Automatic control device for floating winding type plastic cloth of salt pond

An automatic control device and control device technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problem of reducing the service life of plastic sheets (plastic tarpaulins), the inability to simultaneously retract and deploy multiple salt pools, and the difficulty in realizing deployment and traction Synchronization and other issues to achieve the effect of improving reliability and safety, small changes, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

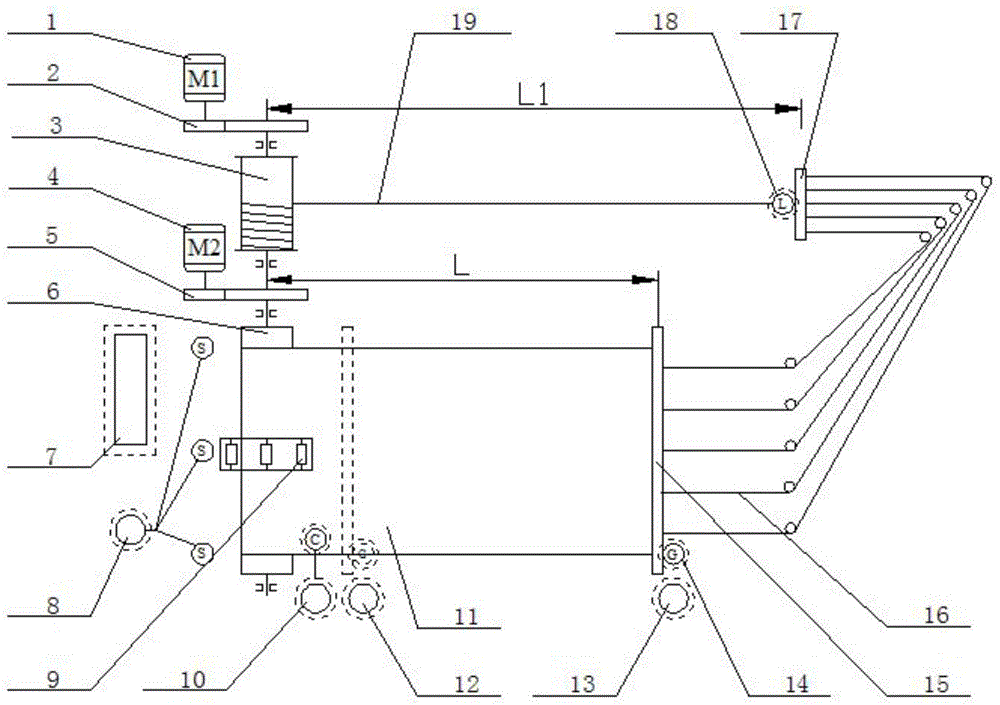

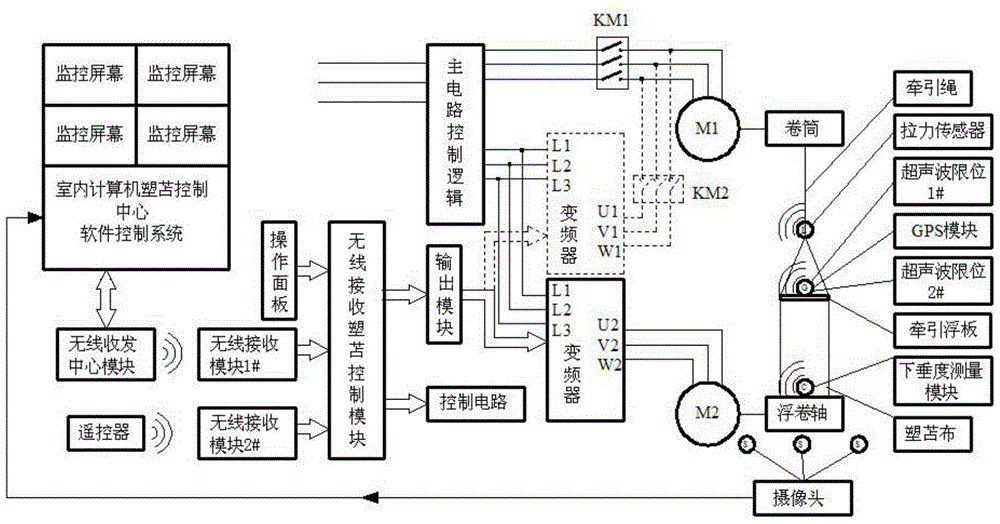

[0024] An automatic control device for floating roll-type plastic thatch in a salt pond, which includes a plastic thatch 11, a floating reel 6, a floating reel motor 4, a floating reel reduction box 5, a traction floating plate 15, a floating plate traction rope, a reel 3, and a reel deceleration Box 2, reel motor 1 and control unit; one end of the plastic thatch 11 is wound on the floating reel 6, the floating reel 6 is driven by the floating reel motor 4 and the floating reel reduction box 5, and the other end of the plastic thatch 11 is fixed on the traction buoy On the plate 15, the traction floating plate 15 is connected and wound on the reel 3 through the traction rope of the floating plate, and the reel 3 is driven by the reel motor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com