A Method for Optimizing the Shear of Steel Plate Head

An optimized, steel plate technology, applied in the direction of shearing devices, shearing machine accessories, metal processing equipment, etc., can solve the problems of large data errors, inability to describe the shape of the slab head, and many external interference factors. Achieve the effect of improving precision, improving shearing efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

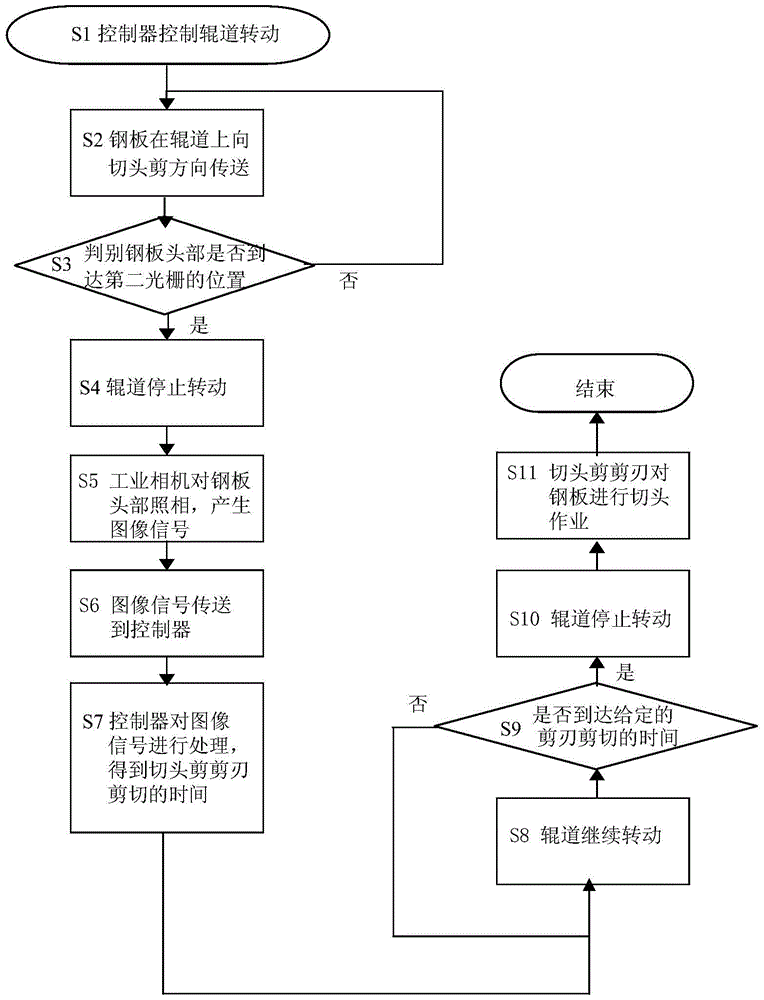

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

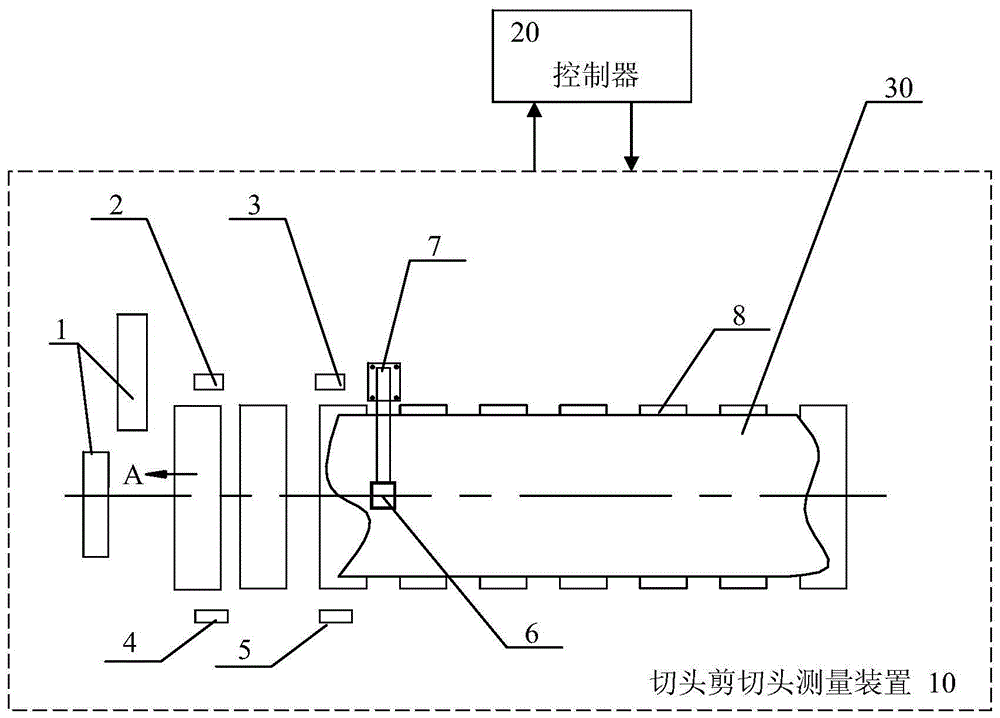

[0047] see figure 1 .

[0048] Such as figure 1 As shown, in order to realize the automation of the cutting head and shearing head in the present invention, in the cutting head and shearing head measuring system used, a set of cutting head measuring device 10 is set before the cutting head shear 1, and the steel plate 30 is measured during operation. The head shape of the steel plate 10 is monitored, and the measured head shape data is transmitted to the controller 20, and the controller 20 controls the start-up time of the cropping shears 1, so that the length of the cutting head reaches the optimum state.

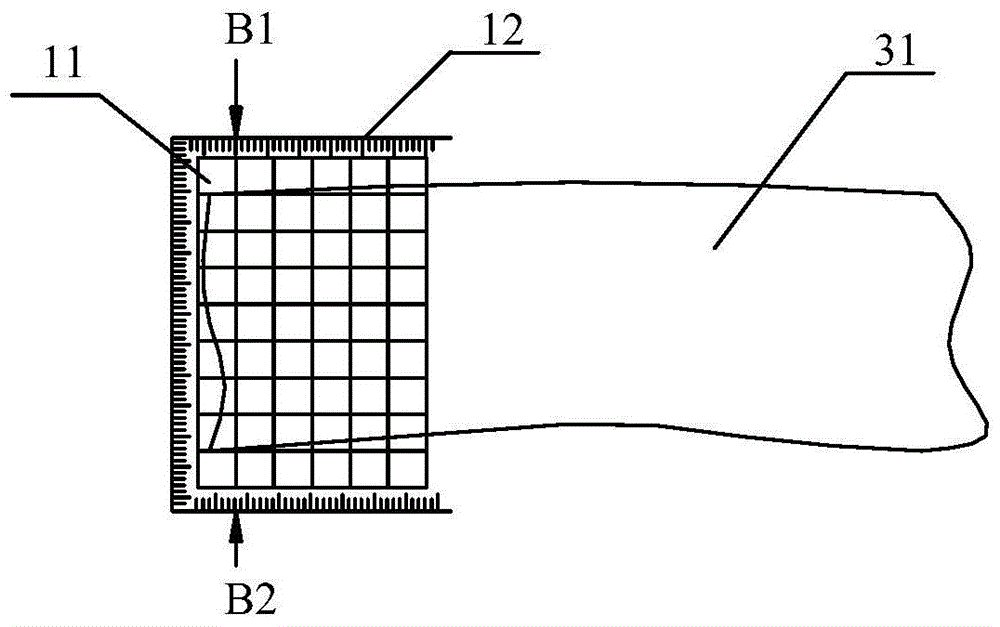

[0049] The cutting head measuring device 10 used in the present invention includes: 2 gratings 2, 3 installed on one side of the roller table 8, wherein the first grating 2 is close to the cutting head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com