Environment-friendly biomass fuel particle forming device

A biomass fuel and particle forming technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of high pressure, large platen load, easy damage, etc., to prevent waste, reduce extrusion force, increase The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

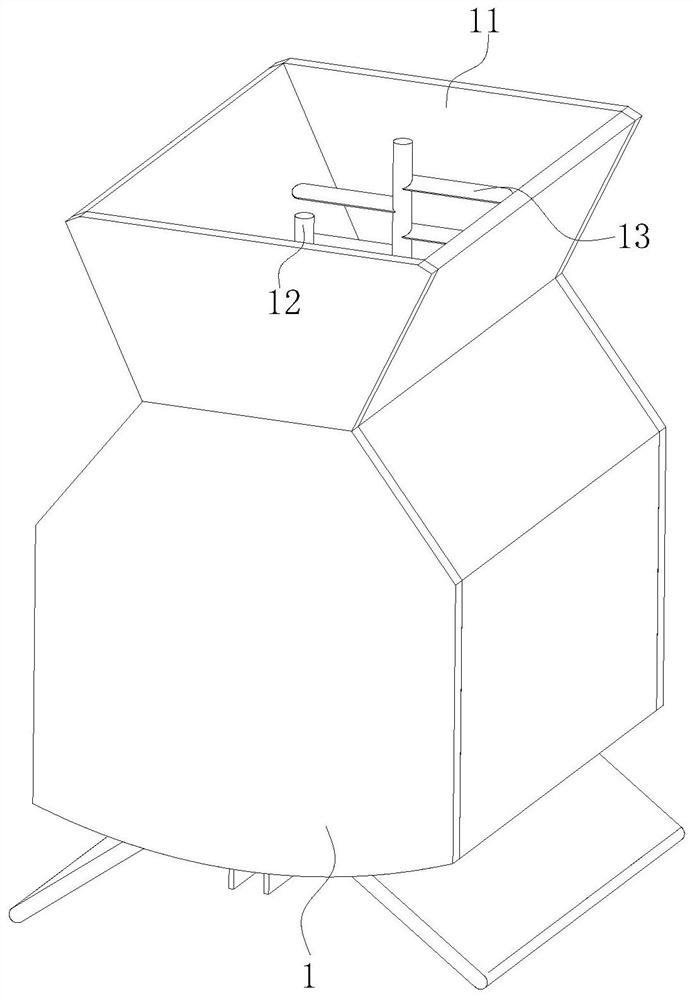

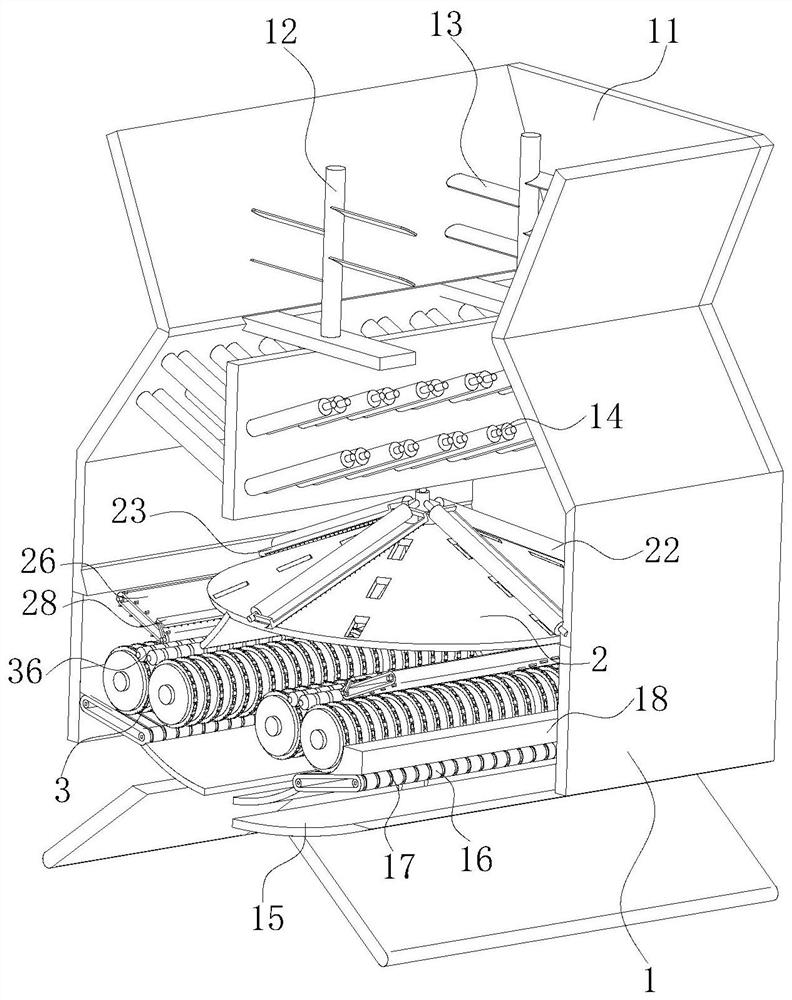

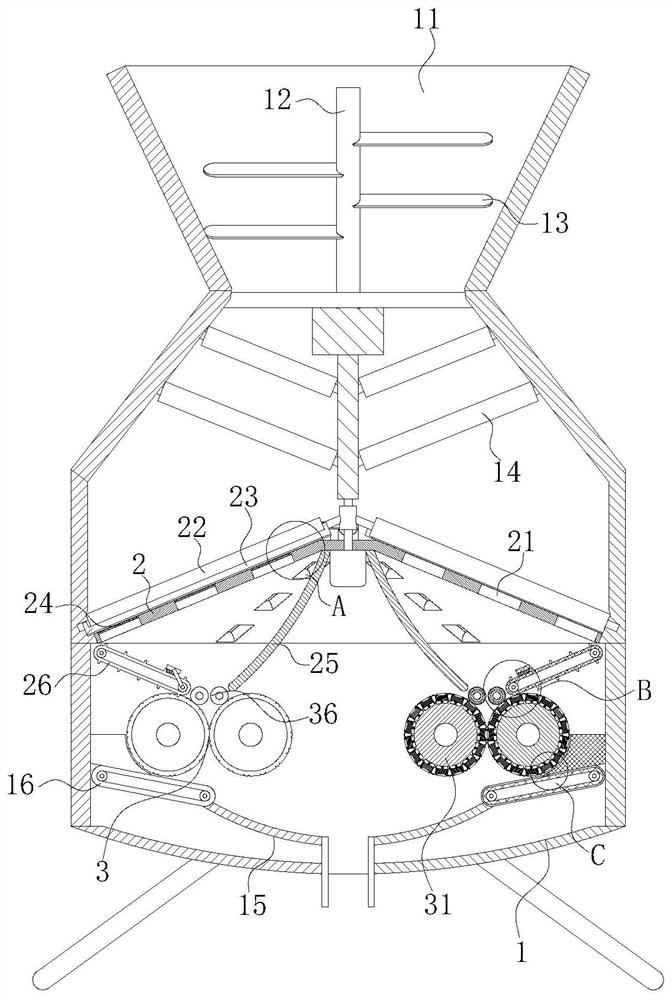

[0030] use Figure 1-Figure 6 An environment-friendly biomass fuel particle molding device according to an embodiment of the present invention is described as follows.

[0031] Such as Figure 1-Figure 6 As shown, a kind of environment-friendly biomass fuel particle molding device according to the present invention includes a body 1; a feed bin 11 is fixedly connected to the upper surface of the body 1, and the feed bin 11 is a trapezoidal design; Under the warehouse 11, there are evenly arranged support plates fixed in the inner wall of the body 1, and the number of support plates is two; the inner wall of each support plate is connected with a rotating rod 12 through the rotation of a motor, and the rotating rods 12 all extend to the inlet. In the feed bin 11; the uniformly arranged rotating blades 13 are fixedly connected in the inner wall of each rotating rod 12, and the rotating blades 13 are all inclined designs; plate, and the partition is fixedly connected to the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com