Textile printing and dyeing equipment with self-adjusting function

A textile printing and dyeing and self-regulating technology, which is applied in textiles and papermaking, textile processing machine accessories, textile material processing, etc., can solve problems such as poor dye penetration, insufficient dyeing, and lack of self-regulating functions, so as to ensure stability , Reduce the effect of fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

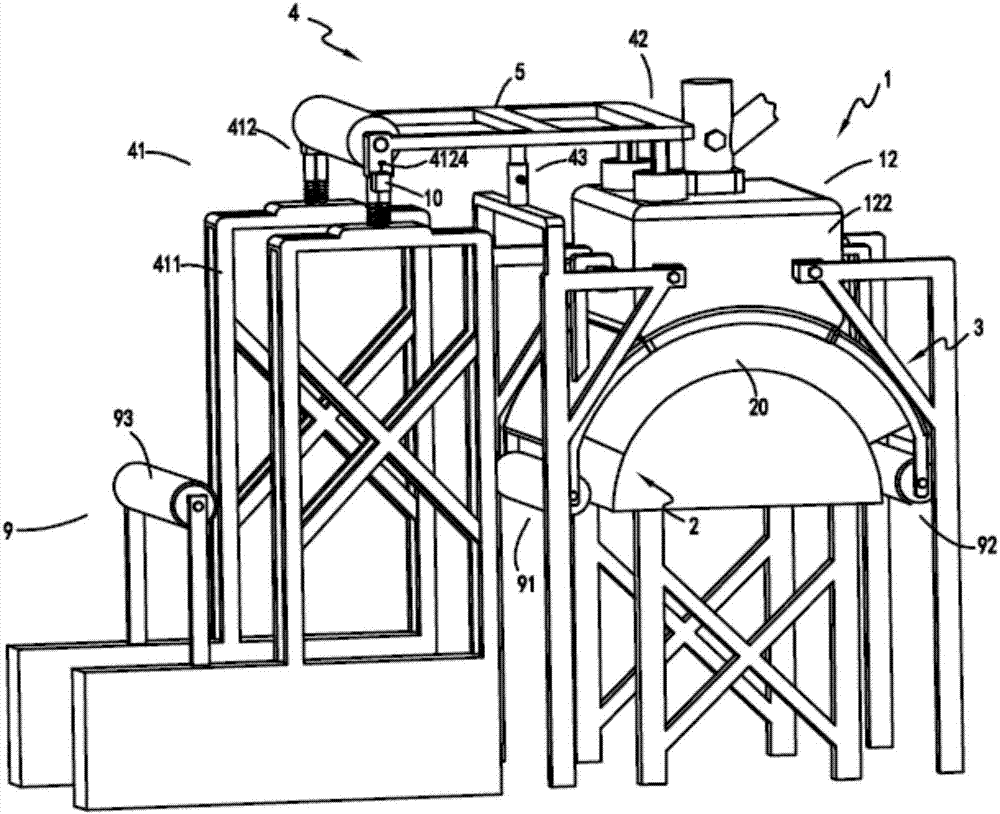

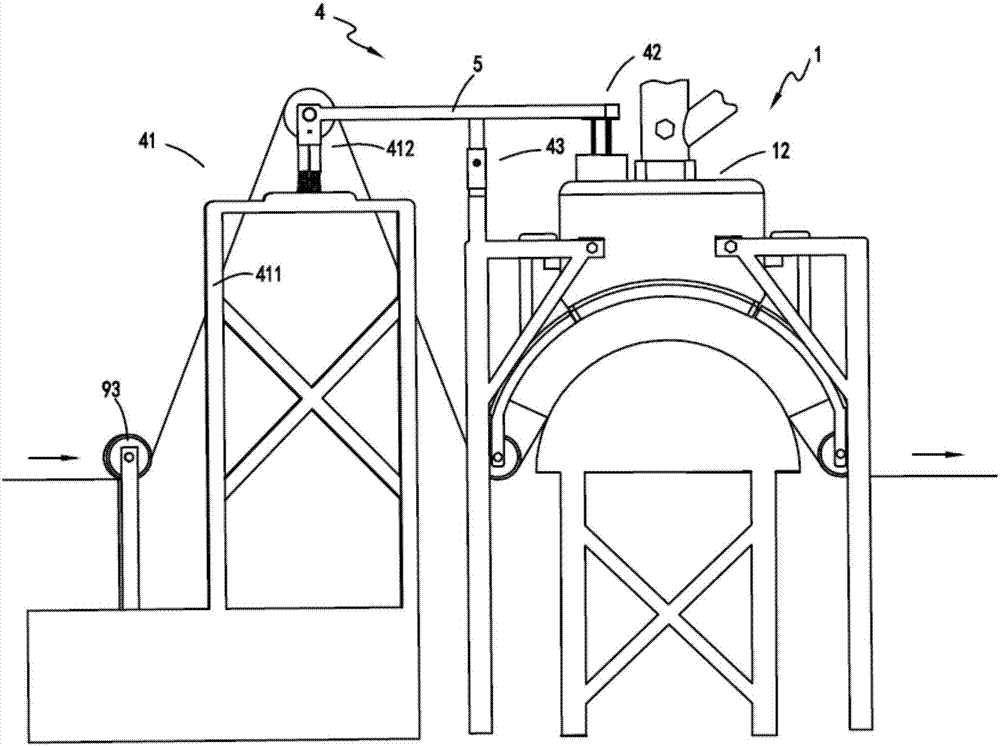

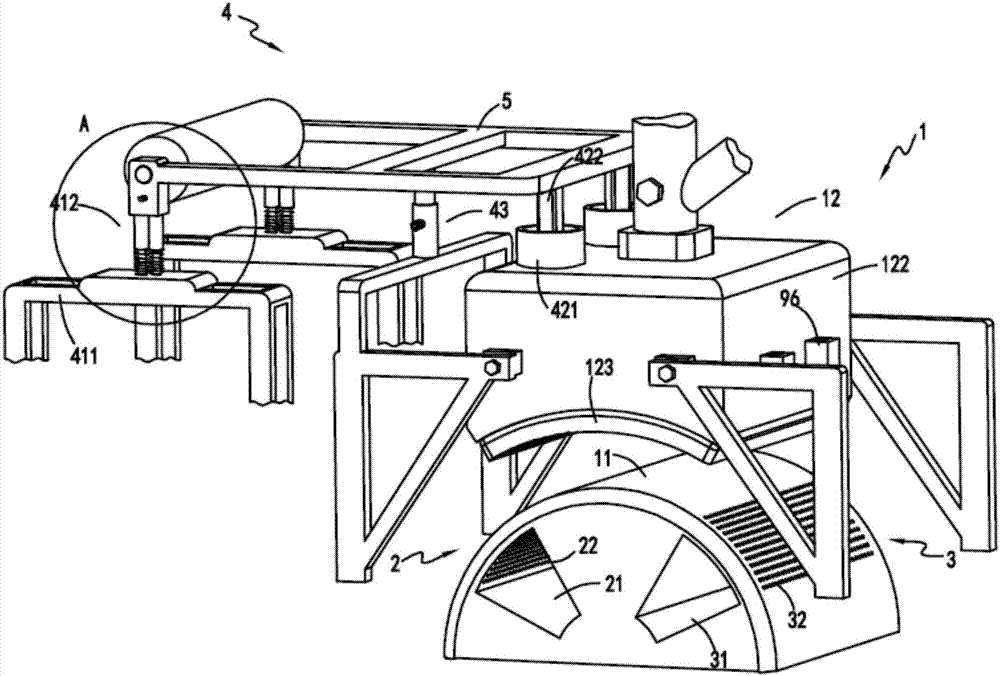

[0039] figure 1 It is a schematic diagram of the structure of textile printing and dyeing equipment with self-regulating function, figure 2 It is a schematic diagram of the front view of the textile printing and dyeing equipment with self-adjusting function, image 3 Schematic diagram of the structure of the regulation part, Figure 4 It is a partially enlarged schematic diagram of the upgrading device, Figure 5 is a schematic cutaway diagram of the spraying mechanism, Figure 6 It is a schematic diagram of the front view of the spraying mechanism and the conduction part, Figure 7 It is a schematic diagram of the structure of the wrinkle-removing part and the dye-absorbing part. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a kind of textile printing and dyeing equipment with self-adjusting function includes a dyeing part 1, and the dyeing part 1 includes a support area 11 and a dyeing mechanism 12 for dyeing th...

Embodiment 2

[0051] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the two ends of the lifting device 412 are also provided with counterweight hooks 4124 on the rotating base 4121 for placing the counterweight code 10 .

[0052] The setting of the weight code 10 is to manually add the weight code 10 to promote the drop of the plug body 422 to achieve sufficient dyeing when the pressure in the pressure chamber 121 is insufficient due to the gravity of the cloth. the injection force.

[0053] Working process: the cloth is transferred to the adjustment part 4 through the cloth guide roller a93, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com