Falling film evaporator having two-phase refrigerant distribution system

A falling-film evaporator, refrigerant technology, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of increasing material cost of cooler, high cost, expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

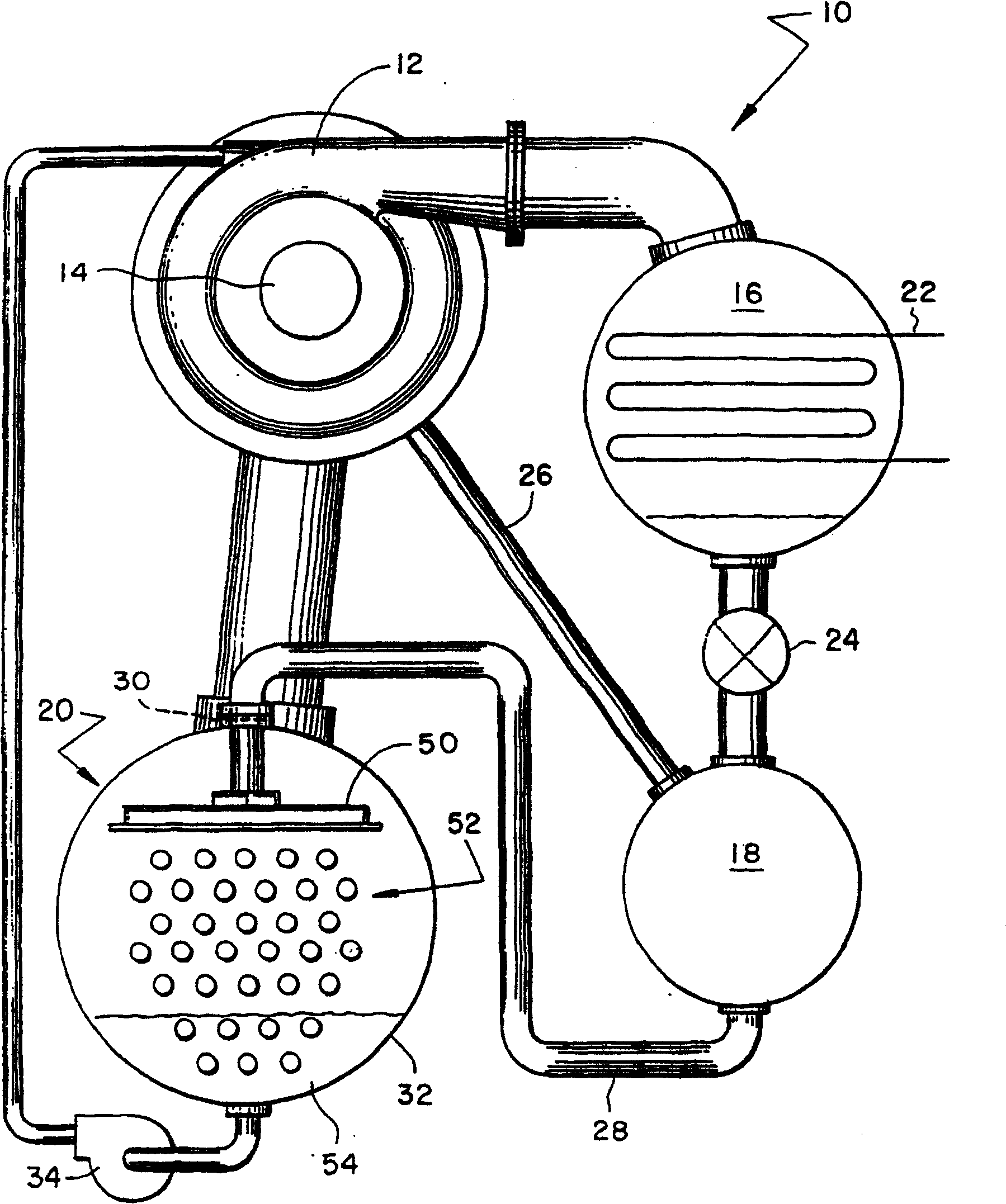

[0032] See first figure 1 , The main components of the chiller system 10 are: a compressor 12 driven by an electric motor 14 , a condenser 16 , an efficiency booster 18 and an evaporator 20 . These components are connected in series to allow refrigerant to flow in a basic refrigerant circuit, which will be more fully described hereinafter.

[0033] In the preferred embodiment, compressor 12 is a centrifugal compressor. It should be understood, however, that falling film evaporators and refrigerant distributors of the type described herein may also be considered in coolers in which the compressor is other than centrifugal and fall within this scope. within the scope of protection of the invention.

[0034] In general, high pressure refrigerant gas fed into condenser 16 is condensed into liquid form by heat exchange with a fluid, usually water, which is fed into said condenser through line 22 . As is the case in most chiller systems, a portion of the lubricant used inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com