Tail gas treatment control device of diesel engine test bench

A diesel engine and exhaust gas treatment technology, which is applied in the test of the engine, the electronic control of the exhaust gas treatment device, the diagnosis device of the exhaust gas treatment device, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

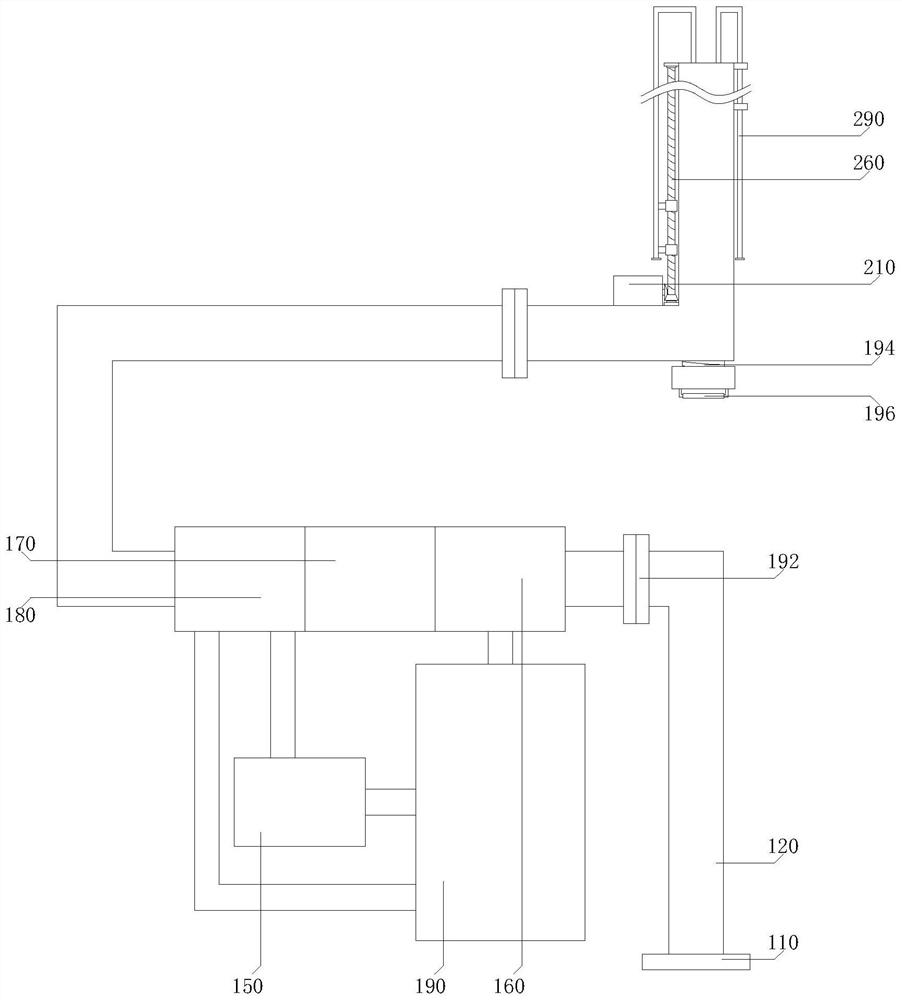

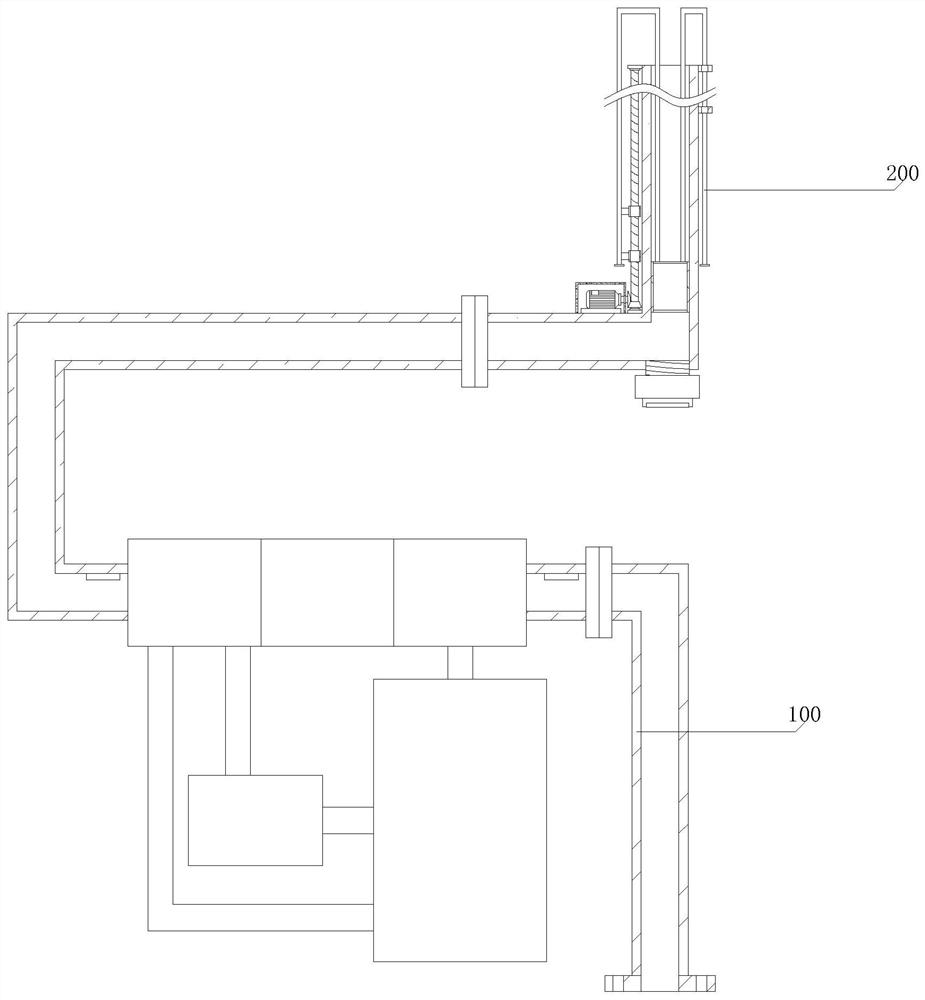

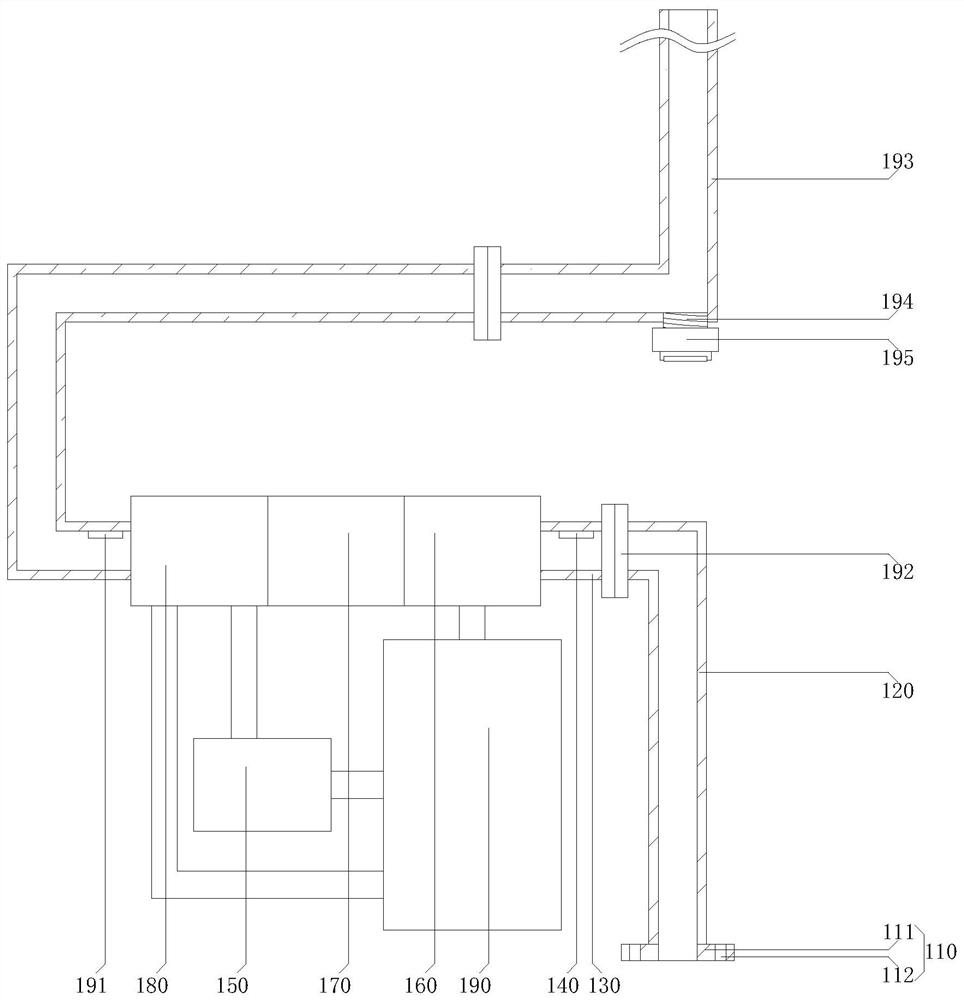

[0033] see Figure 1-4 , the present invention provides a technical solution: a diesel engine test bench exhaust gas treatment control device, including an exhaust gas treatment assembly 100 and a dust cleaning assembly 200 . The dust cleaning assembly 200 is fixed on the exhaust gas treatment assembly 100 , and the control device improves the efficiency of cleaning the dust on the inner wall of the chimney 193 .

[0034] see Figure 1-Figure 3 , the exhaust gas treatment assembly 100 includes a support plate 110, a bench air guide pipe 120, a connecting pipe 130, a first gas detector 140, a urea metering jet pump 150, an oxidation catalyst DOC160, a particle trap DPF170, a selective catalytic reduction device SCR180, and an independent PLC Controller 190, second gas detector 191, chimney 193, hollow threaded column 194 and internal thread cover 195, support plate 110 is welded on the end of platform air duct 120, support plate 110 comprises plate body 111, plate body 111 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com