Switchable cloth dyeing and printing equipment

A printing and dyeing equipment, switchable technology, applied in the field of switchable cloth printing and dyeing equipment, can solve the problems of self-adjustment, flexible switching of different color dyeing boxes, etc., and achieve the effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

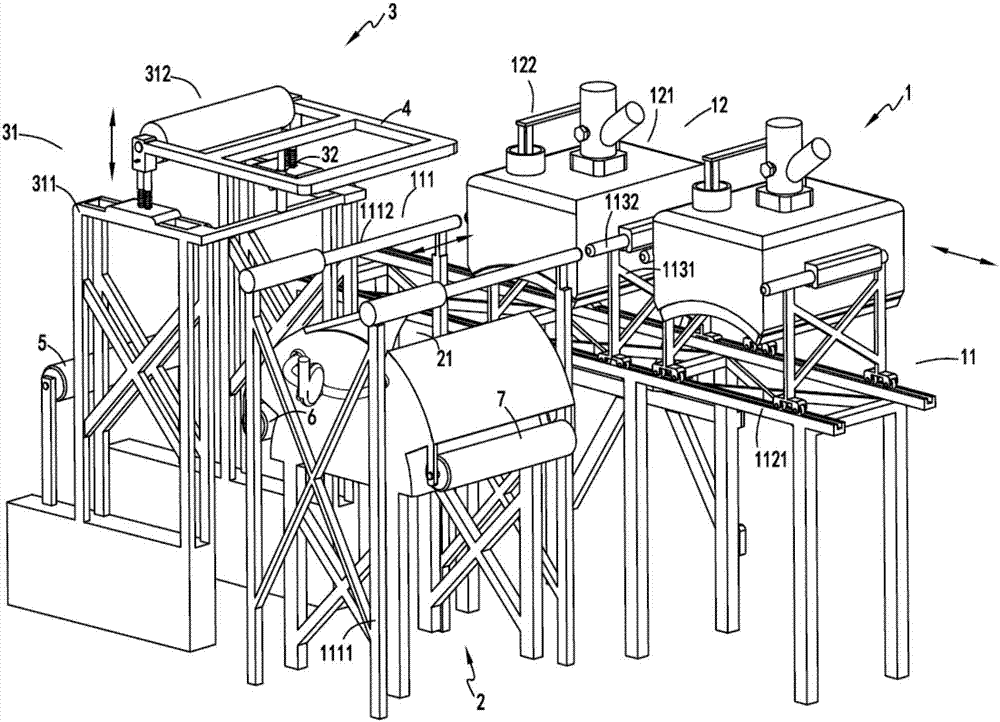

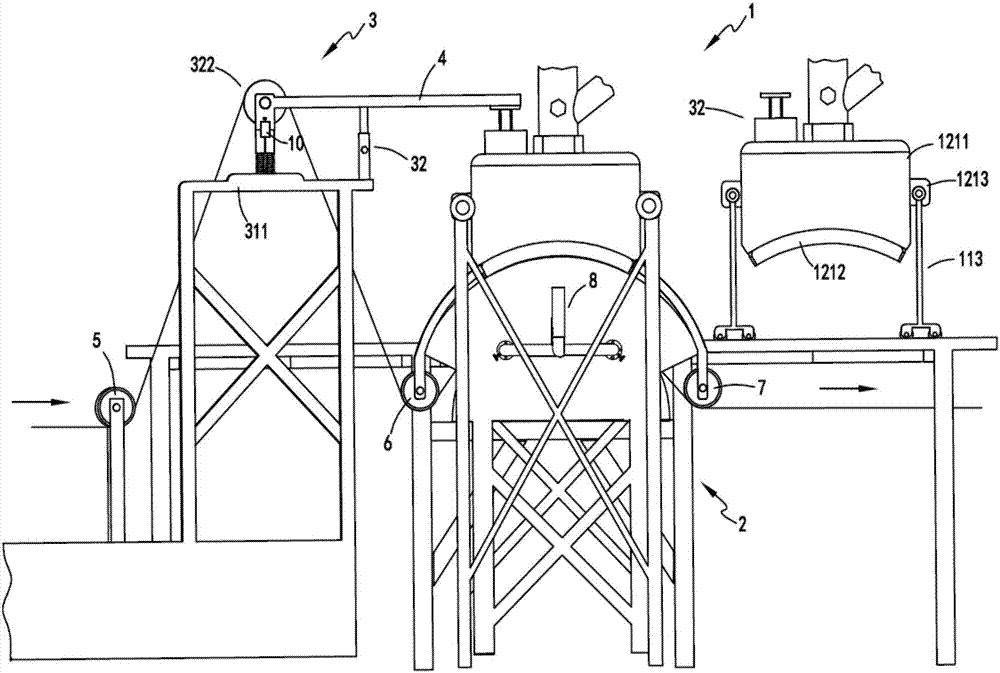

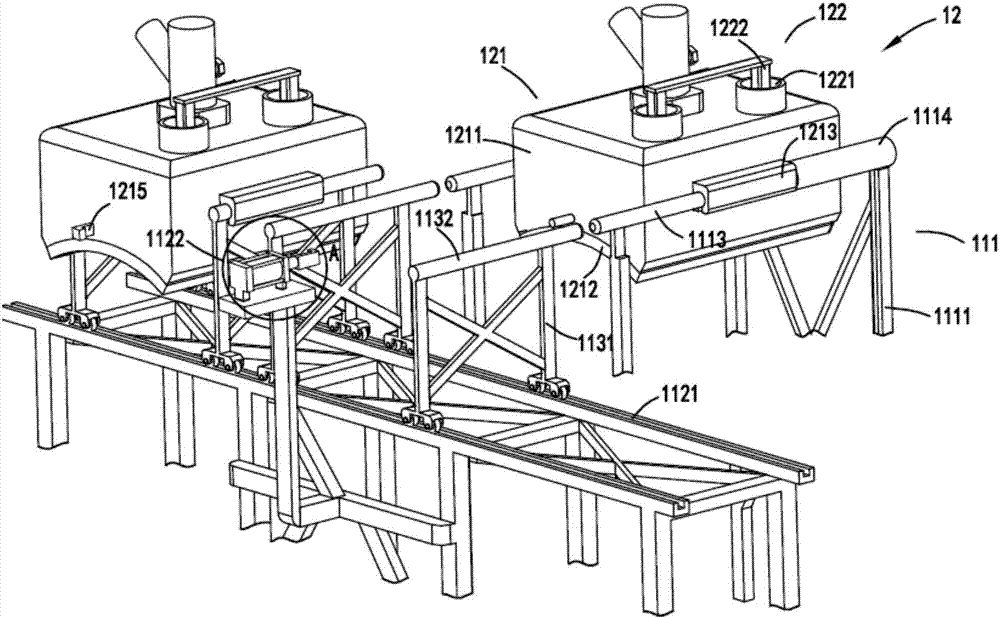

[0048] figure 1 It is a schematic diagram of the switchable cloth printing and dyeing equipment, figure 2 It is a schematic diagram of the front view of the switchable cloth printing and dyeing equipment, image 3 It is a schematic diagram of the switching mechanism and the spraying mechanism, Figure 4 Schematic diagram of the enlarged structure of the positioning push-pull device, Figure 5 It is a schematic diagram of the structure of the spraying device when it is transferred from the walking support unit to the spraying support unit, Figure 6 Schematic diagram of the structure of the regulation part, Figure 7 It is an enlarged schematic diagram of part of the structure of the lifting device, Figure 8 It is a structural schematic diagram of the wrinkle removal unit and the absorption unit, Figure 9 is a cutaway schematic diagram of the wrinkle removal unit, Figure 10 A cutaway schematic diagram of the spraying device, Figure 11 It is a cutaway schematic diagram...

Embodiment 2

[0066] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that a sliding locking device 32 for locking the height of the lifting device 312 and the pressure regulating plug 1222 is provided between the lifting mechanism 31 and the pressure regulating device 122 One end of the sliding locking device 32 is fixed on the frame 311 and the other end is fixed on the fixed frame 4 .

[0067] In order to ensure that the pressure regulating plug 1222 will not slide up and down during the cloth transmission process after the adjustment is completed,...

Embodiment 3

[0069] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is that the outer port of the wrinkle removal hole 232 on the left side is inclined toward the center position on the corresponding arc surface with the center position as the dividing line of the negative pressure chamber a231, and the outer port on the right side is inclined toward the center position. The outer port of the corrugation hole 232 is also inclined towards the central position.

[0070] The negative pressure chamber a231 and the wrinkle removal hole 232 are set in the wrink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com