Yarn tensioning system and method for keeping a yarn which is taken from a yarn storage system to a yarn take-off system of a weaving machine under tension

A tensioning system, yarn output technology, applied in looms, flannel looms, transportation and packaging, etc., can solve the problems of cumbersome, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

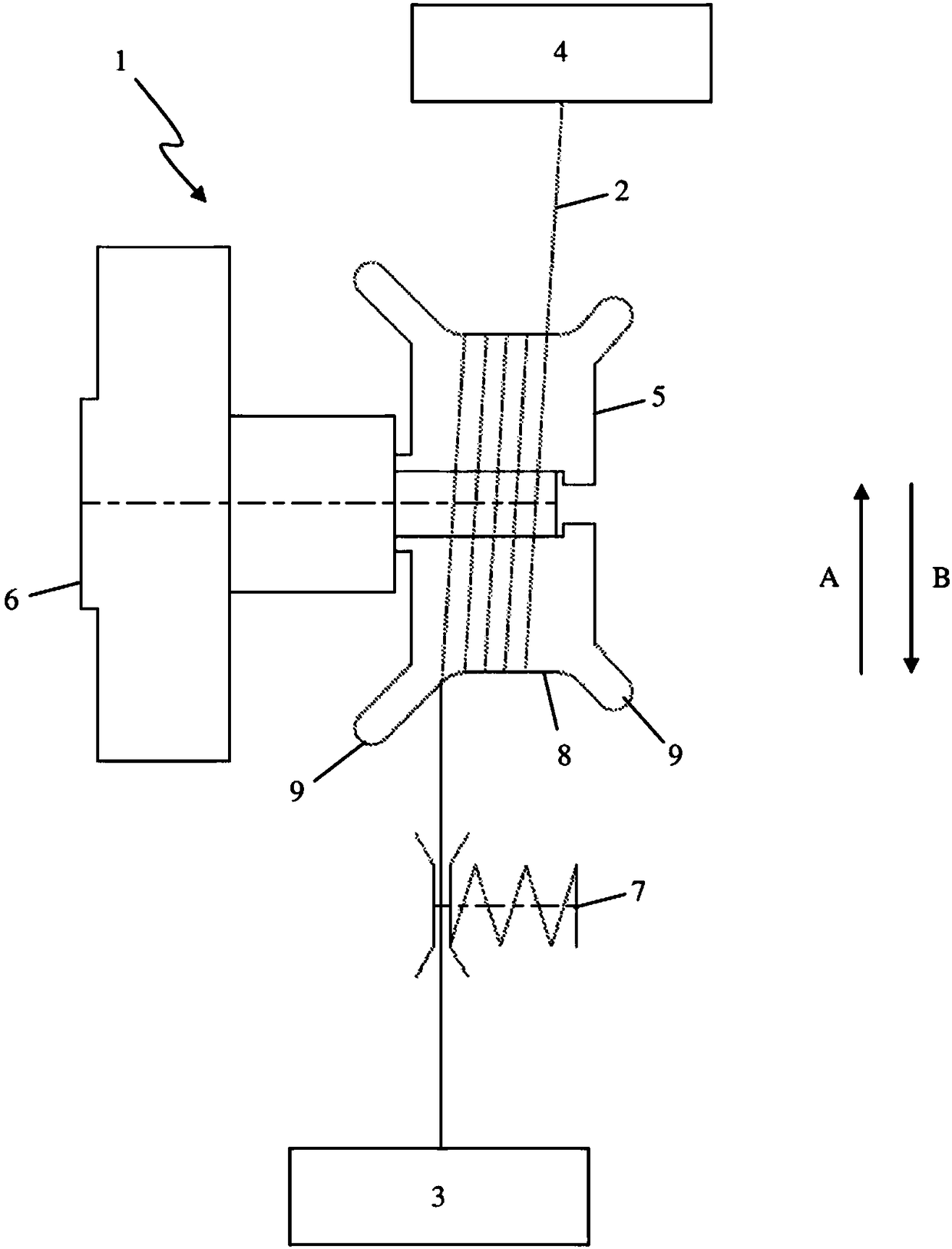

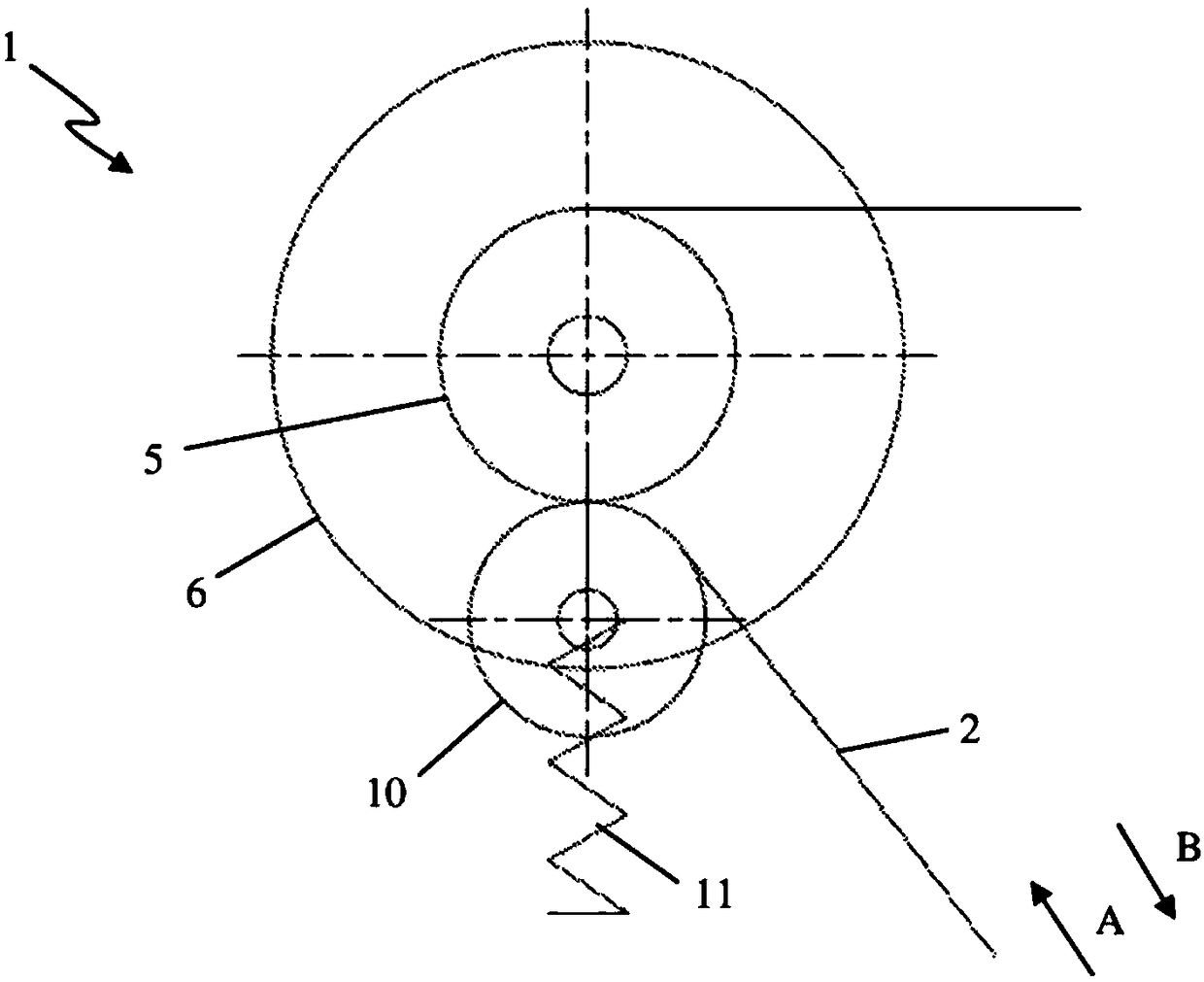

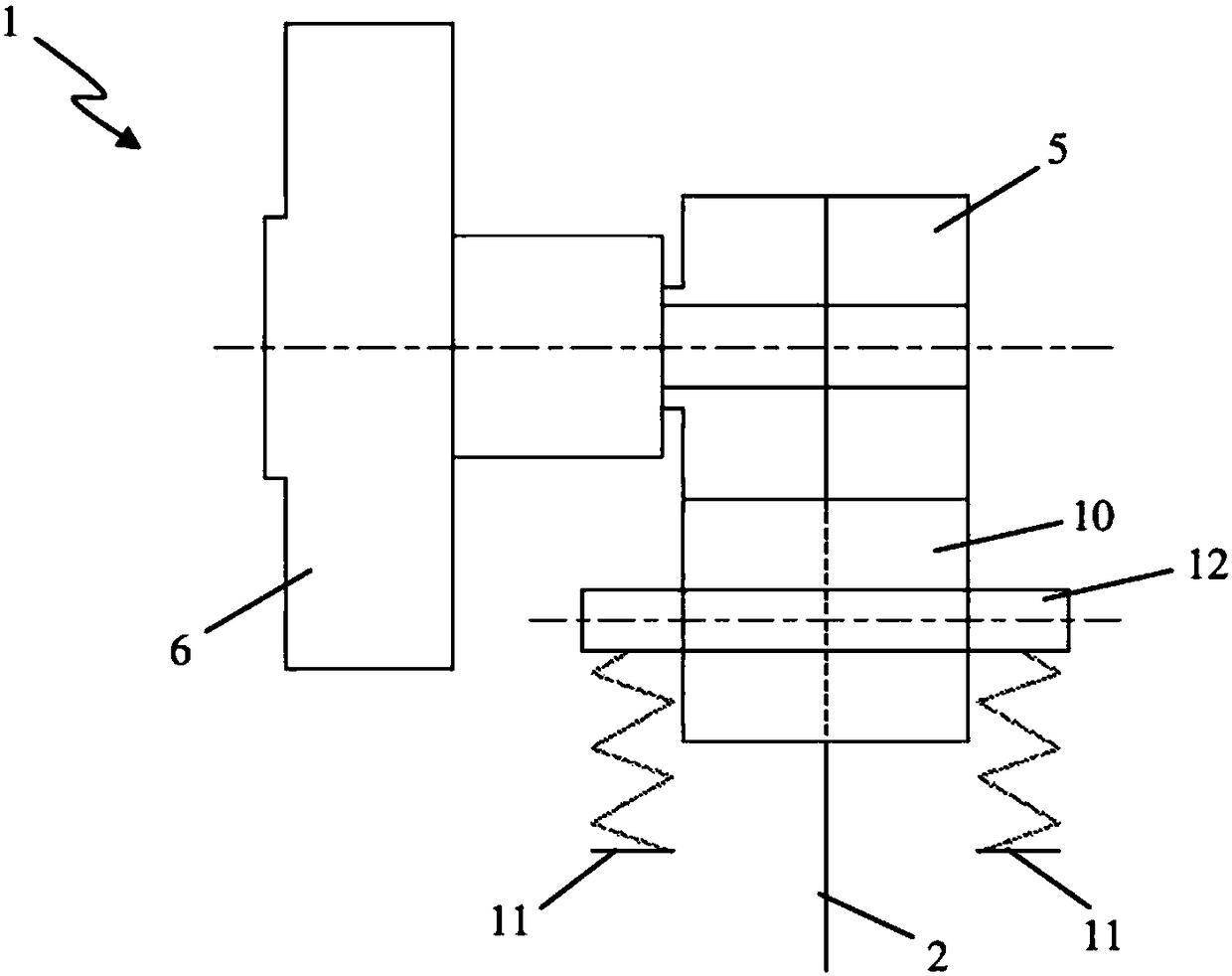

[0060] These figures show some examples of yarn tensioning systems (1) according to the invention.

[0061] Each of these yarn tensioning systems (1) comprises, for each yarn (2) to be tensioned, a rotatably arranged braking roller (5) and a means for supplying the braking roller (5) torque motor (6).

[0062] exist figure 1 In the first embodiment shown, the yarn (2) is withdrawn from the yarn storage system (3) to the yarn delivery system (4) of the loom in a first direction (A), or in a direction (A) A) On the opposite second direction (B) between the braking roller (5) and the yarn output system (4), the yarn (2) is wound several times on the braking roller (5) to limit the yarn (2) Sliding relative to the brake roller (5).

[0063] In order to further limit the sliding of the yarn (2) relative to the braking roller (5), the yarn tensioning system (1) also includes a braking device (7), which is arranged between the yarn storage system (3) and the braking roller (5). b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com