Constant-tension yarn storage device for flat plate winding of carbon fiber yarn and control method

A technology of carbon fiber yarn and control method, which is applied in the field of yarn storage, can solve the problems that the yarn is not moving at a uniform speed, and the yarn tension is difficult to control, etc., and achieve the effect of improving the fiber spreading quality and keeping the yarn speed and tension constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

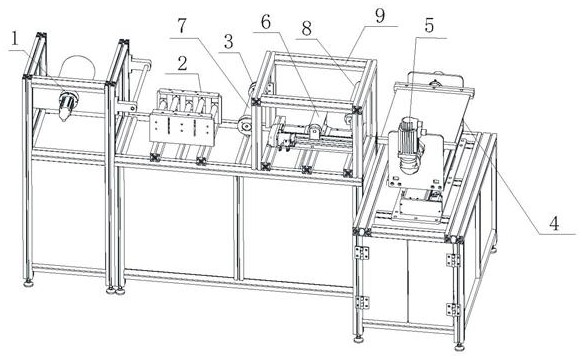

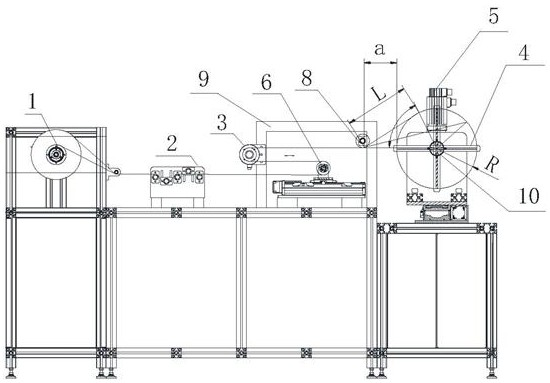

[0039] like Figure 1 to 2 FIG flat carbon fiber yarn is wound with constant tension yarn storage device, comprising:

[0040] Unwinding apparatus 1, the yarn on the bobbin unwinding constant speed operation;

[0041] Exhibition fiber means 2, the yarn fineness development operation;

[0042] Tension detecting means 3 detects yarn tension;

[0043] Receiving winding means for winding the yarn further comprising a yarn winding plate 4 and the drive motor 5, the yarn winding plate 4 is rotated at constant speed drive motor 5 is driven to show the completed fiber yarn wound closed;

[0044] Wherein the developing means and the receiving means fibers between about 2 further provided with an automatic yarn storage device, the automatic yarn storage device for real-time compensation of yarn unwinding discharge apparatus 1 and the amount of the difference between the amount of yarn wound strand receiving plate 4, thereby the yarn is kept constant, the automatic yarn storage device by mean...

Embodiment 2

[0053] The present invention also discloses a constant tension storage yarn control method for flat winding carbon fiber yarn.

[0054] S1: A constant speed flacker is performed on the yarn cylinder using the shaken device 1, and the yarn on the yarn is sequentially wrapped over the screen 4 after the yarn is passed through the extension device 2 and the automatic storage yarn device;

[0055] S2: Set the tapping angle velocity around the yarn plate 4 to rotate 180 ° around the yarn plate 4 is one cycle, calculate the real-time grating amount wound around the yarn plate 4;

[0056] S2: Turn 180 ° in the yarn plate 4 is one cycle, calculate the real-time gaute amount of the discharge device 1, and find the spin angle velocity of the discharge device 1;

[0057] S3: By calculating the difference between the real-time gaute and the real-time spinning amount, the real-time compensation amount of the automatic storage unit is calculated, and the automatic storage unit is set to the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com