Asymmetric split turbine of turbocharger

A turbocharger, asymmetric technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of poor reliability, high cost of variable section turbocharger, complicated control, etc., to achieve good inheritance , Easy to upgrade and switch, reduce the effect of exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

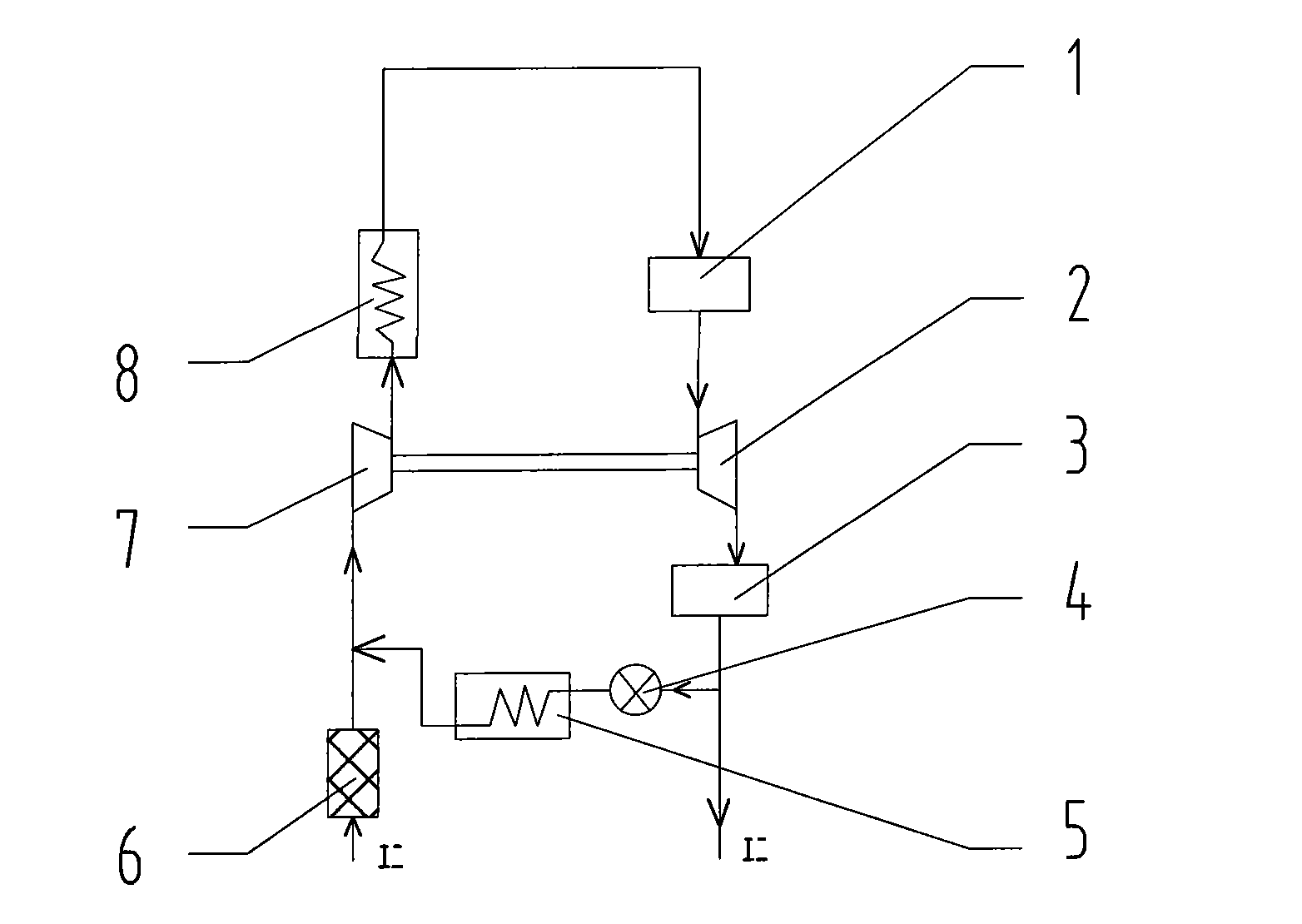

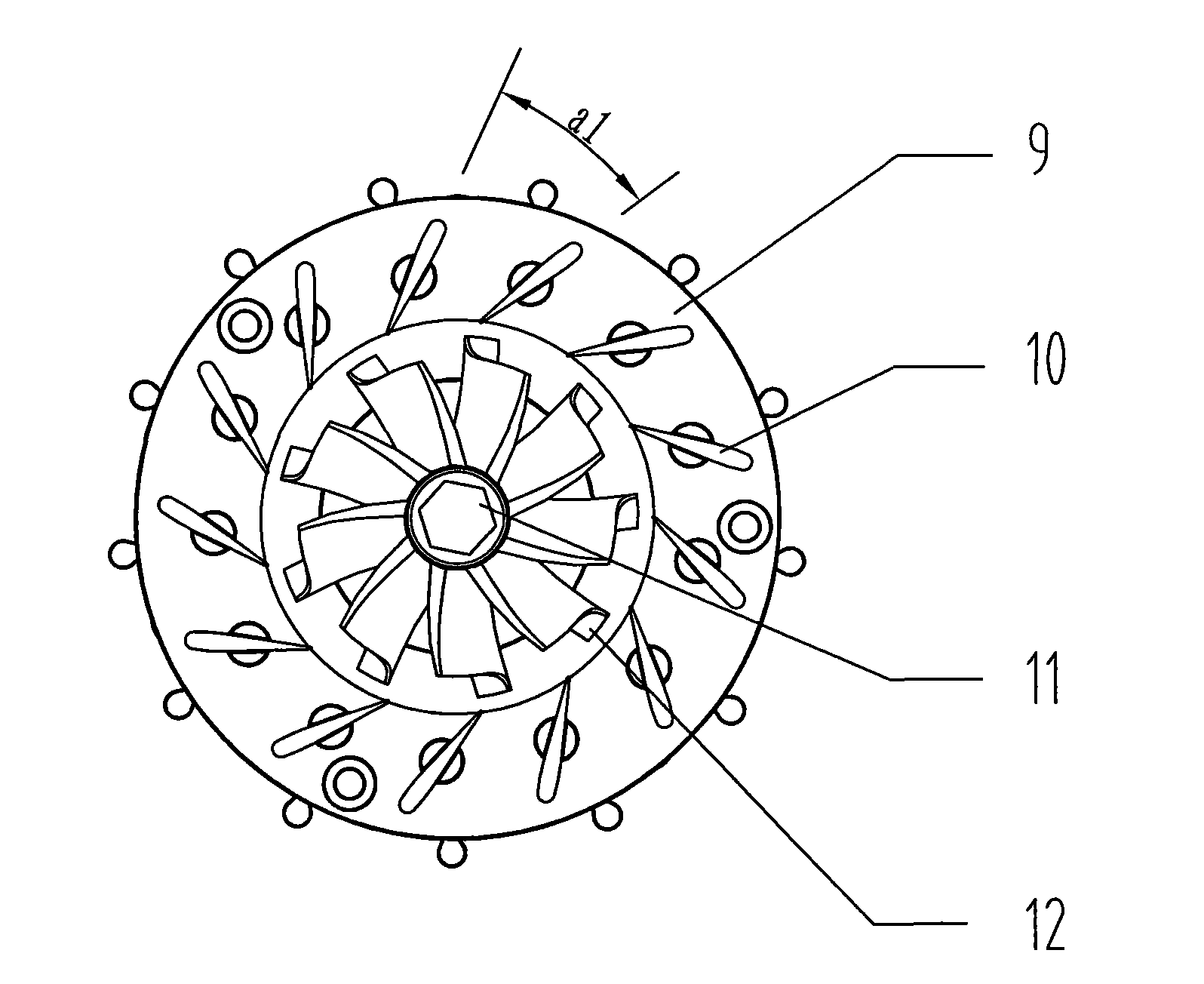

[0036] Example 1, such as Figure 5 As shown, a turbocharger asymmetric split turbine includes an engine, the engine is provided with an engine exhaust pipe 14, a turbine casing 13 and a turbine rotor 11, and the turbine casing 13 is provided with a volute high-pressure flow passage 18 and a volute The A / R value of the low-pressure channel 17 of the casing and the high-pressure channel 18 of the volute is smaller than the A / R value of the low-pressure channel 17 of the volute, and the cross-sectional area of the volute of the high-pressure channel 18 of the volute is smaller than that of the low-pressure channel 17 of the volute vortex cross-sectional area.

[0037] The front end of the volute high-pressure runner 18 is connected with the high-pressure exhaust manifold 15 of the engine exhaust pipe 14, and the front end of the volute low-pressure runner 17 is connected with the low-pressure exhaust manifold 16 of the engine exhaust pipe 14, as Figure 7 As shown, the high-t...

Embodiment 2

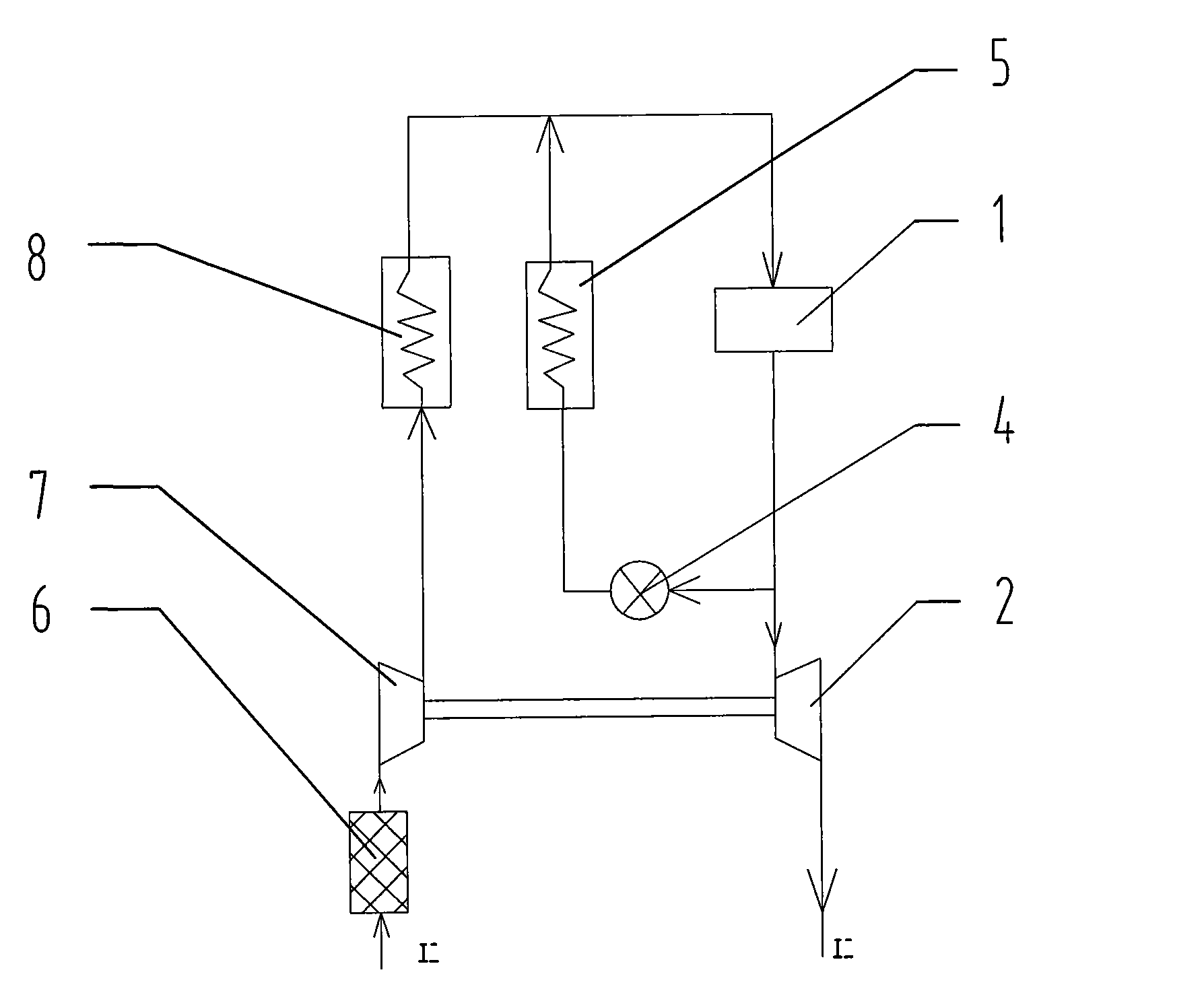

[0039] Example 2, such as Figure 6 As shown, a turbocharger asymmetric split turbine includes an engine, the engine is provided with an engine exhaust pipe 14, a turbine casing 13 and a turbine rotor 11, and the turbine casing 13 is provided with a volute high-pressure flow passage 18 and a volute The A / R value of the low-pressure channel 17 of the casing and the high-pressure channel 18 of the volute is smaller than the A / R value of the low-pressure channel 17 of the volute, and the cross-sectional area of the volute of the high-pressure channel 18 of the volute is smaller than that of the low-pressure channel 17 of the volute vortex cross-sectional area.

[0040] The front end of the volute high-pressure runner 18 is connected to the high-pressure exhaust manifold 15 of the engine exhaust pipe 14, and the front end of the volute low-pressure runner 17 is connected to the low-pressure exhaust manifold 16 of the engine exhaust pipe 14, in order to ensure high-speed supercha...

Embodiment 3

[0044] Example 3, such as Figure 5 As shown, a turbocharger asymmetric split turbine includes an engine, the engine is provided with an engine exhaust pipe 14, a turbine casing 13 and a turbine rotor 11, and the turbine casing 13 is provided with a volute high-pressure flow passage 18 and a volute The A / R value of the low-pressure channel 17 of the casing and the high-pressure channel 18 of the volute is smaller than the A / R value of the low-pressure channel 17 of the volute, and the cross-sectional area of the volute of the high-pressure channel 18 of the volute is smaller than that of the low-pressure channel 17 of the volute vortex cross-sectional area.

[0045] The front end of the volute high-pressure runner 18 is connected with the high-pressure exhaust manifold 15 of the engine exhaust pipe 14, and the front end of the volute low-pressure runner 17 is connected with the low-pressure exhaust manifold 16 of the engine exhaust pipe 14, as Figure 8 As shown, the high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com