On-line continuous concentration detection device for printing and dyeing process liquid

A printing and dyeing process and concentration detection technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as changes in detection accuracy, changes in process liquid density, blockage of process liquid circulation pipes, and achieve constant speed and high concentration detection accuracy , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

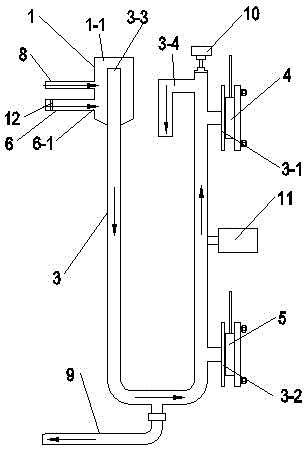

[0038] like figure 1 As shown, an online continuous concentration detection device for printing and dyeing process liquid, including a process liquid buffer container 1, a detection flow pipe 3, a first pressure sensor 4, a second pressure sensor 5 and a liquid inlet pipe 6;

[0039] One end of the liquid inlet pipe 6 communicates with the process liquid buffer container 1;

[0040] One end of the detection flow pipe 3 communicates with the process liquid buffer container 1, and one end of the detection flow pipe 3 is the process liquid circulation inlet 3-3, and the height of the process liquid flow inlet 3-3 is lower than the process liquid buffer container 1 The height of the upper overflow port 1-1; the upper overflow port 1-1 can be as figure 1 The upward opening on the upper top of the process liquid buffer container 1 as shown may also be a gap or an overflow hole or an overflow nozzle on the side wall of the upper part of the process liquid buffer container 1 in the...

Embodiment 2

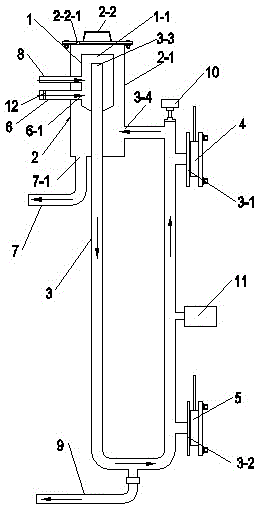

[0048] like figure 2 As shown, the difference between embodiment 2 and embodiment 1 is: an online continuous concentration detection device for printing and dyeing process liquid, which also includes a process liquid recovery container 2, and the process liquid recovery container 2 has a liquid outlet 7-1, And the height of the liquid outlet 7 - 1 of the process liquid recovery container 2 is lower than the height of the upper overflow port 1 - 1 of the process liquid buffer container 1 . In this way, in order to facilitate the recovery of process liquid.

[0049] like figure 2 As shown, the process liquid buffer container 1 is arranged in the process liquid recovery container 2; one end of the liquid inlet pipe 6 penetrates the process liquid recovery container 2 and is connected with the process liquid buffer container 1; the detection flow pipe One end of 3 passes through the bottom of the process liquid recovery container 2 and the bottom of the process liquid buffer c...

Embodiment 3

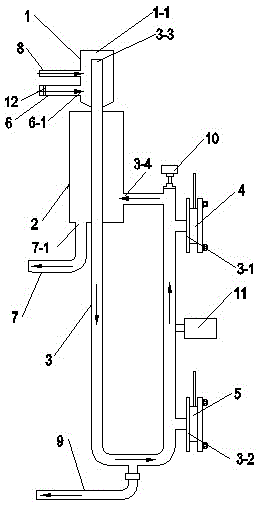

[0055] like image 3 As shown, the difference between embodiment 3 and embodiment 2 is: an online continuous concentration detection device for printing and dyeing process liquid, the process liquid buffer container 1 is arranged above the process liquid recovery container 2, and the process liquid recovery container 2 includes the container body only. Other structures of embodiment 3 are exactly the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com