Method for monitoring distribution of pulverized coal in low-NOx tangential coal-fired boiler

A boiler furnace and coal-burning technology, applied in the combustion method, adjusting the supply of fuel, controlling the combustion and other directions, can solve the problems of poor measurement conditions, abnormal boiler operating parameters, unreasonable air classification intensity, etc., to reduce the impact, reasonable air The effect of grading and meeting emission requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

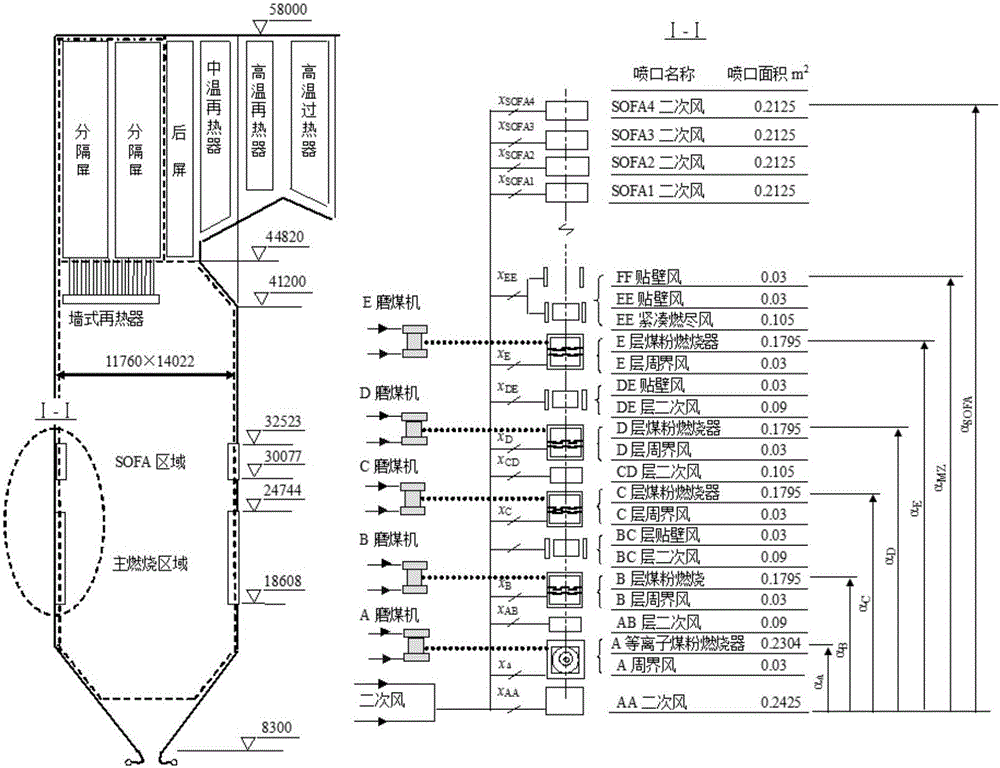

[0066] The implementation object is a power plant boiler, figure 1 It is the layout and area of the furnace, heating surface, air nozzle and fuel nozzle of the boiler, and the division of the combustion zone in the furnace; the boiler is a subcritical, one-time reheating, controlled circulation drum furnace, single furnace, inverted U-shaped open-air Layout, the upper part of the furnace is equipped with a wall reheater, a full large screen and a rear screen superheater; the boiler adopts a positive pressure direct blowing pulverizing system, equipped with 5 sets of RP923 medium-speed coal mills, and each pulverizing system Layer 4 burners supply powder, therefore, n=4 in formula (3) and formula (4), the furnace has 5 layers of coal powder nozzles, which are recorded as A, B, C, D, E from bottom to top, Among them, a plasma igniter is also installed in the pulverized coal nozzle of layer A, and the air and fuel nozzles are arranged tangentially at four corners.

[0067] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com