Driving means and device for working sheet-like material

A driving device and equipment technology, applied in the direction of hoisting devices, portable lifting devices, manufacturing tools, etc., can solve the problem of reducing the maximum tensile strength of the belt, reducing the width of the components, reducing the possibility of collision, and reducing the tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

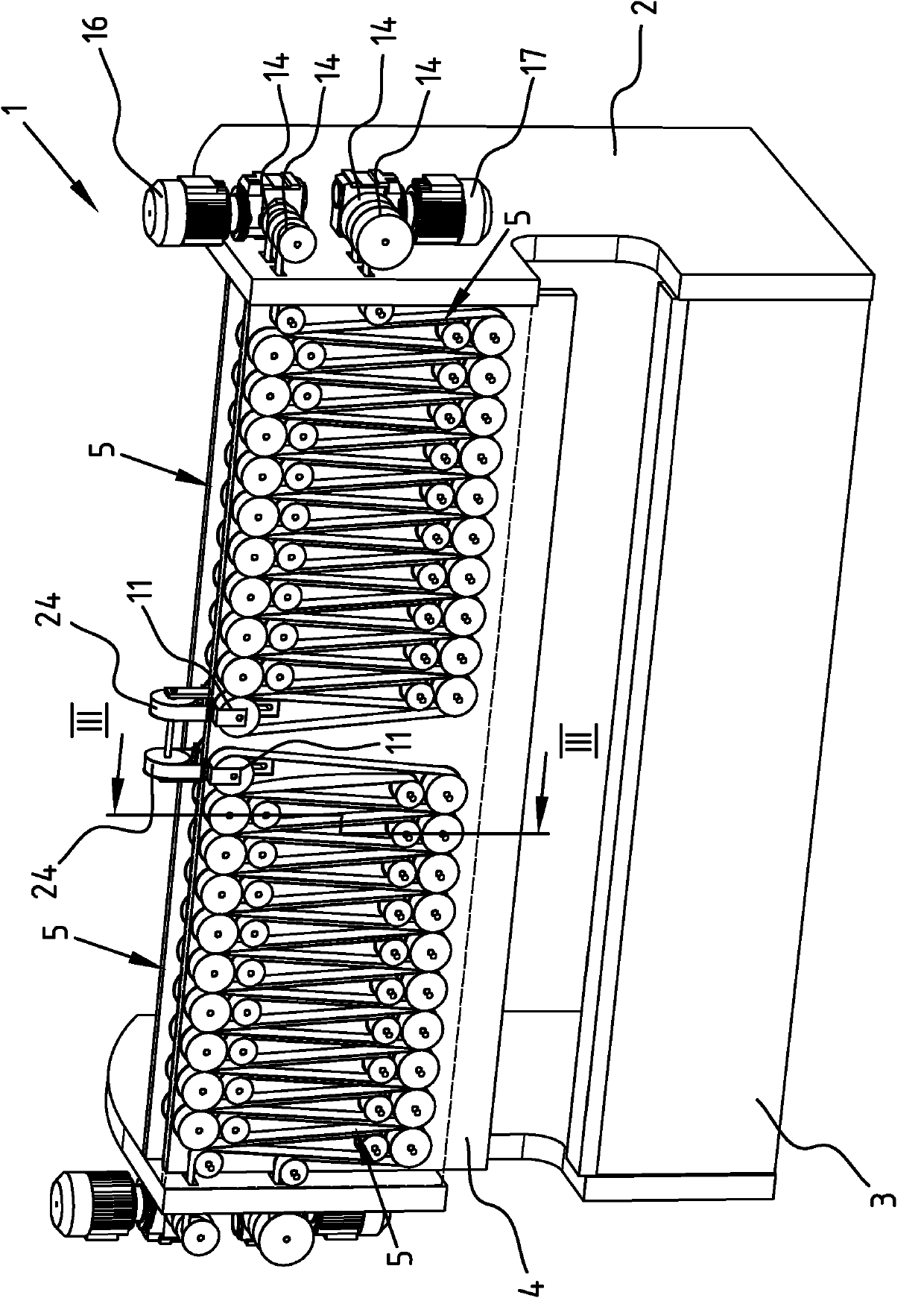

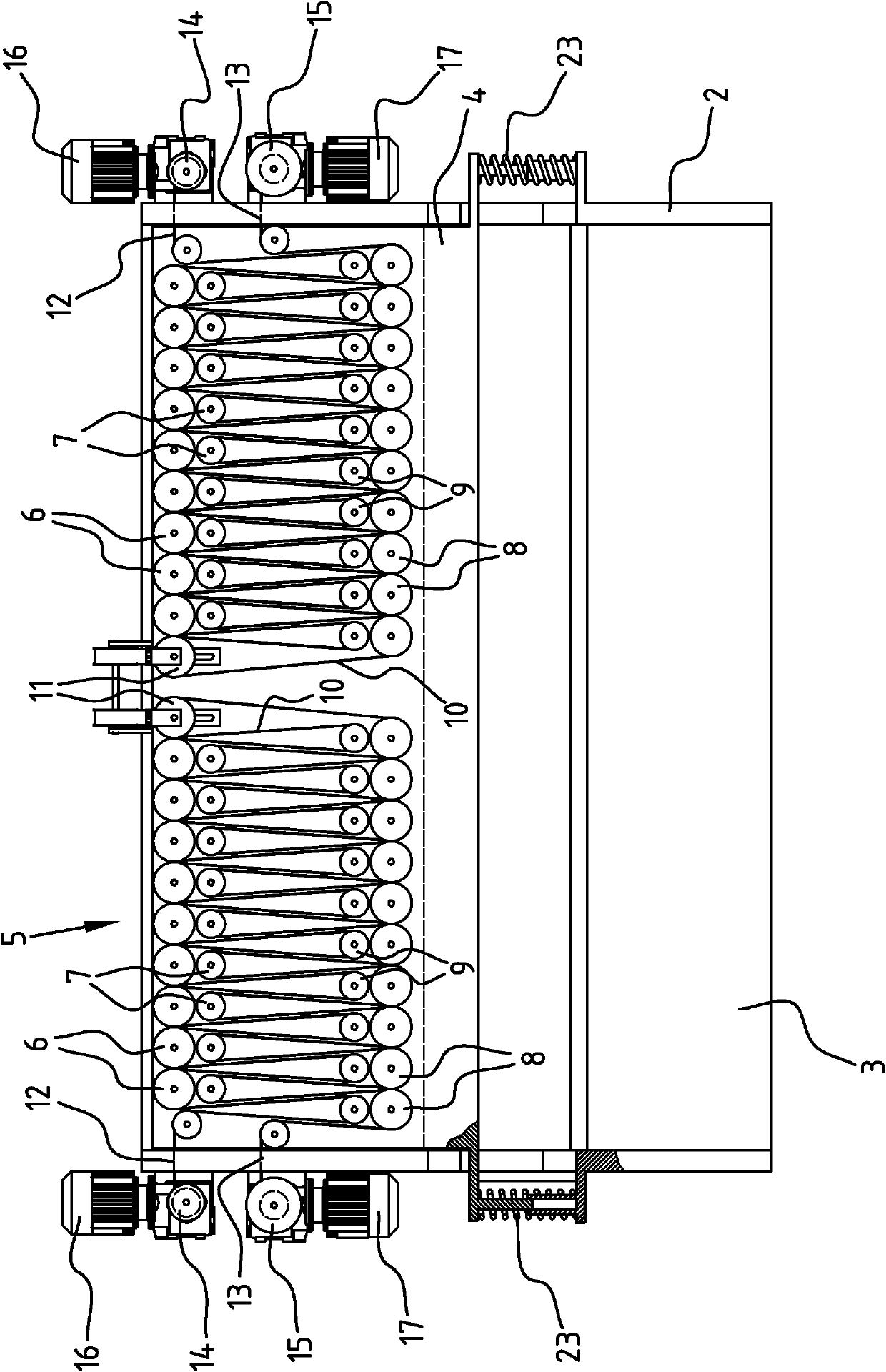

[0035] exist figure 1 , a perspective view of an embodiment of a device 1 according to the invention is shown. The apparatus 1 has a so-called C-frame 2 with: a lower beam 3 fixed to the C-frame 2; and an upper beam 4 which is movable.

[0036] Four drive devices 5 are arranged adjacent to the upper beam 4 . Two drives 5 are arranged on the front side of the beam 4 , while two other drives 5 are arranged on the rear.

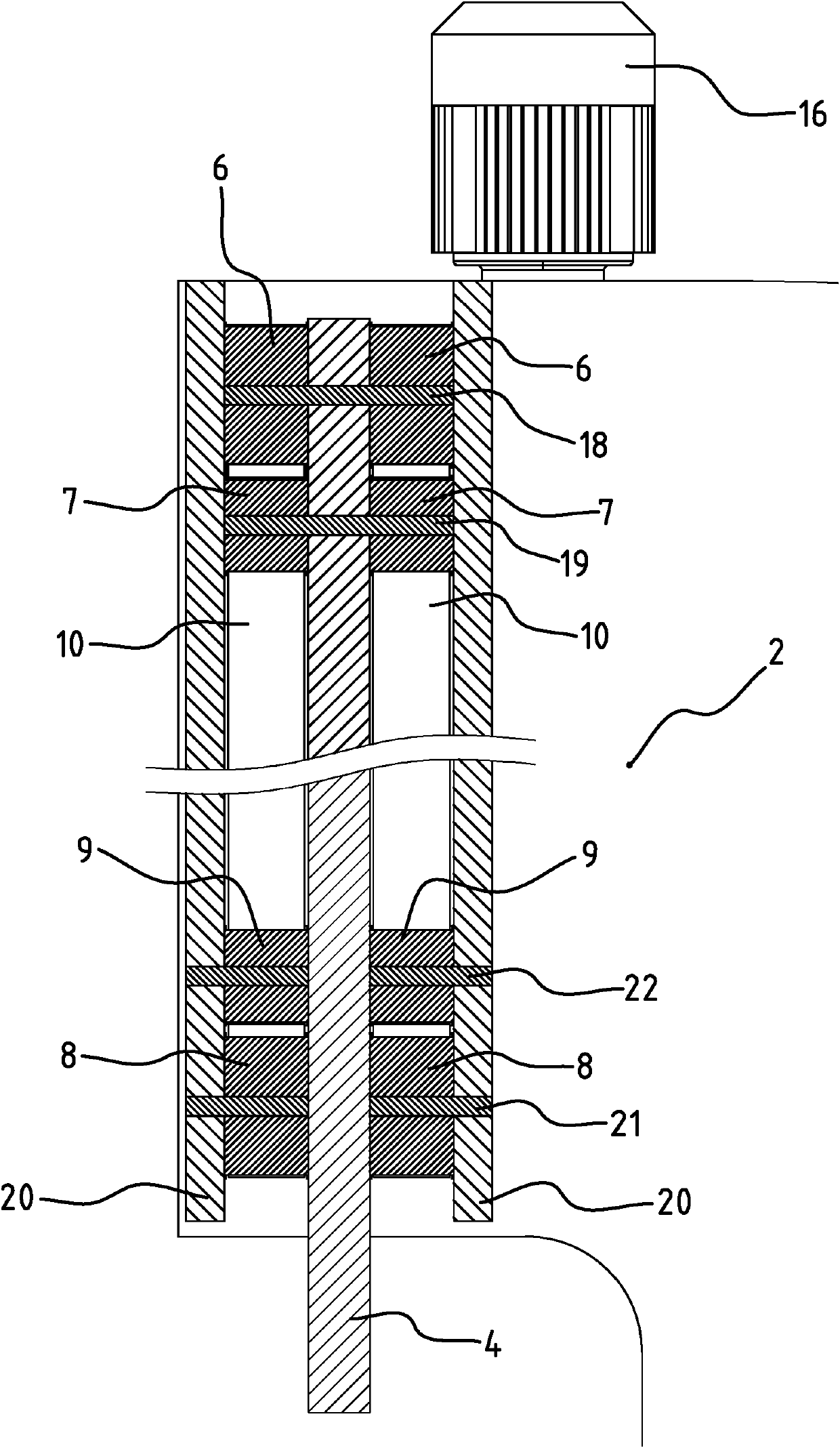

[0037] Each drive 5 has a first set of a row of main rollers 6 and a row of auxiliary rollers 7 and a second set of a row of main rollers 9 and a row of auxiliary rollers 8 .

[0038] Each drive 5 has a belt 10 which winds along the length of the beam 4 between the first set of main rollers 6 and the second set of main rollers 9 and between the first set of auxiliary rollers 7 and the second set The auxiliary roller 8 detours back and forth. Each drive 5 has an idler pulley 11 at which the belt 10 changes direction.

[0039] The belt 10 has a first end 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com