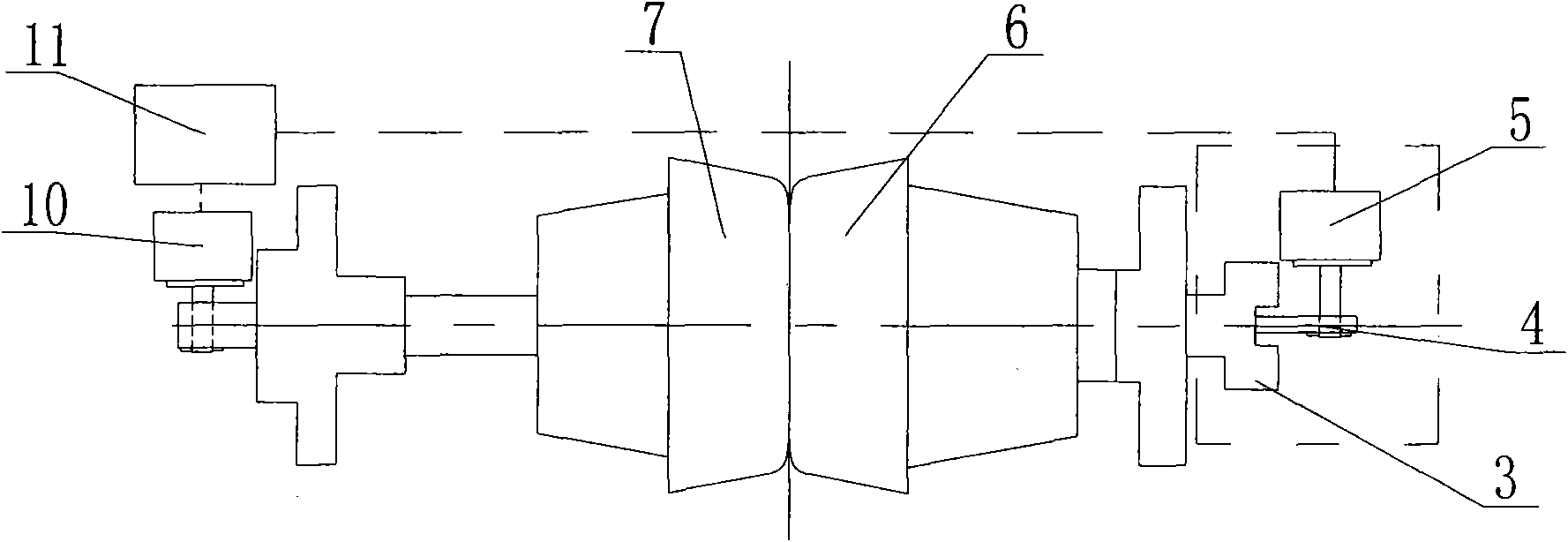

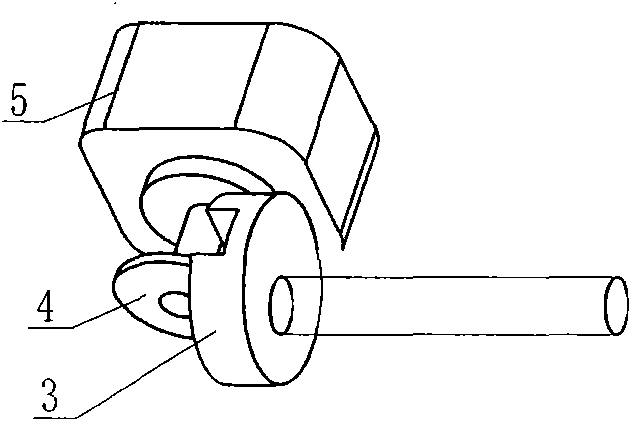

[0021] see Figure 1-Figure 5 , an embodiment of a tension control device for an automatic winding machine of the present invention. It includes a fixed tension disk 7 and a movable tension disk 6, the fixed tension disk 7 and the movable tension disk 6 face opposite to each other and are arranged on the fixed tension disk shaft 15 and the movable tension disk shaft 12 respectively. The fixed tension disc 7 and the movable tension disc 6 are respectively driven to rotate around their axes by a first stepping motor 11 through transmission components.

[0022] One end of the fixed tension disc shaft 15 is equipped with a rotatable fixed tension disc 7, the middle part of the fixed tension disc shaft 15 is covered with a bushing, the other end of the fixed tension disc shaft 15 is equipped with the first gear 16, and the fixed tension disc 7 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com