Fuel cell air supply system and control method

An air supply and fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of undiscovered cathode air intake system, achieve clear control method, fast response speed, and reduce control difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

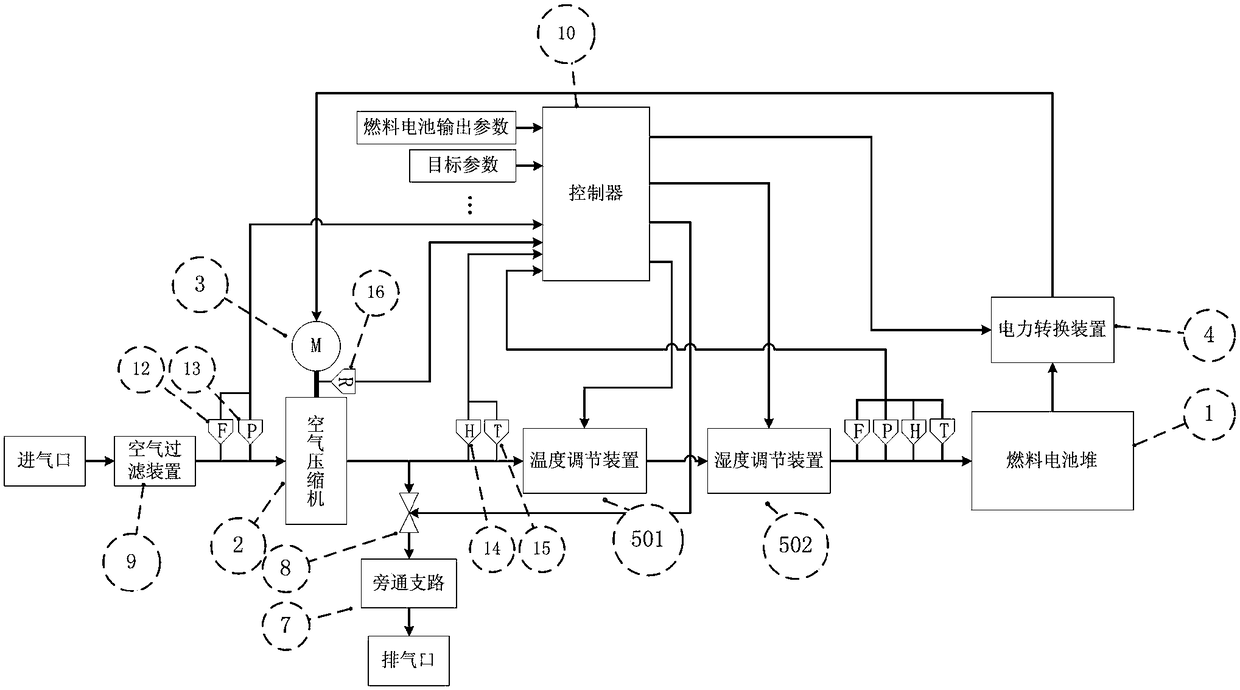

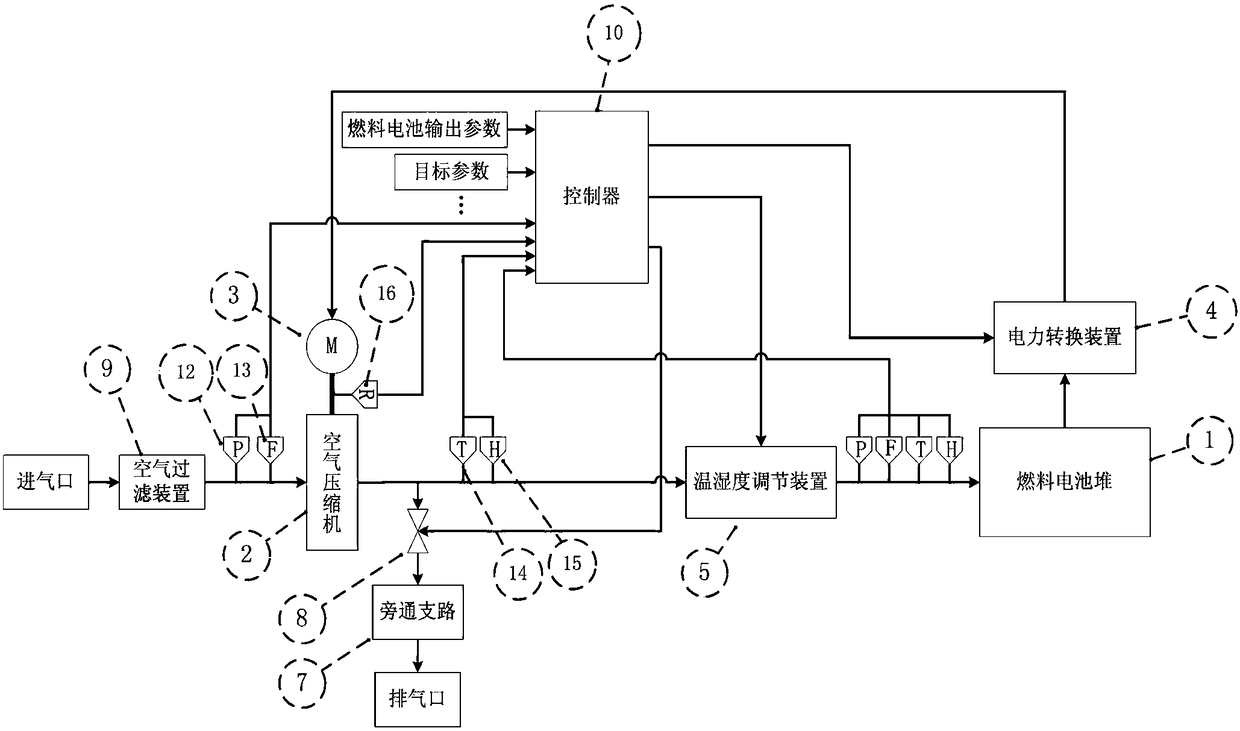

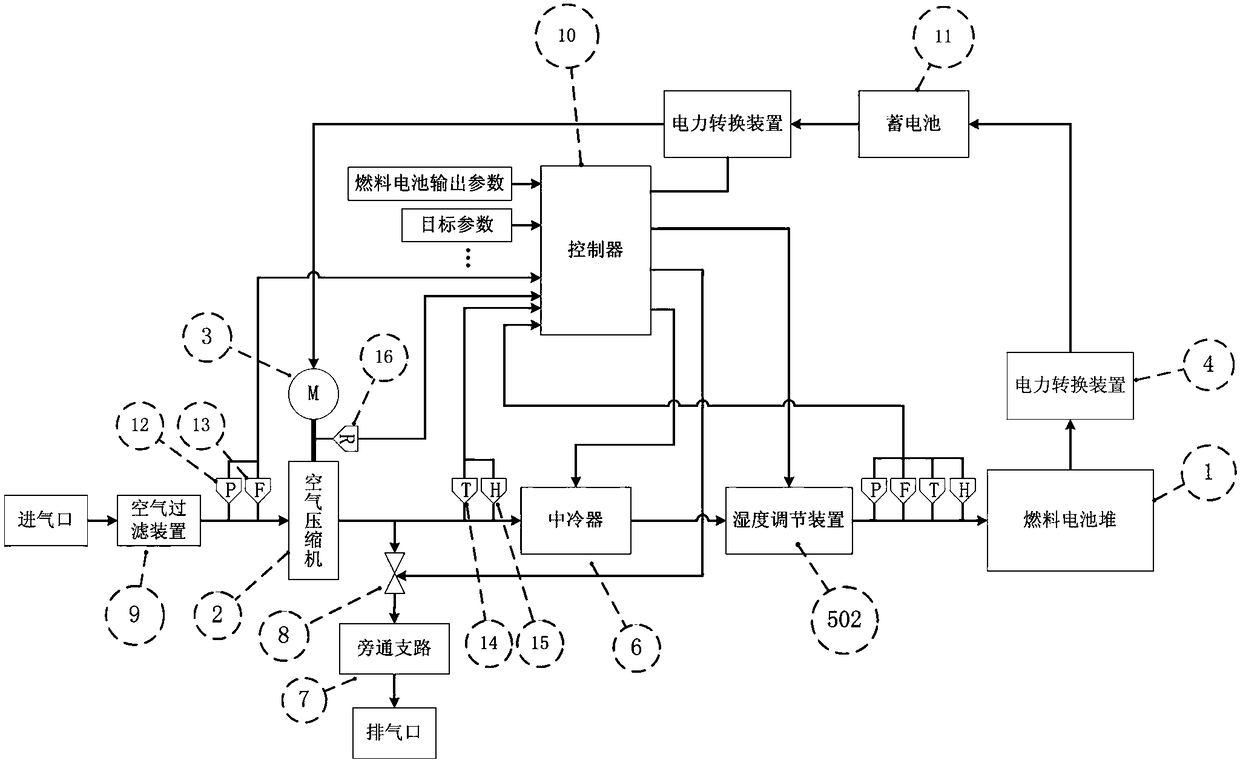

[0049] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0050] The present invention firstly provides a fuel cell air supply system, such as figure 1 As shown, the system includes:

[0051] a fuel cell stack 1 for generating electricity through an electrochemical reaction between an oxidant gas and a fuel gas;

[0052] an air compressor 2 for delivering air as an oxidant gas to the cathode of the fuel cell stack 1;

[0053] The motor 3 is connected with the air compressor 2 and is used to drive the air compressor 2 to work; the motor 3 and the air compressor 2 can be made as one;

[0054]The power conversion device 4 is connected between the fuel cell stack 1 and the motor 3, and is used to adjust the power supplied to the motor 3;

[0055] The temperature adjustment device 501 is connected between the air compressor 2 and the fuel cell stack 1, and is used to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com