Patents

Literature

101results about How to "Prevent wasteful situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

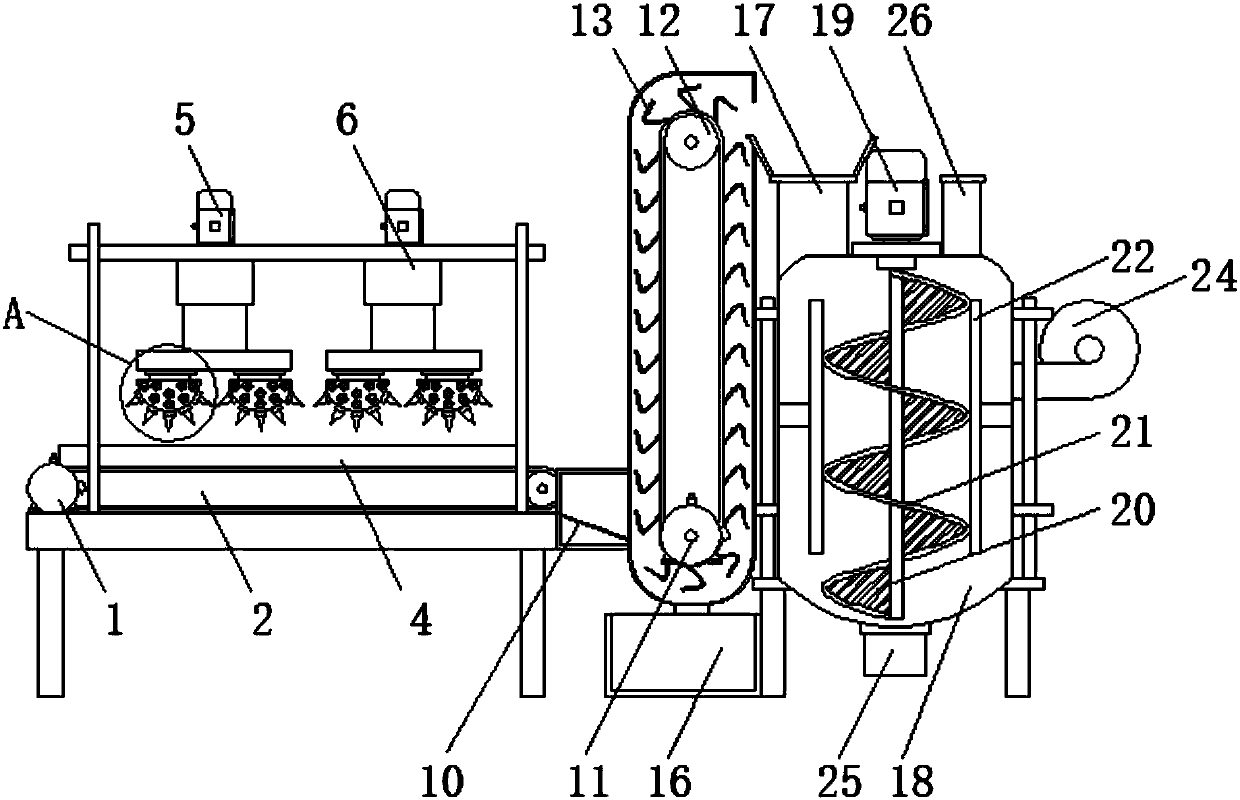

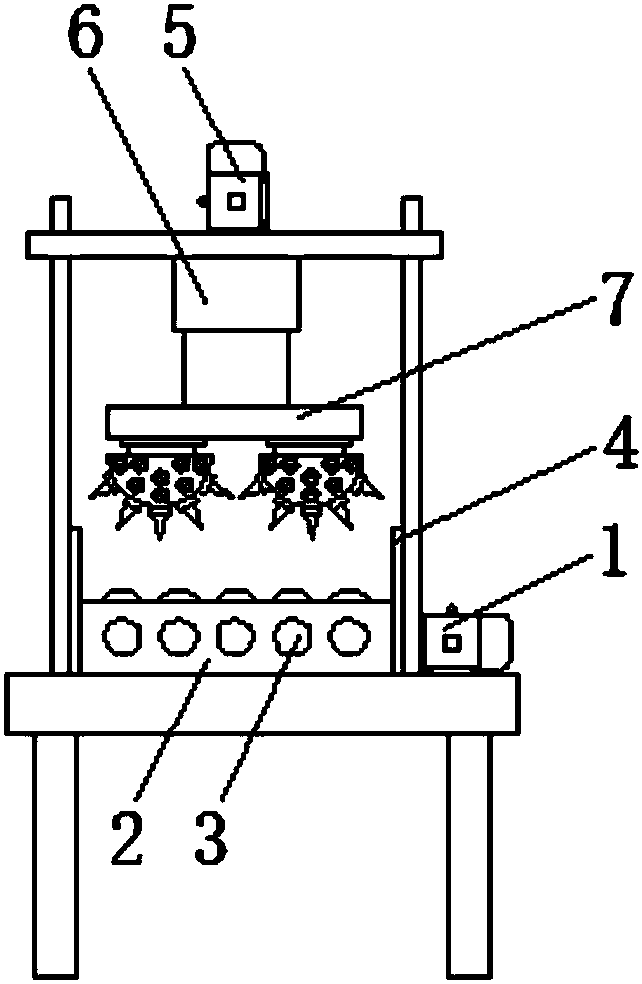

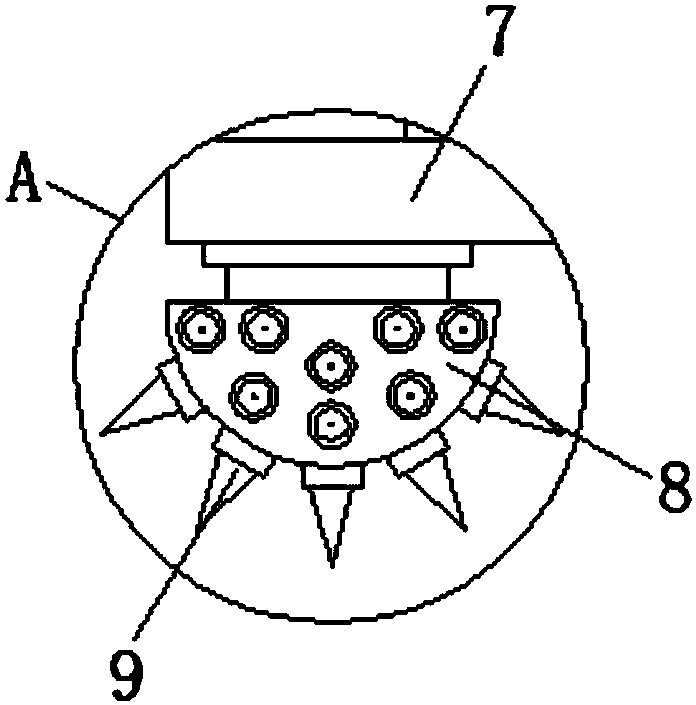

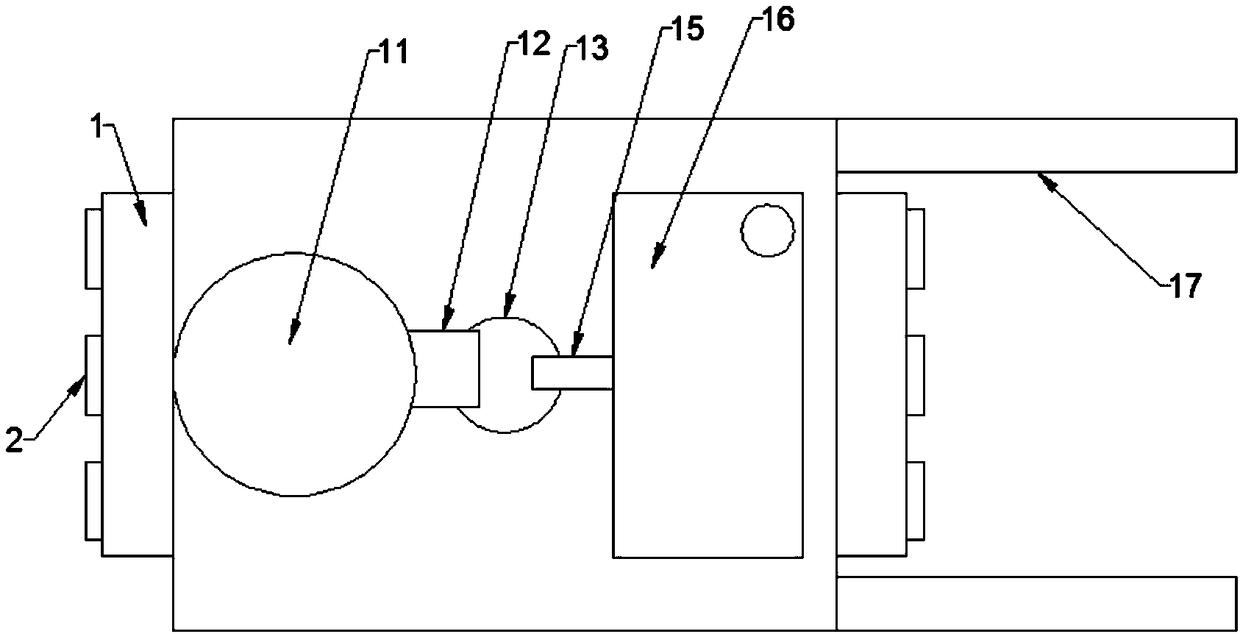

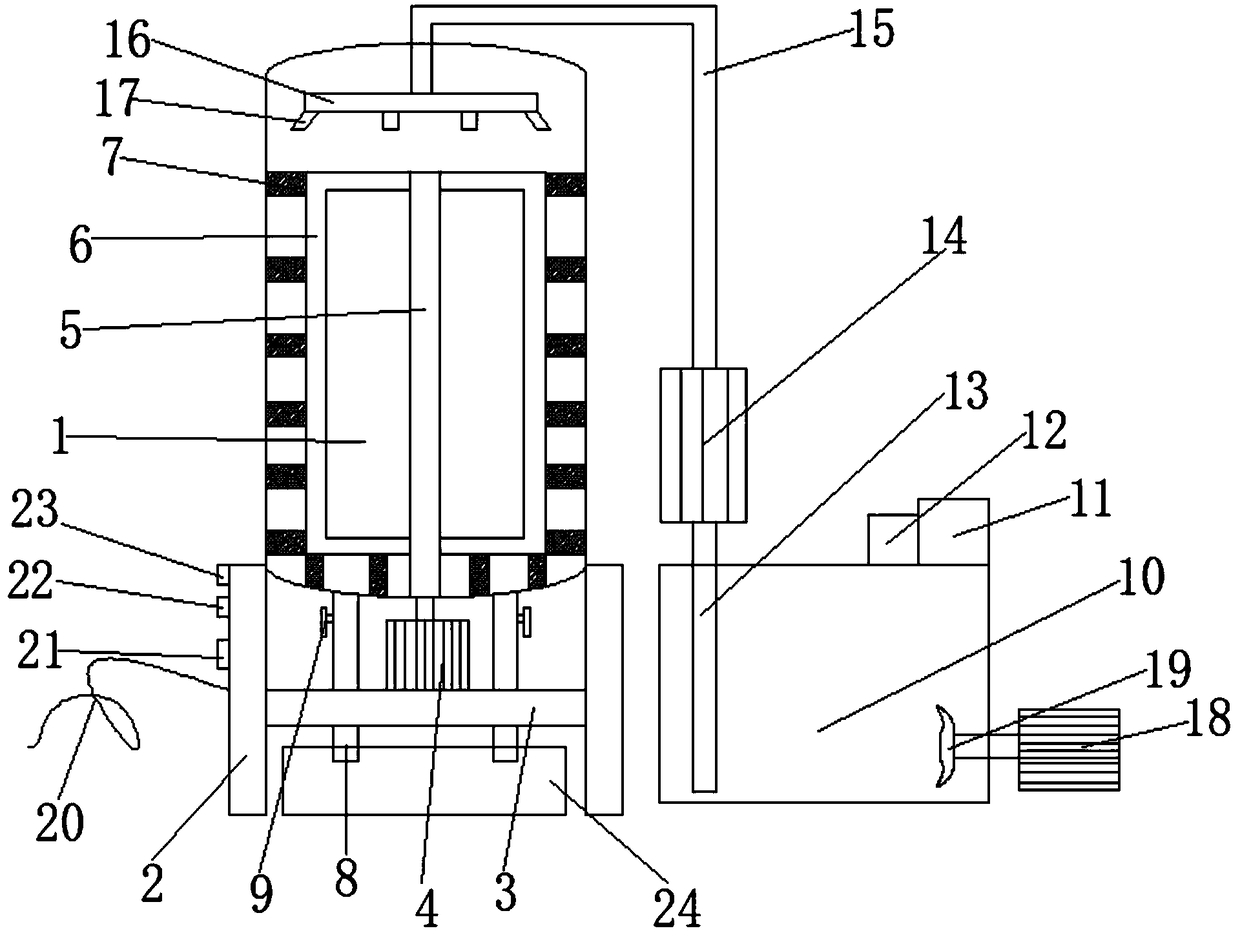

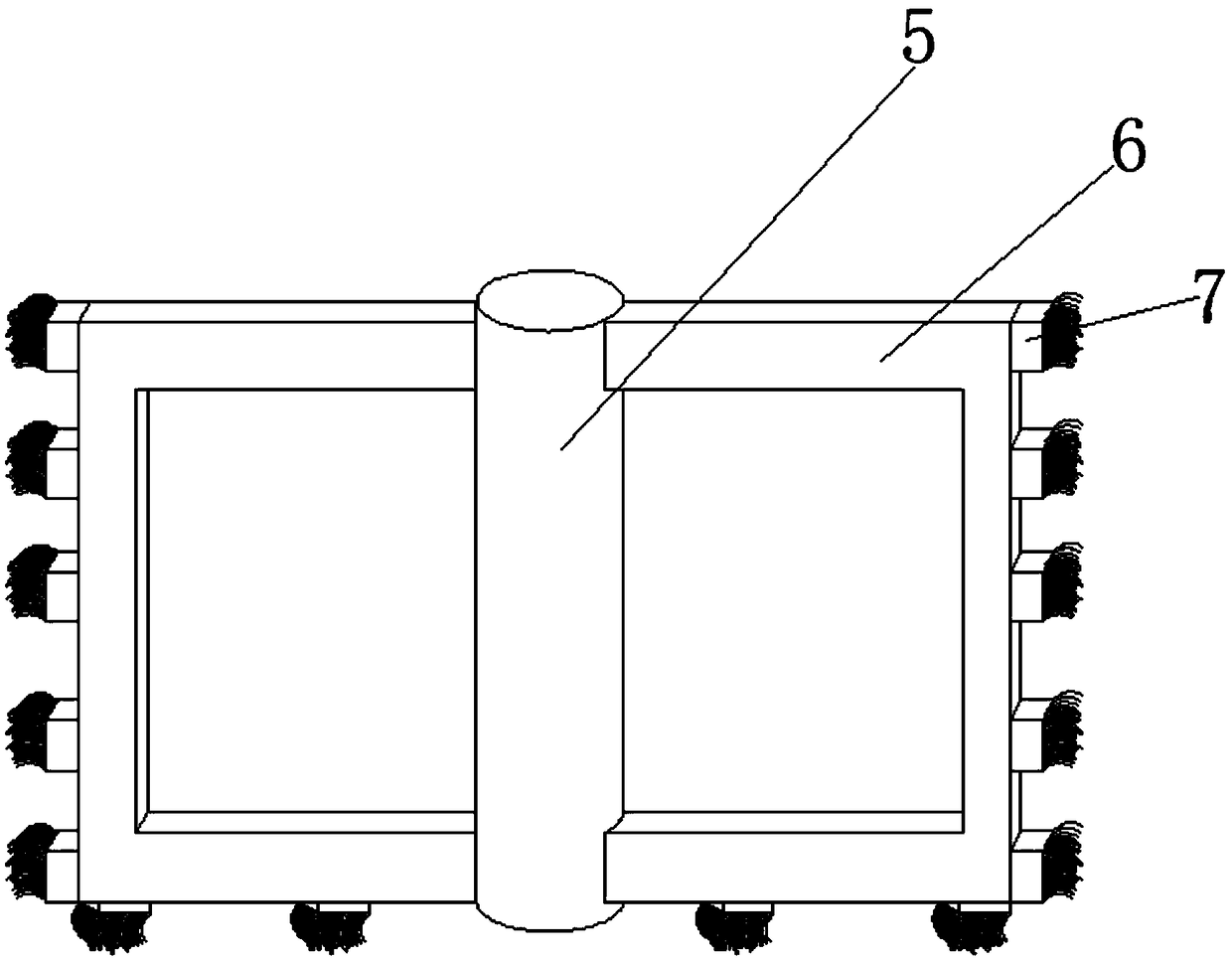

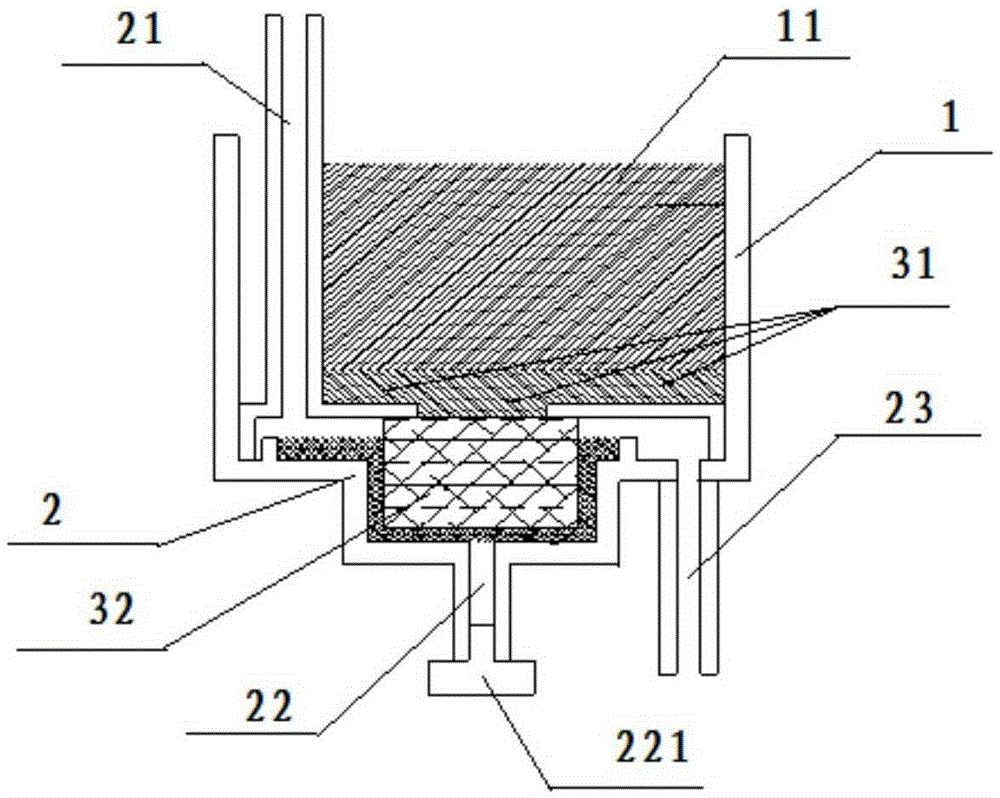

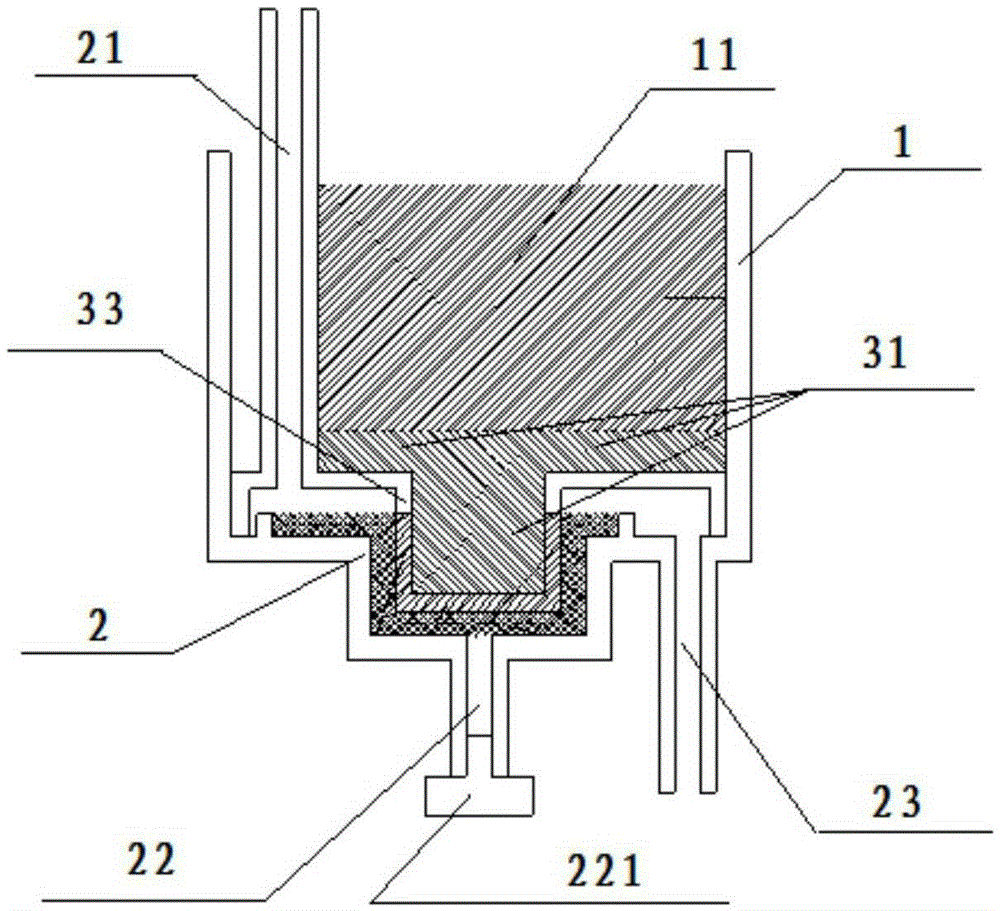

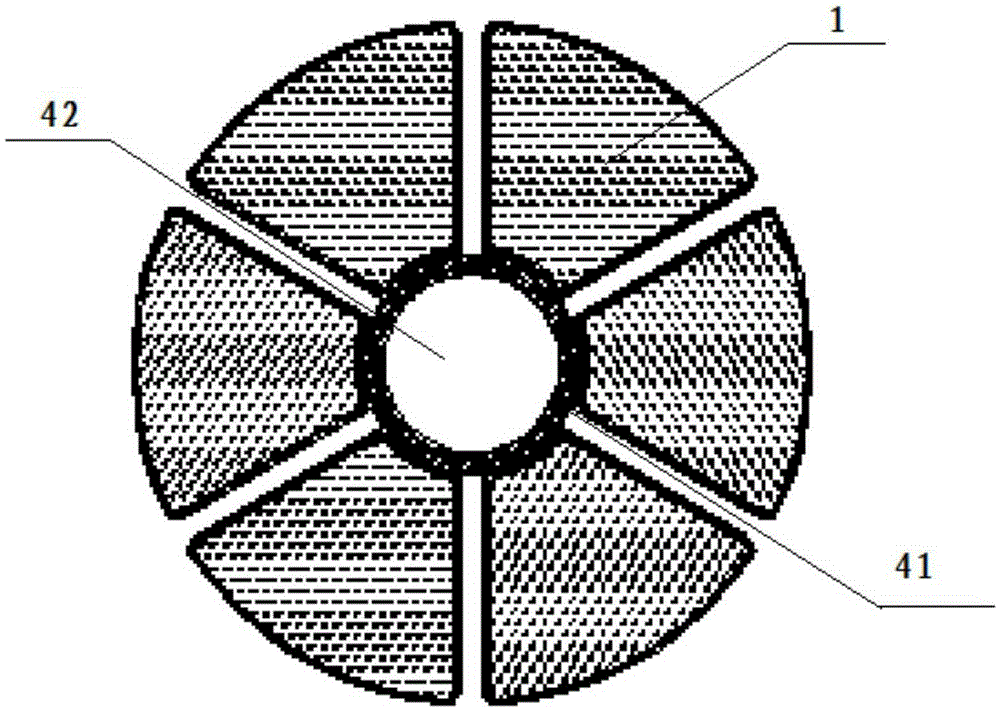

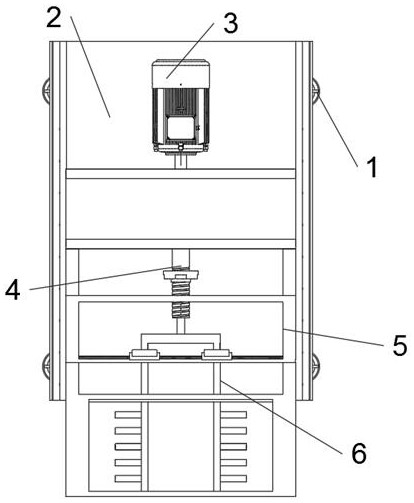

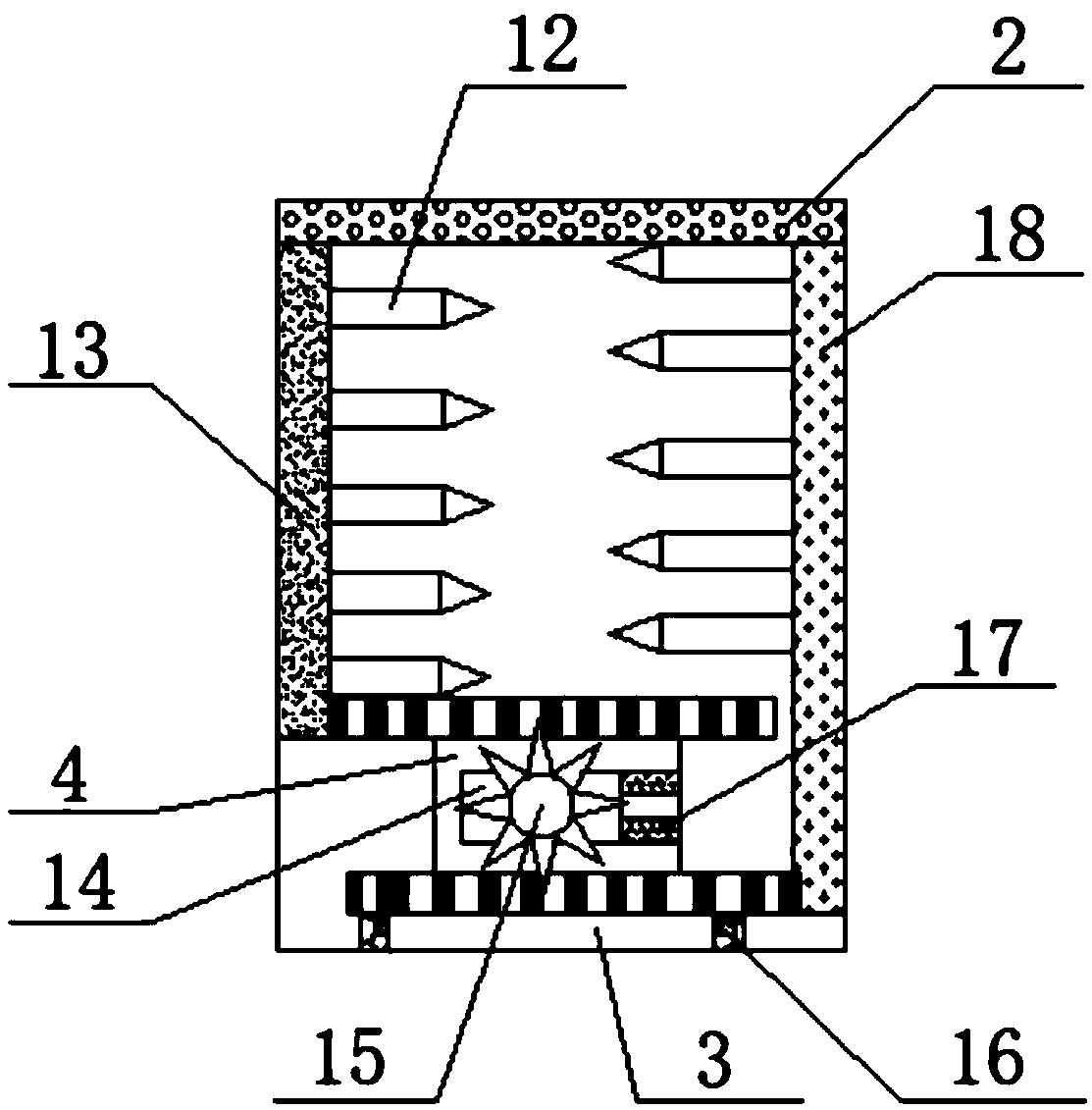

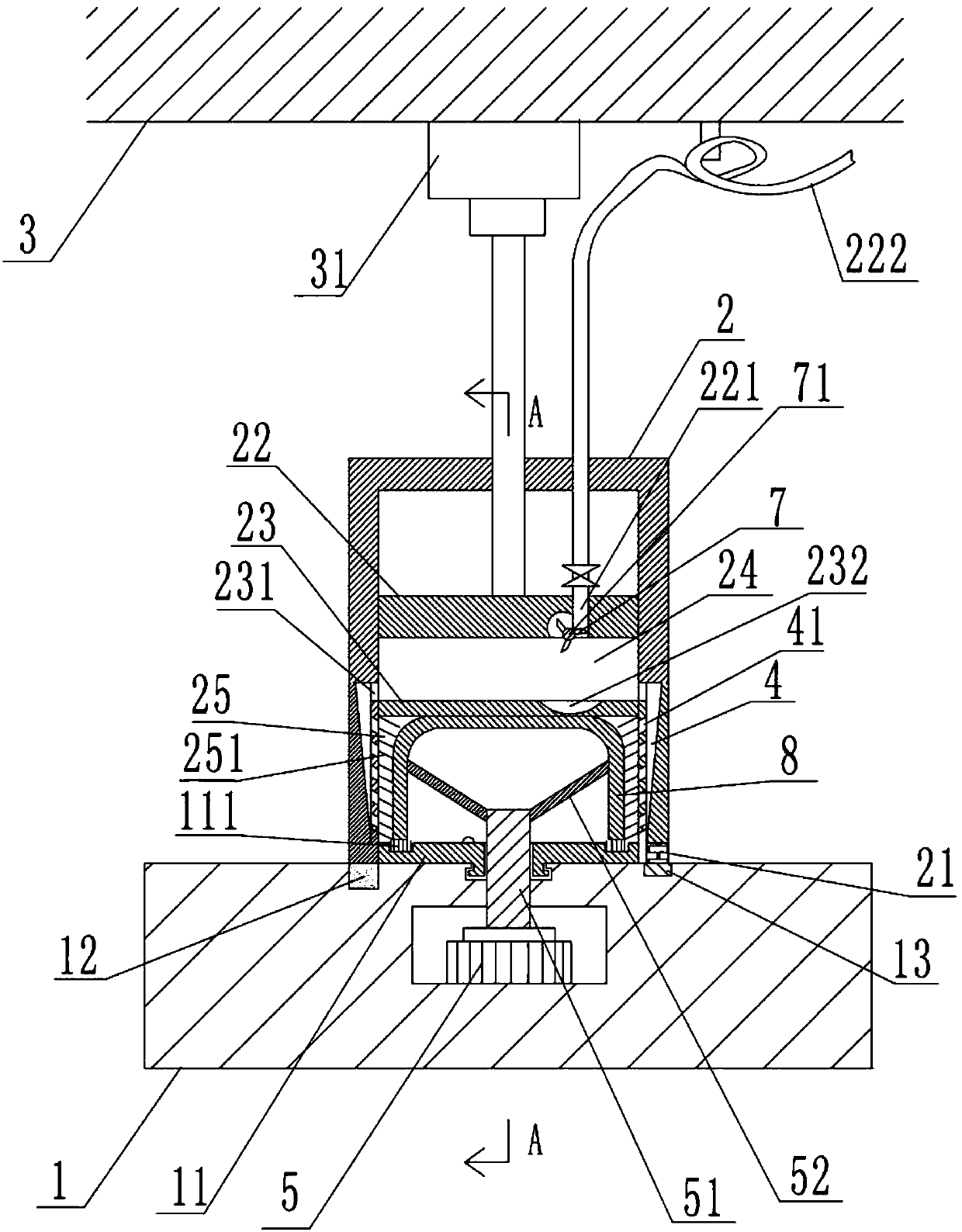

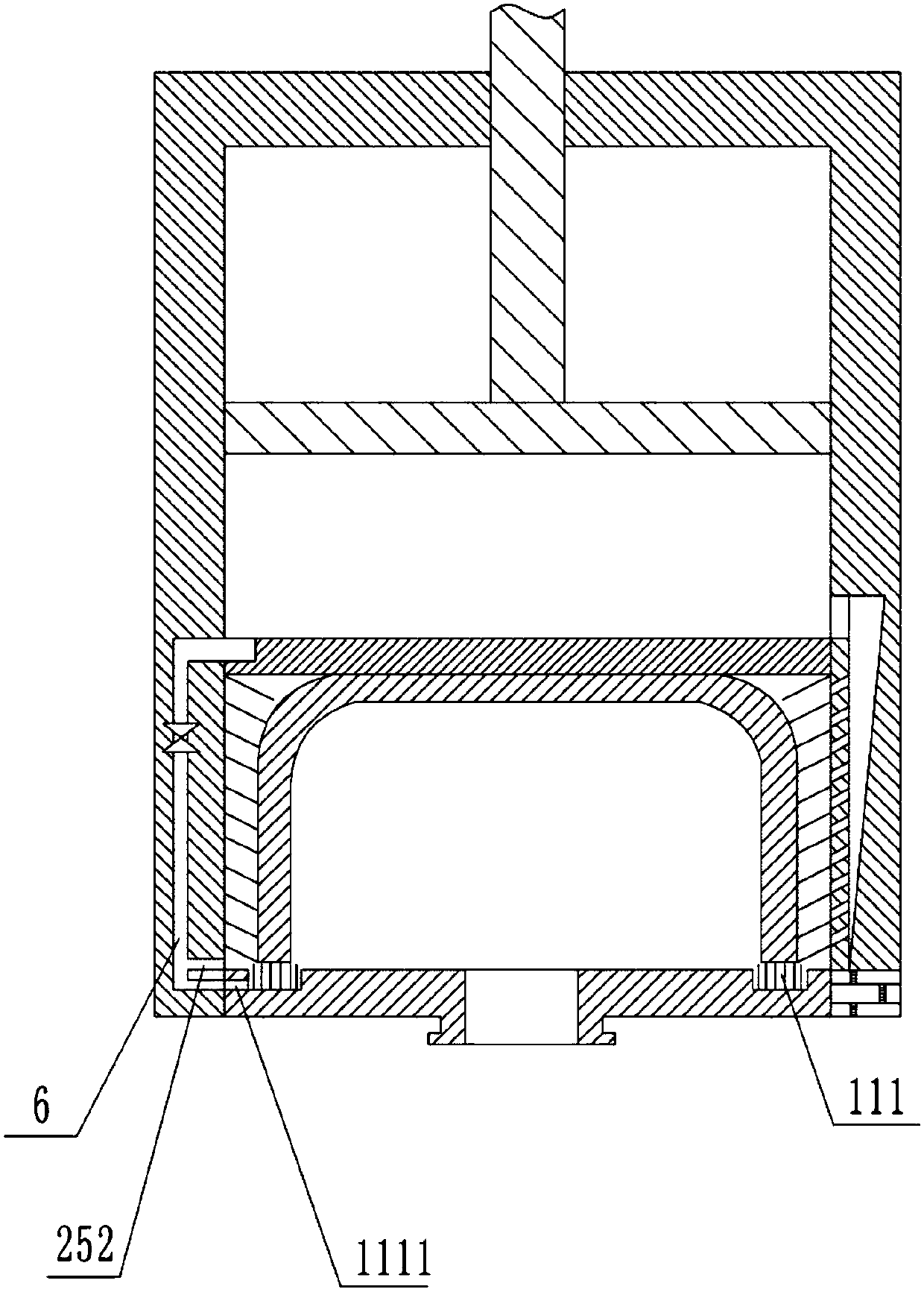

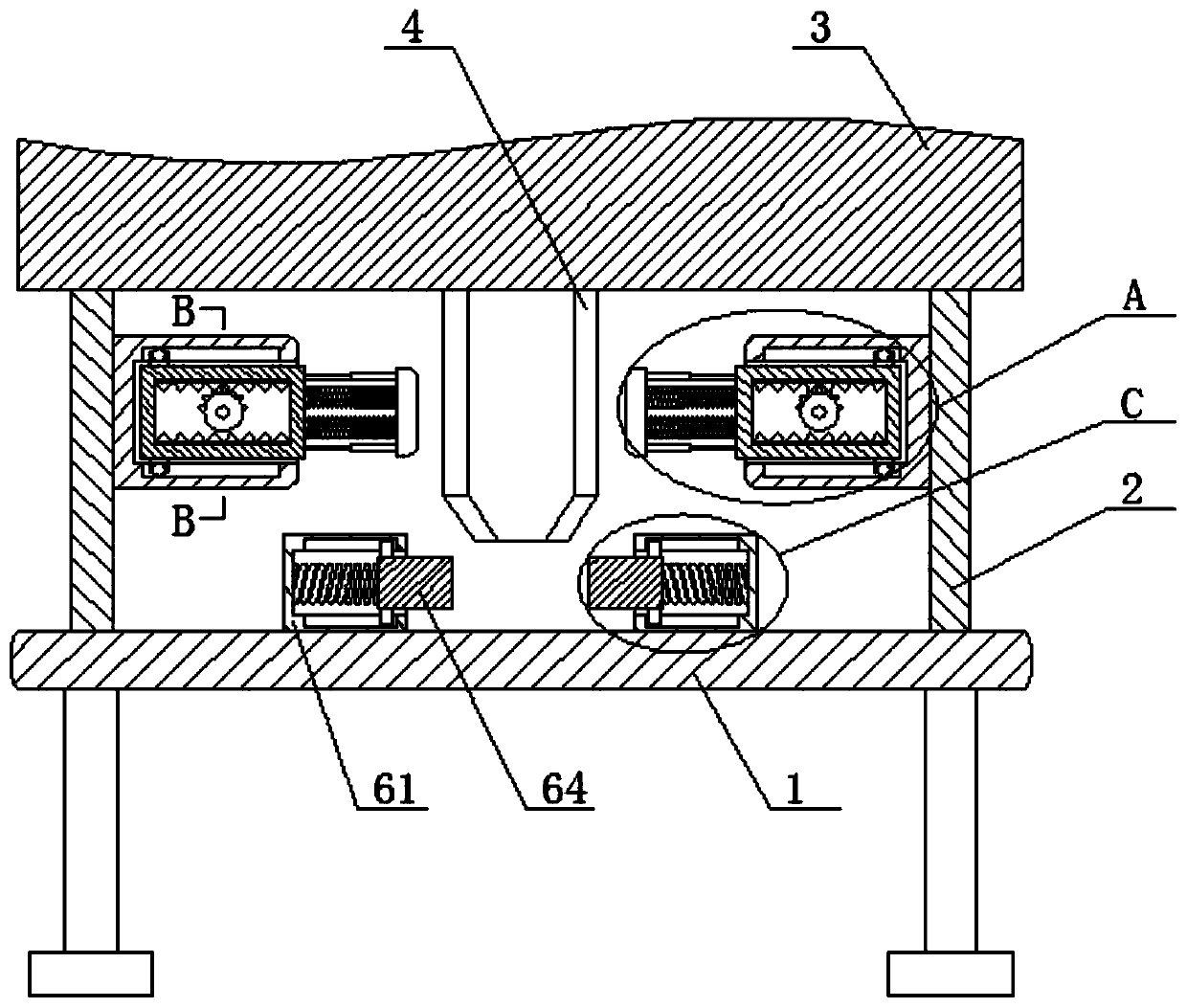

Coal crushing and drying integral device with screening function

ActiveCN107715954AUneven crushingSmash thoroughlyDrying gas arrangementsDrying chambers/containersHydraulic cylinderCinder

The invention discloses a coal crushing and drying integral device with a screening function. The coal crushing and drying integral device comprises a first motor, a bulge, a material tank, a second motor, a filtering net, a filtered substance recycling tank, a rotating shaft and a partition plate, wherein the first motor is connected with a conveying device; the upper end of a telescopic rod is connected with a hydraulic cylinder; a connecting disc is fixed at the lower end of the telescopic rod; a fixed hemisphere is connected with the connecting disc; crushing corns are distributed on the fixing hemisphere; the material tank is arranged at the right end of the conveying device; a lifting device is connected with the right side of the material tank; the lifting device is connected with the second motor; a hopper is fixed on the lifting device; the filtering net is arranged at the bottom of the hopper. Due to adoption of the filtering net on the hopper, the coal crushing and drying integral device with the screening function is capable of screening coal while the coal is conveyed and crushed, then coal cinder in the coal can be collected and treated for a second time, and the situation of coal cinder waste is avoided.

Owner:CHONGQING PERMANENT NEW MATERIAL

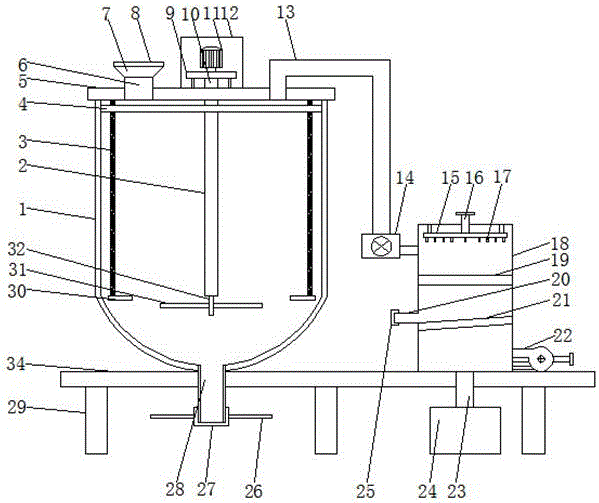

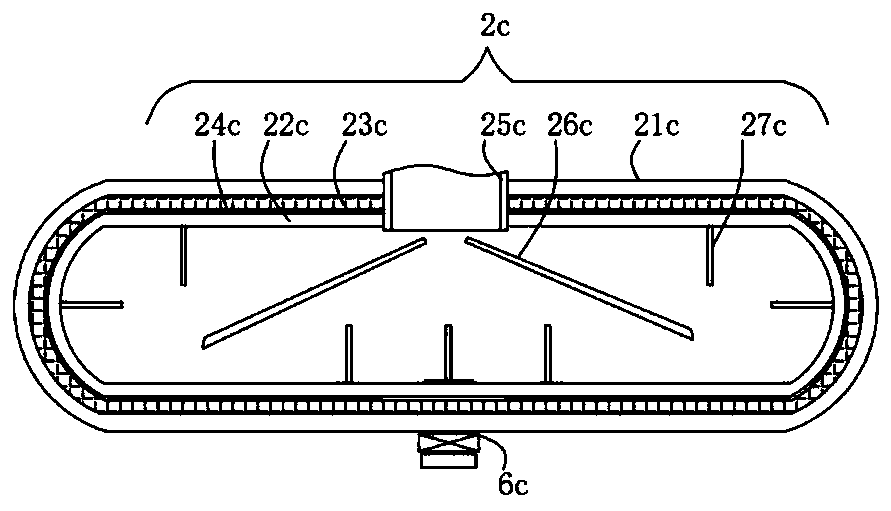

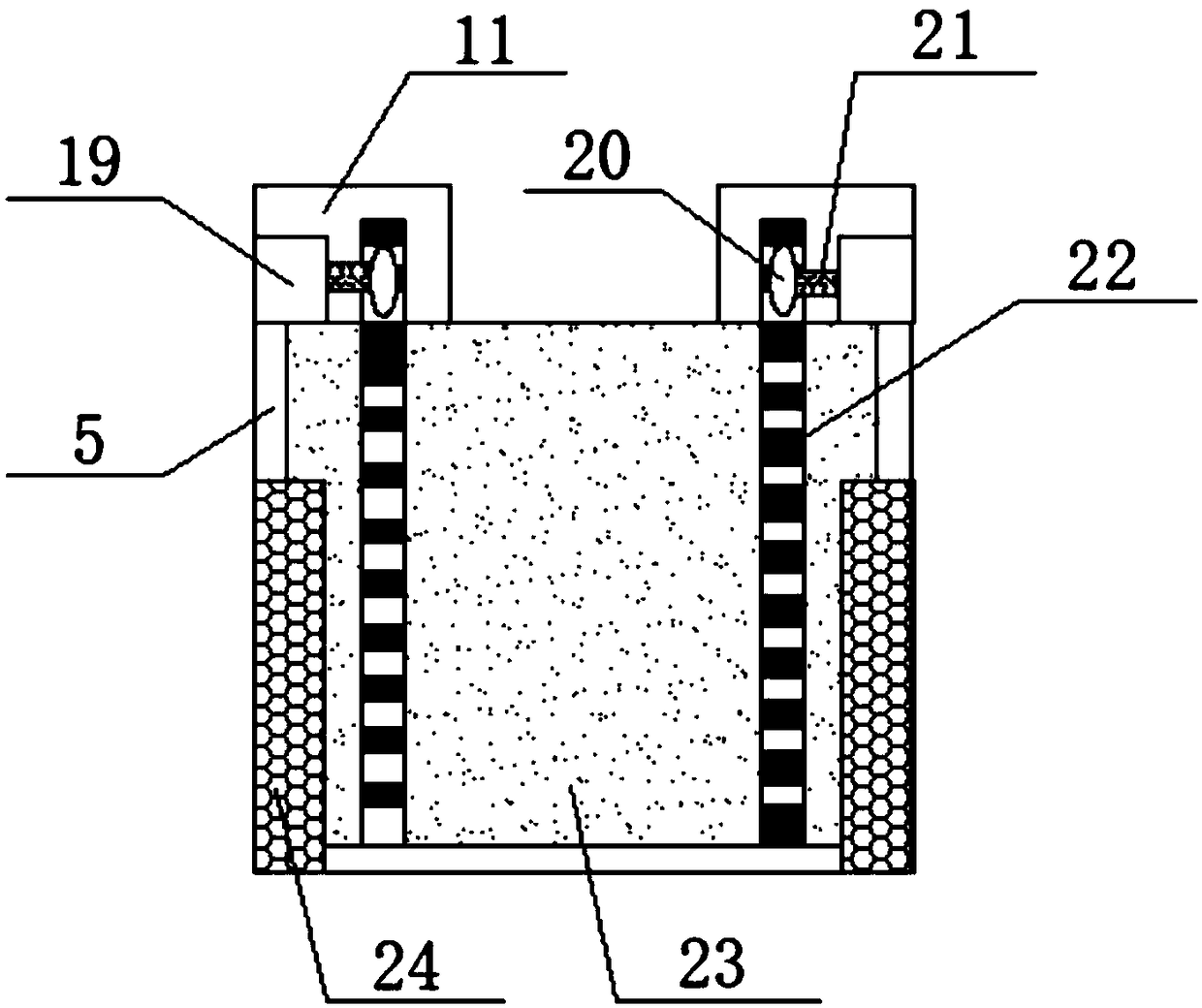

Mixing device of silk-screen ink

InactiveCN106422888AAvoid wastingGuaranteed stabilityRotary stirring mixersTransportation and packagingEngineeringMixing tank

The invention discloses a mixing device for silk-screen ink, which comprises a mixing tank. The top of the mixing tank is provided with a top cover, the middle part of the inner chamber of the mixing tank is provided with a threaded rod, the top of the threaded rod is connected with a rotating shaft, the top of the transmission is connected with a rotating motor, and the top of the threaded rod is fitted with a cleaning plate. Both sides of the inner chamber of the mixing tank are provided with fixed rods, and the bottom of the cleaning plate is provided with a stop block. The bottom of the threaded rod is connected with a stirring rod, the bottom of the mixing tank is provided with a base, the middle part of the bottom of the mixing tank penetrates the base and is connected with a discharge pipe, the bottom of the base is equidistantly connected to a pillar, the bottom of an exhaust pipe is provided with a condenser having a right side connected to a purifying tank, and the inner chamber of the purifying tank is provided with a spray pipe, absorbent and a screen in order from top to bottom. The mixing device has the advantages of cleaning the raw materials in the mixing tank, and solves the problem that the mixing equipment is not environment friendly.

Owner:无锡龙翔印业有限公司

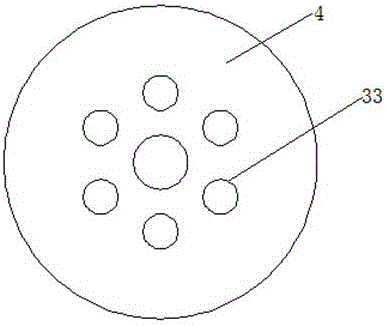

Combustion chamber of gas boiler

InactiveCN1553115AImprove yieldIncrease heat transfer areaWater heatersCombustion chamberPlate heat exchanger

The present invention is featured as follows: water inlet pipe of heat supply is formed at internal of heat exchanger to raise heat exchanging efficiency and heat isolation component is placed on shell of the heat exchanger; heat exchanging tube is formed in double structure as copper tube is inside and aluminium tube is outside, they two are shaped together by rolling and heat absorption fins are structured on peripheral surface of aluminium tube; or heat exchanging tube is formed completely with copper tube with heat absorption fins on peripheral surface of the tube.

Owner:株式会社庆东BOILER

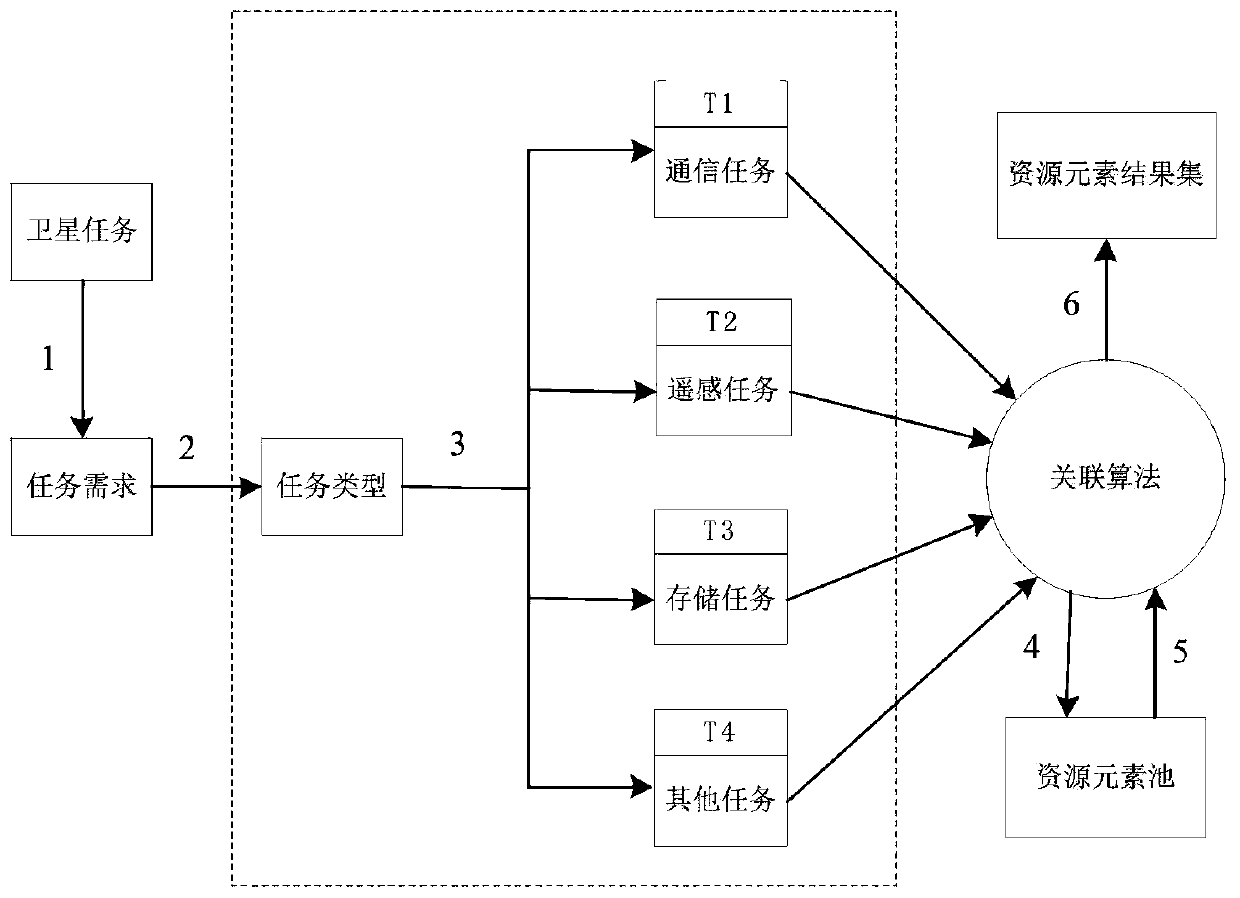

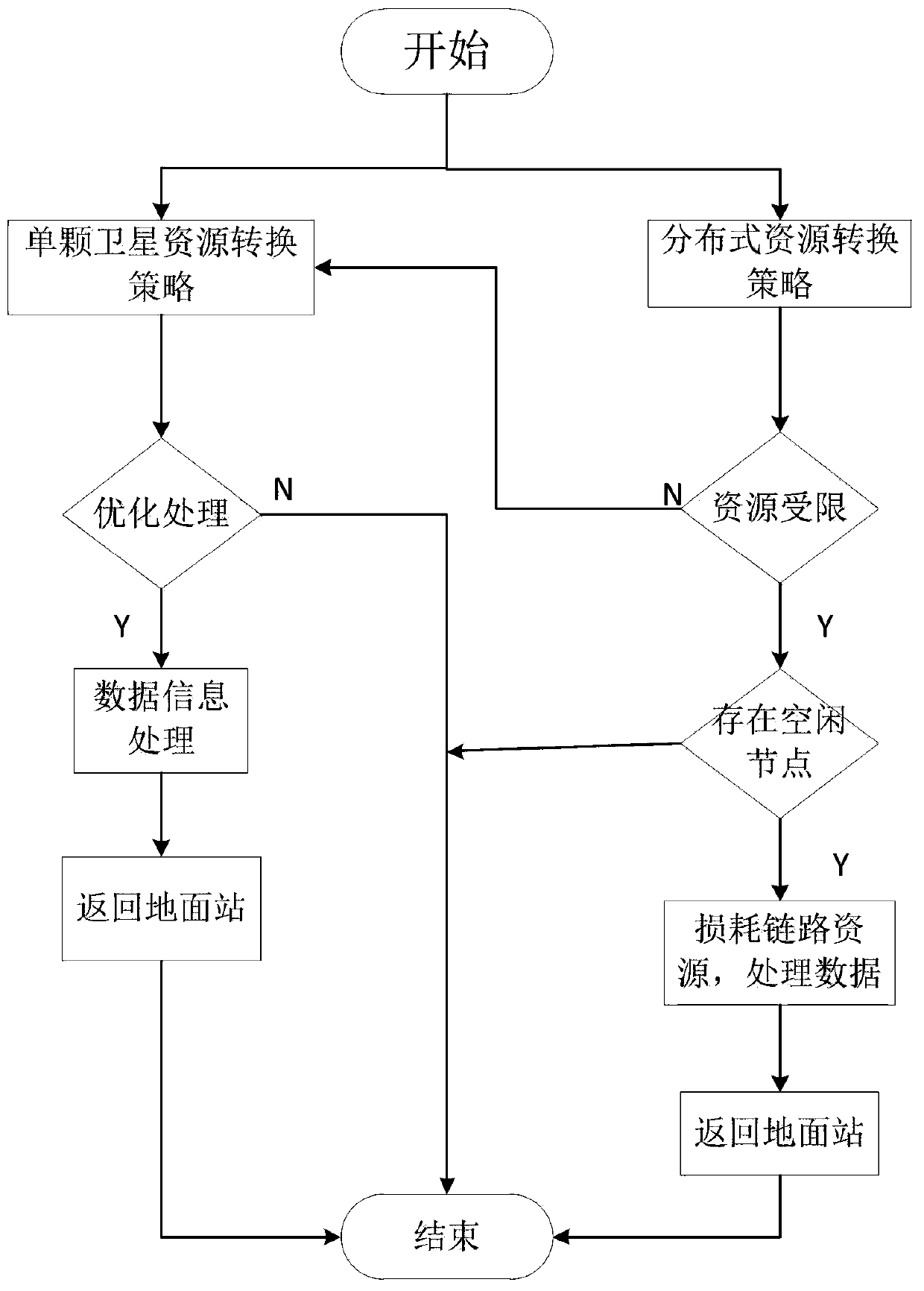

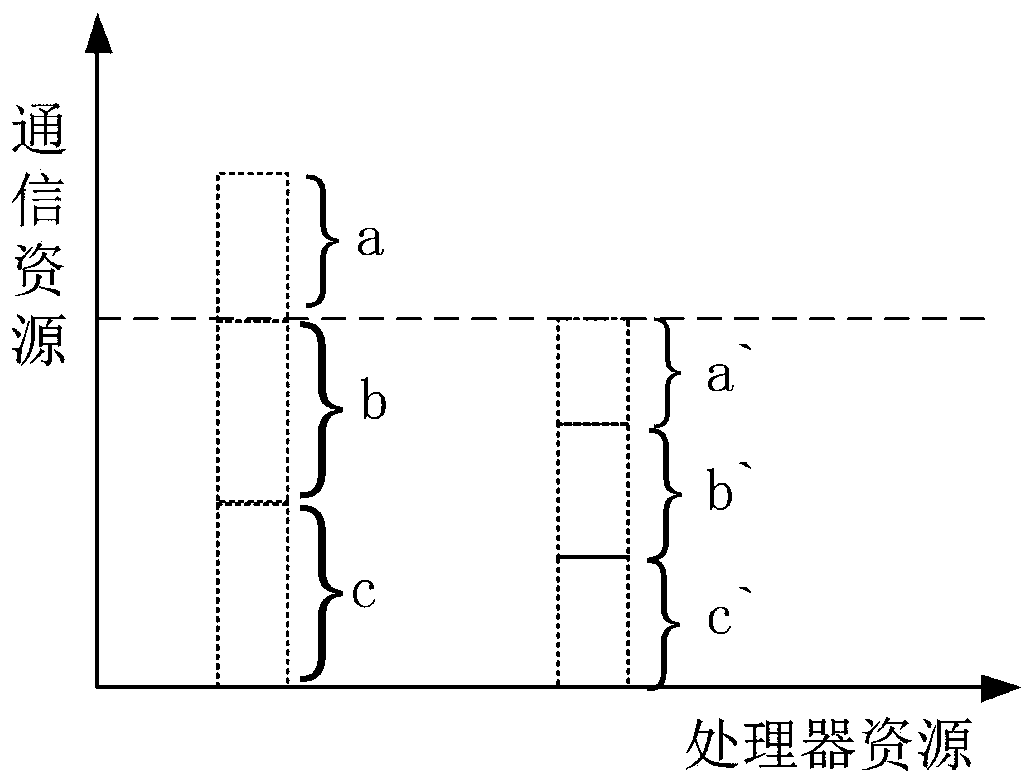

Satellite network resource management method based on resource representation

InactiveCN109981163APrevent wasteful situationsOptimize resource allocationRadio transmissionTransmission monitoringNetwork resource managementResource based

The invention discloses a satellite network resource management method based on resource representation. The method comprises the following steps: analyzing network resources; performing resource characterization; performing resource association; and performing resource collaborative optimization, and designing a single satellite node resource conversion strategy and a distributed resource conversion strategy according to the characteristic that satellite load resources can be shared. Due to the fact that a characteristic parameter representation method is adopted, basic conditions for supporting establishment of a satellite network resource management database are achieved. Due to the fact that the task-oriented characteristic of the satellite network is adopted, the task association algorithm is adopted, the problem of optimizing resource distribution in the satellite network is solved, and the situation that network resources are wasted is prevented. Due to the fact that a collaborative optimization method (resource conversion strategy) is adopted, the purpose of improving the task success rate under the condition that the resources of the satellite network are limited is achieved, and the collaborative optimization capacity among the resources is improved.

Owner:DALIAN UNIV

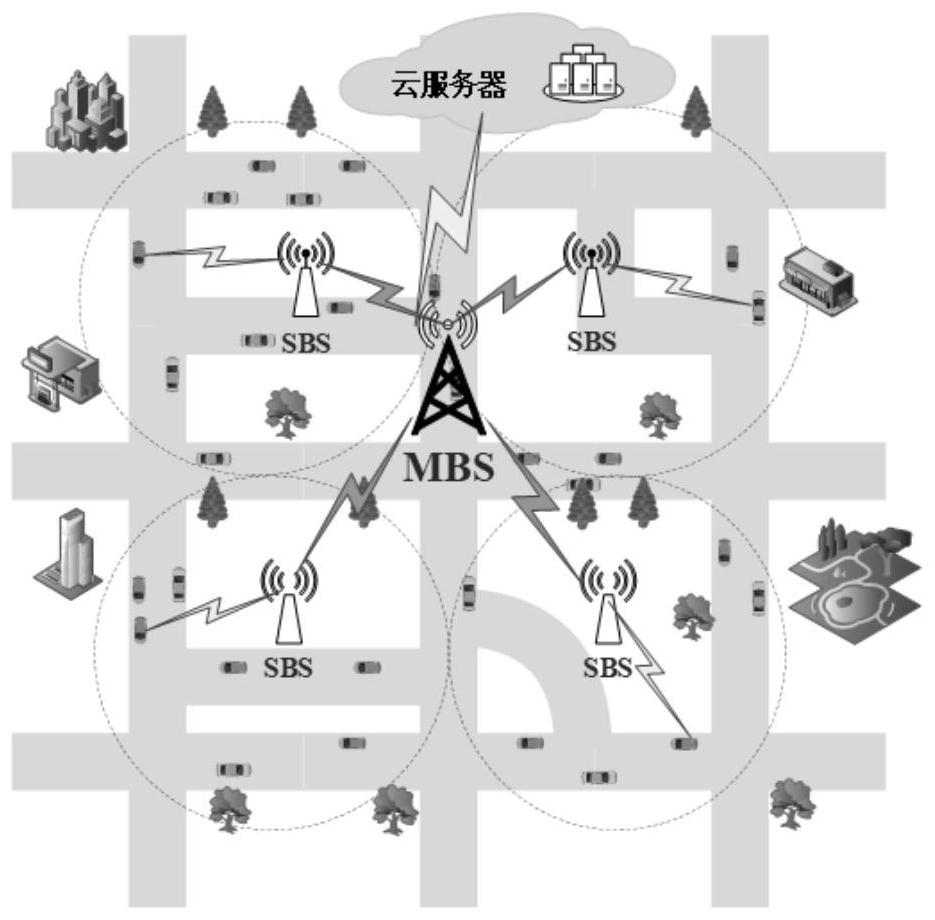

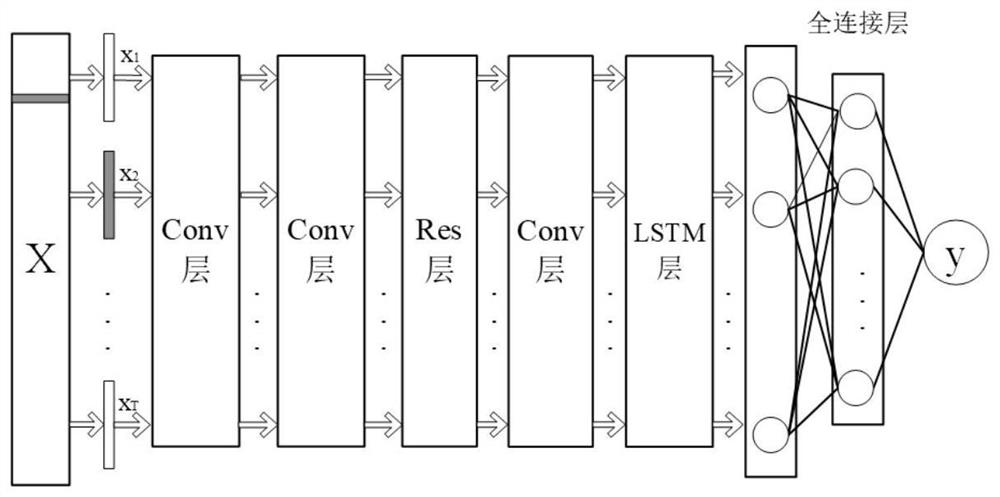

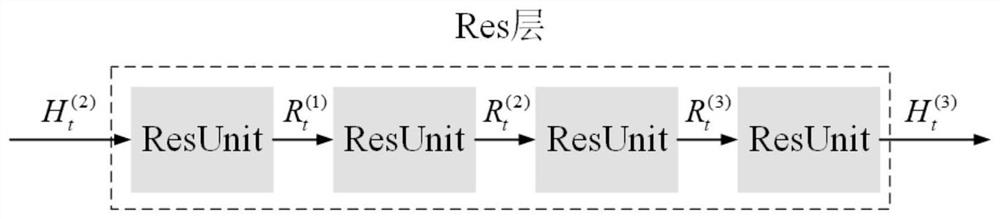

Double-layer cellular Internet-of-Vehicles spectrum allocation method based on vehicle number prediction

ActiveCN112203228AImprove accuracyImprove network utilityParticular environment based servicesVehicle wireless communication serviceResource assignmentData set

The invention discloses a double-layer cellular Internet-of-Vehicles spectrum allocation method based on vehicle number prediction. The double-layer cellular Internet-of-Vehicles spectrum allocation method comprises the following steps of: establishing a network environment; preprocessing an existing vehicle trajectory data set; considering the time correlation and the space correlation among vehicle numbers of a plurality of regions in an actual scene, establishing a vehicle number prediction network model based on a convolution structure and LSTM, and representing the vehicle number prediction network model as a Conv_LSTM network; carrying out resource demand analysis, setting a resource demand function to be a power function, wherein a power exponent changes between 0 and 1; predictingthe number of vehicles in each SBS region at a future moment based on the Conv_LSTM network, and then acquiring resource demand of each small base station SBS at the future moment correspondingly; modeling a problem that MBS allocates resource blocks to SBS of each small base station into a multi-point dyeing problem, providing a dynamic resource allocation algorithm for solving the problem, and allocating RB resource blocks to each independent set in sequence based on the constraints of the total number of the RB resource blocks held by the MBS, so that the resource satisfaction of each SBS is balanced, and the resource utilization rate of the network is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

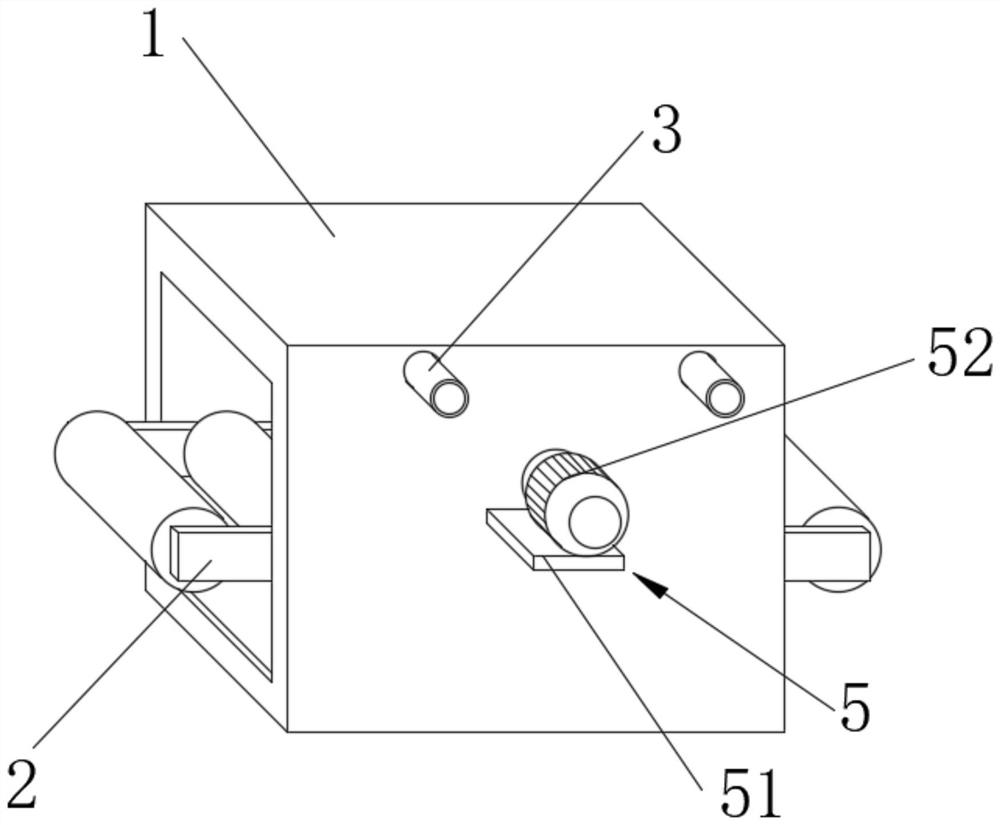

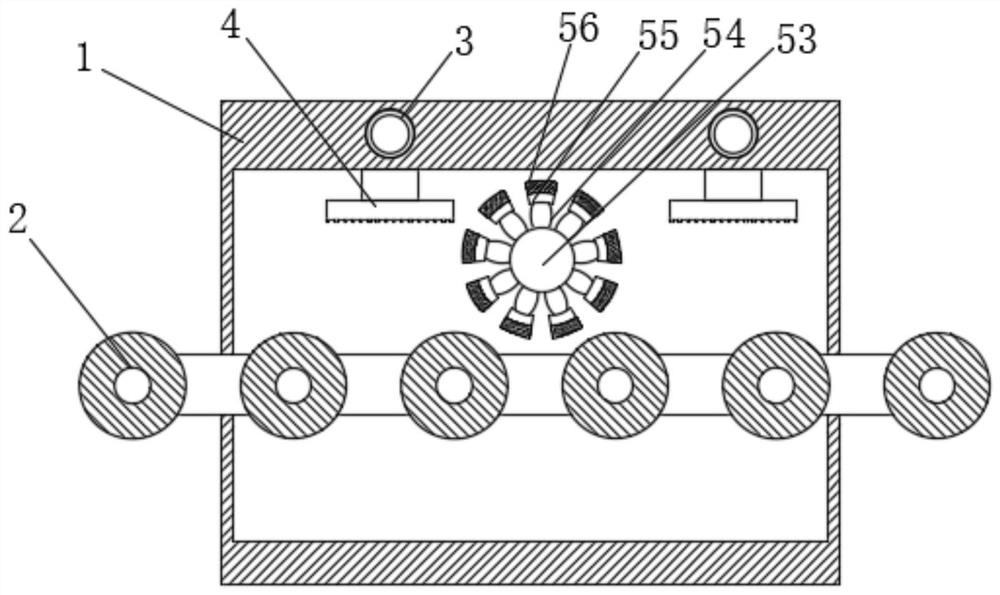

Cleaning and scrubbing device for street lamp plate processing

InactiveCN113369216AQuick drawAvoid wastingCleaning using toolsCleaning using liquidsElectric machineProcess engineering

The invention relates to the technical field of scrubbing devices, and discloses a cleaning and scrubbing device for street lamp plate processing. The cleaning and scrubbing device comprises a processing box, a conveying roller, a water injection pipe and a flushing nozzle, wherein a scrubbing mechanism is arranged in the processing box; the scrubbing mechanism comprises a motor base, a motor, a rotating rod, an elastic sleeve, a brush plate, a brush and a liquid guide pipe, and the liquid guide pipe is composed of a water pipe and a first air bag; a transmission plate, a pressed plate, a guide groove, a first arc-shaped rod and a second arc-shaped rod are arranged in the elastic sleeve, and a fixing rod, a clockwork spring, a transmission rope, a sliding groove and a second air bag are arranged in the brush plate; the first air bag is arranged; thus, when the scrubbing device works, cleaning solutions can be rapidly sucked and discharged onto a brush; therefore, a street lamp plate can be cleaned and scrubbed more efficiently, and through the device, the cleaning solutions cannot be washed away by water when not used; and waste of the cleaning solutions is avoided, and therefore the cleaning and scrubbing cost of the street lamp plate is reduced.

Owner:王园园

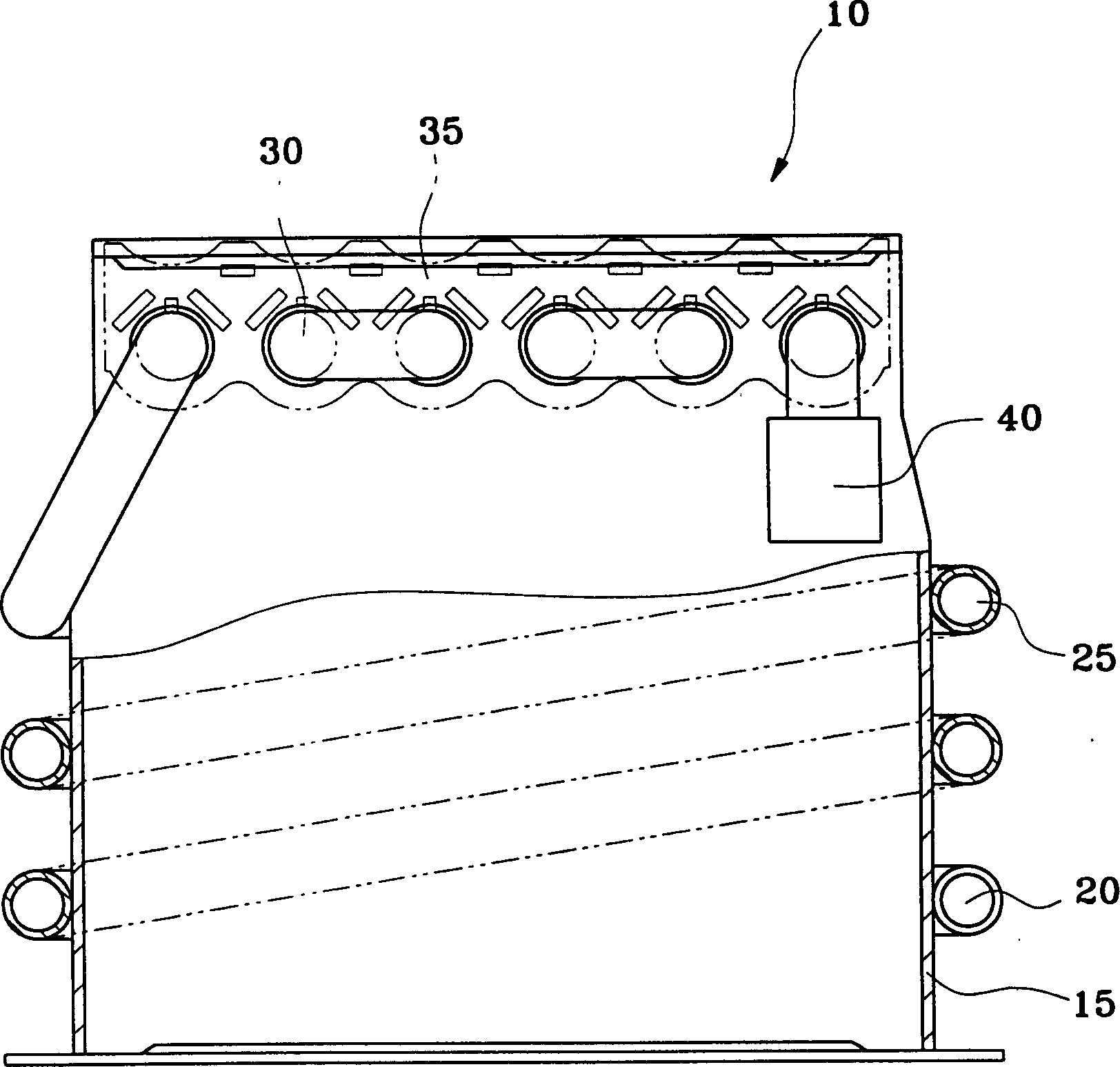

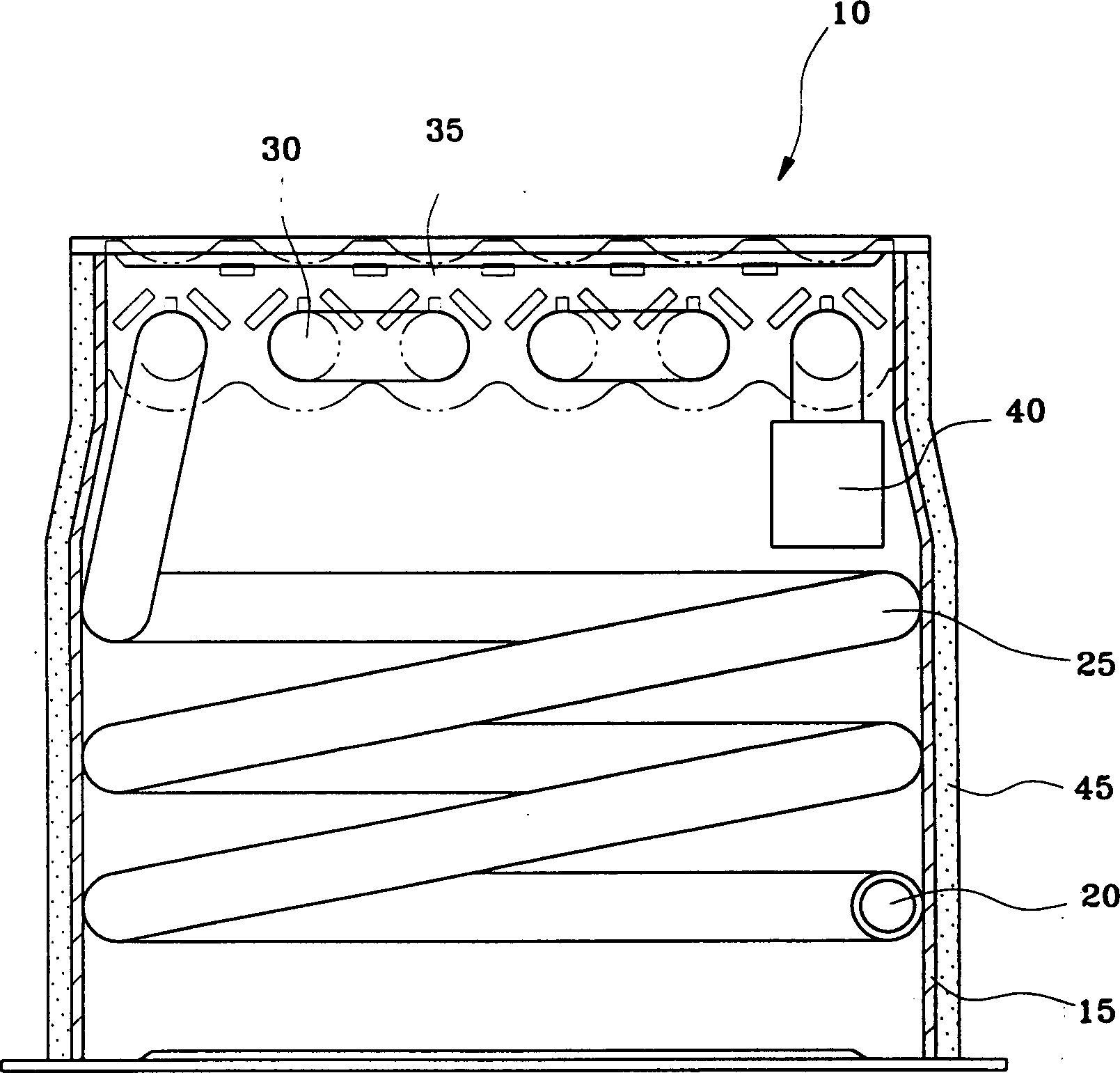

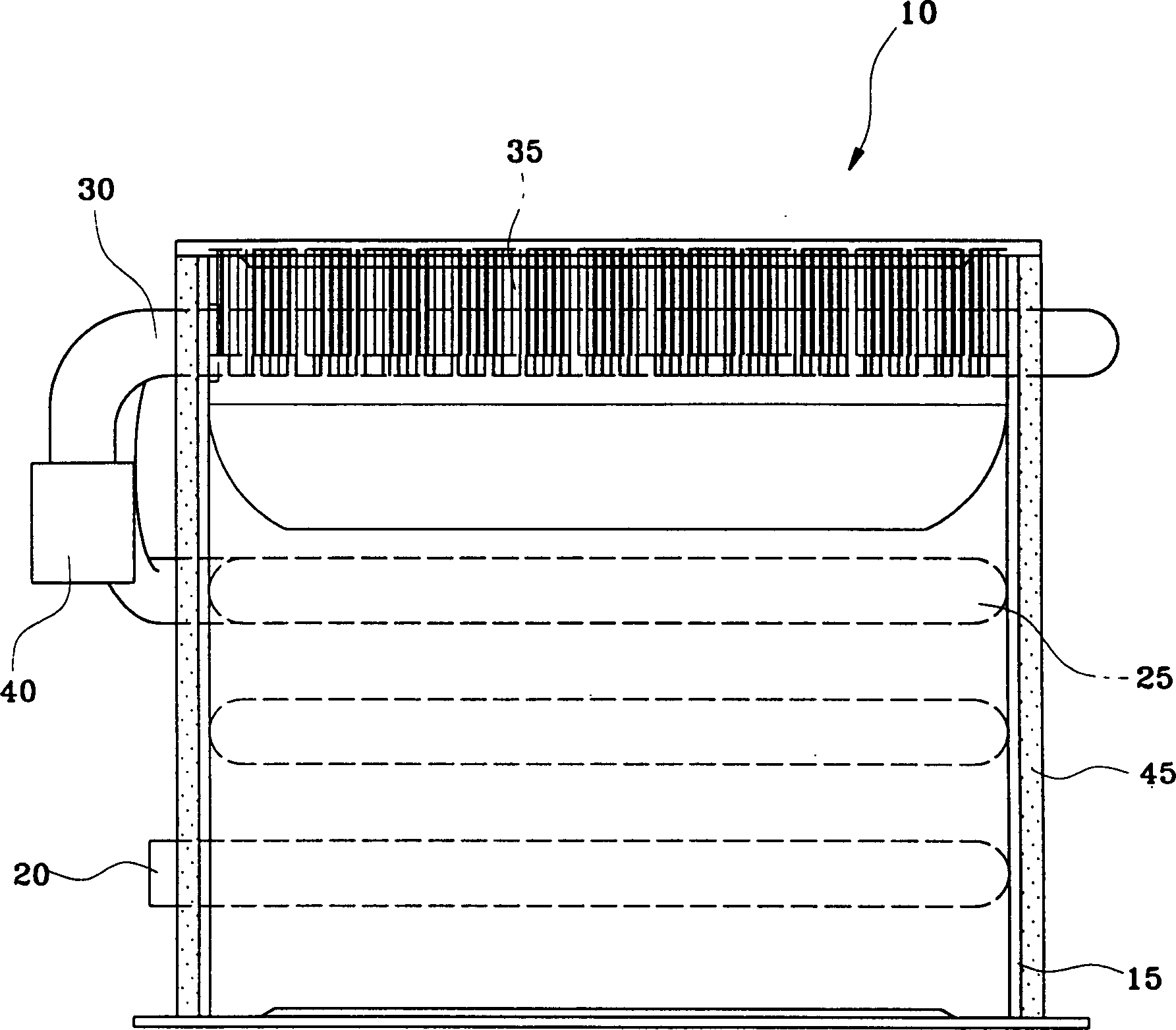

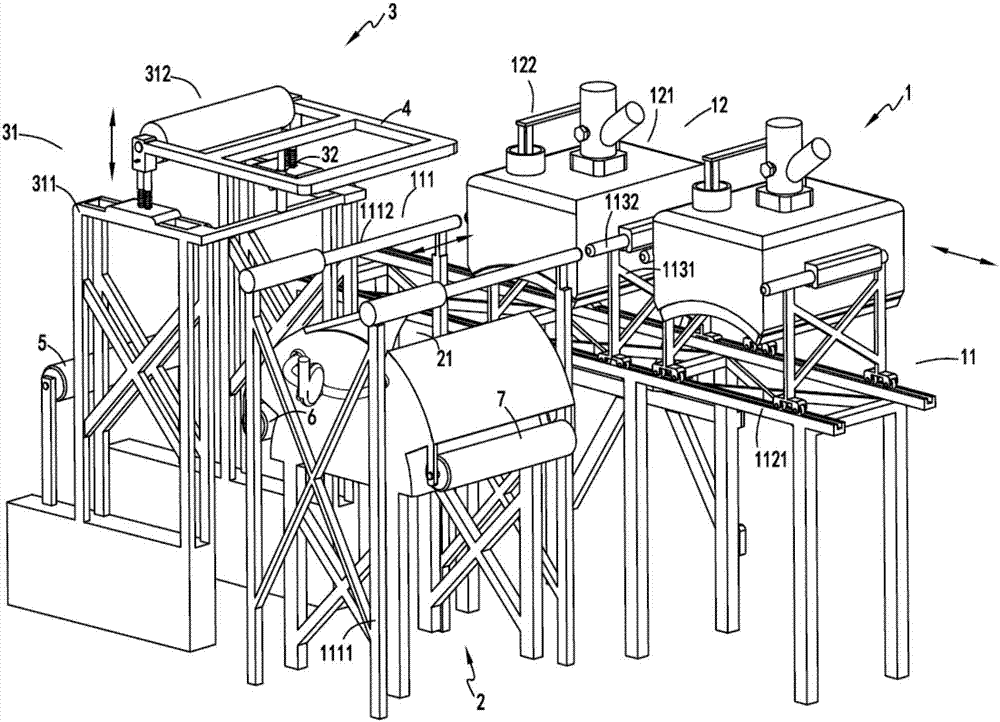

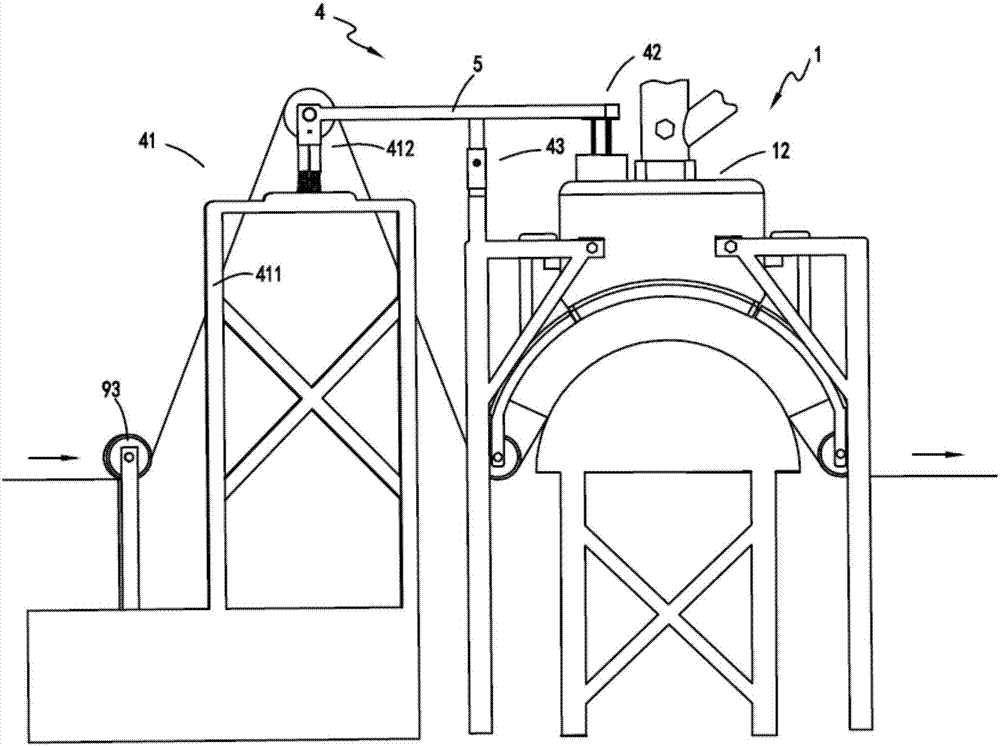

Switchable cloth dyeing and printing equipment

InactiveCN106968065AFlexible switchingAct as a fixed limitTextile treatment machine arrangementsTextile treatment by spraying/projectingInternal pressureWrinkle skin

The invention relates to a switchable cloth printing and dyeing equipment, which includes a dyeing box part, the dyeing box part includes a switching mechanism and a spraying mechanism; the switching mechanism includes a spraying support unit, a switching unit and a walking support unit; the spraying mechanism includes a spraying mechanism device and a pressure regulating device arranged on the spraying device; the spraying part, the spraying part is arranged below the spraying support unit, the spraying part includes a spraying station, and a support is arranged below the spraying station , the front end of the support is provided with a wrinkle removal unit, and the rear end of the support is provided with an absorption unit; the adjustment part, the adjustment part is arranged above the spraying mechanism, and the adjustment part includes a lifting mechanism that moves up and down under the action of gravity of the cloth, and the lifting mechanism Cooperate with the spraying mechanism on the spraying station to drive the pressure regulating device on the spraying mechanism to adjust the pressure inside the spraying device; it overcomes the problem that the equipment does not have the flexibility to switch different color dyeing boxes and does not have the ability to self-adjust the amount of dye injection question.

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

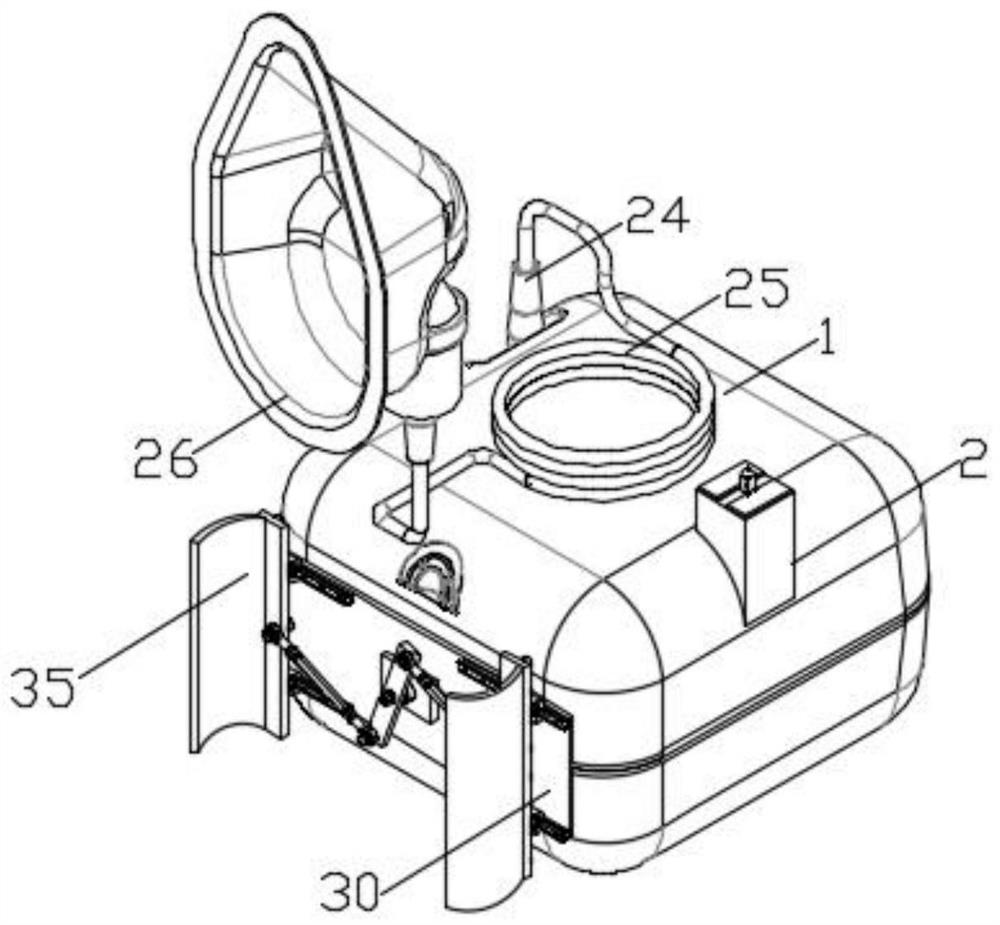

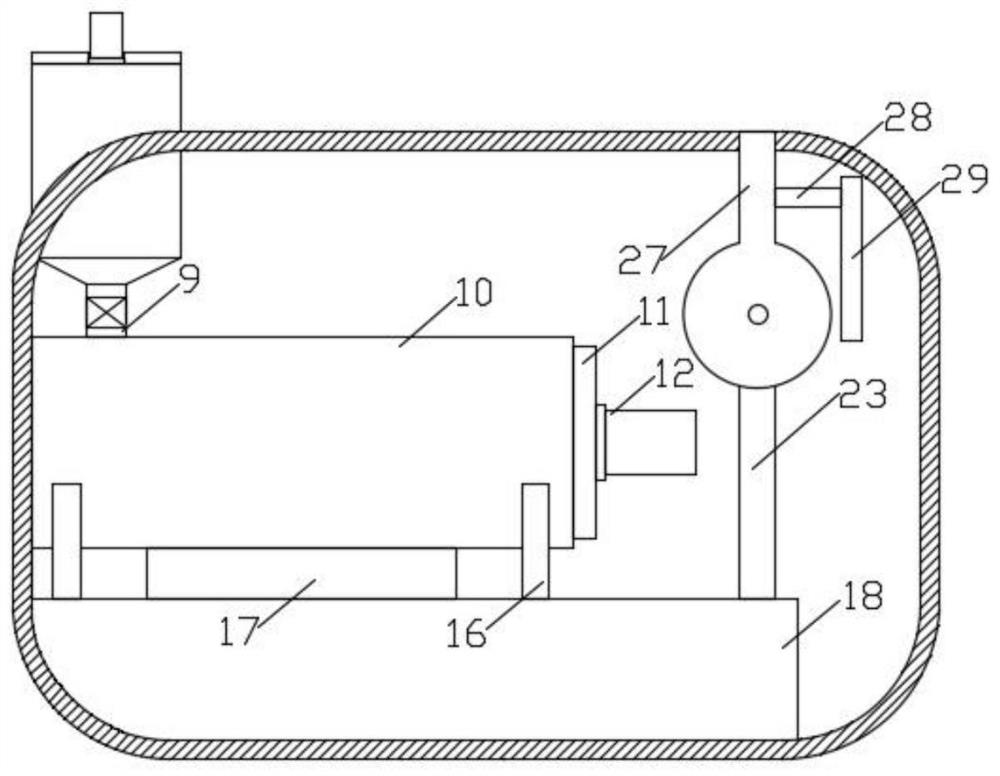

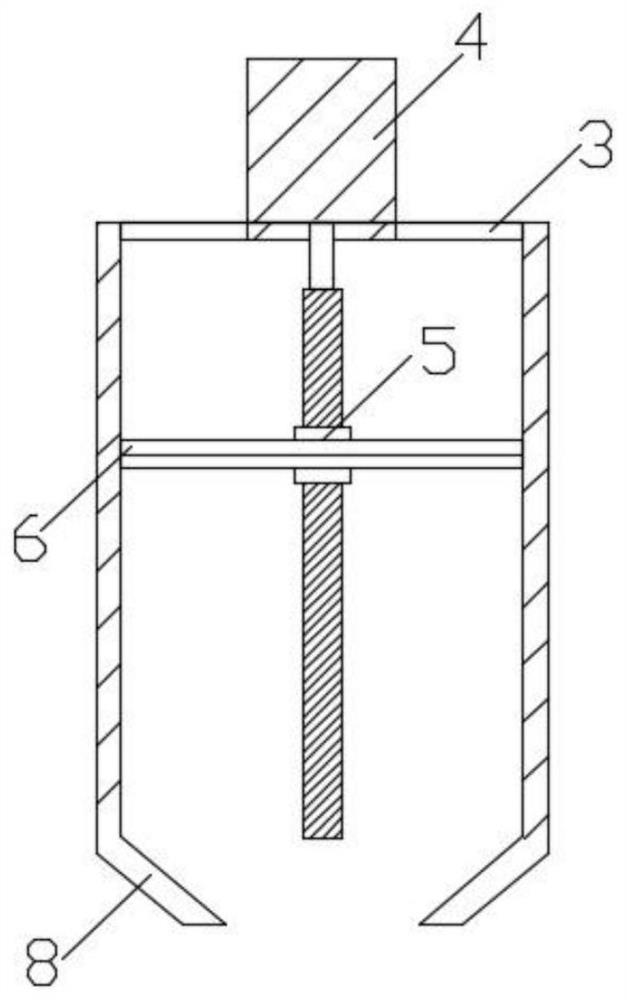

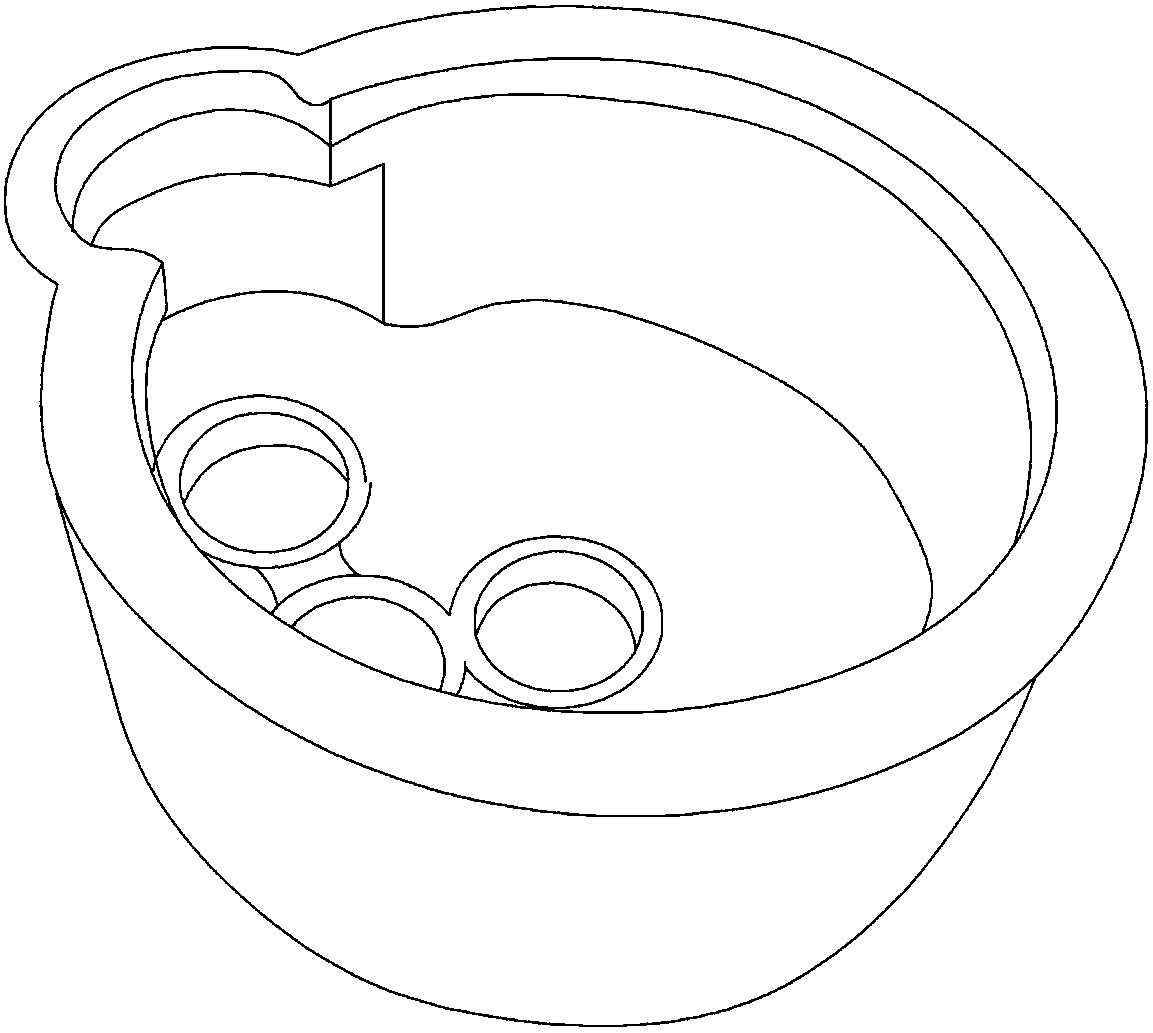

Small atomizer for treating respiratory diseases

ActiveCN111939398AConvenient treatmentAvoid situations that make it impossible to continue treatmentMedical atomisersBiomedical engineeringIntensive care medicine

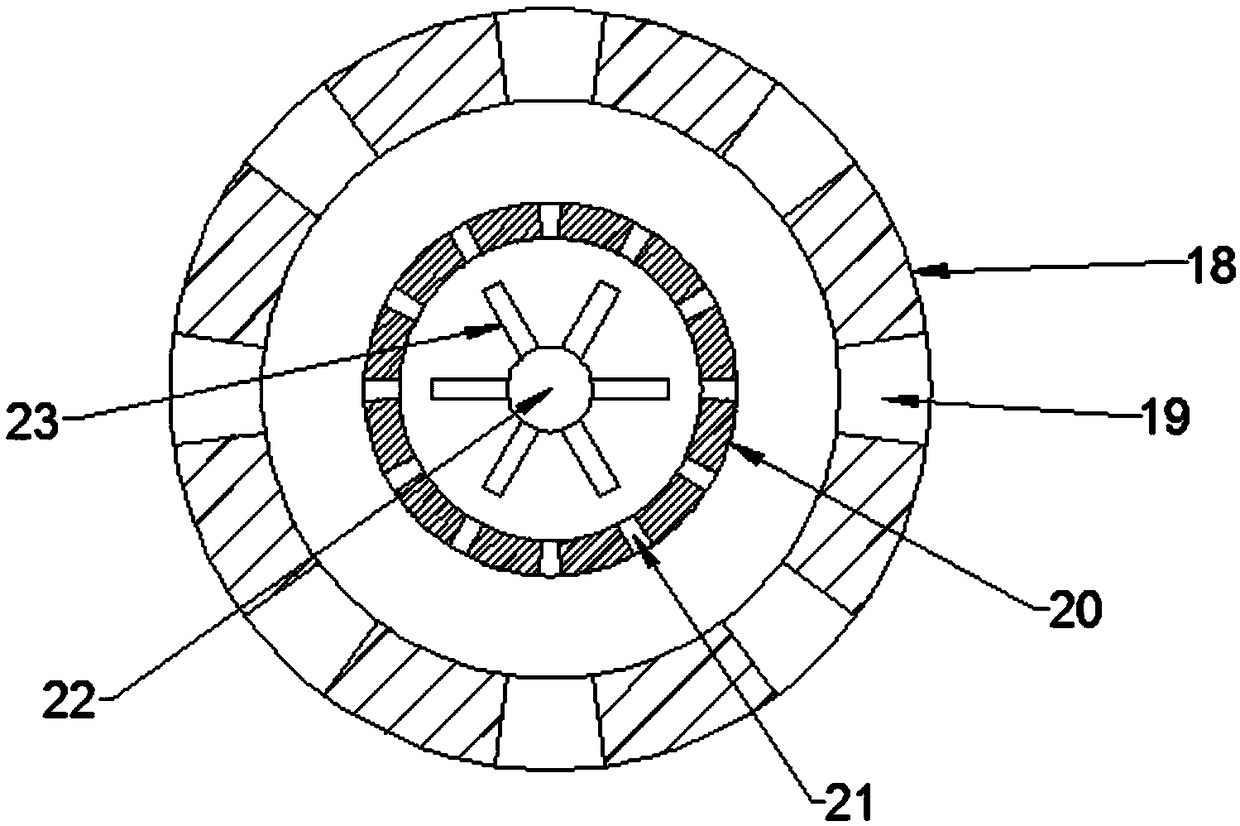

The invention discloses a small atomizer for treating respiratory diseases. The small atomizer is convenient for treating children with respiratory diseases, and clamps the waist of the children through arc waist clamps on two sides to prevent the condition of incapability of continuously treating caused by movement of the children in the treatment process of the children; two liquid inlets are formed in a liquid inlet pipe for conveniently adding different liquid medicines at the same time; through a filter screen frame design capable of repeatedly lifting, the filter screen frame is always in a dynamic environment to prevent blockage of a column filter screen by dust absorbed on the filter screen frame to influence conveying of the liquid medicines; through a scraper on the filter screenframe, the liquid medicines remained on the inner wall of the liquid inlet pipe are scraped to prevent the condition of waste of the remained liquid medicines; and through cooperation between a center tooth and three planet teeth, three stirring rollers stir the liquid medicines, so that the stirring efficiency is high, and the mixing degree of the liquid medicines is high.

Owner:安徽康居人健康科技有限公司

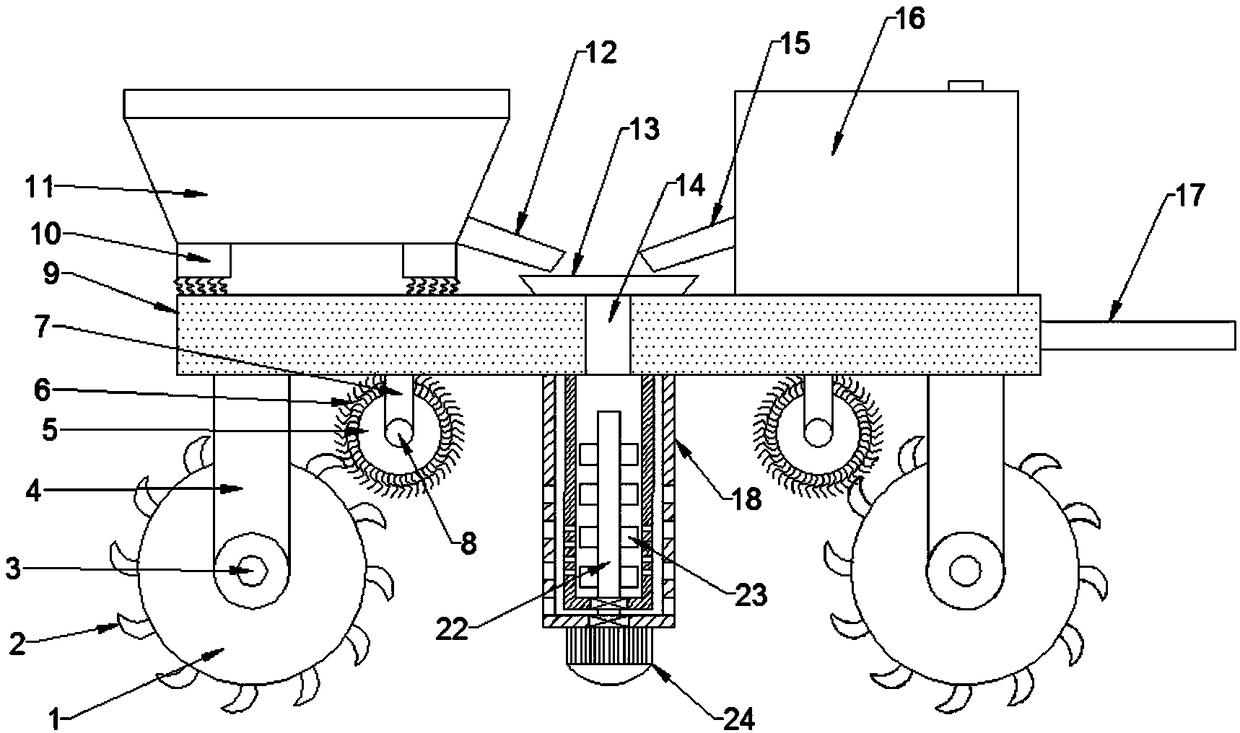

Self-mixing agent spreading vehicle for farmland soil treatment

InactiveCN108702885AImprove processing qualityExpand the scope of sprayingSoil lifting machinesSpadesSoil treatmentWater storage tank

The invention discloses a self-mixing agent spreading vehicle for farmland soil treatment. The vehicle comprises a vehicle plate; mud overturning rollers are rotatably fixed to the bottom of the vehicle plate, a plurality of mud overturning shovels are fixed to the circumferential surfaces of the mud overturning rollers, and cleaning rollers are arranged above the inner sides of the mud overturning rollers; the top surface of the vehicle plate is sequentially provided with a material storage cylinder, a blanking hopper and a water storage tank from left to right; the bottom of the material storage cylinder is fixed to the left top surface of the mud overturning rollers through vibrators, and a material guiding pipe is connected to the right side wall of the material storage cylinder; the blanking hopper and a blanking port are formed in the center of the top surface of the vehicle plate, an outer mixing cylinder and an inner stirring cylinder are arranged under the blanking port, the inner stirring cylinder is sleeved with the outer mixing cylinder, the bottom surface of the outer mixing cylinder is fixedly provided with a stirring motor, a motor shaft of the stirring motor is fixedly provided with a stirring rod, and a plurality of stirring baffles are fixed at the portion, in the inner stirring cylinder, of the rod wall of the stirring rod. According to the self-mixing agentspreading vehicle, through the outer mixing cylinder and the inner stirring cylinder, the agent spreading range is enlarged, and the situation can also be prevented that the waste is caused when agents are put aside for a long time and then oxidized and deteriorated.

Owner:COMMON TECH DEV CO LTD

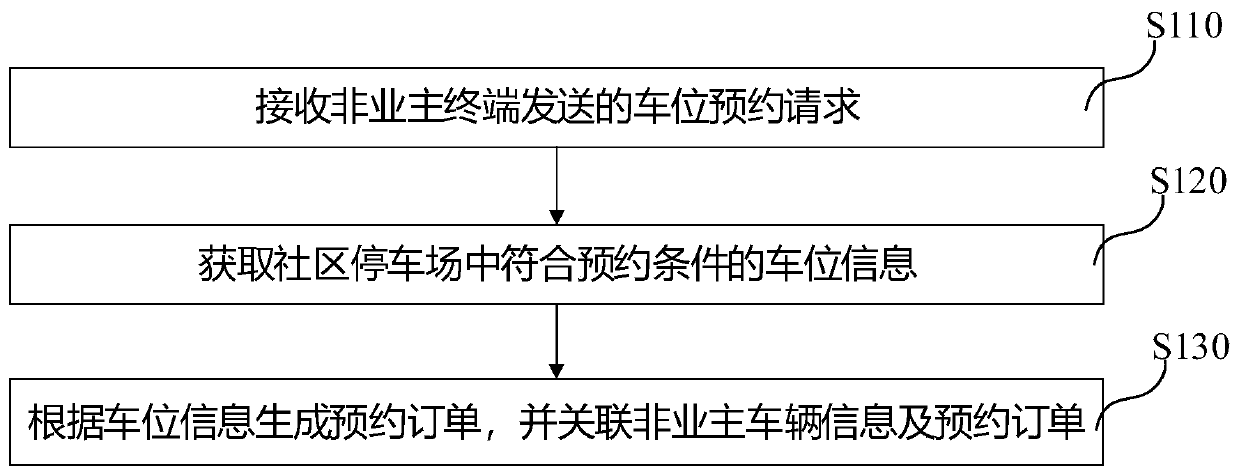

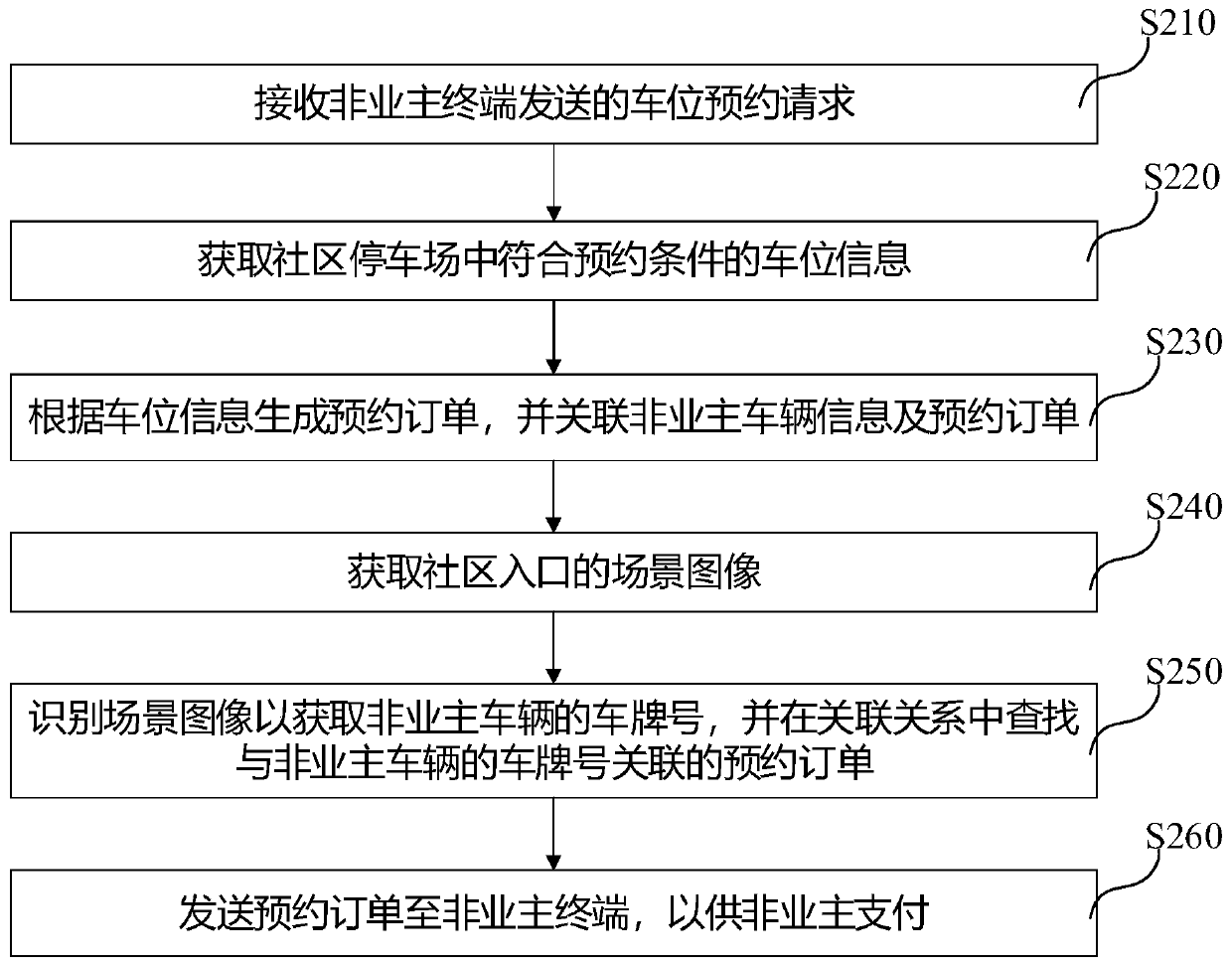

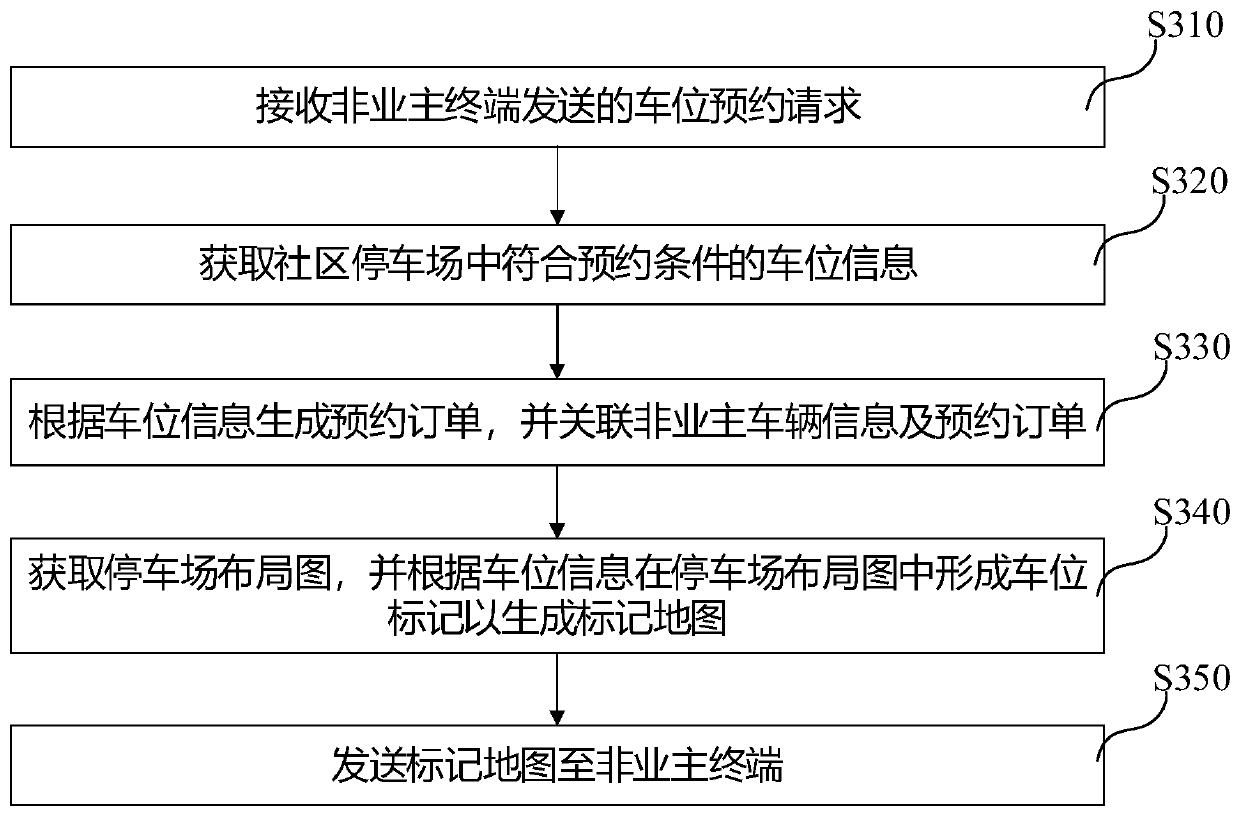

Community parking space management method and system and computer readable storage medium

InactiveCN111192472APrevent wasteful situationsImprove resource utilizationTicket-issuing apparatusIndication of parksing free spacesComputer networkParking space

The invention provides a community parking space management method and system and a computer readable storage medium, and the method comprises the steps: receiving a parking space reservation requestsent by a non-owner terminal, wherein the parking space reservation request comprises the information of a non-owner vehicle; acquiring parking space information meeting reservation conditions in thecommunity parking lot; and generating a reservation order according to the parking space information, and associating the non-owner vehicle information with the reservation order. With application ofthe method, non-owners can reserve the parking spaces in the community parking lot, then parking is conducted in the reserved parking spaces, the situation that the parking spaces of the community parking lot are wasted is prevented, and the resource utilization rate of the parking spaces of the community parking lot is increased.

Owner:EVERGRANDE SMART TECH CO LTD

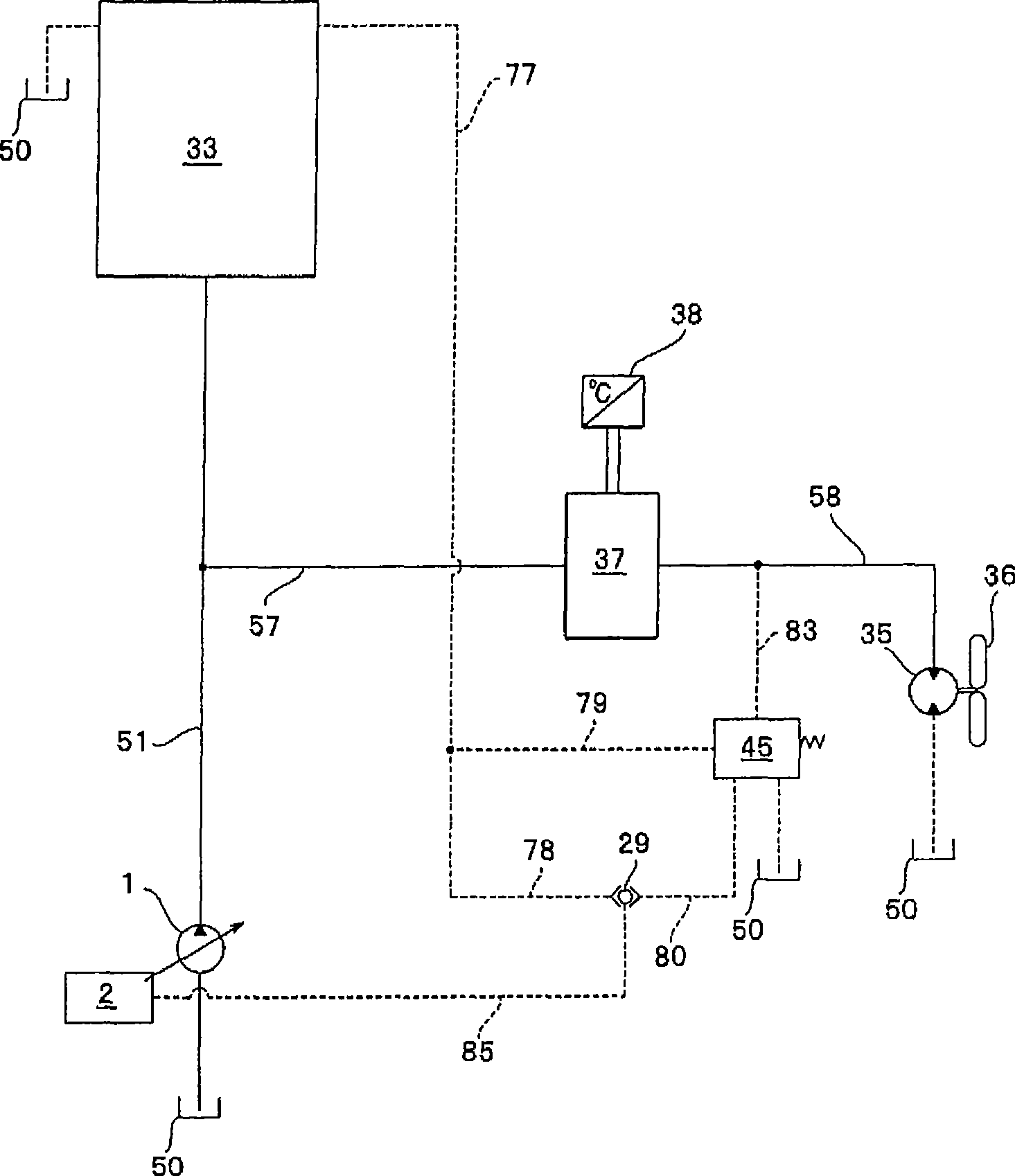

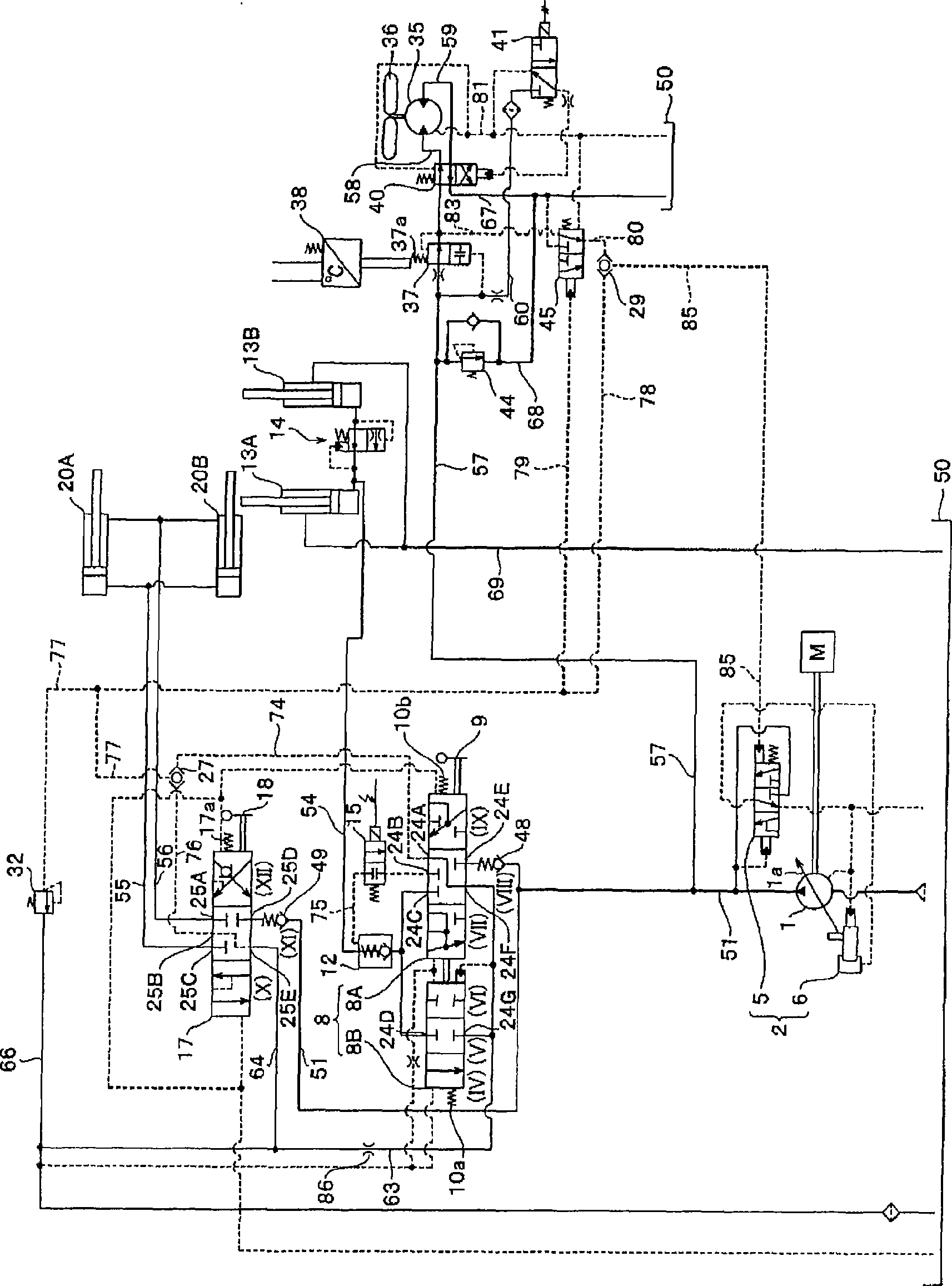

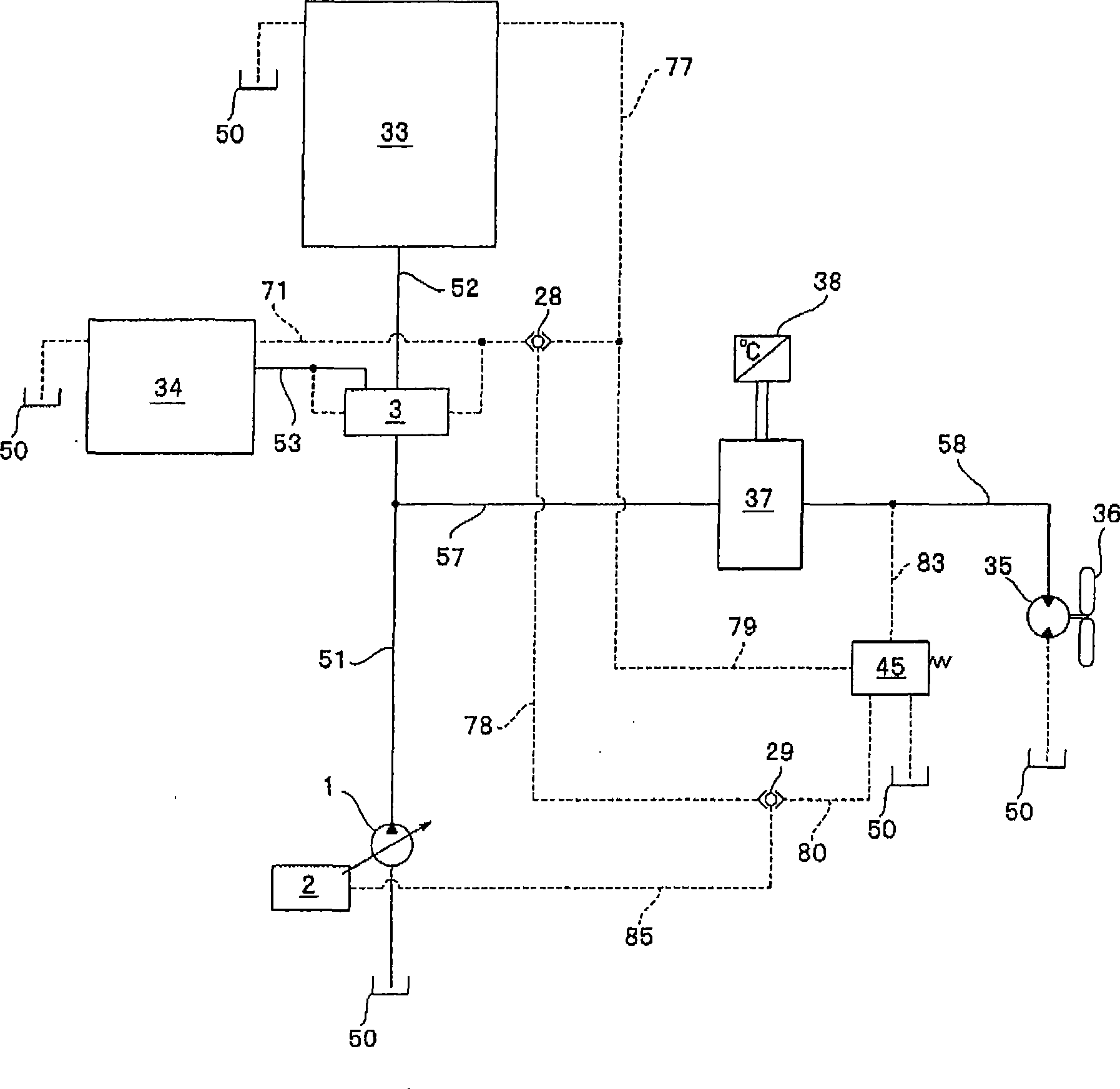

Fan drive system

InactiveCN101506484AControl capacityReduce capacityCoolant flow controlServomotorsHydraulic motorDisplacement control

A flow rate control valve (37) controlled based on coolant temperature is placed in an oil path for supplying oil to a hydraulic motor (35) from a variable displacement pump (1) in which the swash plate angle is controlled by a displacement control device (2). A pilot oil path (83) for detecting load pressure of the hydraulic motor (35) is connected to a shuttle valve (29) via a load pressure separation valve (45). To the shuttle valve (29) are led a maximum load pressure in a working machine circuit (33) and load pressure in a pilot oil path (80). High-pressure-side load pressure selected by the shuttle valve (29) is led to the displacement control device (2) via a pilot oil path (85). The load pressure separation valve (45) is controlled by load pressure from a pilot oil path (79). When load pressure is generated in the working machine, the load pressure separation valve (45) shuts off the communication between the pilot oil path (83) and the shuttle valve (29) to supply tank pressure to the shuttle valve (29).

Owner:KOMATSU LTD

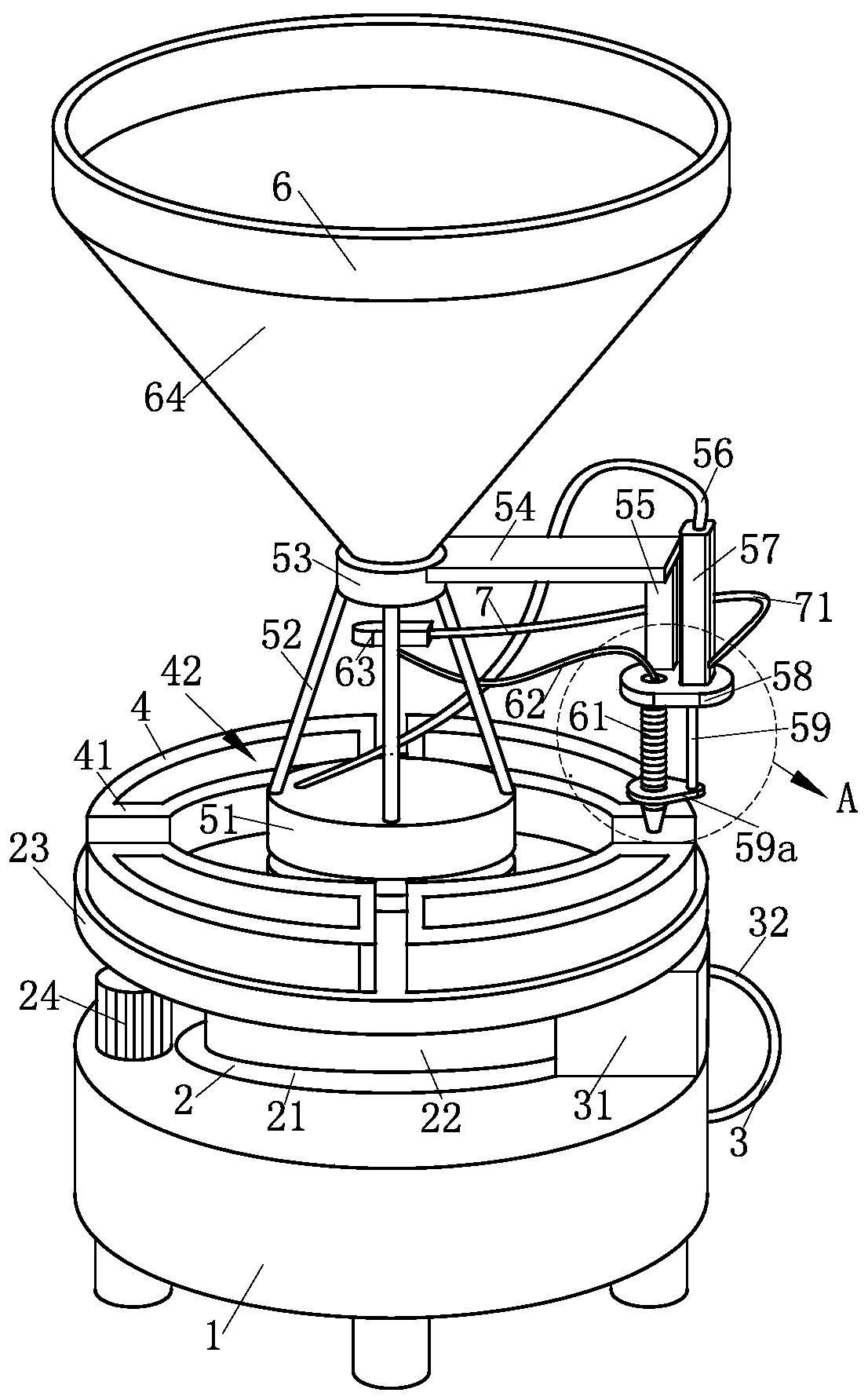

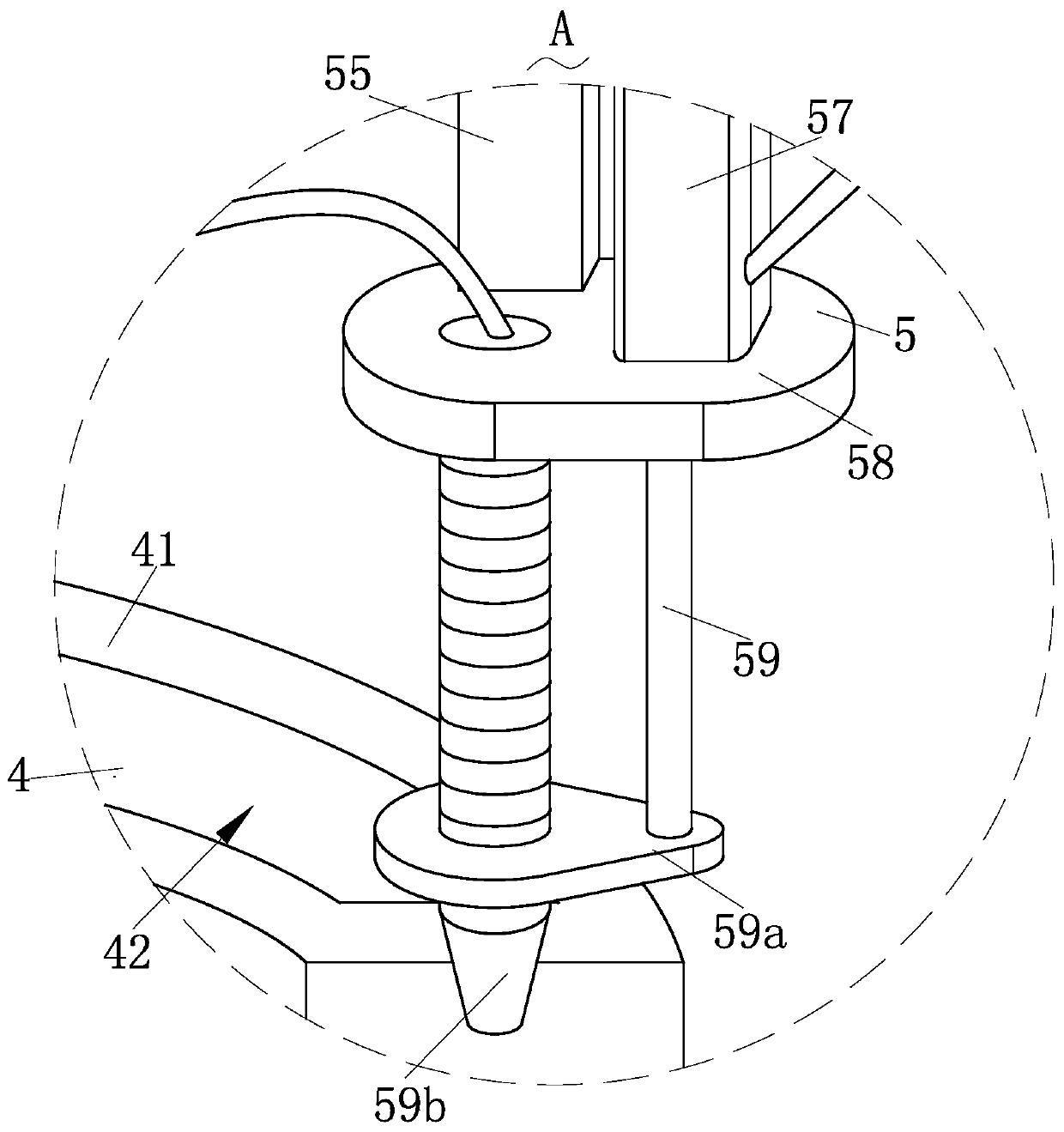

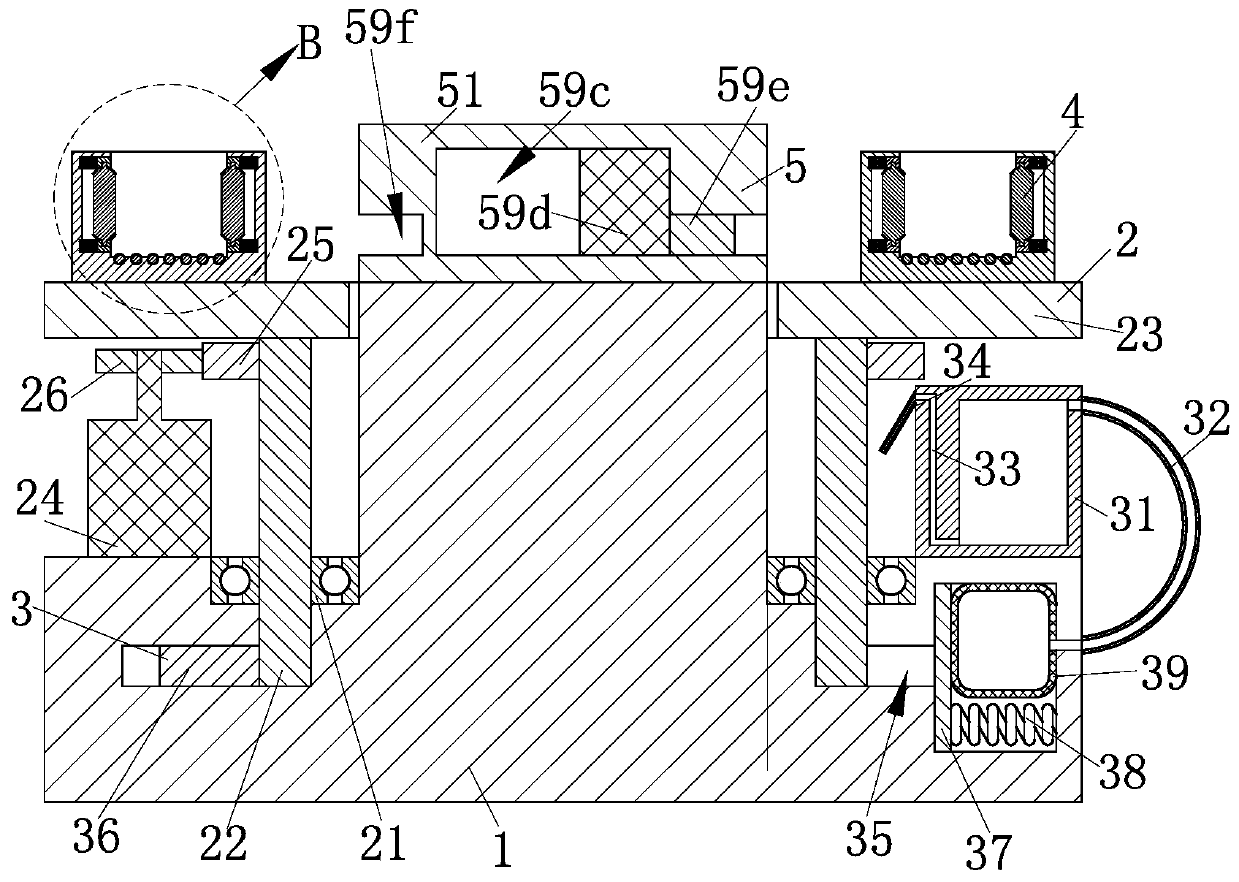

Anti-leakage device for batch filling of liquid skin care products

The invention relates to the field of skin care product filling devices, in particular to an anti-leakage device for batch filling of liquid skin care products. The device comprises a base, a rotatingstructure, a lubricating structure, a placing structure, an anti-leakage structure, a filling structure and an opening and closing structure; the rotating structure works to drive the anti-leakage structure to work, and if the anti-leakage structure works, the limiting protection effect can be achieved when liquid skin care products are filled into the filling bottle, and the occurrence of splashing and leakage during the filling of the liquid skin care product can be avoided; moreover, the anti-leakage structure can drive the opening and closing structure to act on the filling structure while working, so the filling structure can be accurately controlled, thereby achieving the quantitative effect, and avoiding the situation that liquid skincare products are wasted due to the fact that the filling structure is in a leakage state all the time; through the arrangement of the rotating structure on the base, filling bottles fixed to the containing structure on the rotating structure can be rotated to be fed, and the filling continuity can be achieved.

Owner:XINJIANG BAIHEJING BIOTECH CO LTD

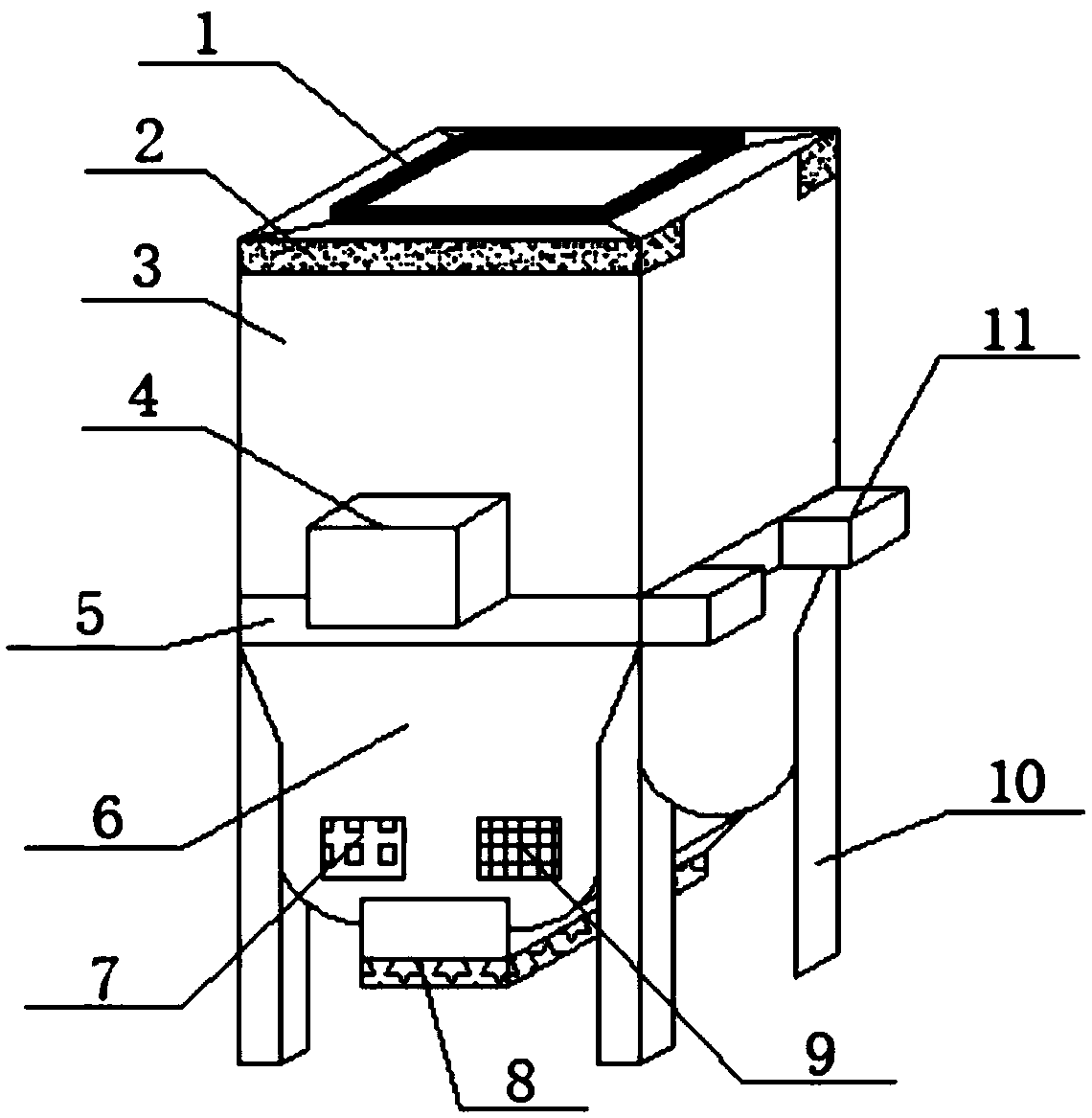

Highly-clean energy-saving boiler

The invention discloses a highly-clean energy-saving boiler which comprises an energy-saving boiler body, a supporting frame, an electric rotation machine A, a water tank and a booster water pump. Thesupporting frame is mounted at the bottom of the energy-saving boiler body, a motor frame is mounted on the inner side of the supporting frame, the electric rotation machine A is mounted at the upperend of the motor frame, a cross water pipe is mounted at the inner upper end of the energy-saving boiler body, a sprayer is mounted at the lower end of the cross water pipe, a water outlet pipe is mounted at the upper end of the cross water pipe, the booster water pump is mounted at the tail end of the right side of the water outlet pipe, and a water inlet pipe is mounted at the lower end of thebooster water pump. The boiler is practical, the inner wall of the energy-saving boiler is flushed by water sprayed by the sprayer mounted at the lower end of the cross water pipe, rotation of a rotating rod drives a cleaning arm to rotate in the energy-saving boiler in the flushing process, rotation of the cleaning arm drives a cleaning brush to clean the inner wall of the energy-saving boiler, so that the inner wall of the energy-saving boiler is effectively cleaned, and the energy-saving boiler is suitable for wide popularization and use.

Owner:河南硕之家环保科技有限公司

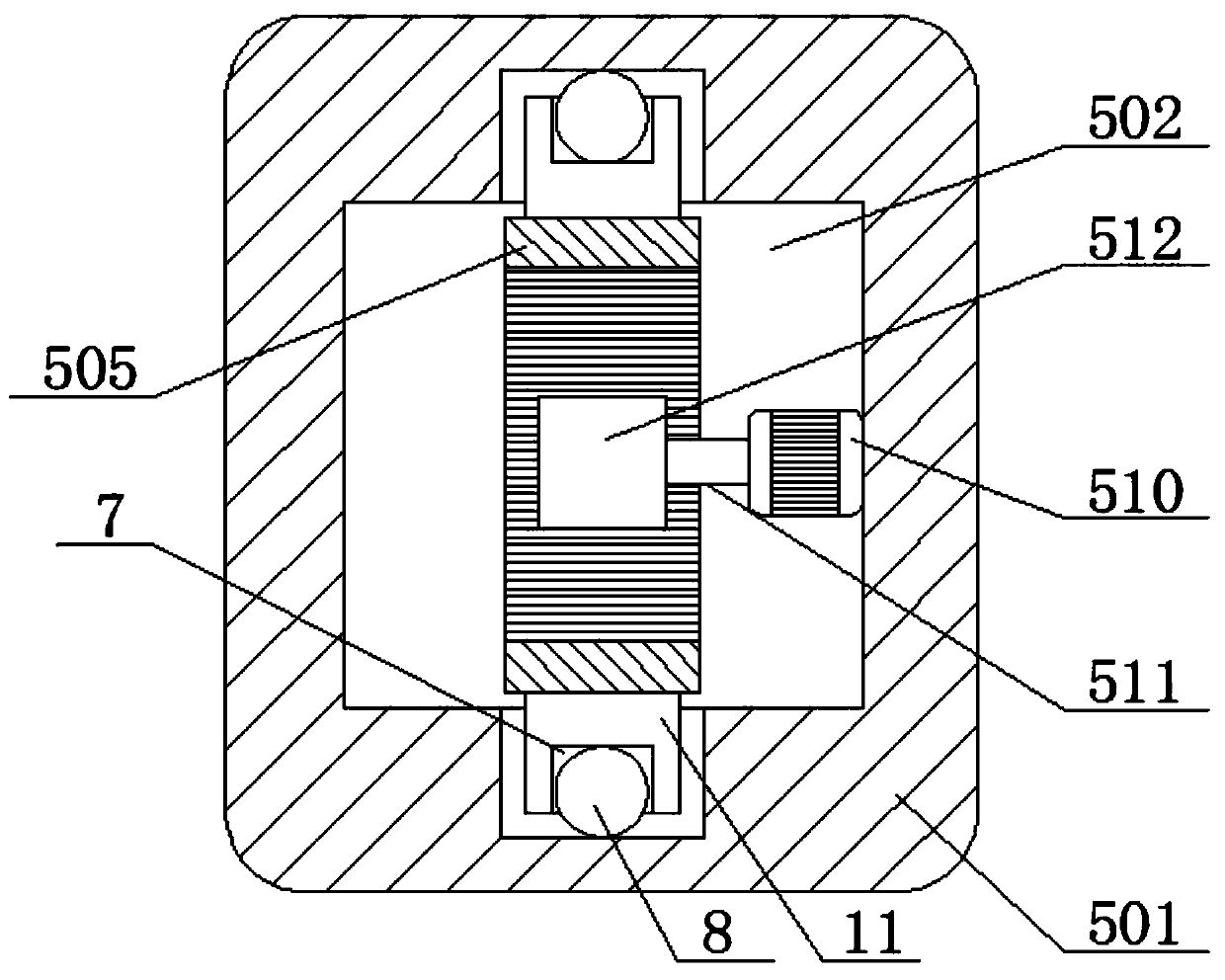

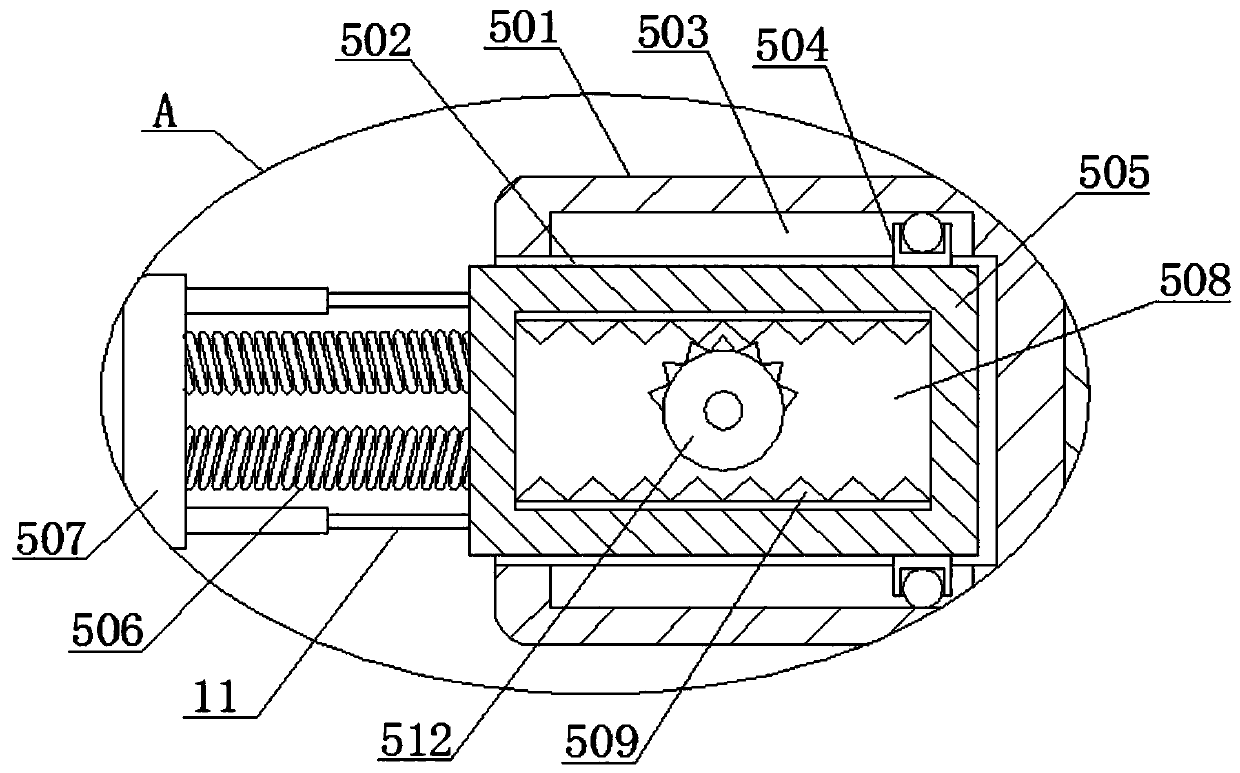

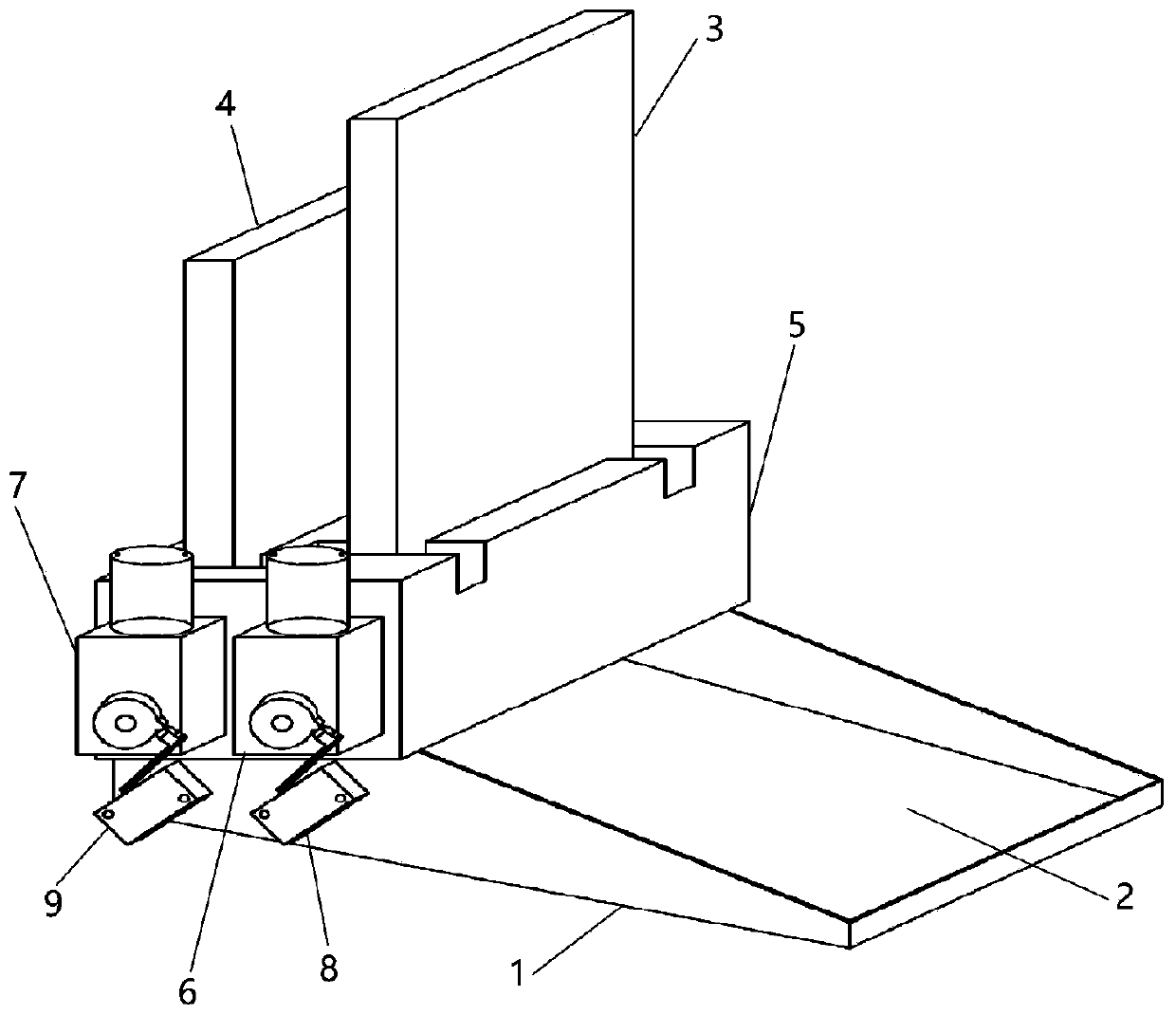

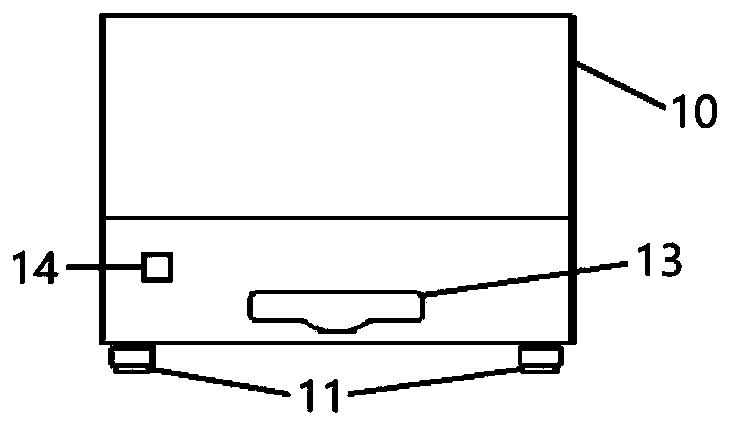

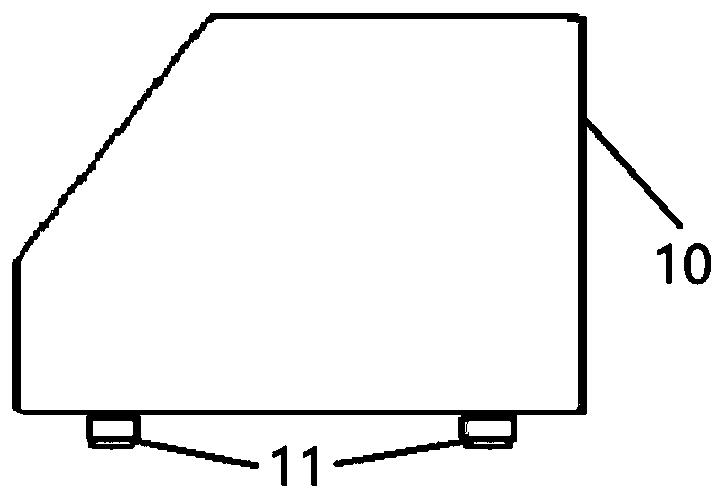

Spraying device for box of electric hoist

InactiveCN107930959APrevent sprayingReduce wasteLiquid surface applicatorsRotary stirring mixersHydraulic cylinderElectric machinery

The invention relates to the technical field of machines or equipment for spraying surfaces of objects or other workpieces with liquid or other fluid by a jetting method, in particular to a spraying device for a box of an electric hoist. The spraying device for the box of the electric hoist comprises a spraying table, a spraying cover and a fixing part, wherein the spraying cover is positioned below the fixing part; the spraying table is positioned below the spraying cover; a hydraulic cylinder is fixed on the fixing part; the inside of the spraying cover is slidably connected with a piston; an output end of the hydraulic cylinder extends into the spraying cover and is fixedly connected with a piston; a partition is fixedly arranged in the spraying cover; the inside of the spraying cover is divided into a material cavity and a paint spraying cavity by the partition from top to bottom; the piston is positioned in the material cavity; a feeding channel which communicates with the material cavity below the piston is formed in the piston; a first paint brush is arranged on a side wall of the paint spraying cavity; a paint channel which communicates with the material cavity is formed ina side wall of the spraying cover and communicates with a paint spraying hole; a placement cavity is formed in the spraying table; and a motor is arranged in the placement cavity. By the scheme, paint can be prevented from being sprayed to the ground, and paint waste is relieved.

Owner:河南巨人起重机集团有限公司

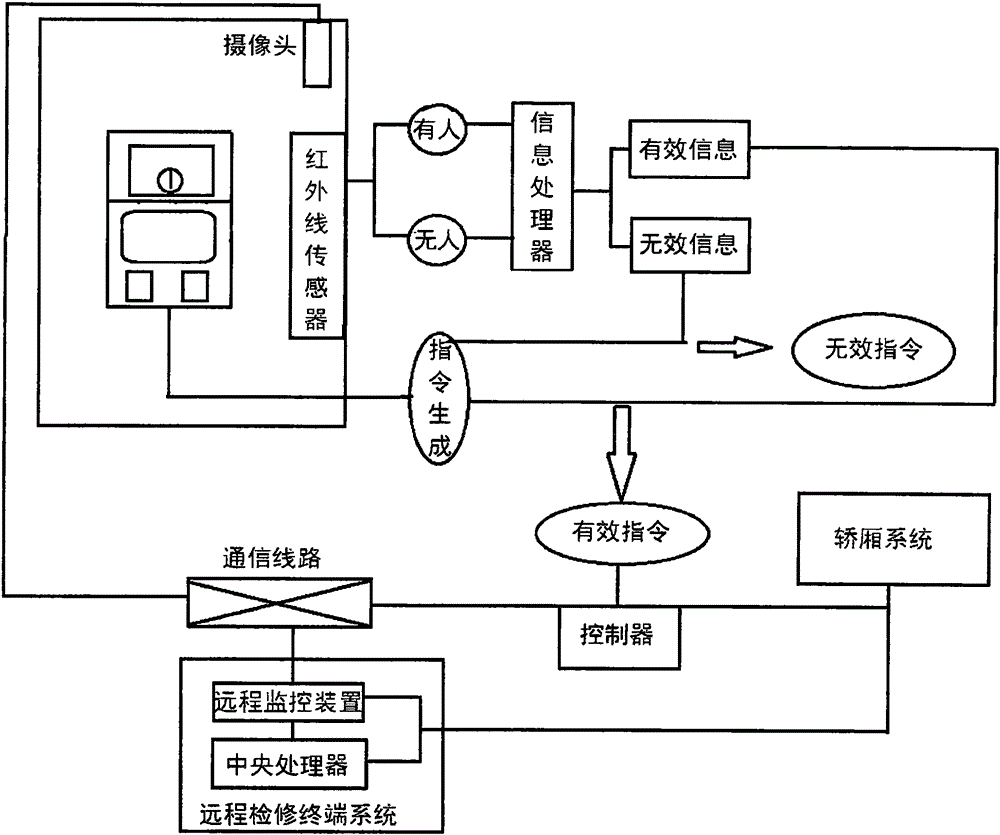

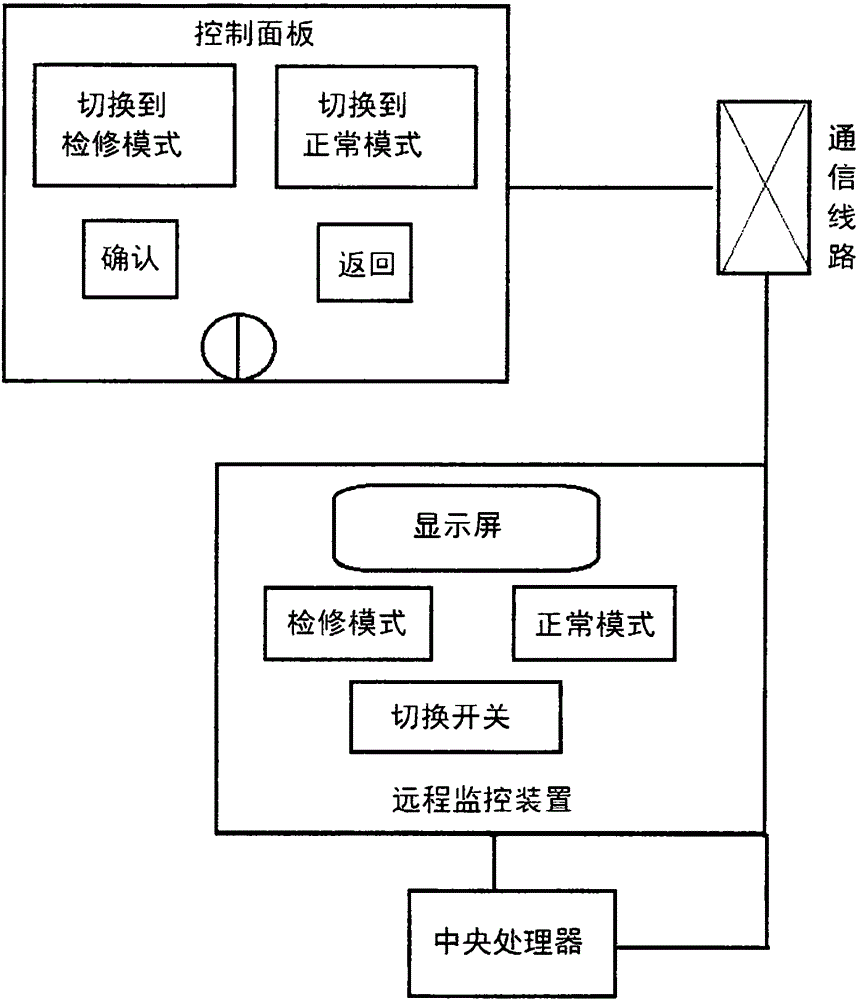

Lift running inspection button system

InactiveCN105016155APrevent wasteful situationsEasy maintenance and operationElevatorsEmbedded systemTerminal system

The invention discloses a lift running inspection button system. The lift running inspection button system comprises an infrared sensor and a control panel which are arranged in a lift car. The infrared sensor is connected with an information processor, and the information processor is connected with a lift car system through the controller. The control panel is divided into an upper part and a lower part, the upper part is provided with an inspection operating button, and the lower part is provided with a daily operating button. A control box is arranged outside the inspection operating button and provided with a connection lock. A camera is installed on the top of the lift car and connected with a remote inspection terminal system through a communication line. By means of the lift running inspection button system, the situation that the lift resource is wasted when a lift is operated mischievously is effectively prevented; the inspection operating button is arranged at the upper part of the control panel, so that workers inspect the lift conveniently; the inspection situations in the lift are transmitted to the remote inspection terminal system of the lift through the camera, and the effective docking of the inspection work of the lift is realized.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

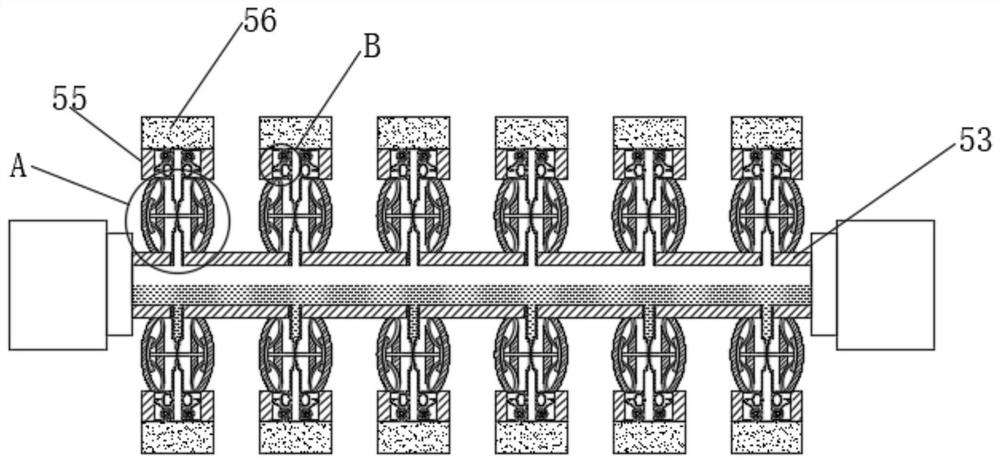

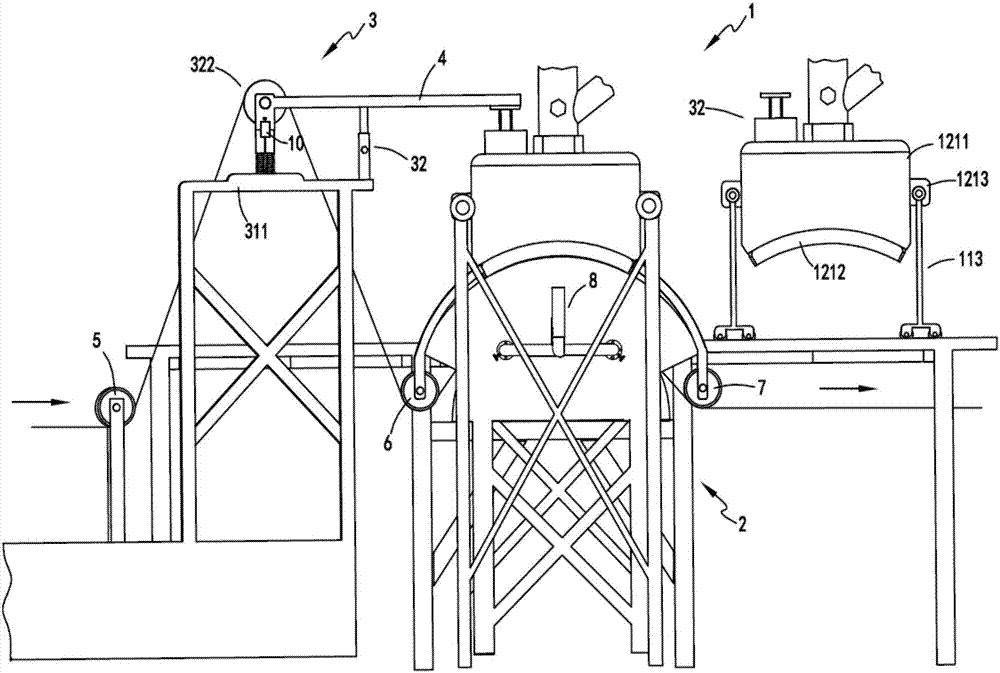

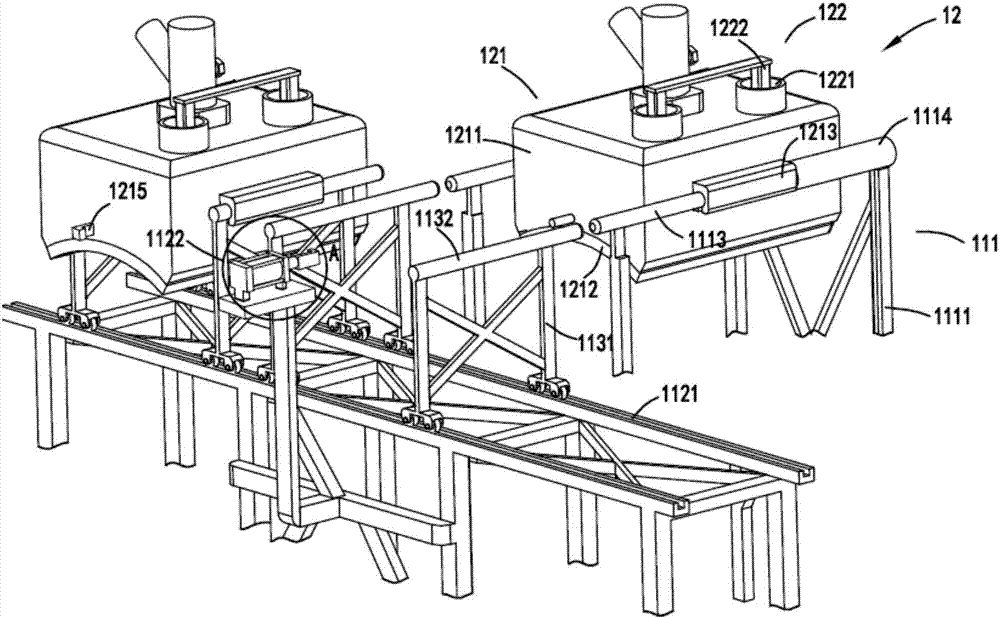

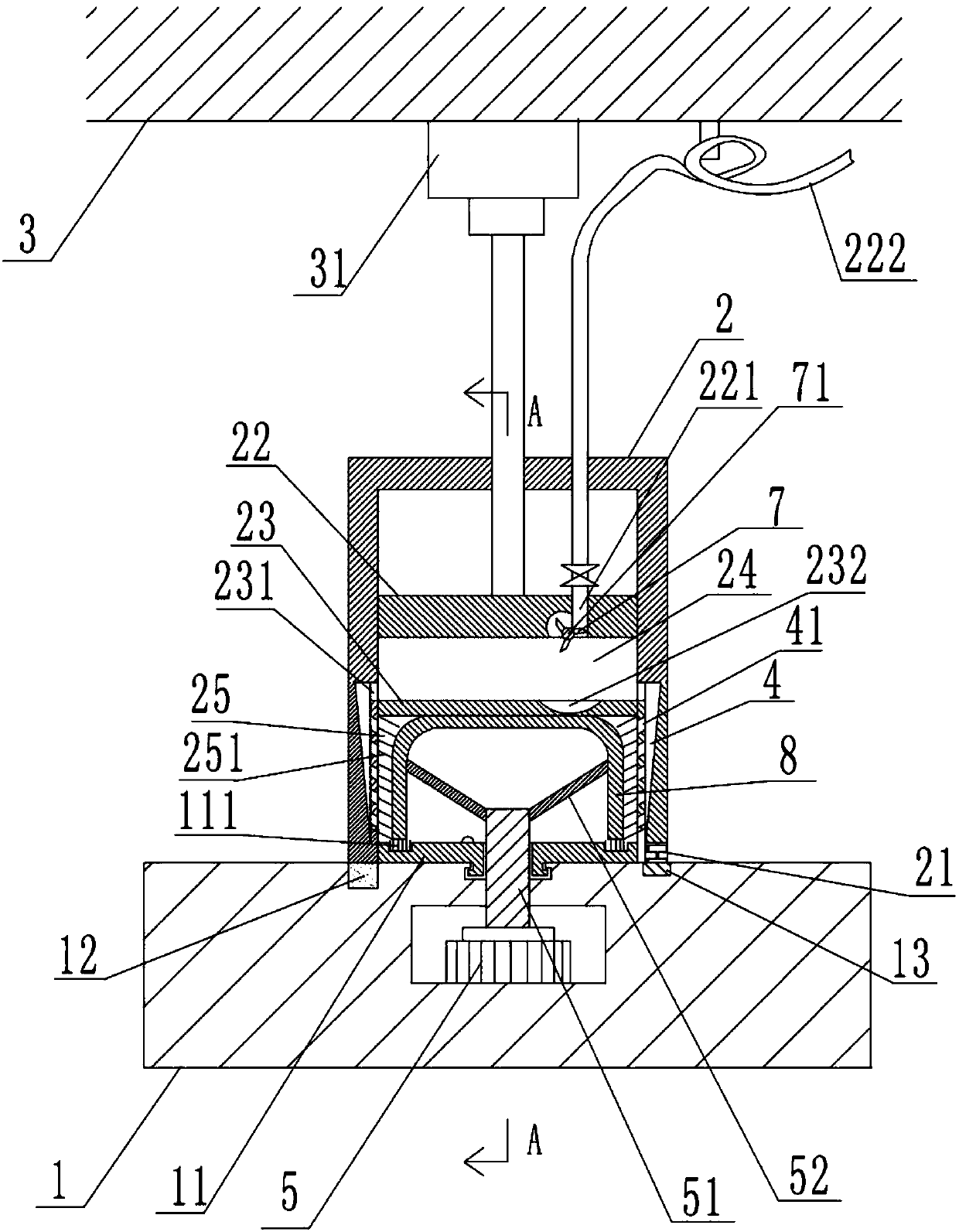

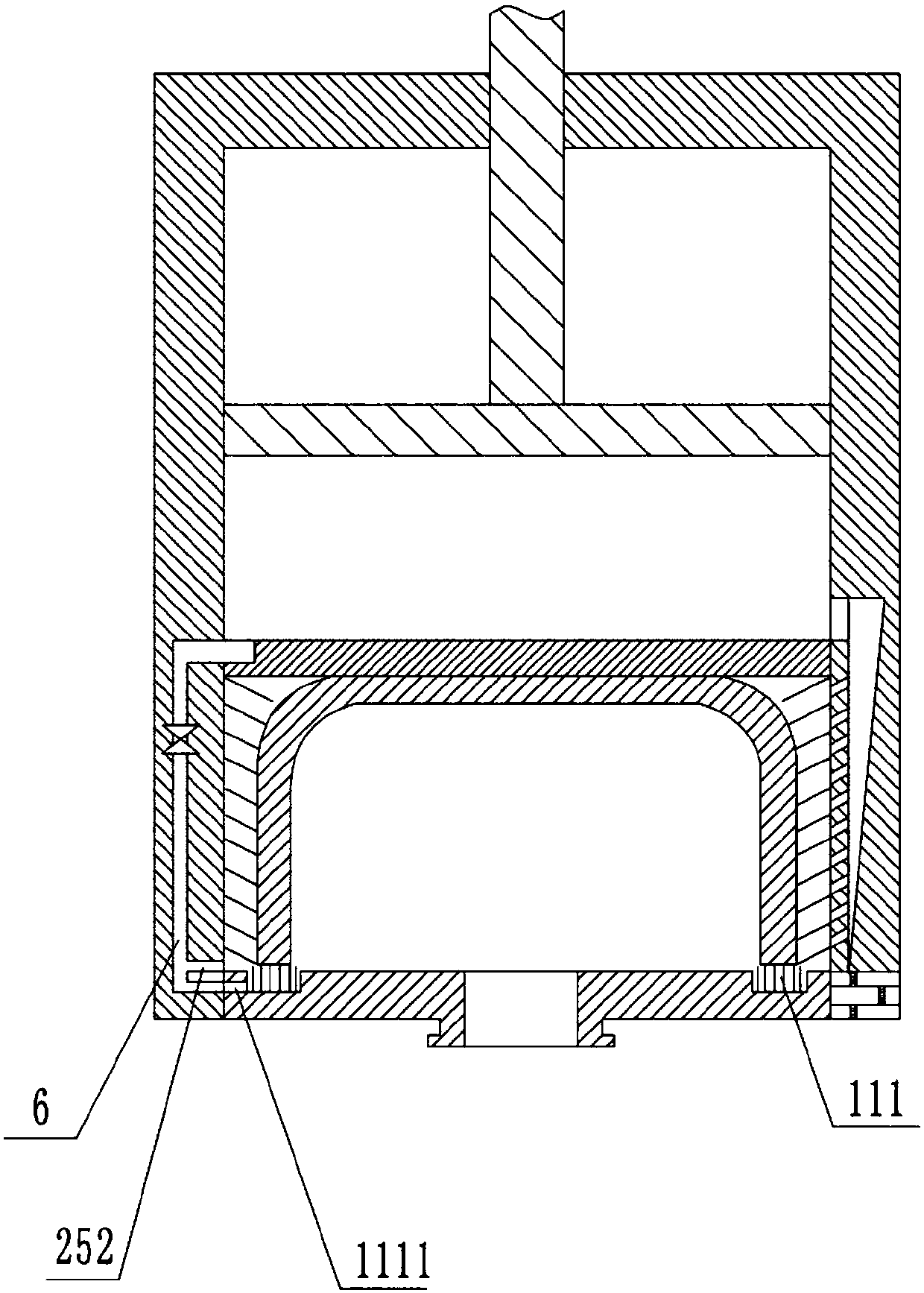

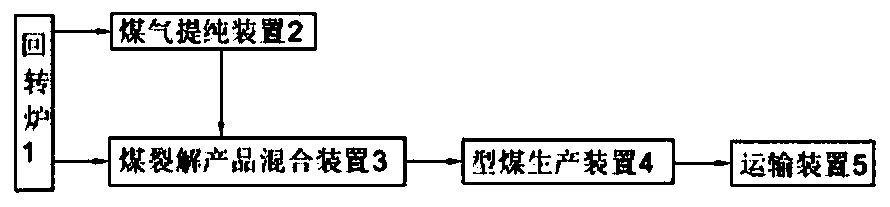

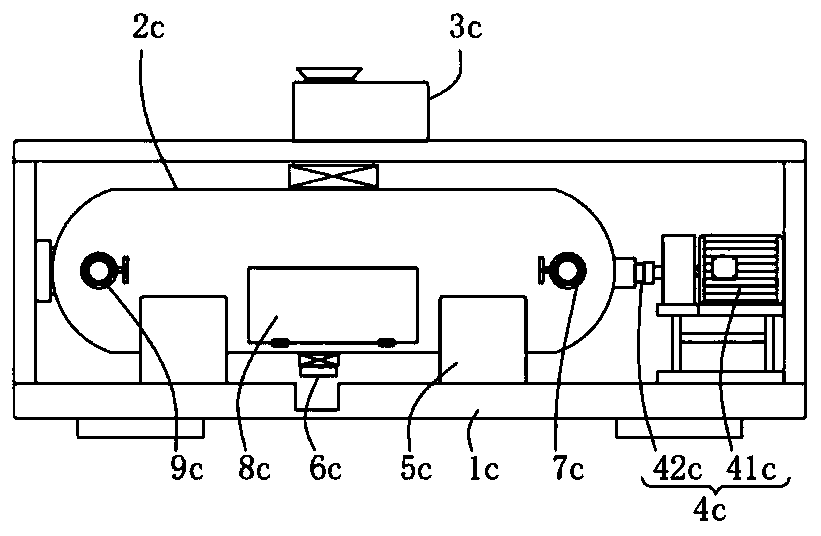

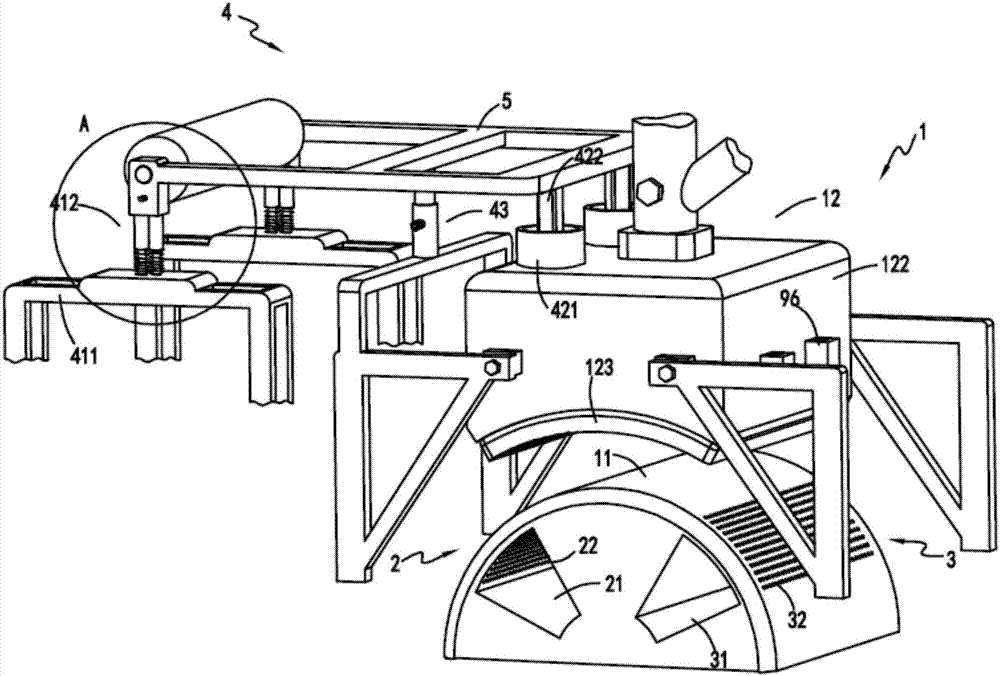

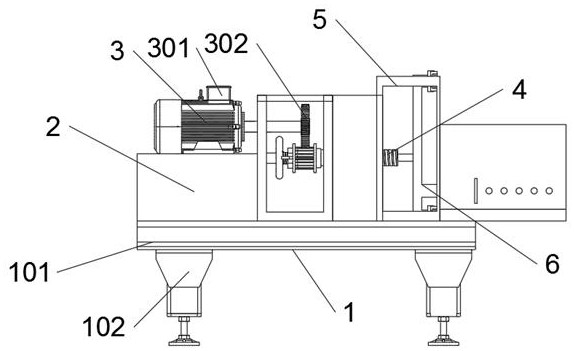

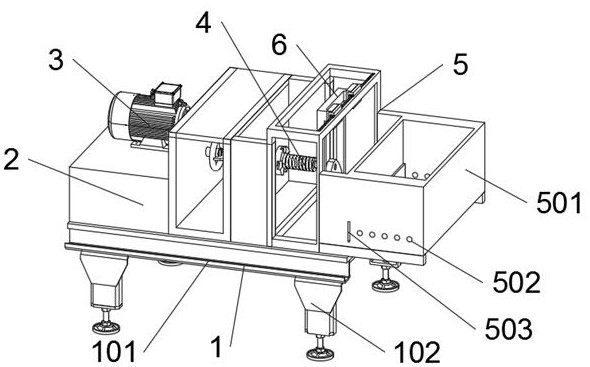

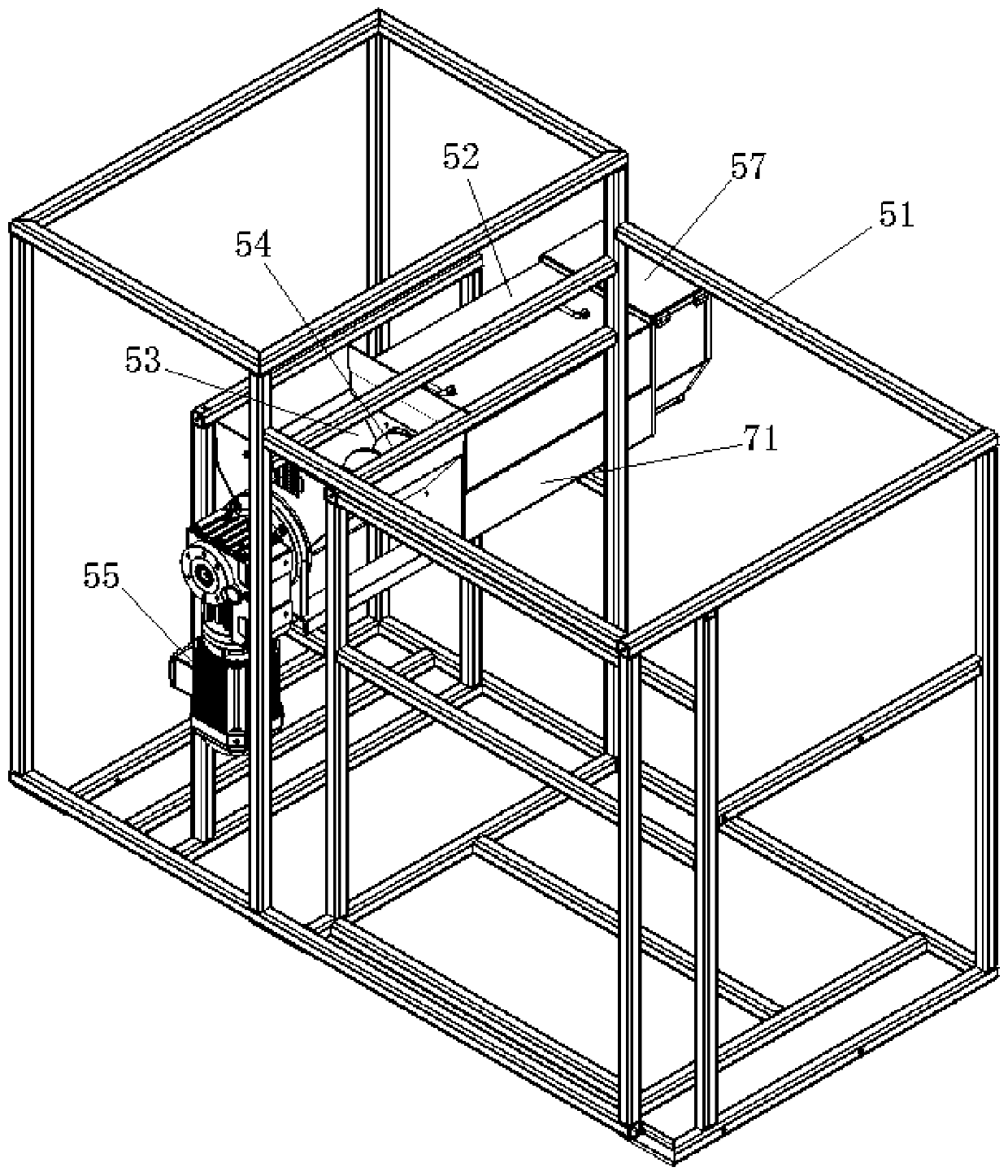

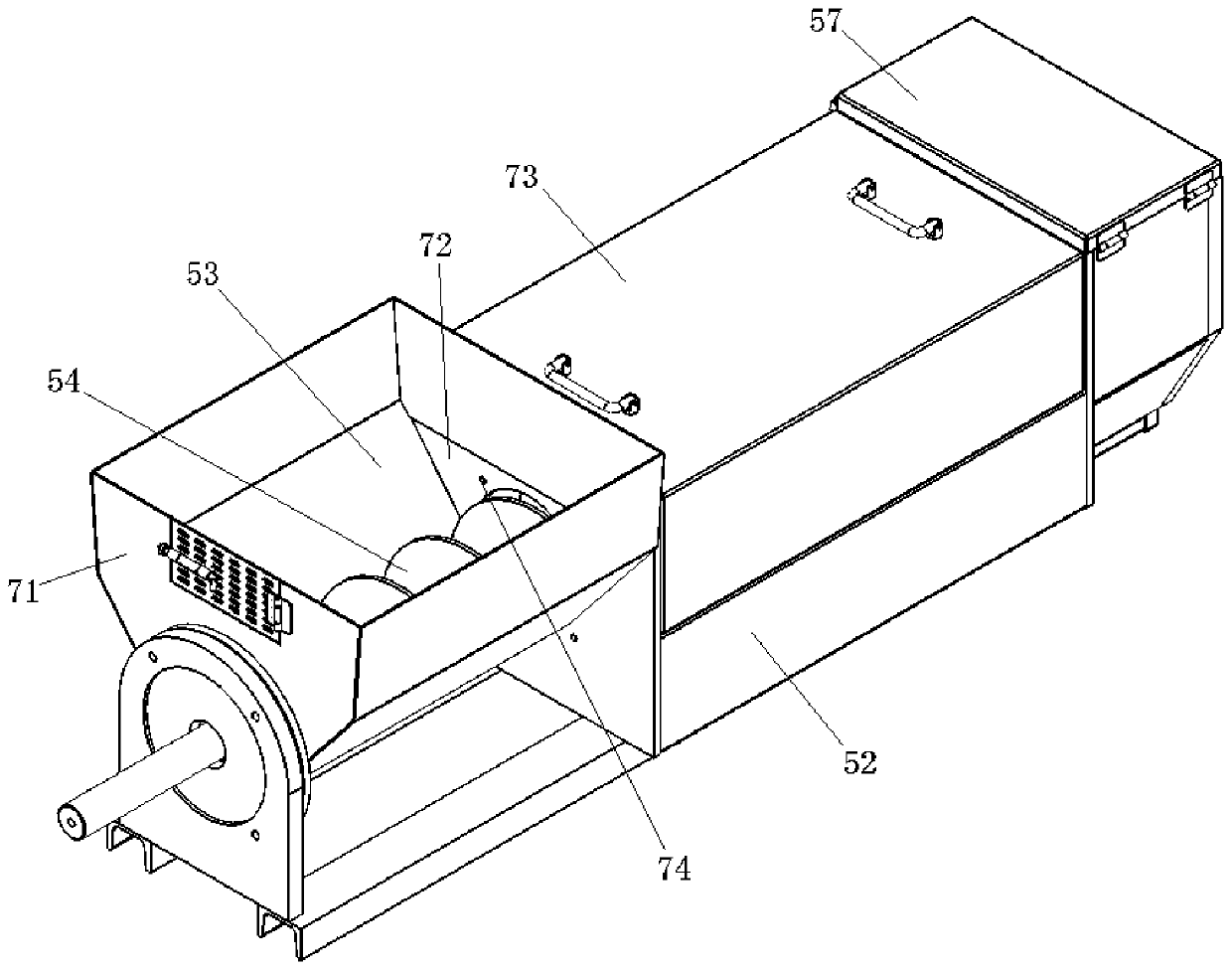

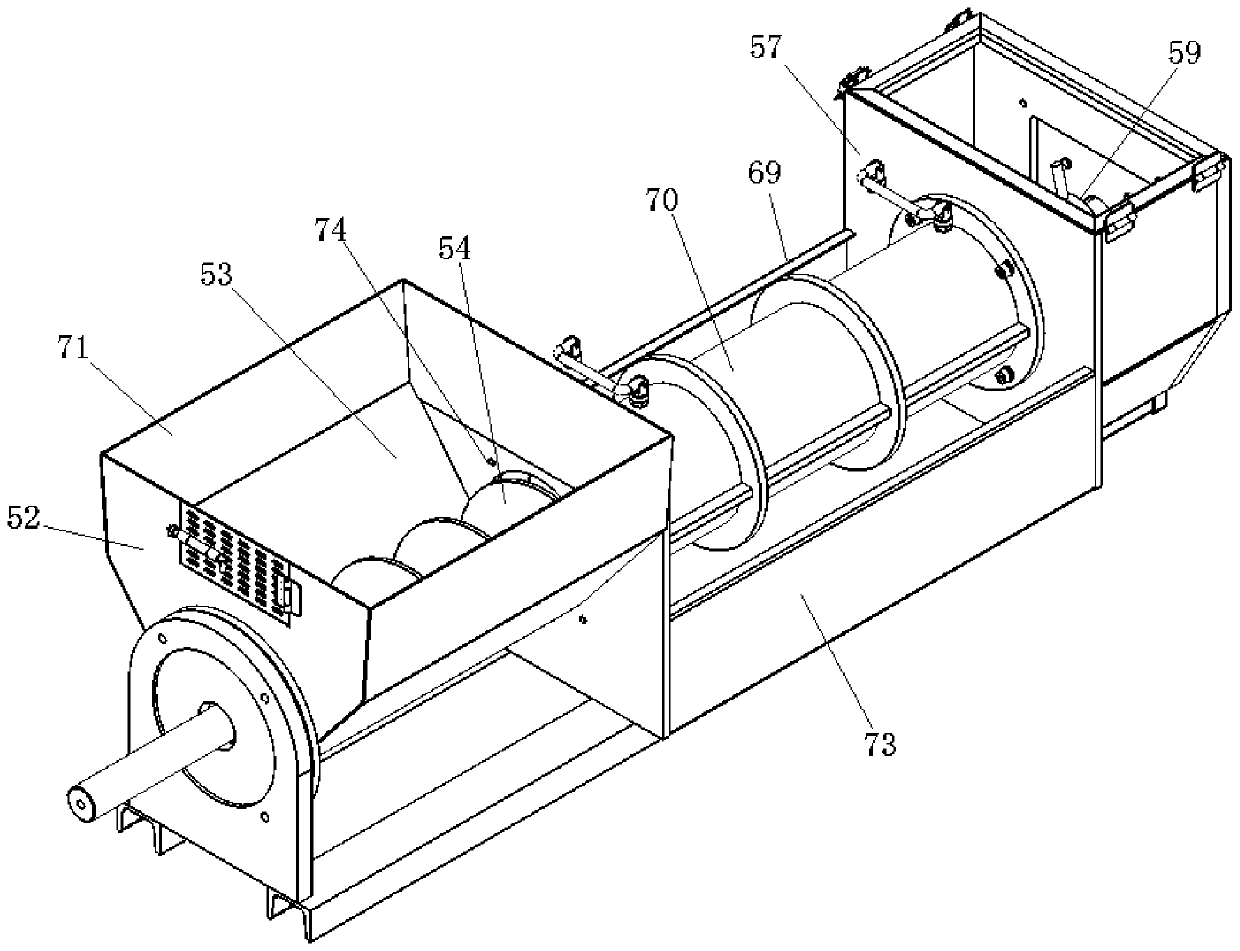

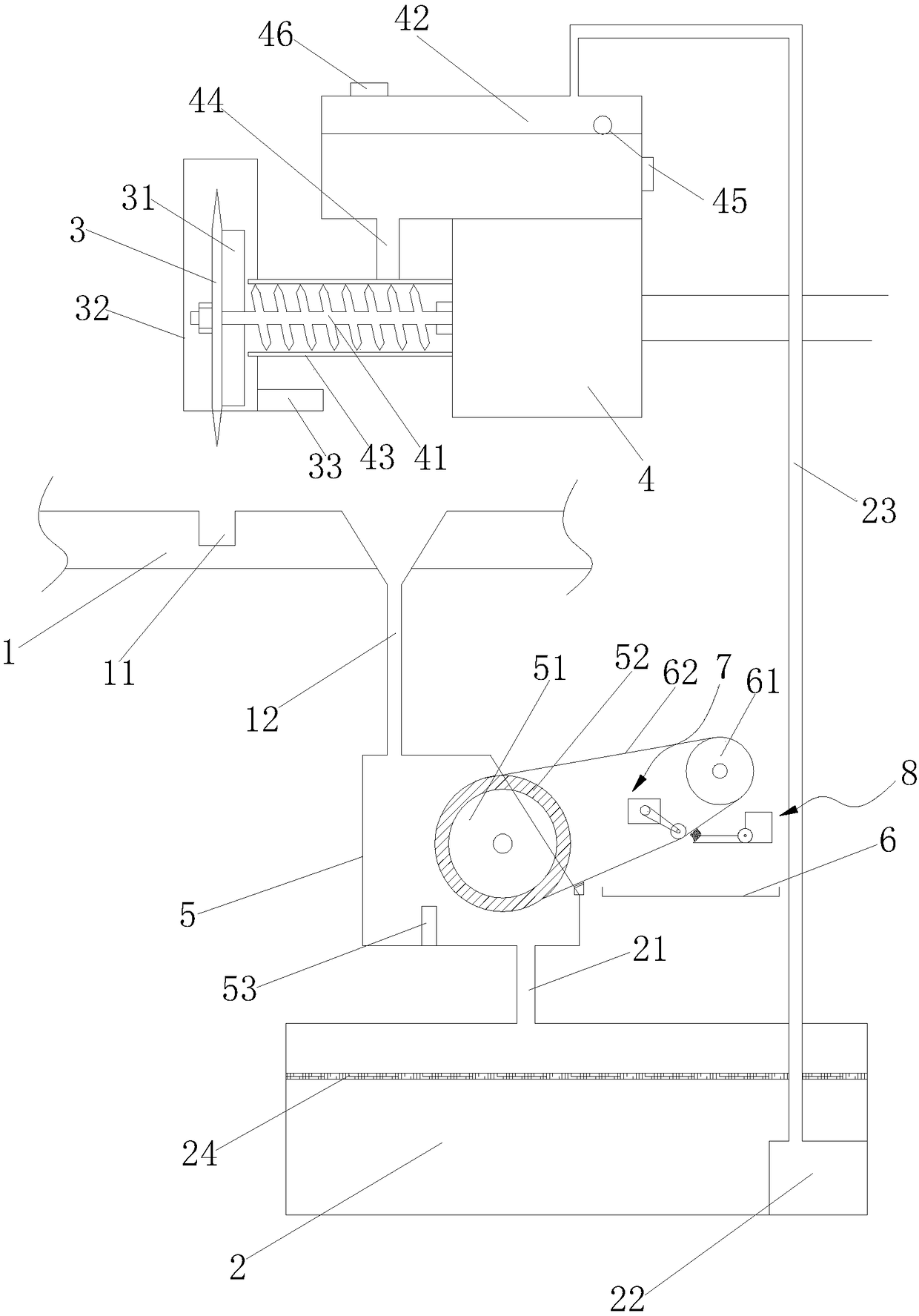

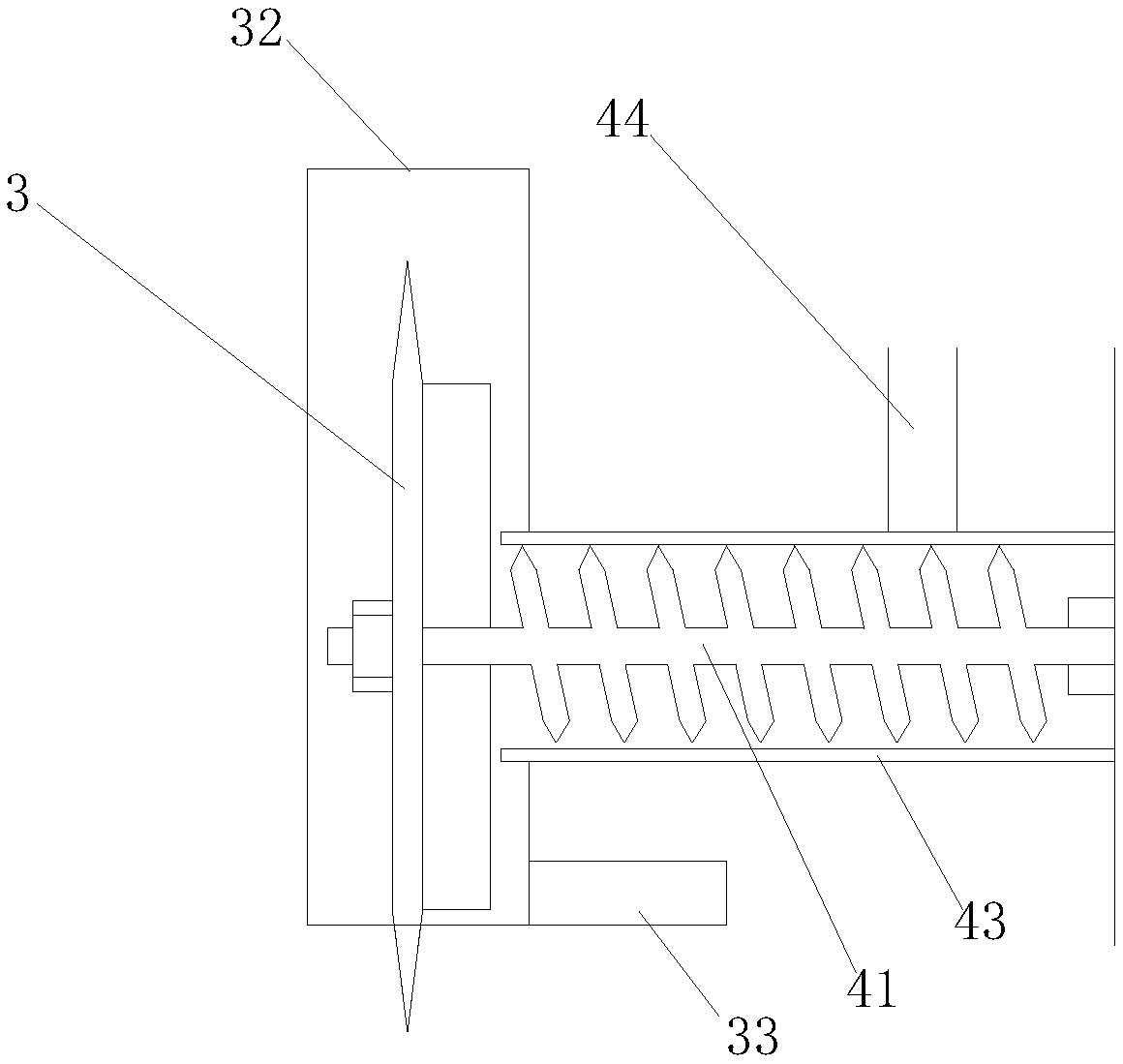

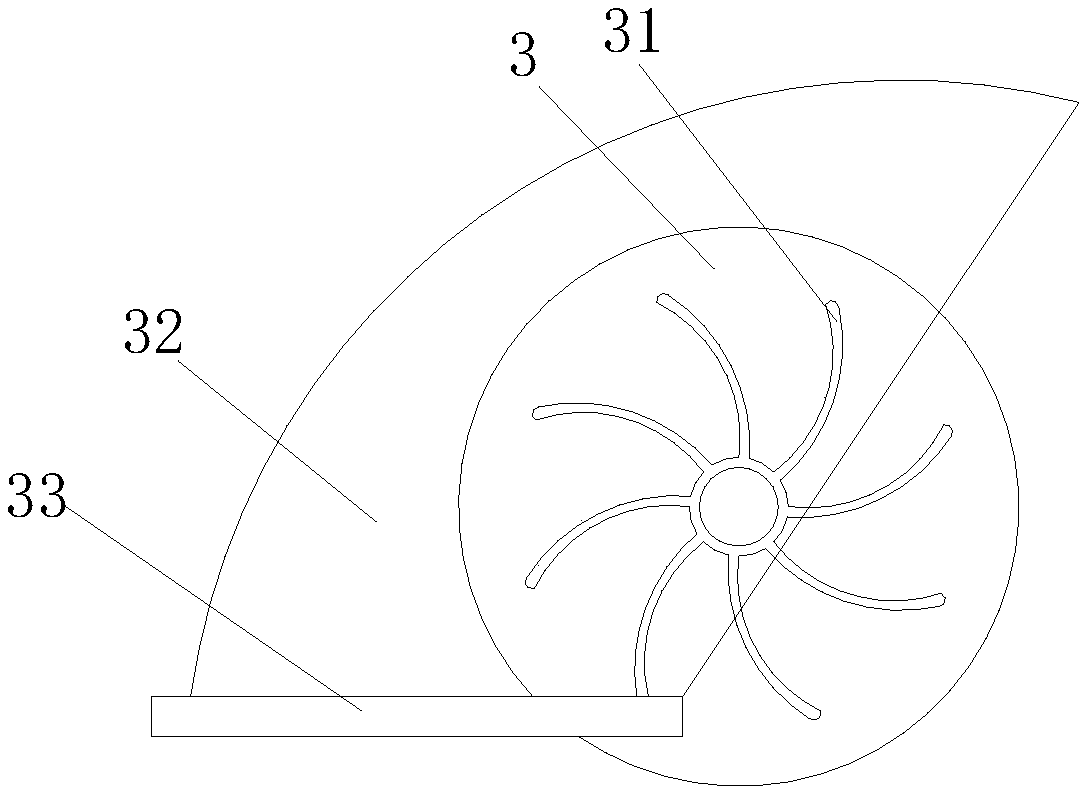

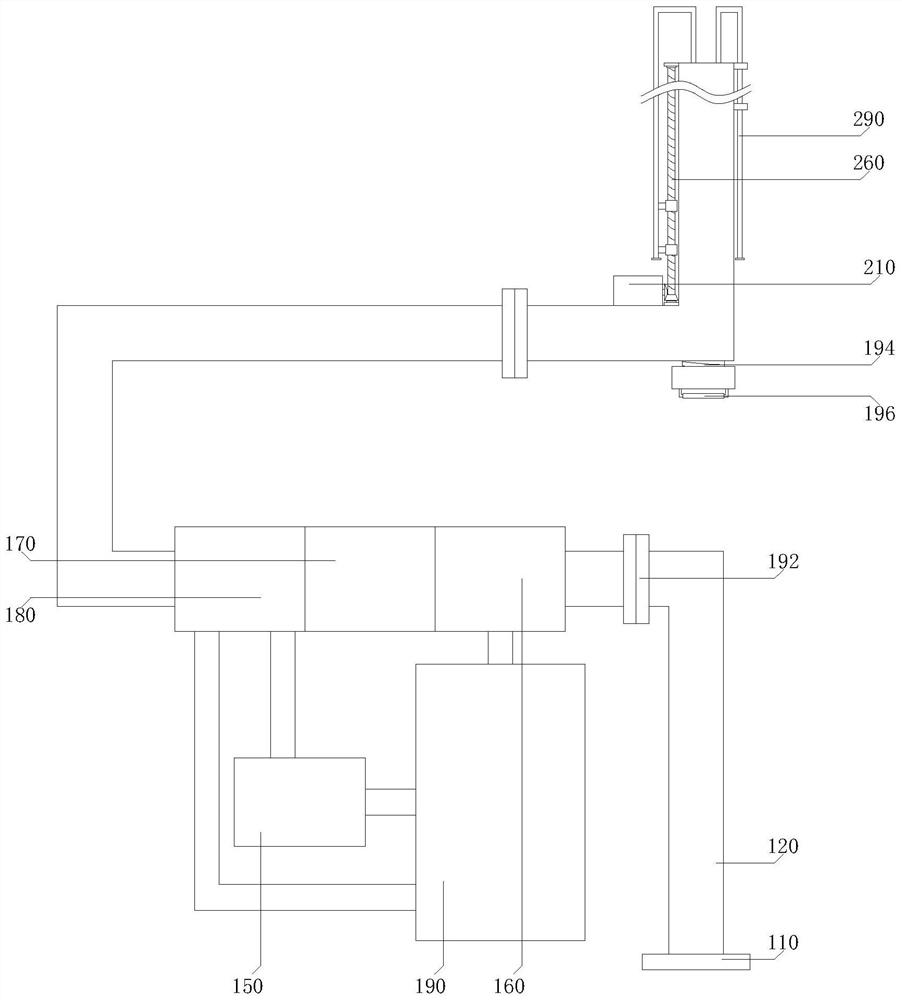

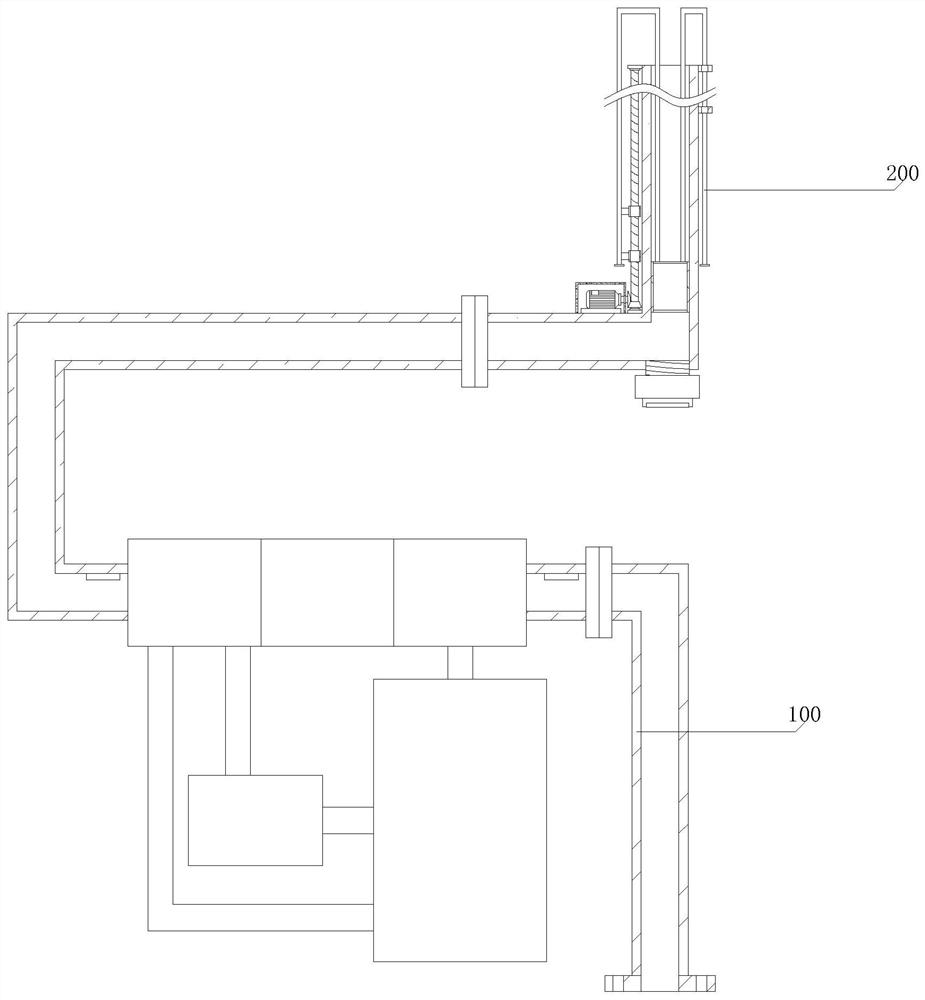

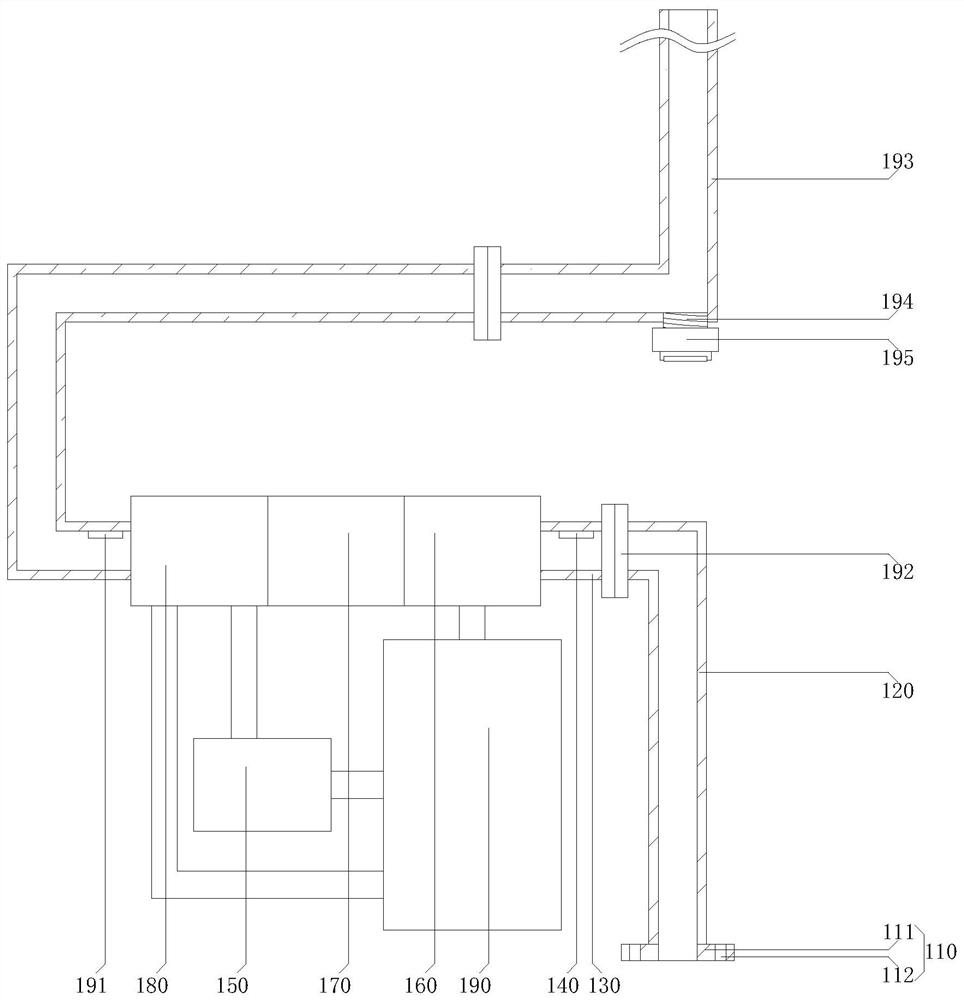

Cracking quality-separation utilization production system of briquette prepared from coal with small particle size

The invention provides a cracking quality-separation utilization production system of briquette prepared from coal with a small particle size. The cracking quality-separation utilization production system of briquette prepared from coal with a small particle size is characterized in that the system includes a rotary furnace, a gas purification device, a coal cracking product mixing device, a briquette production device and a conveying device, and cracked products in the rotary furnace are conveyed to the gas purification device and the coal cracking product mixing device. The cracking quality-separation utilization production system of briquette prepared from coal with a small particle size provided by the invention can greatly increase the contact area between gas and a desulfurizer, improves the desulfurization efficiency and the quality of purification, makes the effect of mixing better, has the advantages of energy saving, environmental protection and energy conservation, can detect the pressure of the gas, make the mixing of tar more fully through multiple mixing treatment, can improve the quality of products, is more environmentally friendly and energy-saving, has the advantages of green cycle, improves the quality of the products, reduces the cost, and improves the economic benefit.

Owner:内蒙古蓝色火宴科技环保股份公司

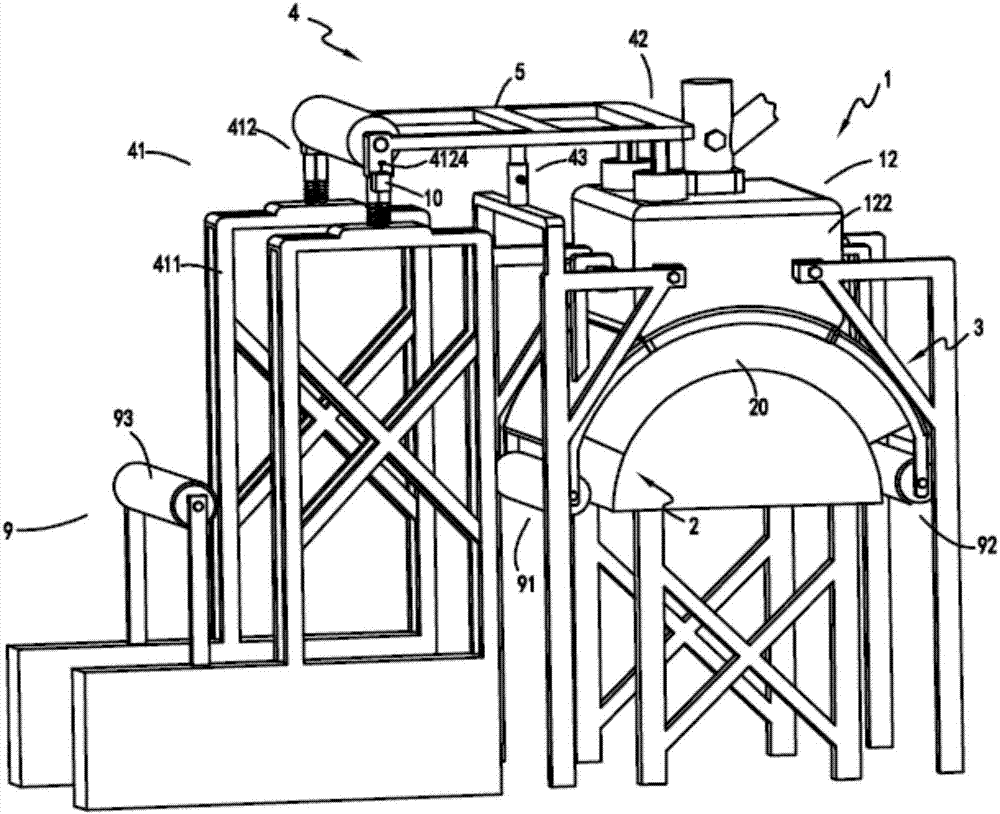

Textile printing and dyeing equipment with self-adjusting function

InactiveCN107034603AStrong sprayThe spray force is smallTextile treatment machine partsLiquid/gas/vapor treatment of indefinite length materialsTextile printerEngineering

The invention relates to textile printing and dyeing equipment with a self-adjusting function. The textile printing and dyeing equipment comprises a dyeing part, a wrinkle removal part, a dyestuff absorption part and an adjusting part, wherein the dyeing part comprises a supporting area and a spray-painting mechanism which is used for dyeing cloth of the supporting area, the wrinkle removal part is arranged at the front end of the dyeing part, and is used for conducting wrinkle removal treatment on the cloth before the cloth enters the supporting area, the dyestuff absorption part is arranged at the rear end of the dyeing part, and is used for promoting absorption of dyestuff through the cloth, the adjusting part is arranged above the dyeing part and comprises a lifting mechanism which moves up and down under the effect of gravity and a pressure adjusting mechanism which is driven by the lifting mechanism to adjust the pressure in a pressure cavity of the spray-painting mechanism. The problems that the dyeing effect is poor caused when equipment cannot adjust the spraying dose of the dyestuff by itself while dealing with cloth of different thicknesses, and dyeing is uncompleted and the dyestuff is poor in infiltration performance when a cloth wrinkle situation exists in a spray-painting process are overcome.

Owner:CHANGXING JIAPU YIHANG TEXTILE FACTORY

Planting frame

InactiveCN105340623AImprove the effectPromote plant growthSelf-acting watering devicesReceptacle cultivationPipingRoot system

The invention discloses a planting frame. The planting frame comprises a soil-accommodating shell and a water storage device, wherein a water hole is formed in the bottom of the soil-accommodating shell; the water storage device is arranged at the bottom of the soil-accommodating shell and is communicated with the inside of the soil-accommodating shell through the water hole, and a water inlet pipe is arranged at the top of one end of the water storage device. In the work process, soil required for planting can be added to the soil-accommodating shell firstly, then required plants are planted in soil, soil can absorb water in the water storage device through the water hole, water can be supplied from the bottom of the soil, so that the water absorbing effect of root systems of the plants is improved, growth of the plants is effectively promoted, and the situation of water resource waste caused by water evaporation is effectively prevented.

Owner:金银石

Fertilizing device capable of accurately applying fertilizer for agricultural cultivation

ActiveCN112262645AIncrease speedPrevent derailmentFertiliser distributersAgricultural scienceGear wheel

The invention provides a fertilizing device capable of accurately applying fertilizer for agricultural cultivation, relates to the technical field of agricultural equipment, and solves the problems ofexcessive fertilizer in partial regions and no fertilizer in partial regions due to incapability of realizing uniform quantity during crop fertilization at present, and low working efficiency due tosingle-line fertilization basically adopted in current fertilizing equipment. The fertilizing device capable of accurately applying the fertilizer for agricultural cultivation comprises a bottom mechanism, a power mechanism, a transmission mechanism, a storage mechanism and a reciprocating mechanism, and the top of the bottom mechanism is fixedly connected with the bottom of a frame mechanism; andthe power mechanism is fixedly connected to the rear position of the top of the frame mechanism. Circular baffles are arranged at the two sides of a gear B to prevent the gear B and a gear A from derailing when a transmission shaft rotates, so that the limiting effect is achieved; and the rear ends of the baffles are attached to the front ends of chutes, so that waste caused by falling of the fertilizer from the chutes is prevented.

Owner:神木市绿佳源农业服务有限责任公司

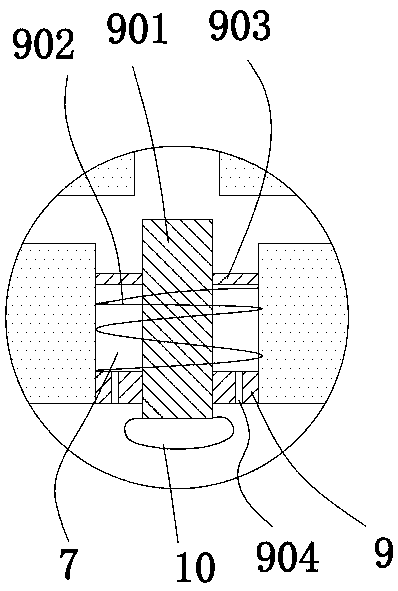

Stranding cage discharging system and discharging method for swill separation

ActiveCN111113984ARealize extrusion dehydration functionAdjust outputPressesElectric machineStructural engineering

The invention discloses a stranding cage discharging system and discharging method for swill separation. The stranding cage discharging system comprises an extruding frame, an extruding shell, a spiral rod, an extruding motor and a locking mechanism. The extruding shell is internally provided with two or more communicating extruding cavities, and provided with water outlets. The spiral rod is rotatably mounted in the extruding shell and penetrates through all the extruding cavities. The extruding motor rotates to drive the spiral rod to rotate, and thus kitchen swill located in the extruding cavities is extruded from one end of a shell body to the other end of the shell body. The locking mechanism comprises a locking shell, a discharging assembly, a spring and pressure blocks. The lockingshell is mounted at the other end of the extruding shell and provided with a circular through groove. The discharging assembly comprises a pressing rod and a discharging block, and the discharging block is of a circular-truncated-cone structure and is coaxially connected with the spiral rod. The pressing rod and the discharging block are coaxially connected and rotatably mounted in the locking shell. The discharging efficiency is improved, the working time is reduced, the moisture content can be adjusted, the suitable living environment for subsequent biodegradation is guaranteed, the rate ofsubsequent degradation is increased, and the effect of subsequent degradation is improved.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Highway bridge roadbed pavement auxiliary construction device and construction method thereof

ActiveCN113250047AImprove construction efficiencyImprove qualityClimate change adaptationRoads maintainenceStructural engineeringRaw material

Owner:ZHENGZHOU COMM PLANNING SURVEY & DESIGN INST

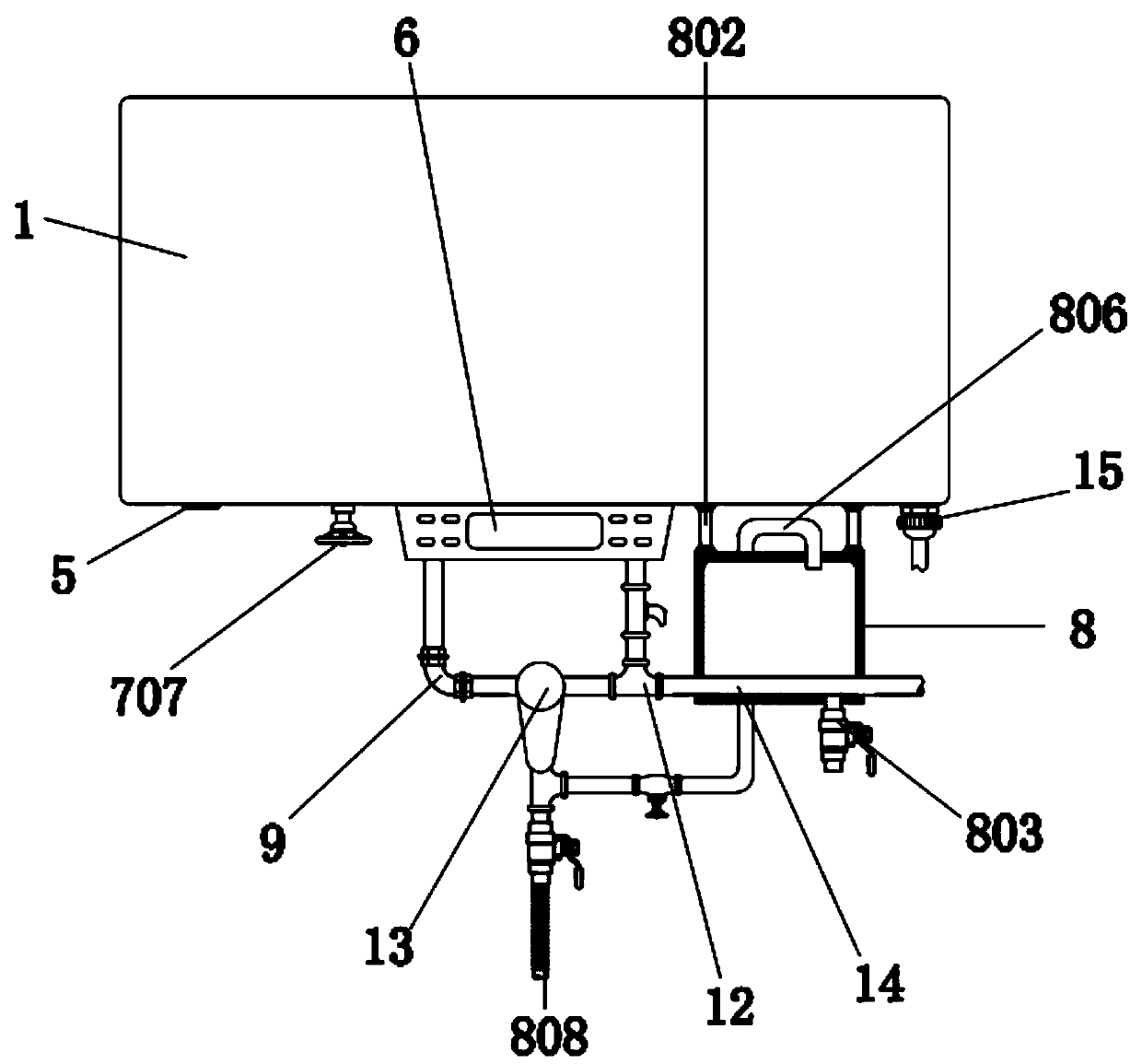

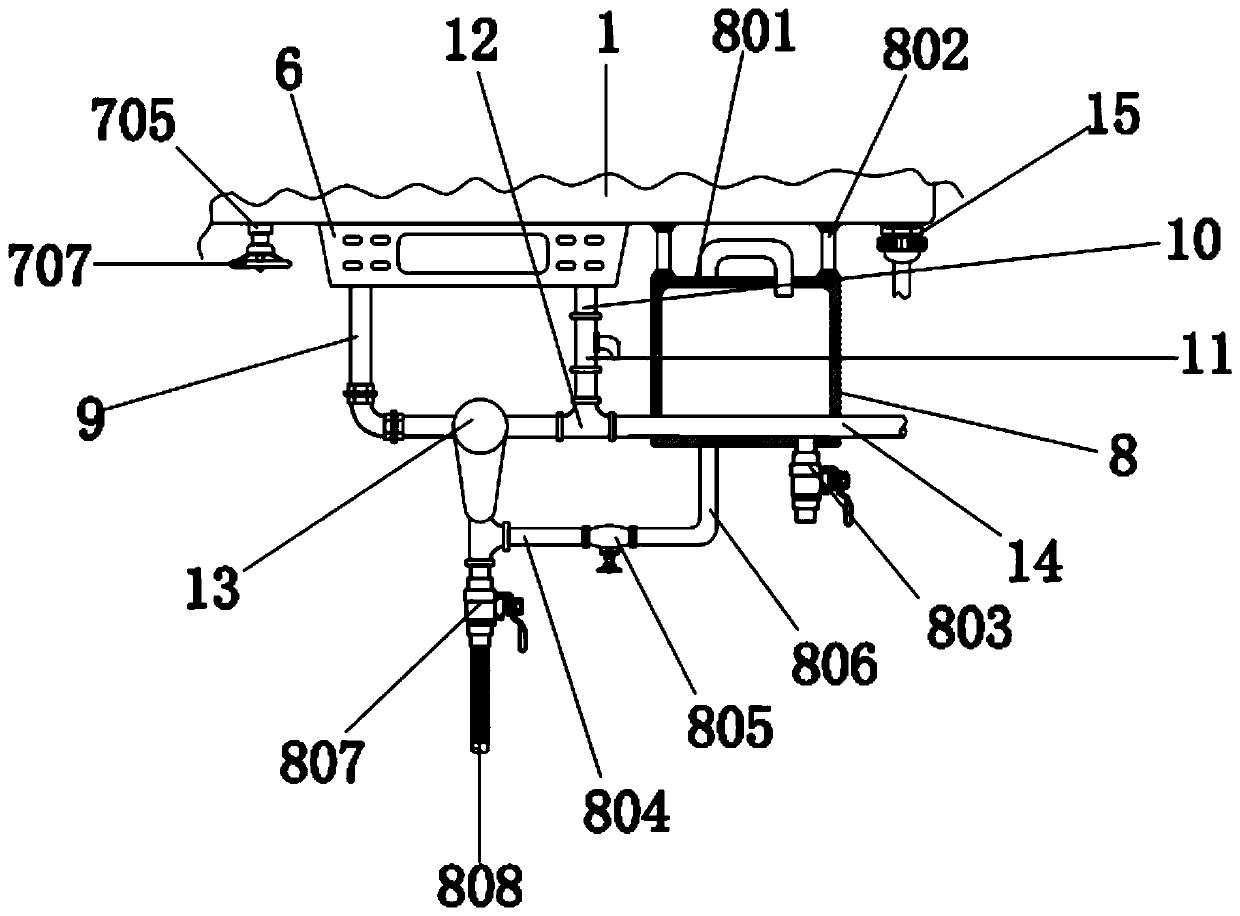

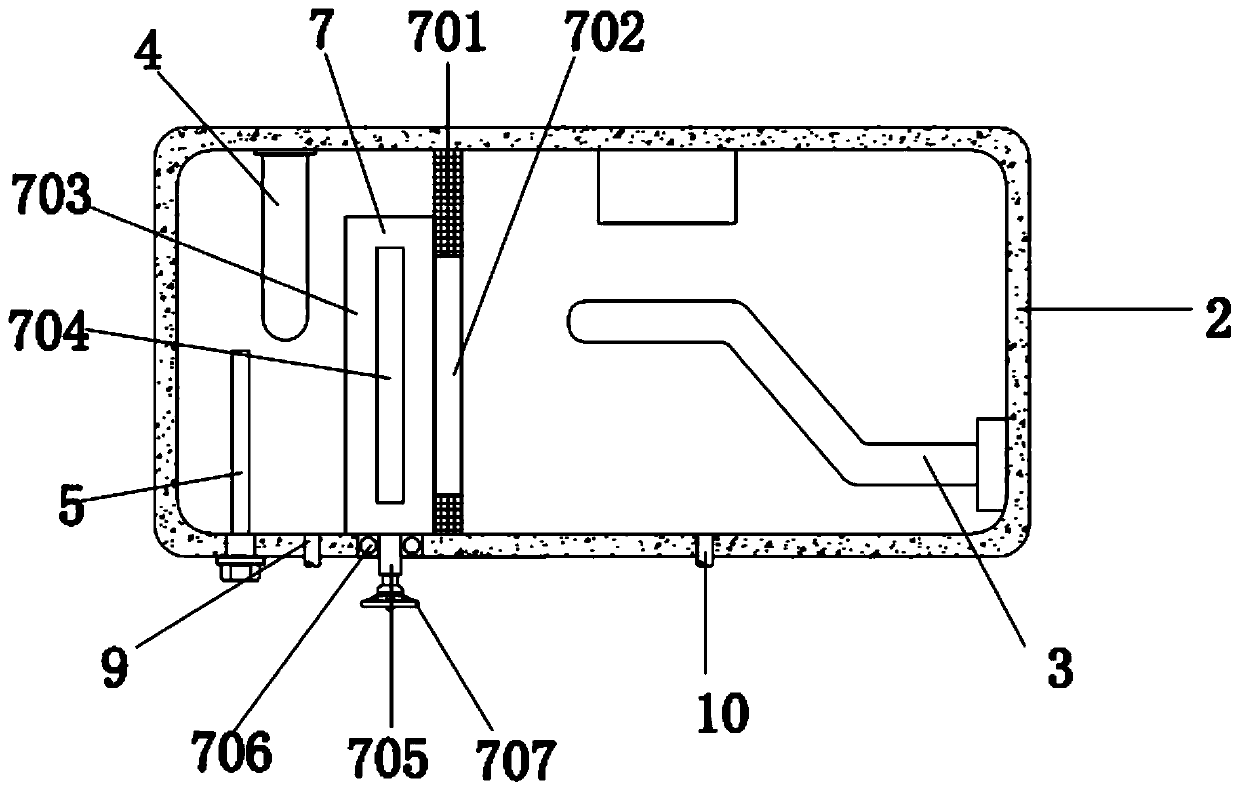

Rapid heating type electric water heater with cold water storage and reutilization mechanism

InactiveCN110657571AHeating fastMeet the urgent need to use hot waterMechanical apparatusWater heatersWater storageThermodynamics

The invention discloses a rapid heating type electric water heater with a cold water storage and reutilization mechanism. The rapid heating type electric water heater comprises a machine shell and aninner container. The inner container is fixedly connected in the machine shell. A first electric heater is mounted on the right side in the inner container. A second electric heater is mounted on theleft side of the top end in the inner container. A magnesium rod is mounted on the left side of the bottom end of the inner container. An electric control assembly is mounted on the front side of thebottom end of the outer wall of the machine shell. According to the rapid heating type electric water heater with the cold water storage and reutilization mechanism, through cooperation between the machine shell, the inner container, the first electric heater, the second electric heater, the electric control assembly and a rapid heating mechanism, a rotary knob is rotated by 90 degrees, the innerpart of the inner container can be divided into two areas, the second electric heater and the first electric heater heat the two areas at the same time, water nearby a water inlet of a hot water pipecan be rapidly heated, and the requirement that users are badly in need of hot water is met.

Owner:MEIOU ELECTRONICS

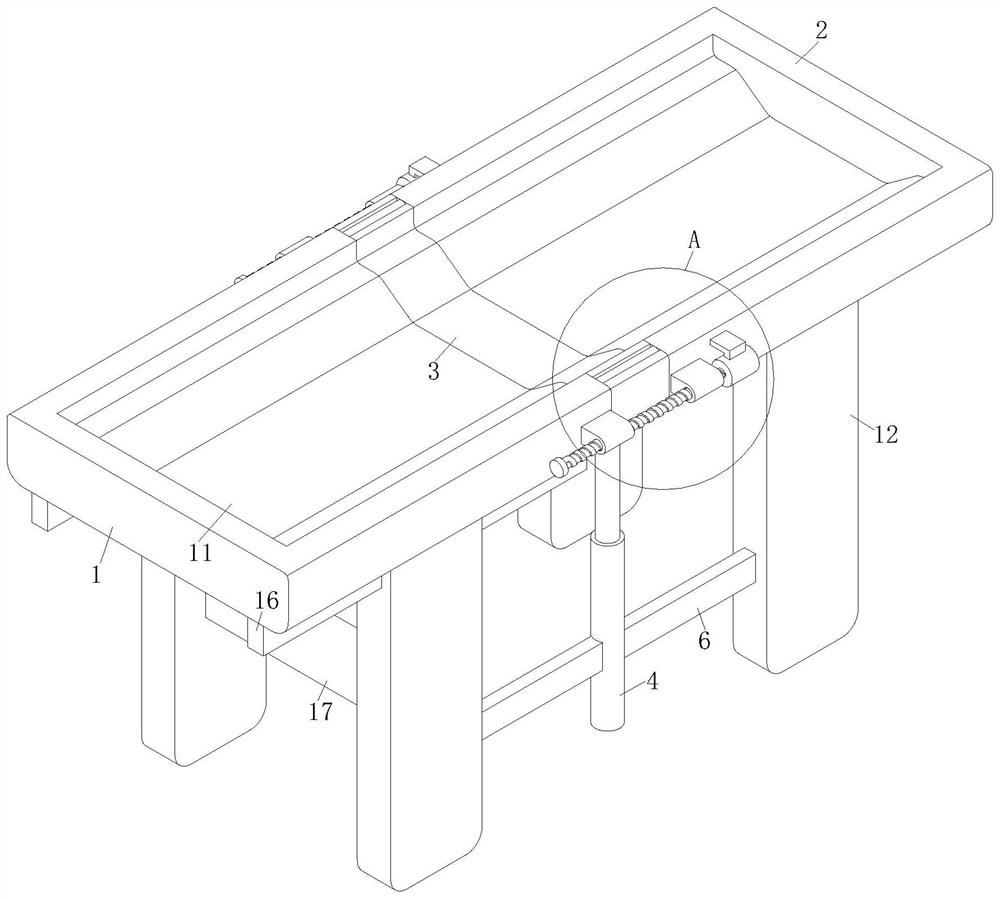

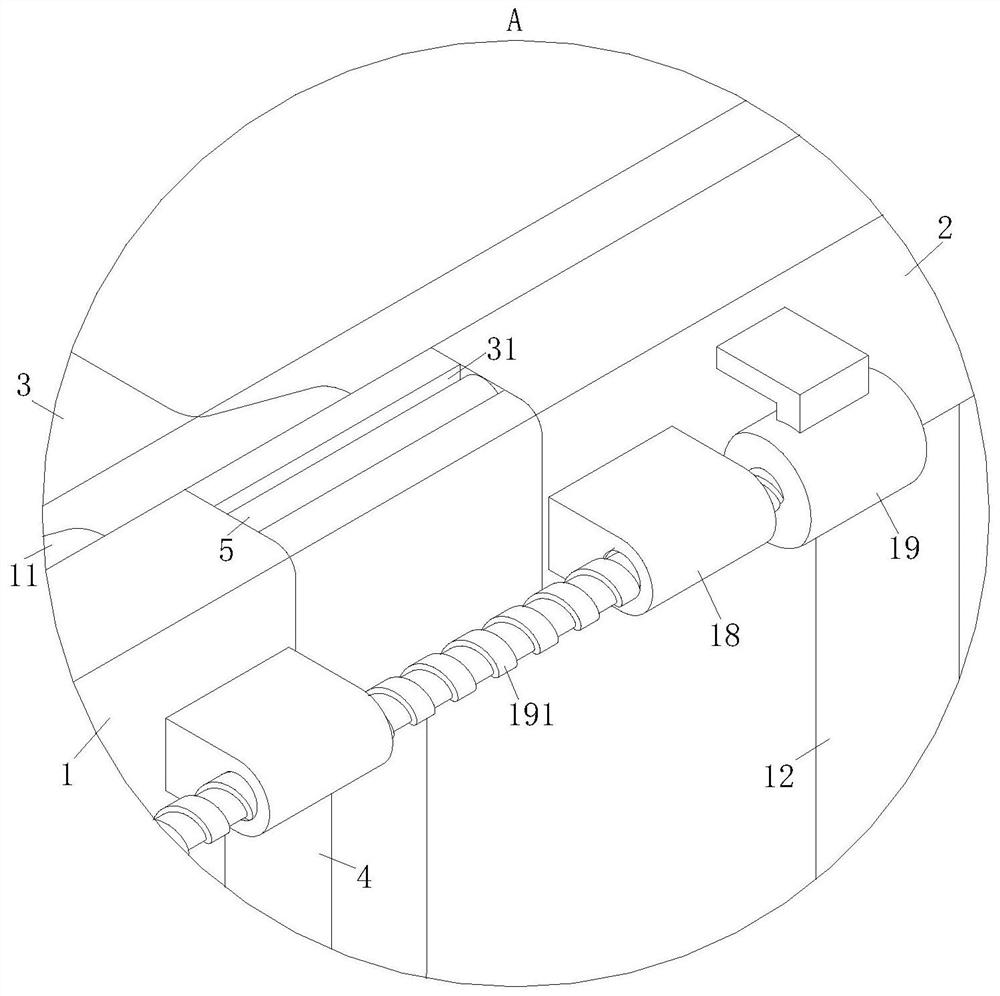

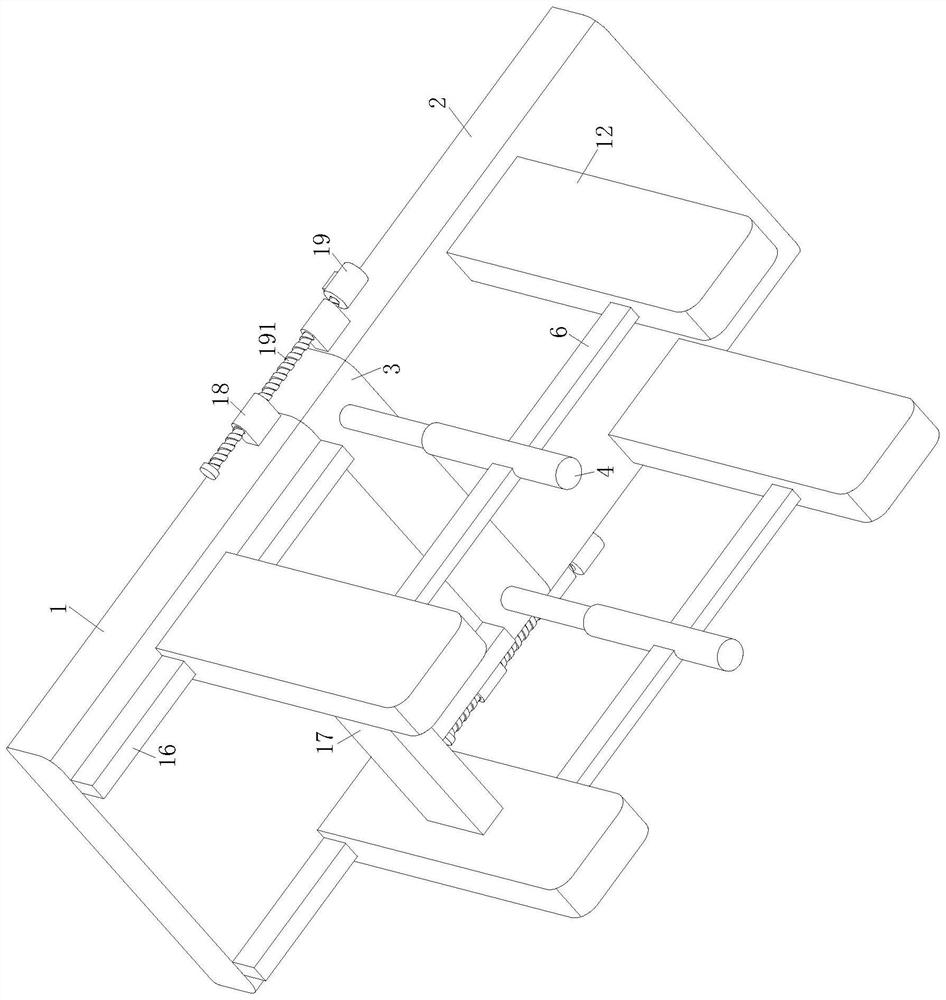

Cooling liquid circulating integrated device for fracturing pump valve box cutting machine tool

ActiveCN108941762APrevent wasteful situationsAvoid wear and tearMetal sawing accessoriesMaintainance and safety accessoriesScrapMagnetic layer

The invention discloses a cooling liquid circulating integrated device for a fracturing pump valve box cutting machine tool. The cooling liquid circulating integrated device sequentially comprises a cutting device, a working table, a scrap iron removing device and a liquid storage tank I from top to bottom; and the cutting device comprises a saw blade and a motor, a spiral shaft is arranged between the saw blade and the motor, the left end of the spiral shaft is welded to the center of the saw blade, and the right end of the saw blade is in transmission fit with the motor. The situation that cooling liquid is seriously wasted through a direct-spraying cooling mode is prevented, in order to avoid the situation, the cooling liquid circulating integrated device uses the cooling liquid in a circulating mode to achieve the saving purpose, the used cooling liquid is effectively filtered, main impurities-scrap iron are adsorbed and removed through a magnetic layer on a driven roller, and abrasion of the scrap iron to the surface of a workpiece is prevented.

Owner:安徽添御石油设备制造有限公司

Tail gas treatment control device of diesel engine test bench

PendingCN113756920AMeet emission requirementsPrevent wasteful situationsInternal combustion piston enginesExhaust apparatusEngine testingPtru catalyst

The invention provides a tail gas treatment control device of a diesel engine test bench, and belongs to the technical field of tail gas treatment equipment. The tail gas treatment control device of the diesel engine test bench comprises a tail gas treatment assembly and a dust cleaning assembly. The tail gas treatment assembly comprises a supporting plate, a bench gas guide pipe, a connecting pipe, a first gas detector, a urea metering injection pump, an oxidation catalyst DOC, a particle catcher DPF, a selective catalytic reduction device SCR, a PLC independent controller, a second gas detector, an exhaust chimney, a hollow threaded column and an inner threaded cover; the supporting plate is fixed to the end of the bench gas guide pipe; the connecting pipe is fixed between the bench gas guide pipe and the exhaust chimney; when the control device is used, dust on the inner wall of the exhaust chimney is scraped off by a scraping sleeve; then, the dust runs out through the hollow threaded column; and the control device improves the cleaning efficiency of the dust on the inner wall of the exhaust chimney.

Owner:GUANGXI YUCHAI MASCH CO LTD

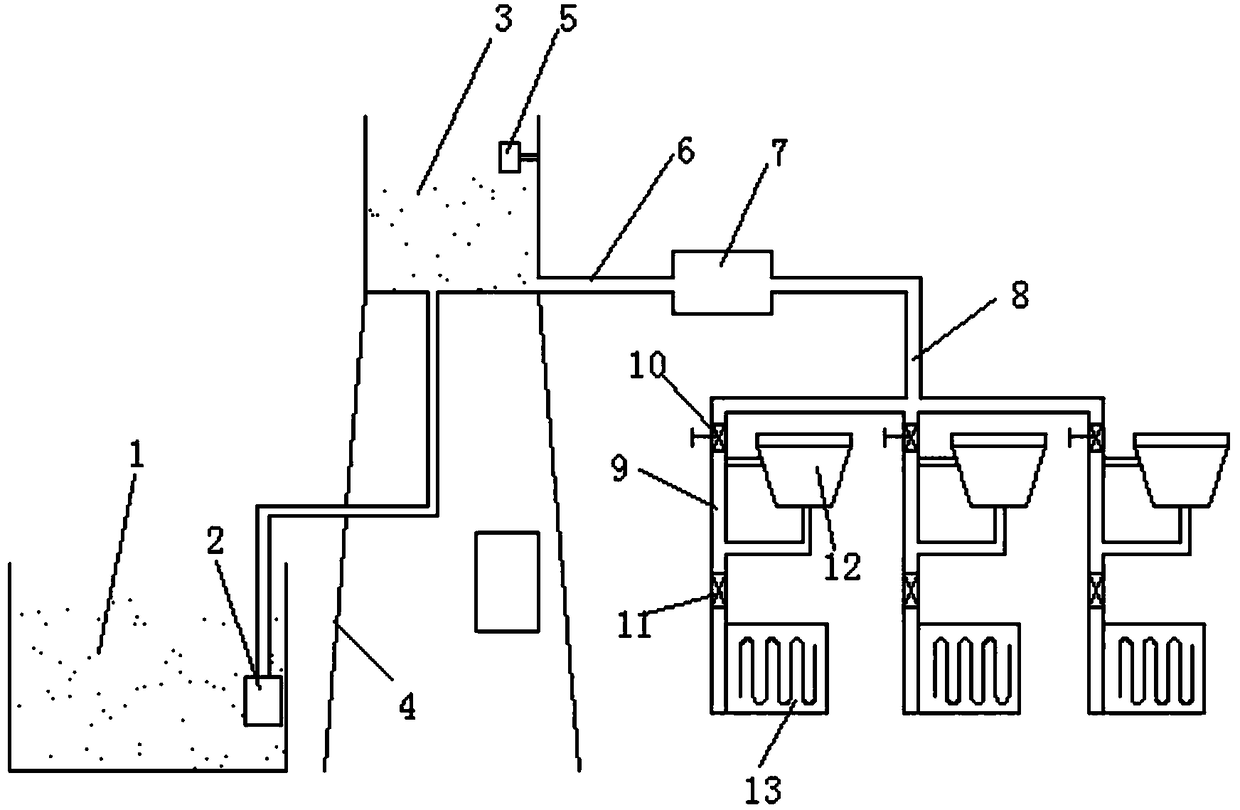

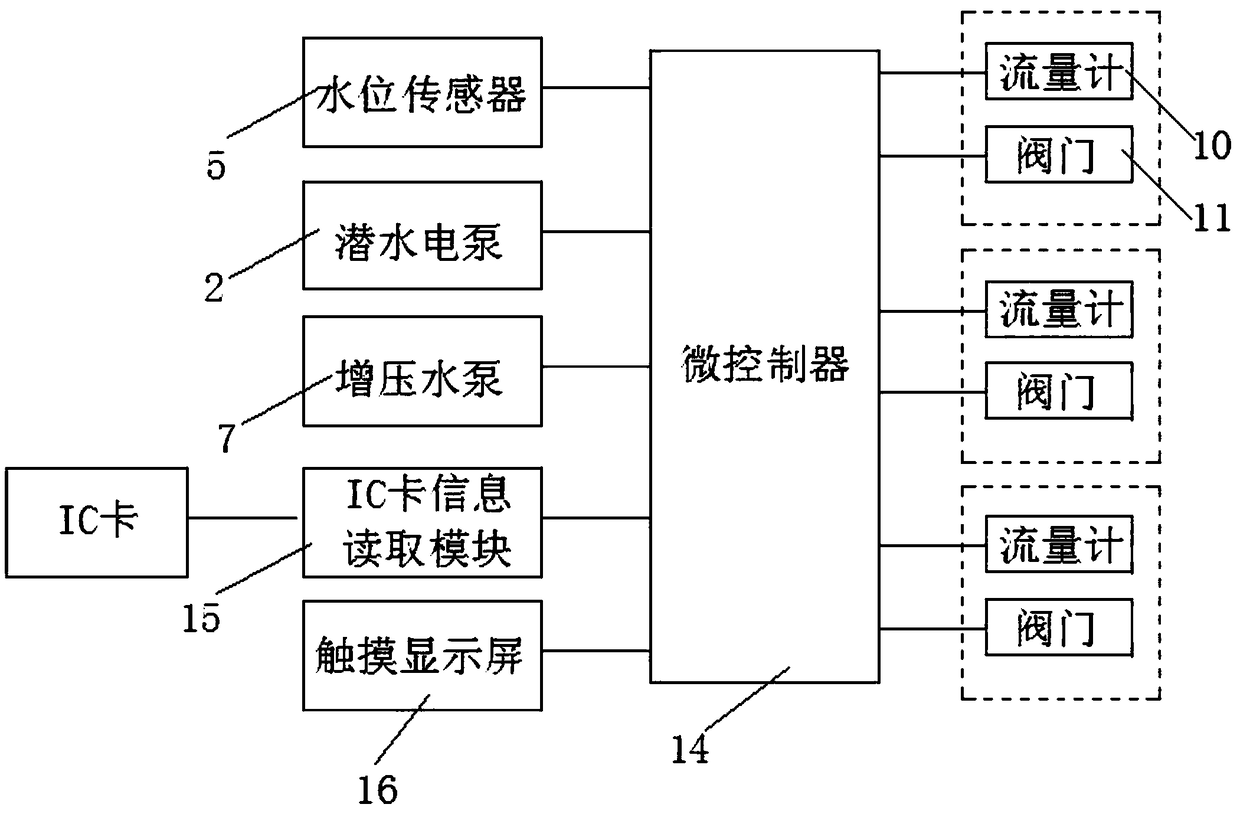

Automatic diversion irrigation system for agricultural production

PendingCN108782149ASimple structureEasy to irrigateWatering devicesPressurised distribution of liquid fertiliserAgricultureIrrigation

The invention belongs to the field of irrigation systems and discloses an automatic diversion irrigation system for agricultural production. A submersible electric pump is arranged in a water storagetank, a water level sensor is arranged in a water storage box which is connected with a first output pipe, and the first output pipe is connected to a booster water pump and a diversion device in sequence; flow meters and on-off valves are arranged on second output pipes in sequence; water conveying hoses are connected to the other ends of the second output pipes; a control device is further arranged on a bracket and comprises a microcontroller, an IC card information reading module and a touch display screen; the submersible electric pump, the water level sensor, the booster water pump, the IC card information reading module and the touch display screen are connected to the microcontroller, and the flow meters and on-off valves of the second output pipes are both connected to the microcontroller. According to the system, the utilization efficiency of water resources is high, diversion irrigation can be conducted according to different crops, and the water conveying amount can be adjusted according to requirements.

Owner:合肥三益江海智能科技有限公司

Coal mine coal crusher

The invention discloses a coal mine coal crusher. The coal mine coal crusher comprises a primary crushing bin and a secondary crushing bin. The upper surface of the primary crushing bin is provided with a coal inlet. Fixing grooves are fixedly connected to upper portion of an inner cavity of the primary crushing bin. An outer cover is welded to the lower portion of the front surface of the primarycrushing bin. The left side inside the primary crushing bin is provided with a clamping plate A, the lower portion of the clamping plate A is provided with a guide rail, the upper portion of the clamping plate A is slidably connected inside the fixing groove, and the right side inside the primary crushing bin is provided with a clamping plate B. According to the coal mine coal crusher, multi-stage crushing treatment is adopted, coal passes through the primary crushing bin, a motor C drives a gear A to pass through guide rails on the lower portions of the clamping plate A and clamping plate Bto pull the clamping plate A and the clamping plate B to move towards each other, and large pieces of coal are crushed into small pieces under the action of crushing needles, so that later-stage crushing treatment is facilitated, the crushing effect is greatly improved, and the crushing efficiency is greatly improved.

Owner:赵飞飞

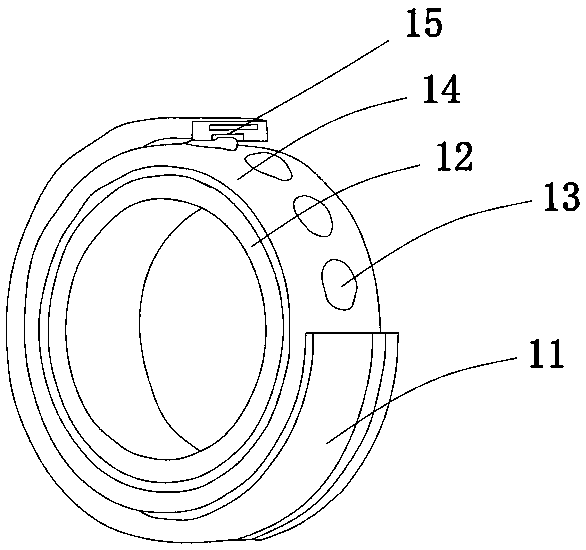

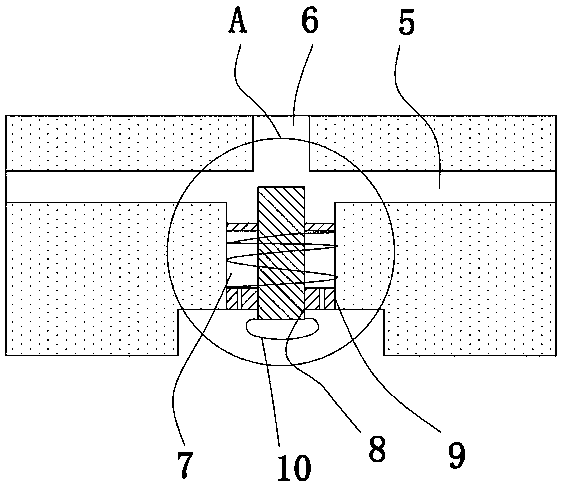

Rolling bearing

PendingCN110886768AAvoid spillingPrevent wasteful situationsBall bearingsBearing componentsOil canPhysics

The invention provides a rolling bearing. The rolling bearing comprises a bearing outer ring, a bearing inner ring, balls and a retainer. The rolling balls are used for driving a valve ball to move, after the highest point of each ball is in contact with the valve ball, the valve ball drives a valve rod and a valve element to move upwards, flow guiding holes are conductive with oil outlet holes, lubricating oil flows through inner oil rings, oil storage bins and the oil outlet holes in sequence and is scattered on the outer walls of the balls, is further driven into the retainer with the rolling of the balls, with the rolling of the balls, all the balls can be lubricated, and the lubricating effect is good; in addition, after the highest point of each ball passes through, driven by a spring, the valve rod and the valve element are reset, the flow guiding holes are not conductive with the oil outlet holes, the lubricating oil is prevented from being scattered on the outer wall of the retainer, and thus the situation of wasting the lubricating oil can be effectively prevented.

Owner:LUOYANG WEICHUANG BEARING MOLD

Electric hoist box body outer wall spraying process

ActiveCN107931068AGuaranteed uniformityGuaranteed fixed effectPretreated surfacesCoatingsSurface layerLacquer

The invention relates to the technical field of machines or devices adopting a jetting method for coating the surface of an object or surfaces of other workpieces with liquid or other fluid, in particular to an electric hoist box body outer wall spraying process. The electric hoist box body outer wall spraying process includes the following steps of firstly, grinding, secondly, cleaning, thirdly,temperature setting, fourthly, preparing a spraying device, fifthly, priming paint spraying, sixthly, middle layer paint spraying, and seventhly, surface layer paint spraying. By means of the technical scheme, oil paint is prevented from being sprayed on the ground, and waste of the oil paint is reduced; and the adhesive force of the oil paint can also be enhanced.

Owner:河南巨人起重机集团有限公司

Pellet filling device of plastic granulator

InactiveCN110451106APrevent wasteful situationsEasy to fillLarge containersSolid materialEngineeringFill device

The invention relates to the technical field of pellet filling devices, and discloses a pellet filling device of a plastic granulator. The device comprises a supporting table, wherein the side wall ofthe top of the supporting table is symmetrically and fixedly with supporting plates, the tops of the two supporting plates are fixedly connected with a granulator jointly, the bottom center of the granulator is provided with a discharging hopper, and the portions, close to the tops, of the opposite side walls of the two supporting plates are provided with knocking mechanisms; and each knocking mechanism comprises a mounting block, a mounting groove, two first sliding grooves, two first sliding blocks, a reciprocating plate, two first springs, a knocking block, a reciprocating hole, two racks,a motor, a rotating shaft and a special-shaped gear, wherein the mounting blocks are fixedly connected on the side walls, close to the discharging hopper, of the supporting plates, the mounting blocks and the discharging hopper are located on the same horizontal plane, and the mounting grooves are formed in the side walls, close to the discharging hopper, of the mounting blocks. According to thepellet filling device of the plastic granulator, knocking is performed on the discharging hopper, thus preventing the situation that pellets are adhered to the inner hopper wall of the discharging hopper, which leads to waste.

Owner:高邮亚普塑业有限公司

Cigarette taker

Owner:SHANDONG BINZHOU TOBACCO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com