Electric hoist box body outer wall spraying process

A technology of electric hoist and box body, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc. It can solve the problems of difficult cleaning, scattered on the ground or other places, and peeling off of the sprayed layer, so as to ensure uniformity performance, ensure the fixing performance and the quality of the coating, and ensure the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

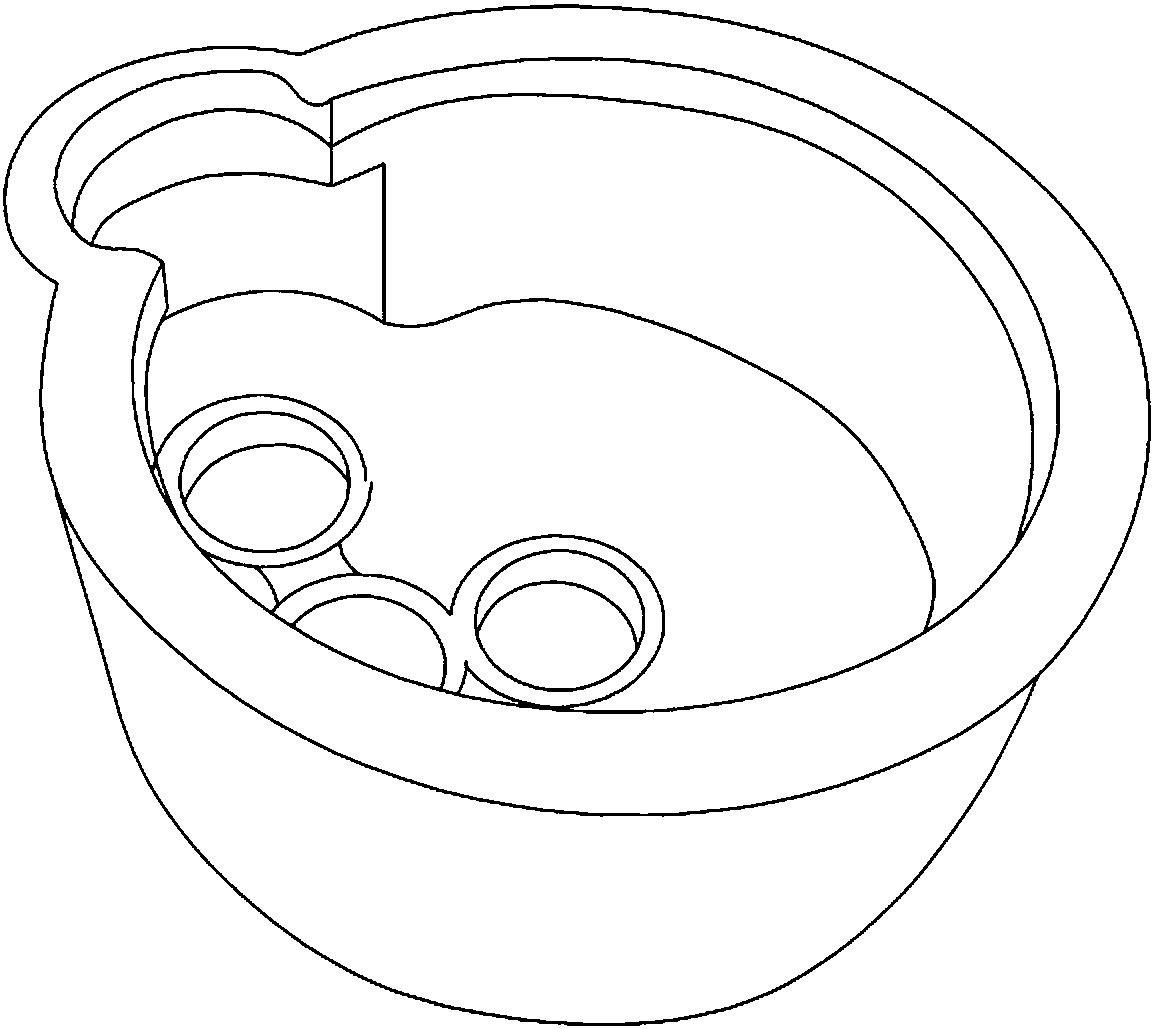

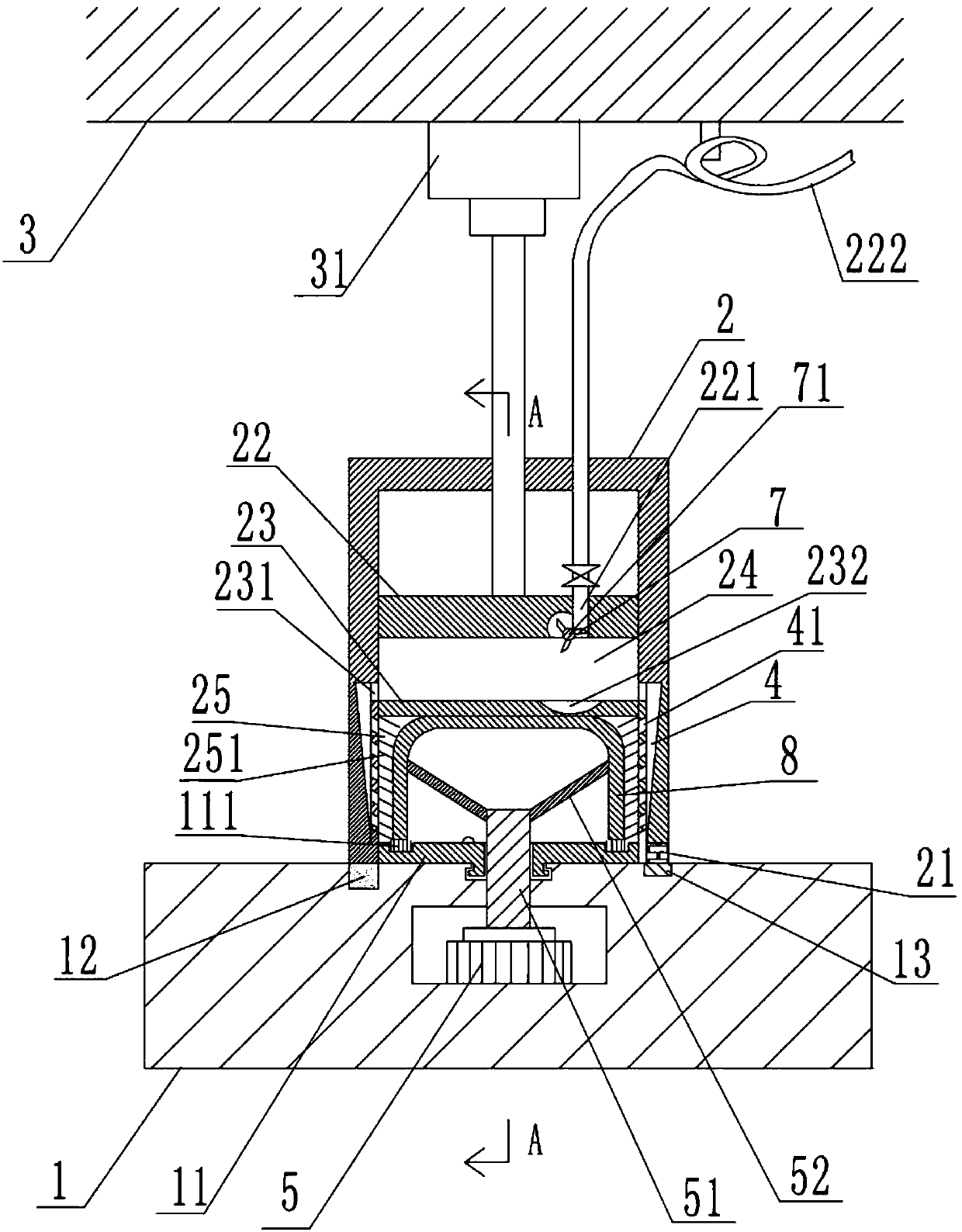

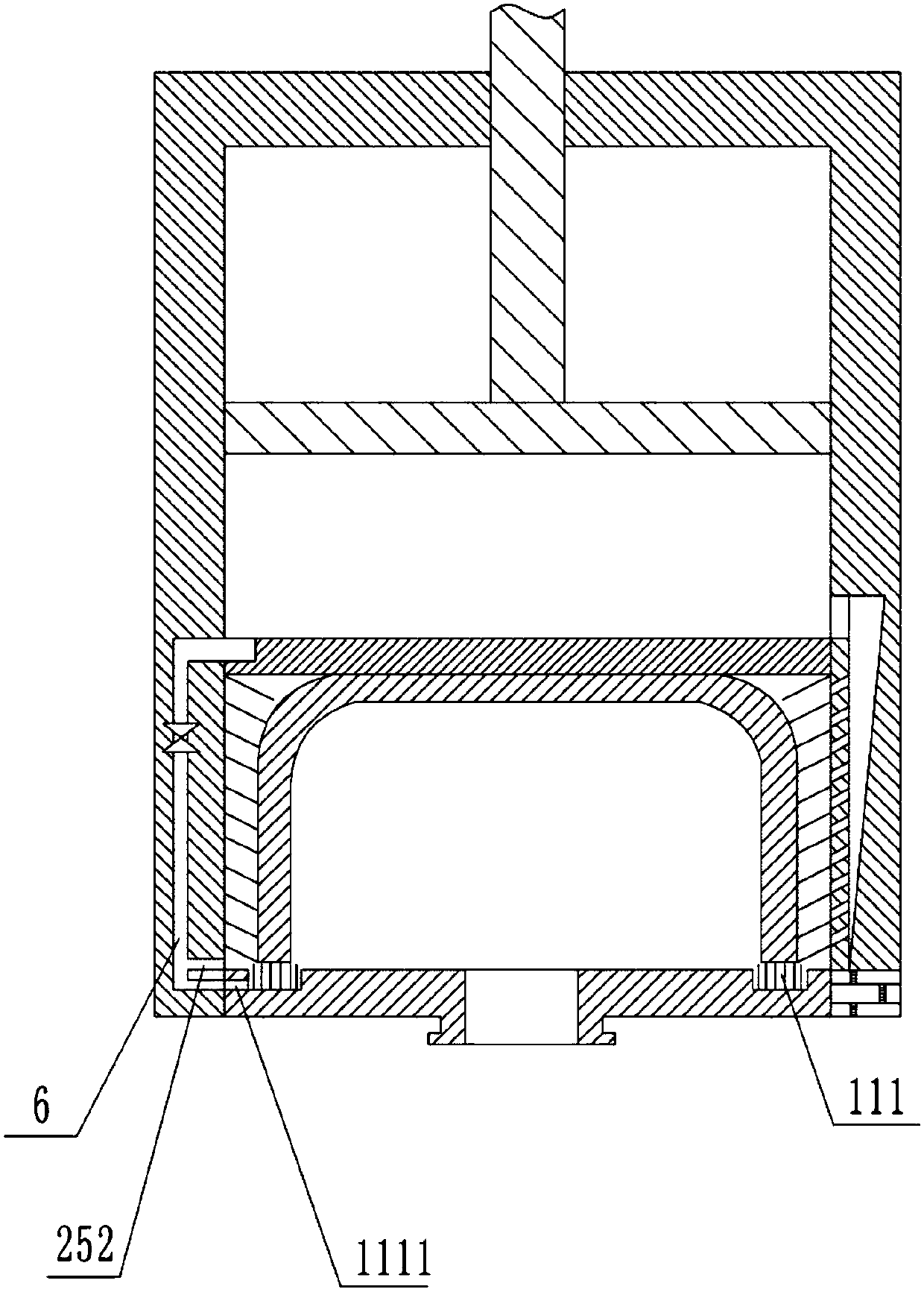

[0030] Such as figure 1 , figure 2 with image 3 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0031] The spraying process of the outer wall of the electric hoist box is as follows:

[0032] Step 1. Grinding: use sandpaper to grind the outer wall of the electric hoist box to be sprayed;

[0033] Step 2. Cleaning: Clean the outer wall of the electric hoist box polished in step 1, and then dry it;

[0034] Step 3. Temperature setting: ensure that the ambient temperature for spraying is 15-30°C;

[0035] Step 4, prepare a spraying device: the spraying device includes a spraying station 1, a hydraulic cylinder 31, a fixed part 3 and a spraying cover 2 driven by the hydraulic cylinder; the spraying cover 2 is located under the fixed part 3, and the spraying station 1 is located at the spraying cover 2 Below; hydraulic cylinder 31 is fixed on the fixed part 3. The spraying table is equipped with a rotating part for rotatin...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

[0050] In step five, step six and step seven, the hydraulic cylinder 31 drives the piston 22 to move upward after 1 minute after the paint is sprayed. The rotational speed of the motor is 500r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com