Control method of BOPP (Biaxially-oriented Polypropylene) biaxial stretching system

A control method and biaxial stretching technology, applied in the field of control, can solve problems such as interaction, difficulty in realization, and inability to describe separately, so as to improve decoupling ability and reduce longitudinal thickness deviation and transverse thickness deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

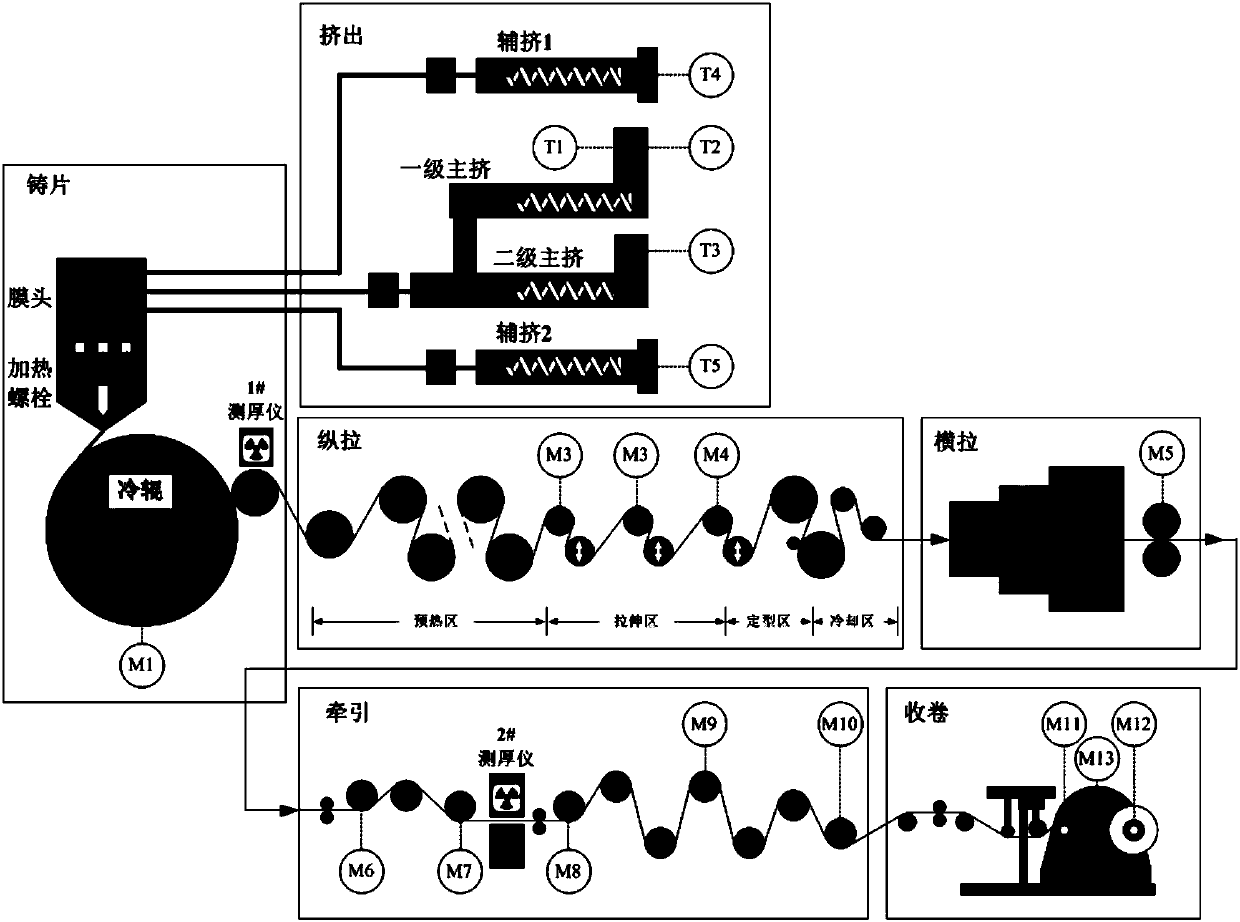

[0044] First, the BOPP biaxially stretched system will be described. like figure 1 As shown, the BOPP biaxial stretching system includes six subsystems: extrusion, casting, longitudinal stretching, transverse stretching, traction and winding.

[0045] Among them, the extrusion system is mainly composed of primary extrusion, secondary extrusion, first auxiliary extrusion, second auxiliary extrusion and filter. Specifically, the function of the first-stage main extrusion is to make the material receive the heat from the external heater, and reach a semi-molten state under the shear and compression of the screw, and quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com