Coal mine coal crusher

A crusher and coal technology, applied in the direction of grain processing, etc., can solve the problems of different sizes of coal particles, random flying of coal debris, poor crushing effect, etc., and achieve complete coal crushing, improved crushing efficiency, and improved crushing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

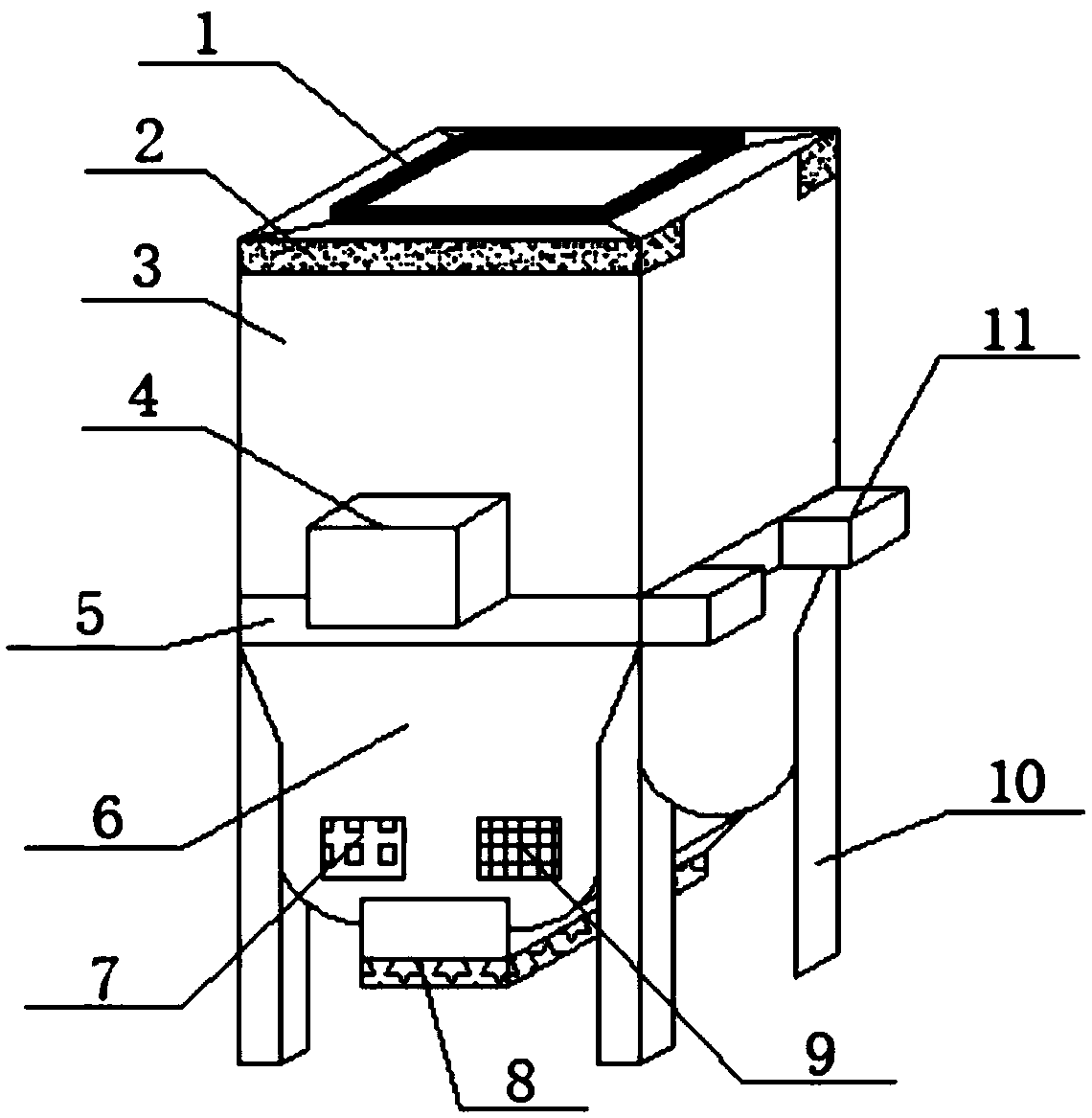

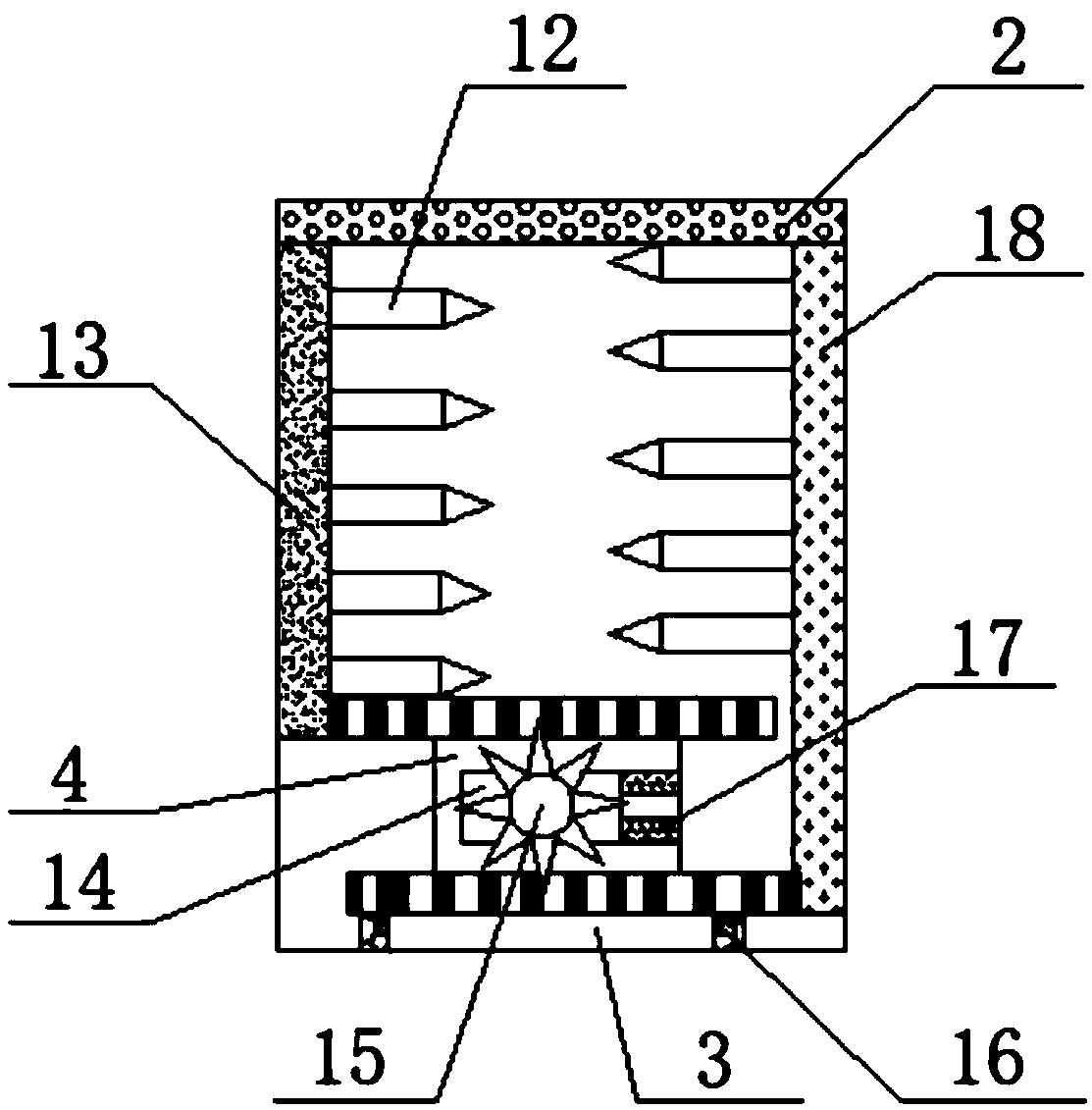

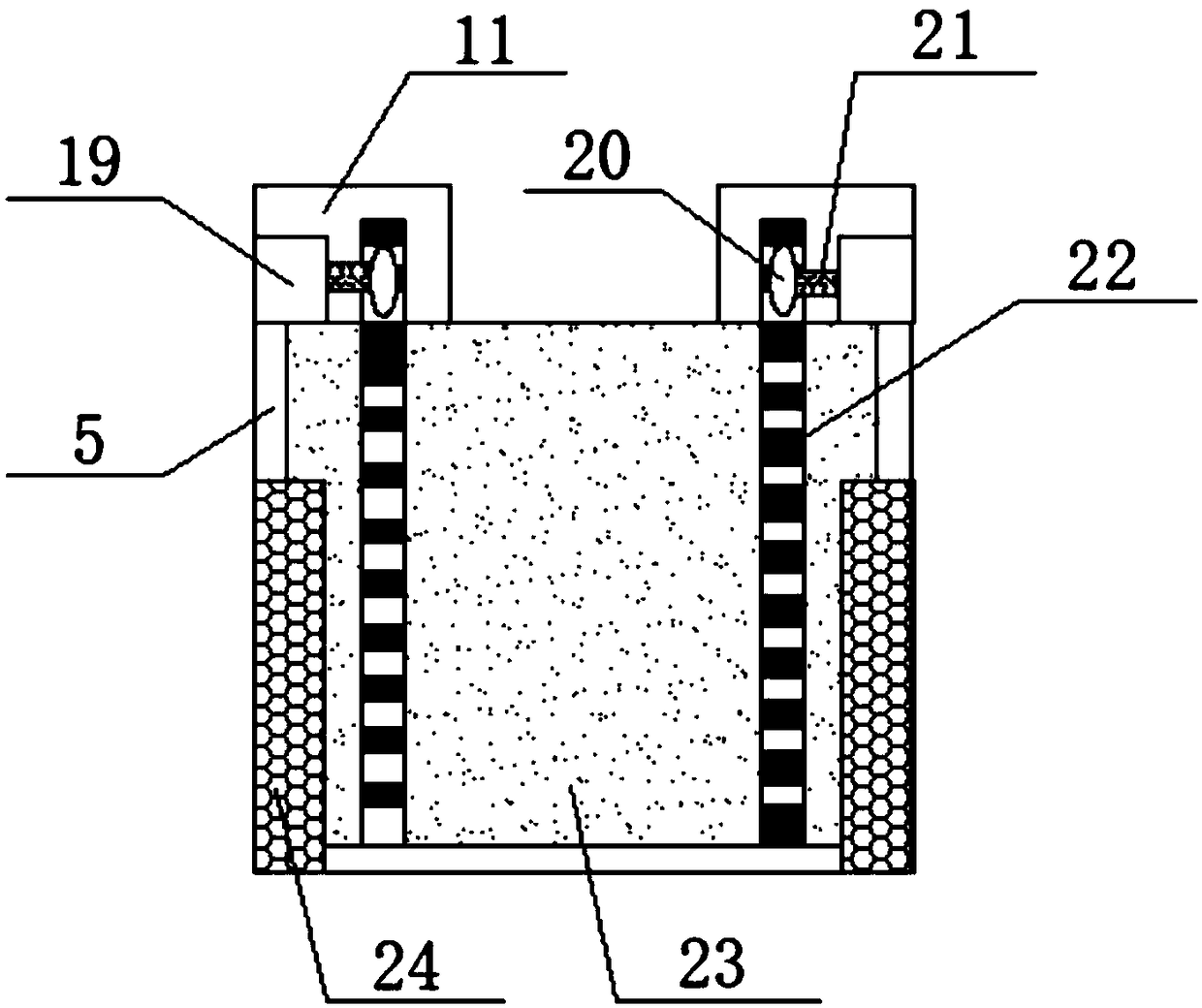

[0021] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a coal mine crusher of the present invention includes a primary crushing bin 3 and a secondary crushing bin 6, the primary crushing bin 3 is used to break large pieces of coal into small pieces of coal, and the secondary crushing bin 6 is used for coal The final crushing of the primary crushing chamber 3 is provided with a coal inlet 1 on the upper surface of the primary crushing chamber 3, and coal is added to the primary crushing chamber 3 from the coal inlet 1. Groove 2 is used to fix the splint A13 and splint B18 inside the primary crushing bin 3. The lower part of the front of the primary crushing bin 3 is welded with an outer cover 4. The outer cover 4 is used to protect the motor C14. The left side of the primary crushing bin 3 is installed with a The splint A13, and the lower part of the splint A13 is provided with a guide rail, which is used for the transmission of the gear A15. At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com