Highway bridge roadbed pavement auxiliary construction device and construction method thereof

A technology for highway bridges and construction devices, which is applied in the directions of roads, roads, and road repairs, can solve problems such as the troublesome and laborious removal of subgrades, and the impact of construction efficiency of highway bridges, subgrades and pavements, and achieves the improvement of construction efficiency, quality, and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

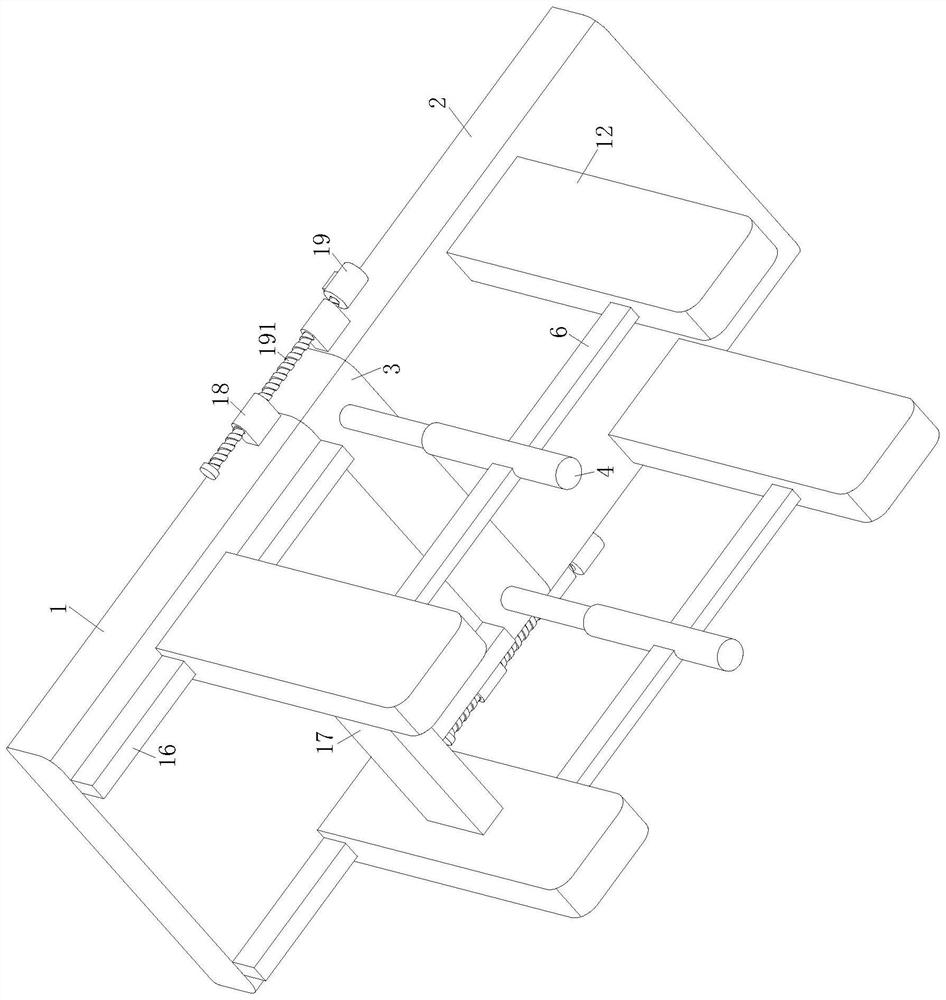

[0049] As an embodiment of the present invention, a groove 13 is provided on the adjacent side of the No. 1 mold 1 and No. 2 mold 2; the cross-sectional shape of the groove 13 is arc-shaped, and the groove 13 is slidably connected with the sealing strip 14 The sealing strip 14 is consistent with the cross-sectional shape of the groove 13; the groove 13 is provided with a spring 15; one end of the spring 15 is connected to the groove bottom of the corresponding groove 13, and the other end is connected to the corresponding The sealing strip 14; the edge of the end face of the sealing strip 14 away from the spring 15 is rounded;

[0050] When working, the electric push rod 4 drives the supplementary mold 3 to move between the first mold 1 and the second mold 2, and the two sealing strips 14 will follow the corresponding groove 13 under the extrusion of the supplementary mold 3. Sliding, so that the sealing strip 14 will move into the corresponding groove 13, when the supplementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com