Patents

Literature

104results about How to "Guaranteed adhesion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

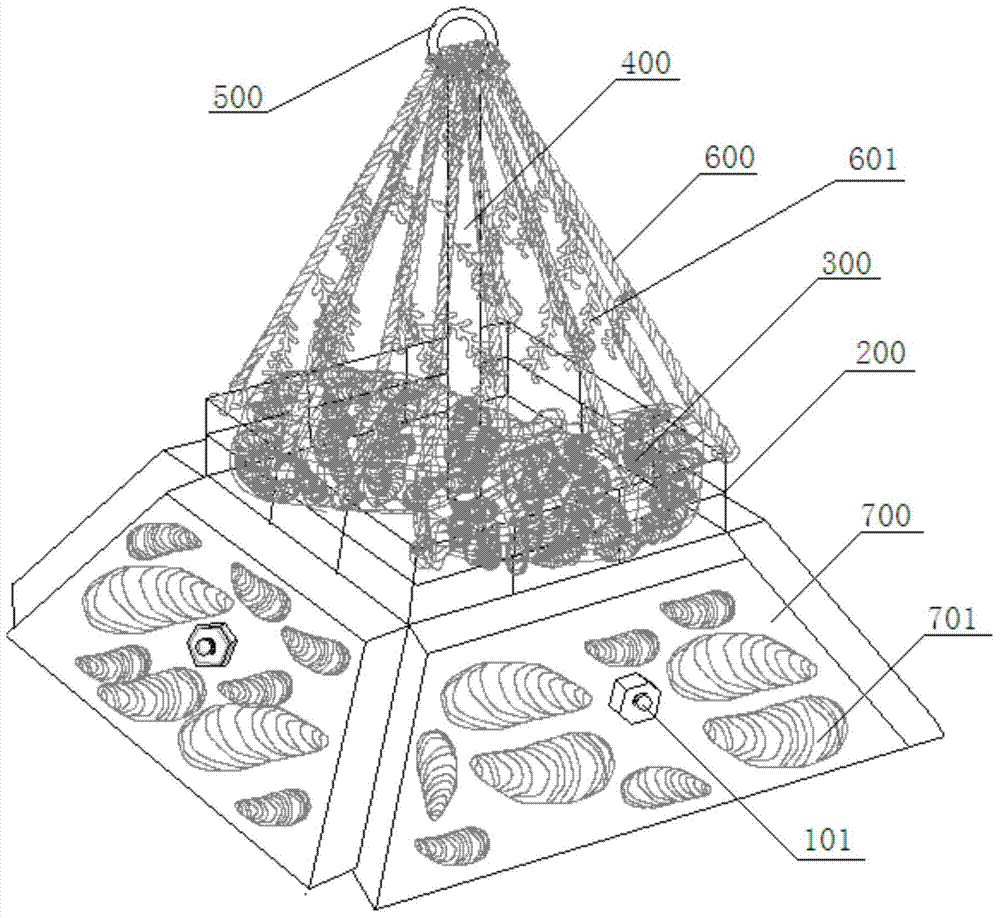

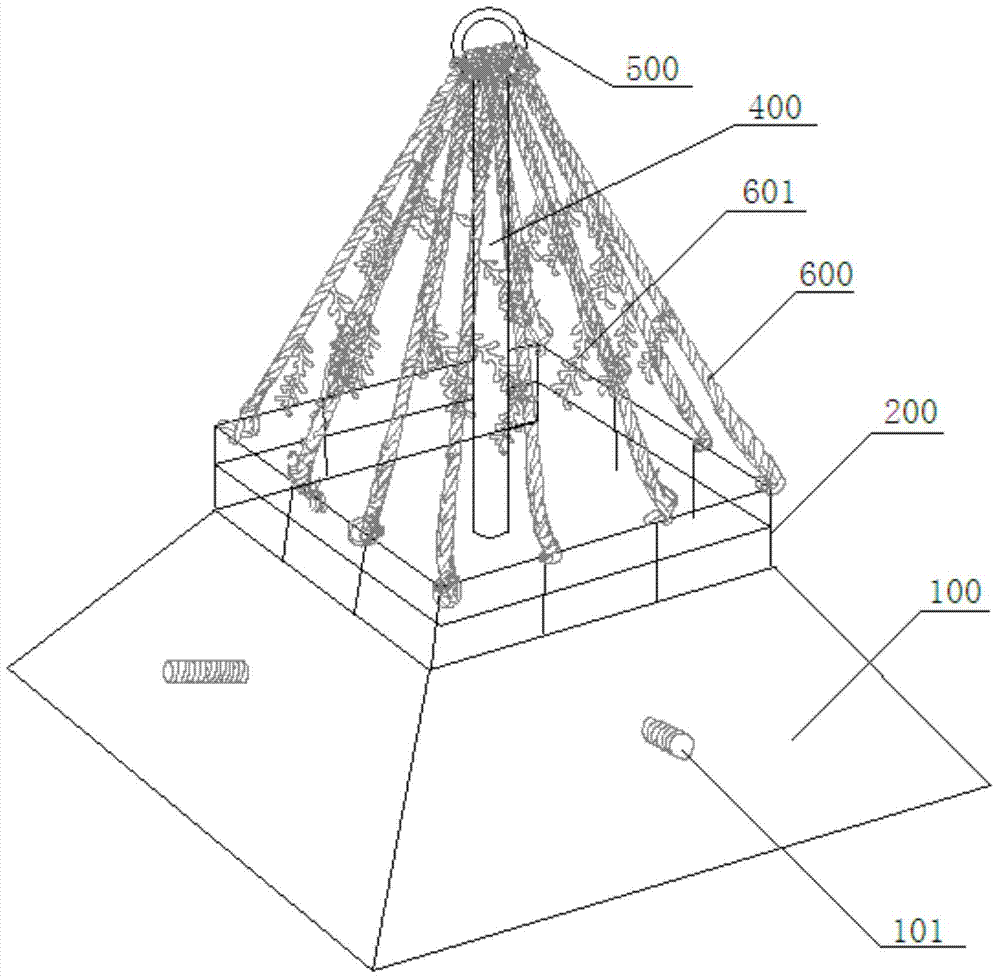

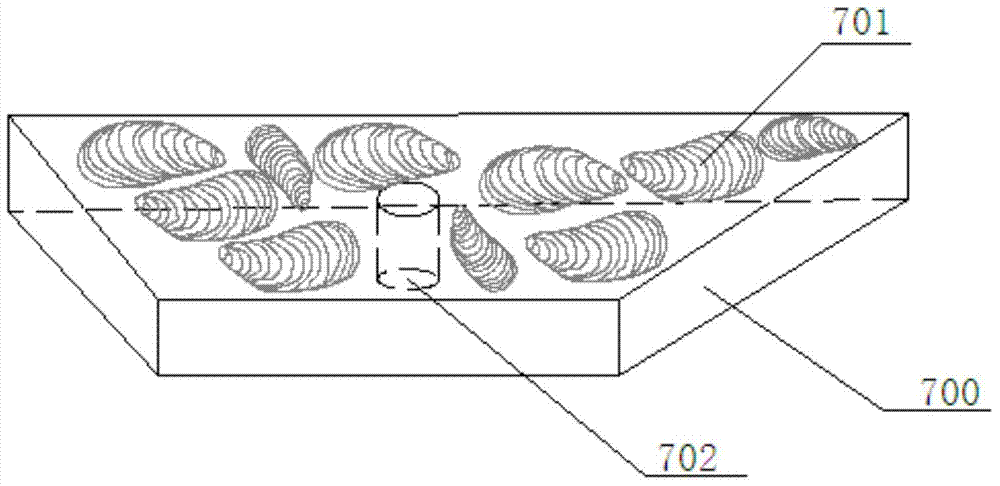

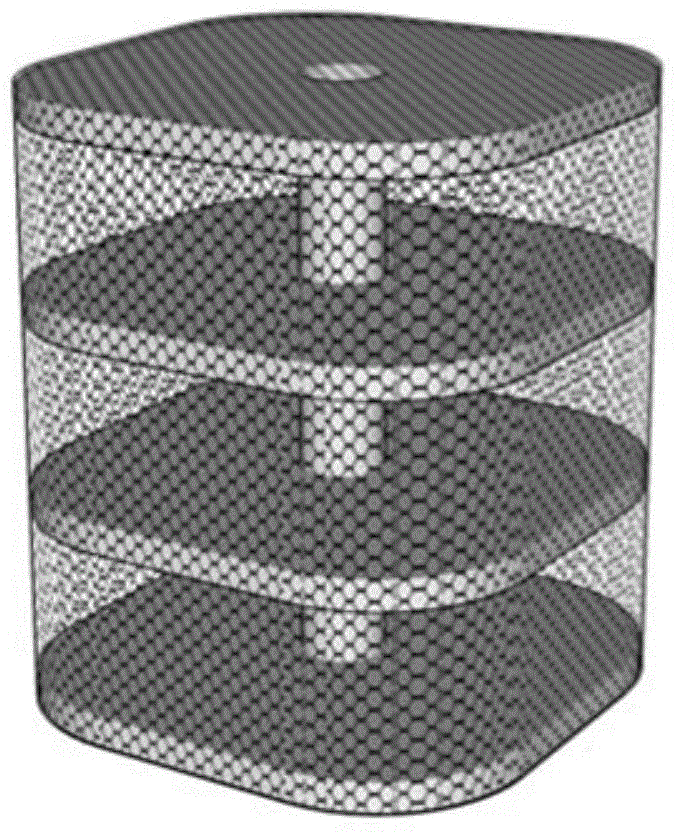

Composite type artificial algal reef

ActiveCN103609424AEasy to carryGuaranteed adhesion effectClimate change adaptationPisciculture and aquariaSporeConch

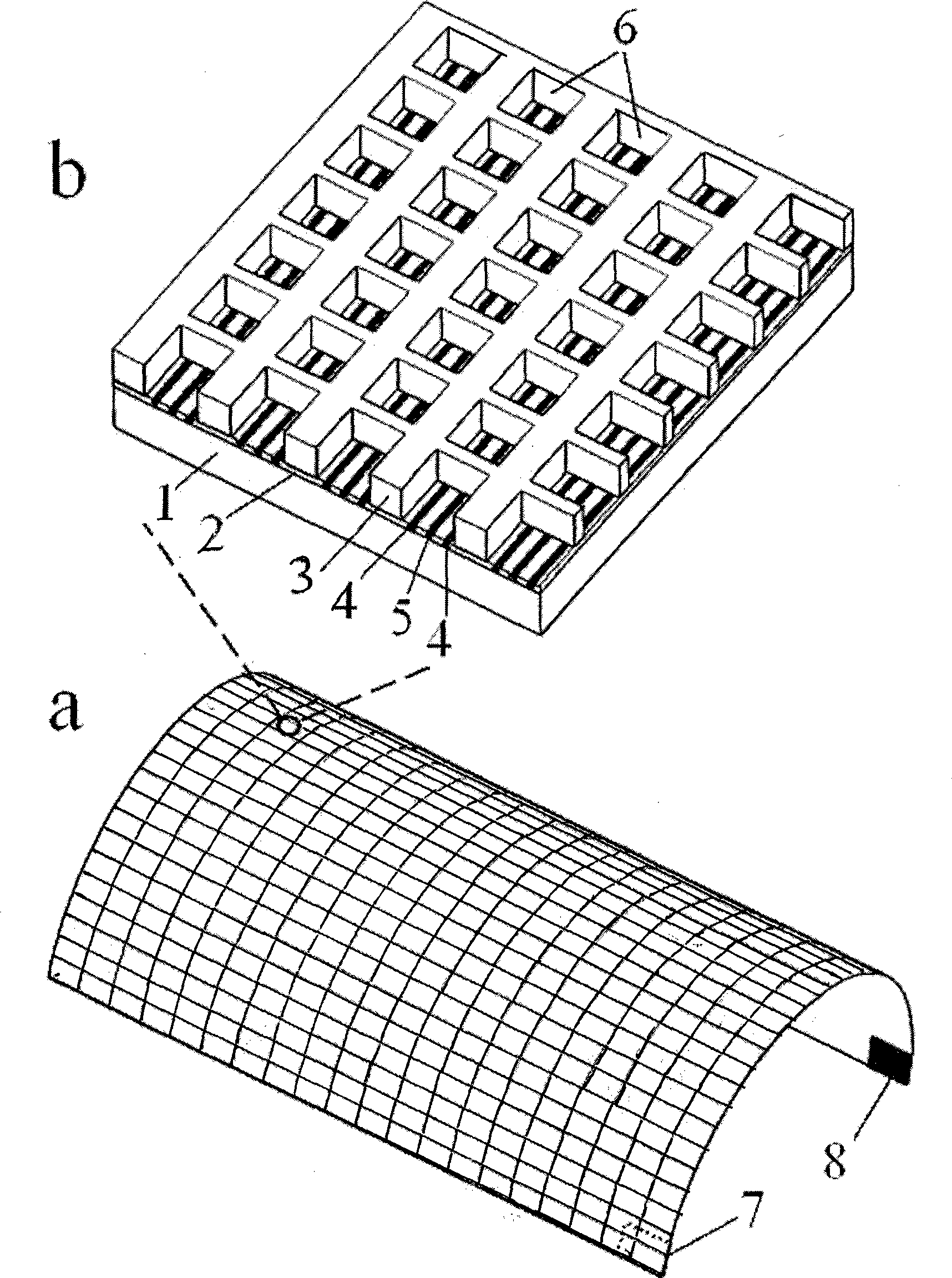

The invention discloses a composite type artificial algal reef comprising a mature algal reef and a seedling reef. The mature algal reef comprises a solid base. The upper surface of the solid base is embedded with a metal frame, wherein the shape of the metal frame is identical to that of the upper surface of the solid base and the size of the metal frame is identical to that of the upper surface of the solid base. A conch net bag is arranged in the metal frame. The center of the upper surface is embedded with a metal stand column. A steel ring is welded to the upper end of the stand column. A plurality of seedling ropes are fixed between the metal frame and the steel ring. The seedling reef is fixed to the side face of the solid base of the mature algal reef, and algal seedlings are attached to the seedling reef. By the adoption of the composite type artificial algal reef, the attaching effect of alga is guaranteed, the repair period of an algae field is shortened, the success rate of repair and reconstruction of the algae field is improved, the adhesive rate of the seedlings is increased, and the seedling reef is firm, durable, small in size, light, and convenient to carry; the net bag made of waste conches is placed in the metal frame, and a biophile reef can be composed through diffusion and attachment of spores of fronds on the seedling ropes; resource utilization of the waste conches is achieved, and composite type artificial algal reef has the advantages of being economical and easy and convenient to use.

Owner:SHANGHAI OCEAN UNIV

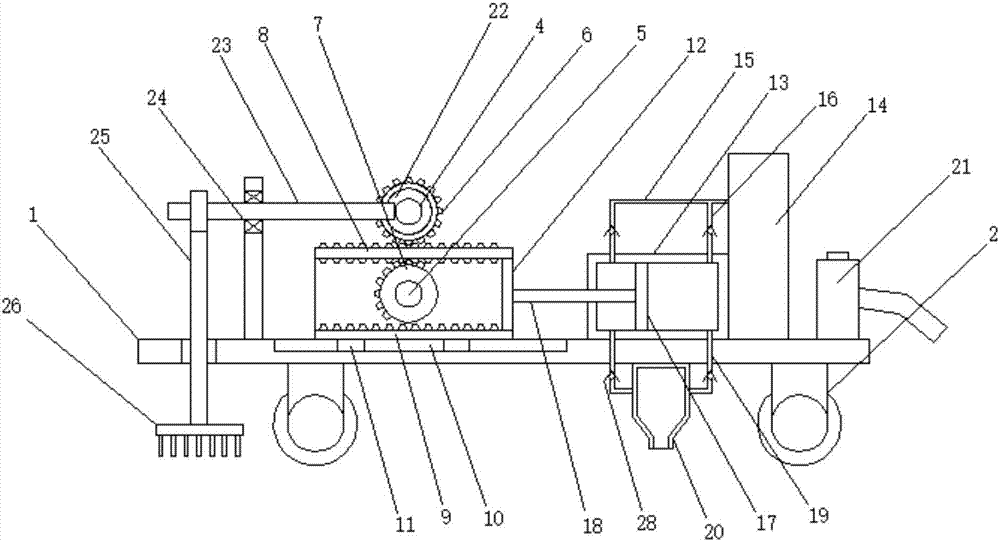

Road parking continuous marking device with cleaning effect

InactiveCN107313337AGuaranteed adhesion effectSimple structureRoad cleaningRoads maintainenceTransverse axisRoad surface

The invention discloses a continuous line-drawing device with cleaning for road parking, which comprises a horizontal plate, a first bracket is arranged on the top of the horizontal plate, a second horizontal shaft is arranged on the first bracket, and the second horizontal shaft There is a semi-circular gear on the top, a double-sided rack meshed with it is arranged above the semi-circular gear, and a lower rack meshed with it is arranged below the semi-circular gear. The right side of the end surface of the horizontal plate is provided with paint A box and a cylinder body, the cylinder body is provided with a piston, the left side of the piston is provided with a piston rod fixedly connected to the connecting plate, and the lower end surface of the horizontal plate is also provided with a line-drawing nozzle. The present invention has a simple structure and can Continuously paint the line while moving, and at the same time clean the road surface before the line drawing, which ensures the adhesion between the road surface and the line drawing paint. The line drawing efficiency is high, the effect is good, the operation is simple, and the practicability is strong.

Owner:王陈伟

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

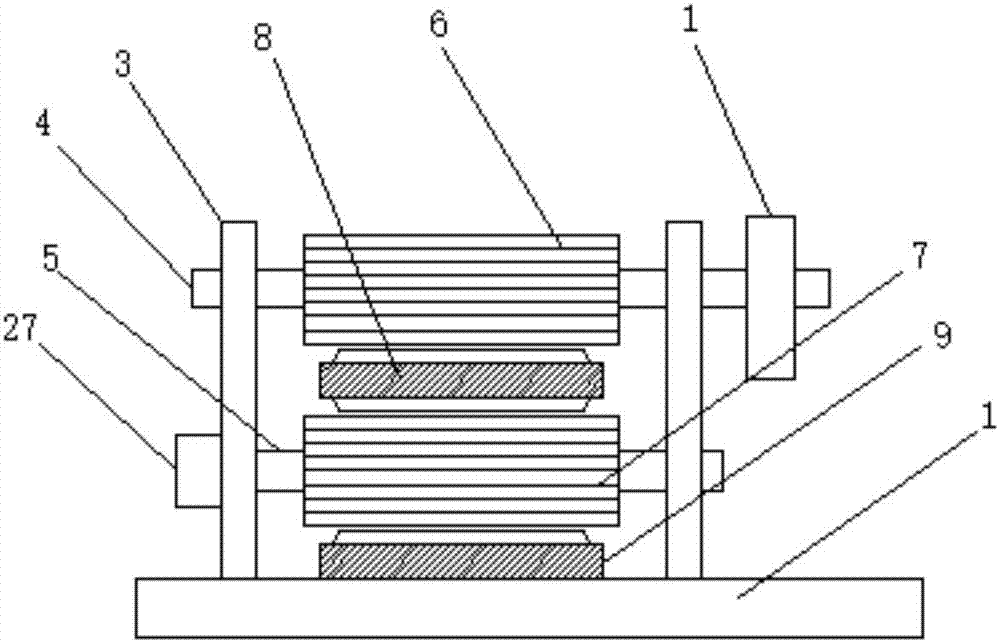

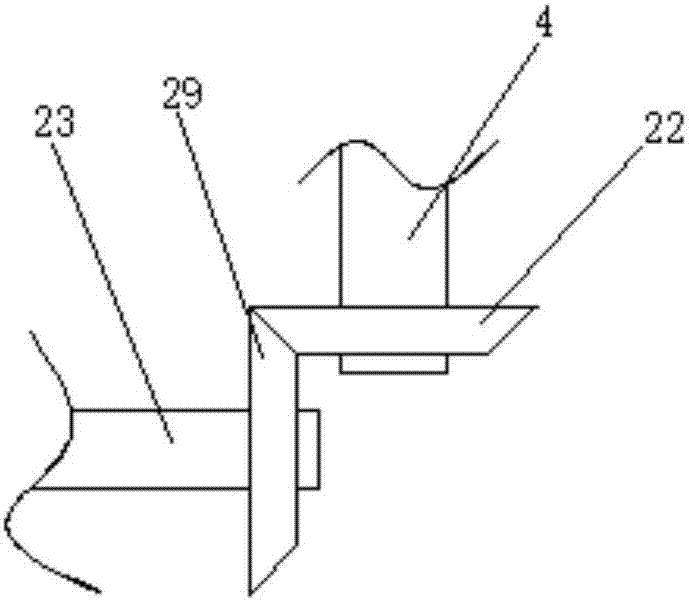

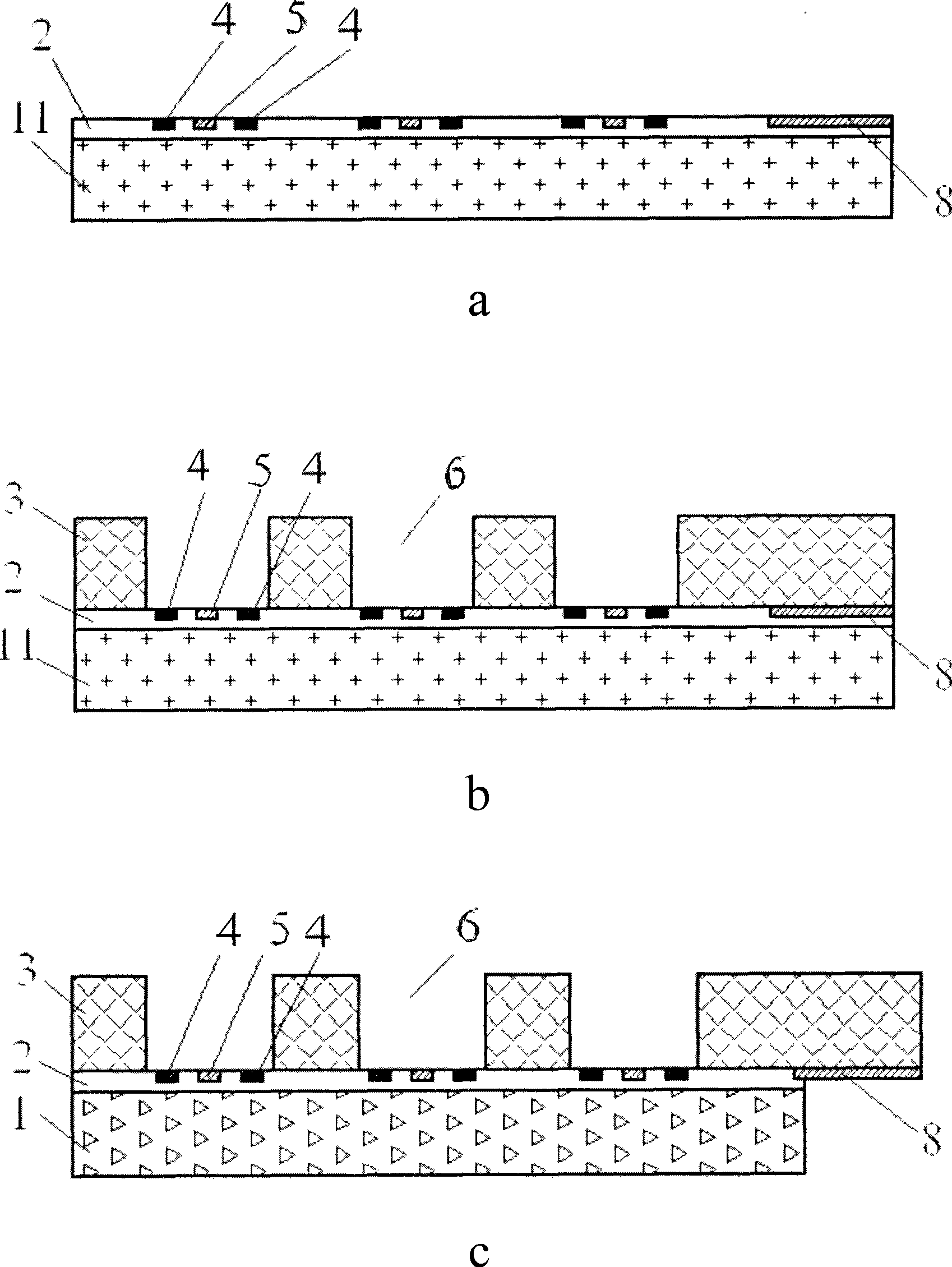

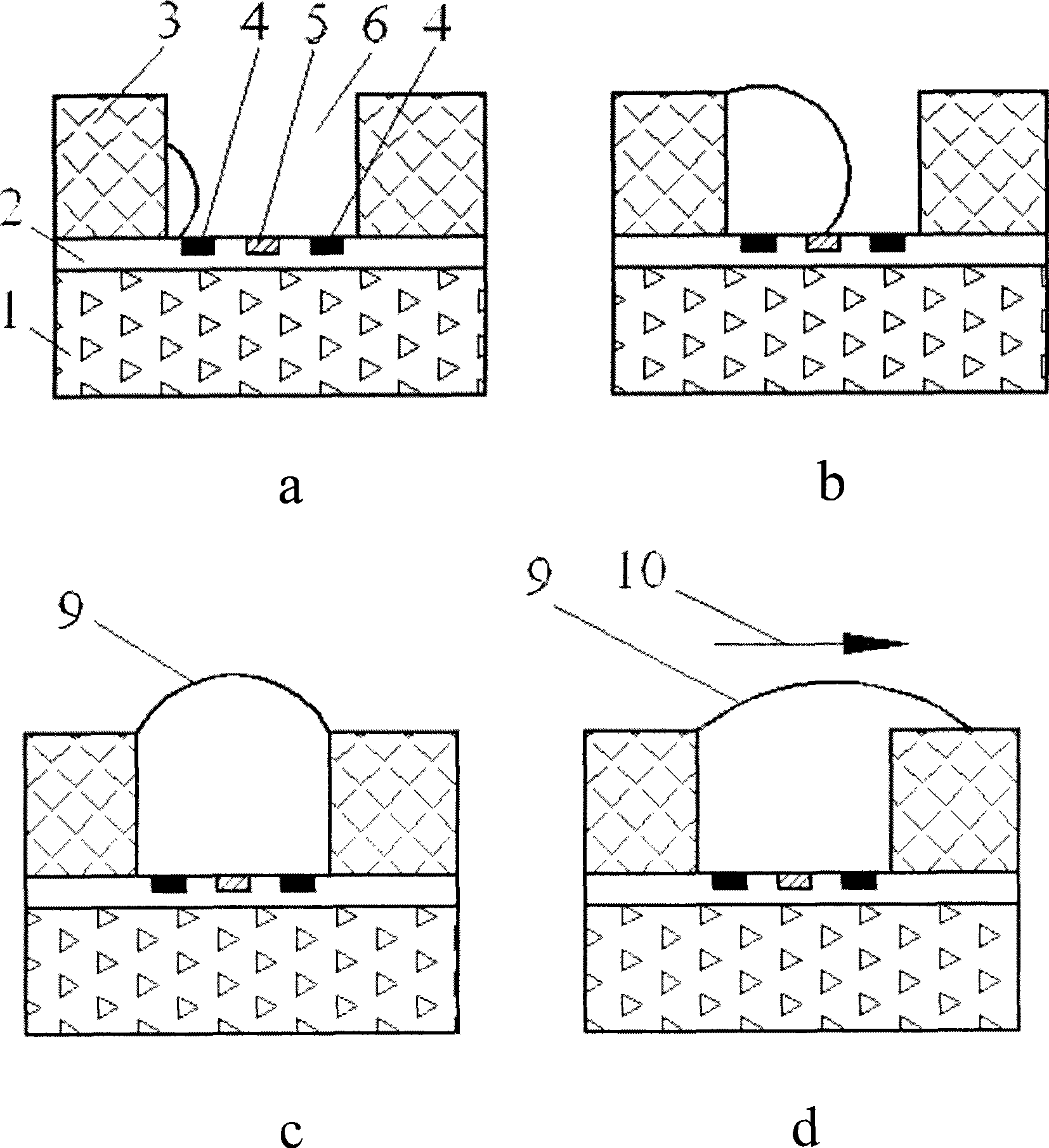

Flexible MEMS resistance reducing covering and method of manufacturing the same

InactiveCN101486438AAchieve residencyImplement auto-replenishmentTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisMicrobubbles

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

Method for preparing multi-arc ion plating aluminium titanium chrome silicon yttrium nitride multi-component ultra-hard reaction film

InactiveCN101230448AQuality improvementGuaranteed repeatabilityVacuum evaporation coatingSputtering coatingAlloyTitanium

The invention relates to a method of preparing a multi-component super-hard reaction film for a multiple-arc ion-plated nitride of titanium, aluminum, chrome, silicon and yttrium. The method includes the following steps in sequence: the confirmation of the deposition technique and the design of the components of the target material (1); the preparation of a alloy target (2); the selection and pre-processing of a workpiece sample (3); the confirmation of the quantity of the electric arc source (4); the confirmation of the deposition technique (5); the acquirement of a transition layer (6); the processing of vacuum heating (7) and the rotation of the workpiece sample. The method confirms the variation range of the components of the Ti, Al, Cr, Si, Y elements in the complex Ti-Al-Cr-Si-Y alloy target and causes the super-hard reaction film of the (TiAlCrSiY)N to have the advantages of strong adhesive power (larger than or equal to 180 N) and high hardness (larger than or equal to HV3200).

Owner:SHENYANG UNIV

Sealing device

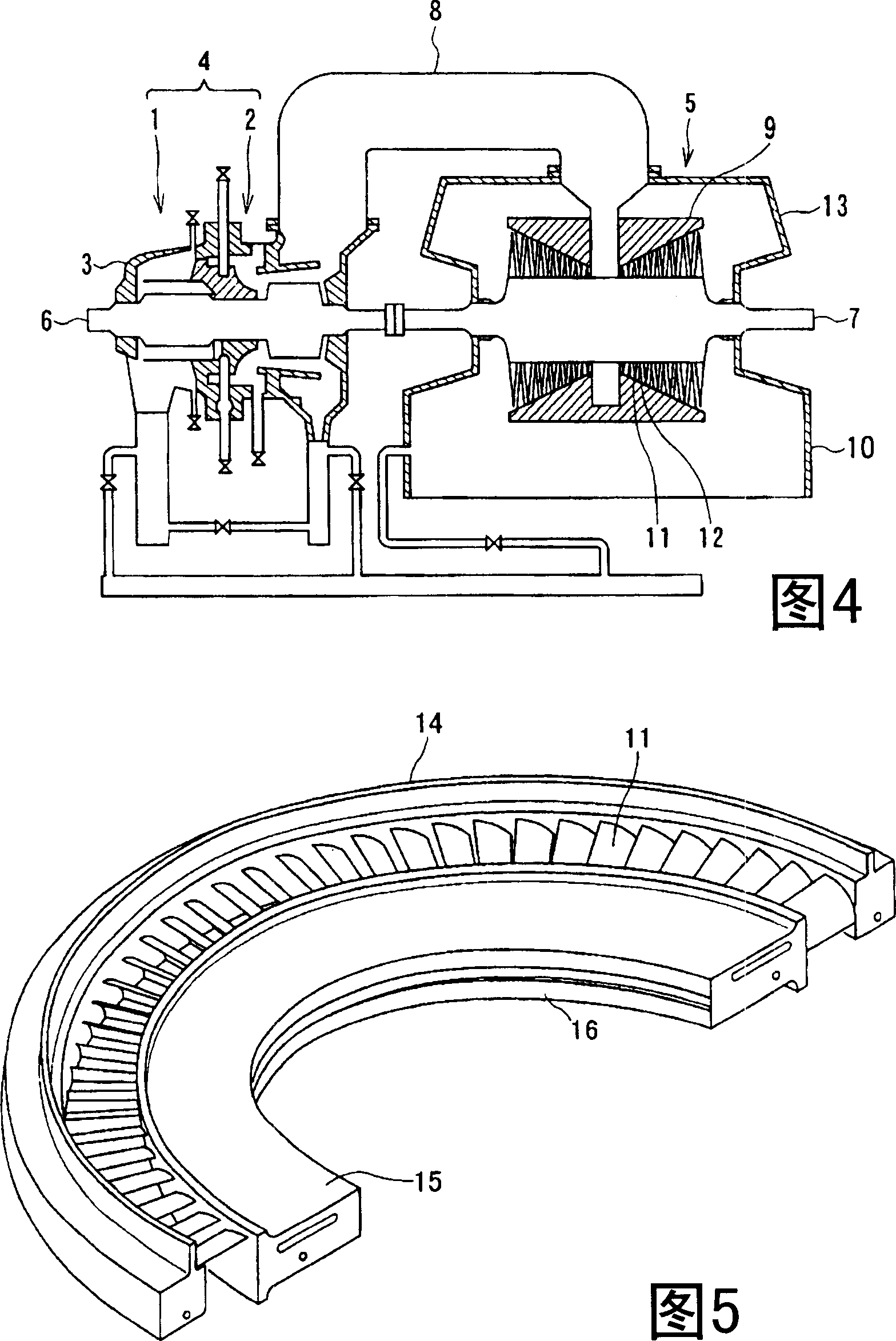

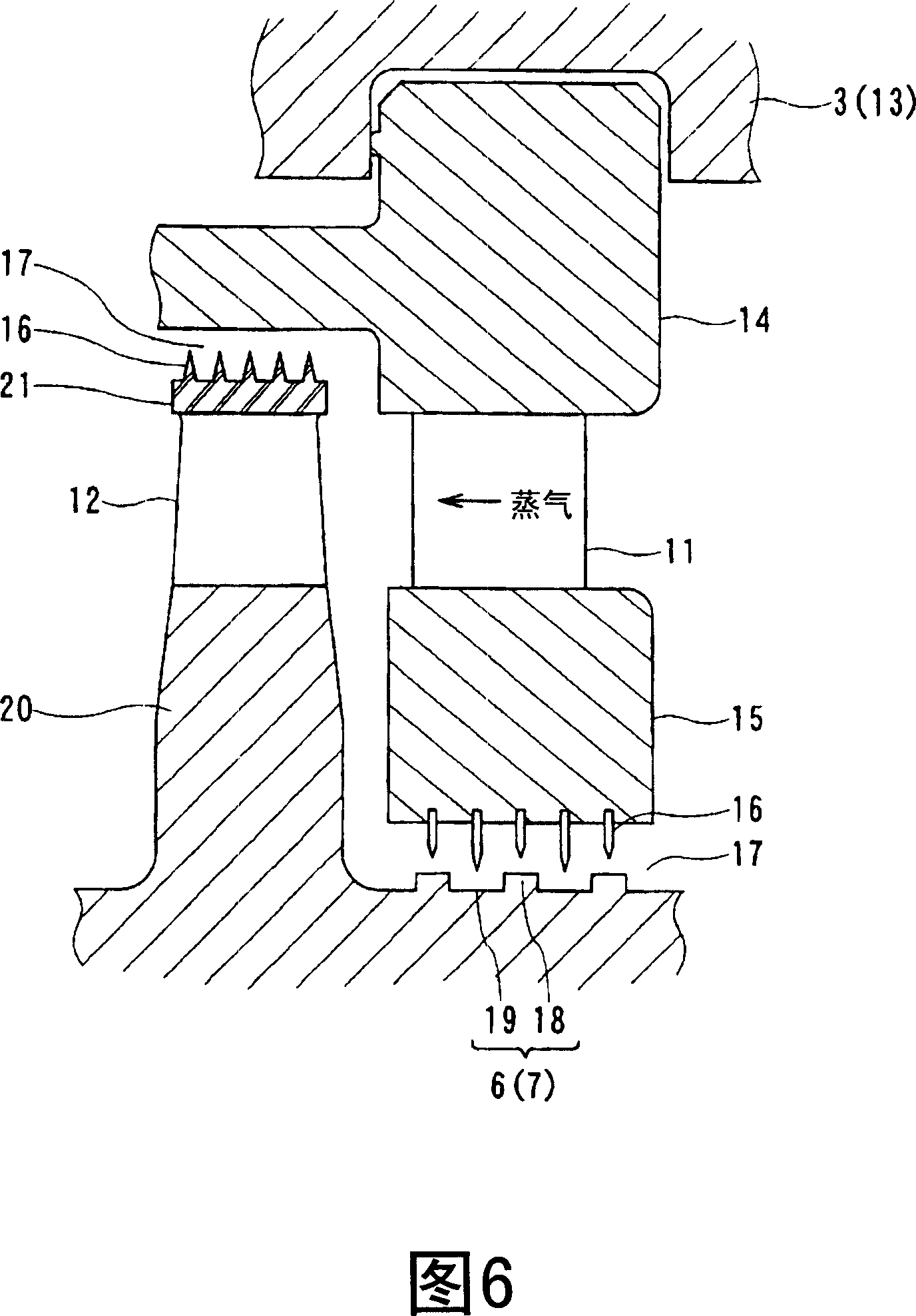

InactiveCN1987165AGuaranteed adhesion effectReduce leakageEngine sealsLeakage preventionEngineeringBond coat

A sealing device by which the leakage of fluid is further reduced by securely maintaining the adhesion between a base material and an abradable layer and further strengthening the prevention of fluid leakage is provided. The sealing device according to the present invention includes seal strips provided to either one of a rotating portion or a stationary portion forming a gap therebetween; and a coating layer provided to a base material of the rotating portion or the stationary portion so that the coating layer faces the seal strips. The coating layer is composed of an abradable layer and a bond coat layer.

Owner:KK TOSHIBA

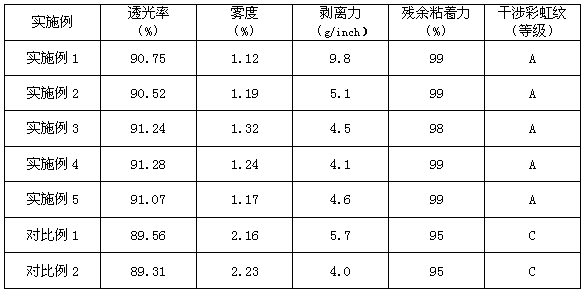

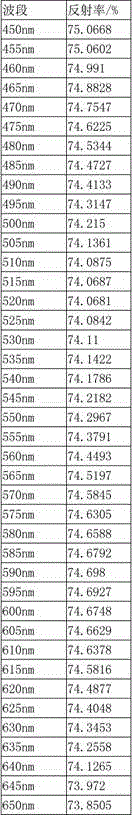

Polyester release film for optics

The invention discloses a polyester release film for optics. The release film is obtained through bidirectional stretching, and is operated according to the following steps of: fusing and extruding polyester chips onto a casting sheet roller, and cooling, thereby obtaining polyester thick sheets; stretching the polyester thick sheets longitudinally, and coating waterborne organic silicone elastomer coating materials with the solid mass content of 5%-10% on at least one surface on line; and stretching horizontally again after preheating, thereby obtaining the polyester release film for optics through heat setting and winding. The release film provided by the invention is high in coating level degree, low in interference rainbow lines, low in haze, and high in transmissivity, and can be widely applied to components of various displays such as a polarizer, a polarizer protection film and organic EL (electroluminescence) for a panel display.

Owner:HEFEI LUCKY SCI & TECH IND +2

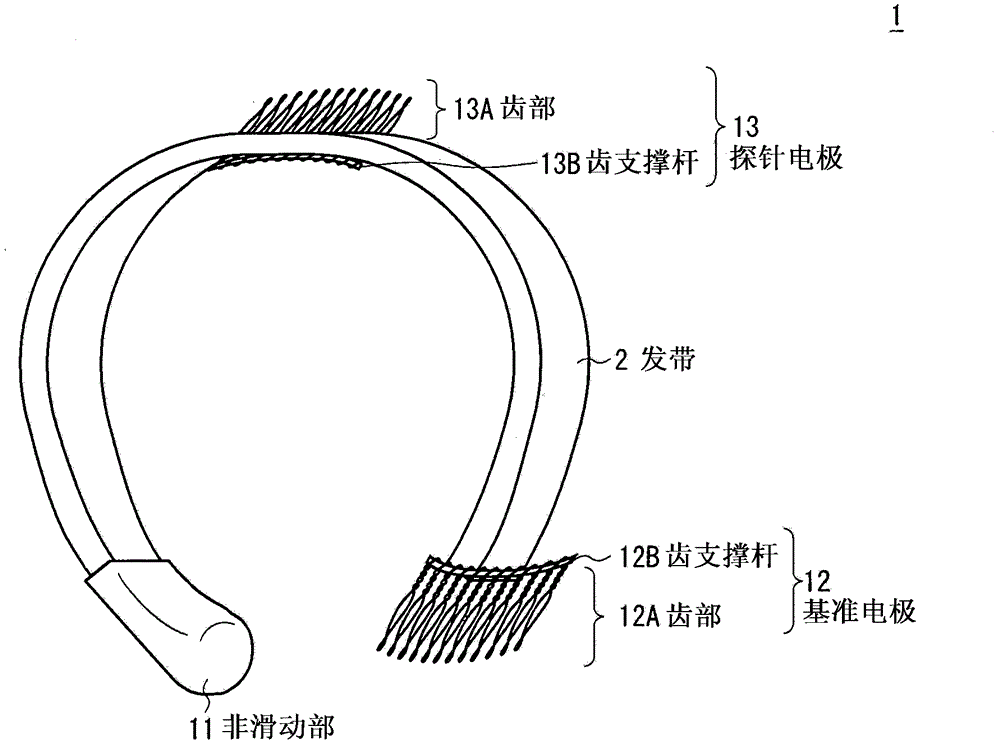

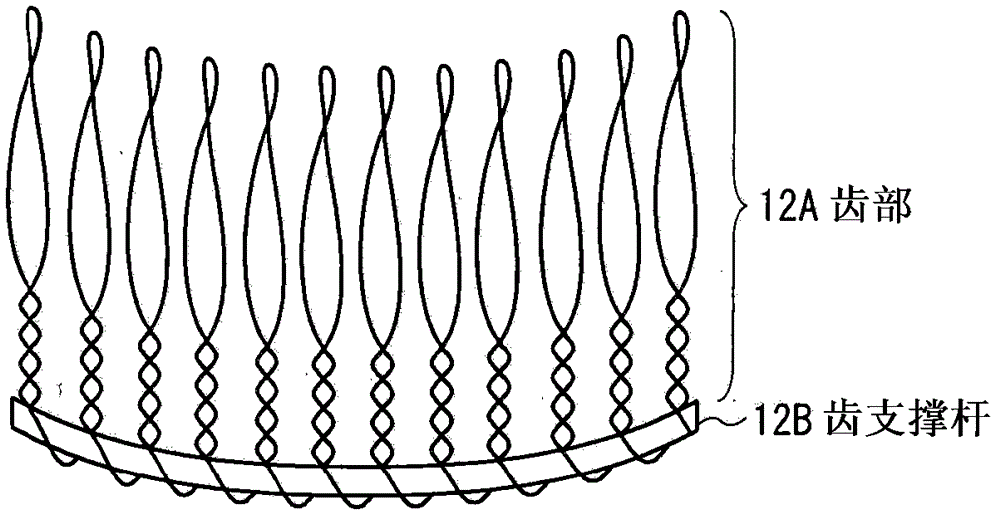

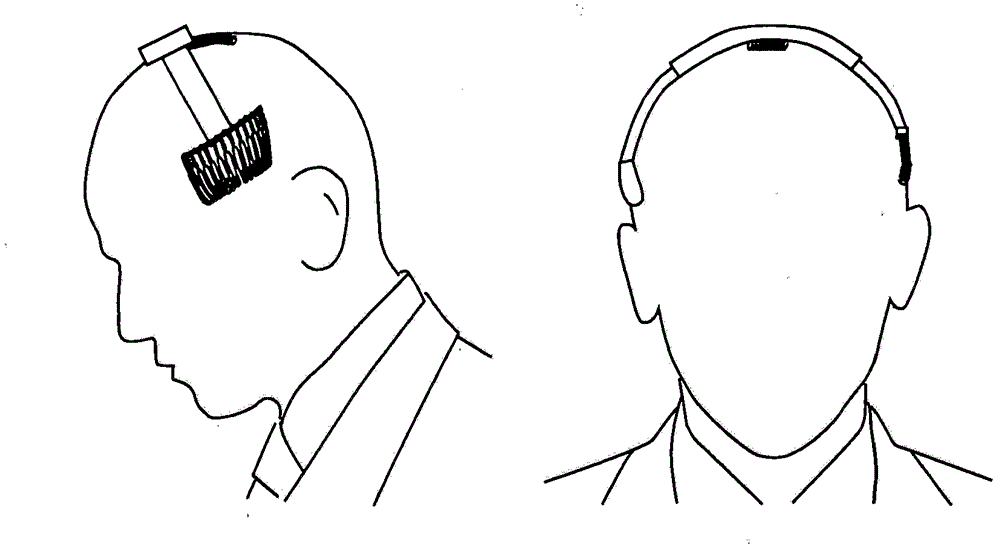

Bio-signal Measurement Equipment

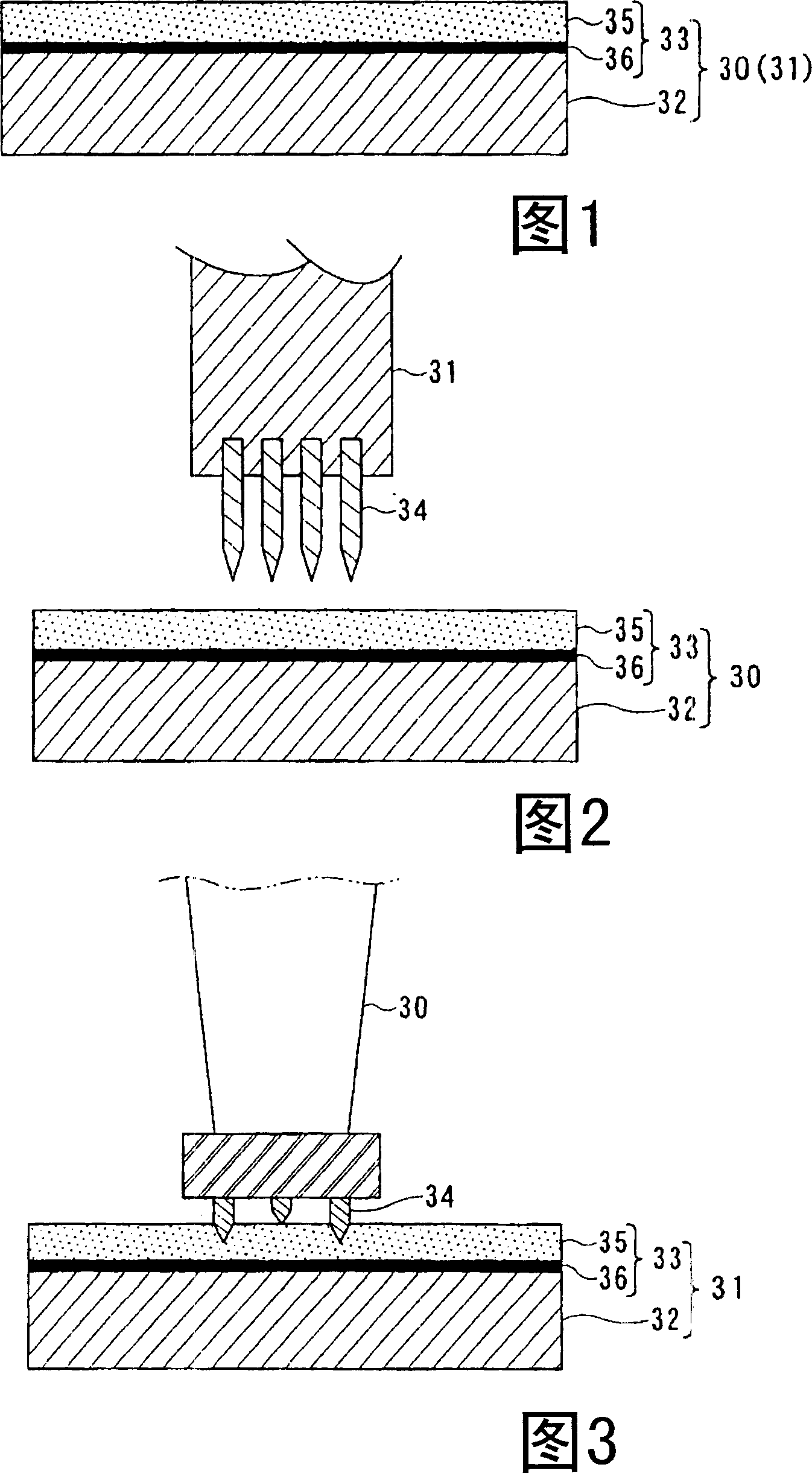

InactiveCN102802516AGood adhesionGuaranteed adhesion effectElectroencephalographyElectro-oculographyEngineeringMeasurement precision

Disclosed is bio-signal measurement equipment which makes it possible to improve measurement accuracy without imposing an excessive burden on the subject. The bio-signal measurement equipment is employed for measurement of bio-signals in the head and includes a support body capable of supporting the head and electrodes provided on the support body. An electrode is provided with a plurality of teeth constituted by: annular portions comprising a pair of annularly-formed conductive wires; and rod-shaped portions formed in the shape of rods by winding the wires of each pair in opposite directions. One end of the rod-shaped portions in the plurality of teeth is directly or indirectly fixed to the support body.

Owner:SONY CORP

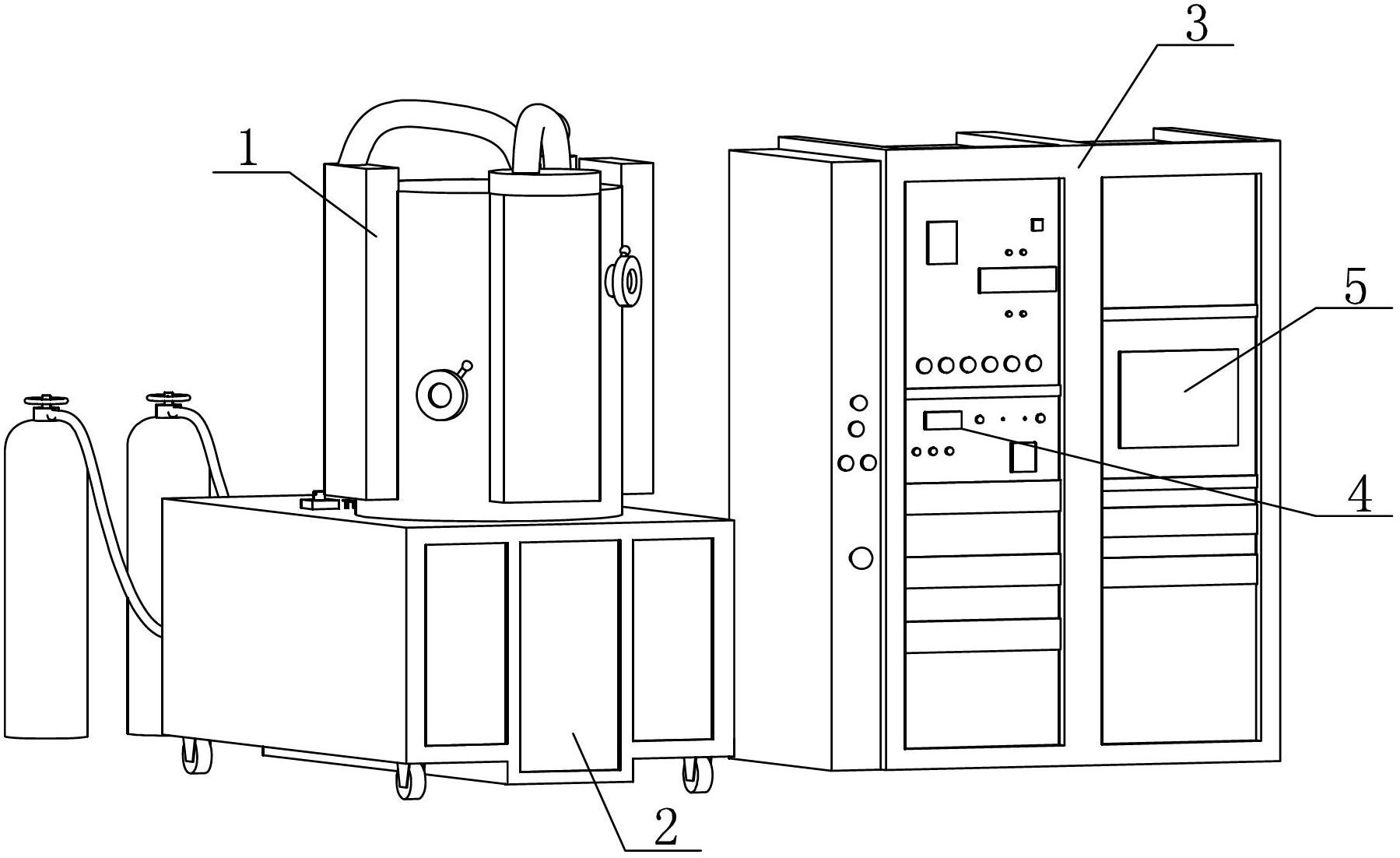

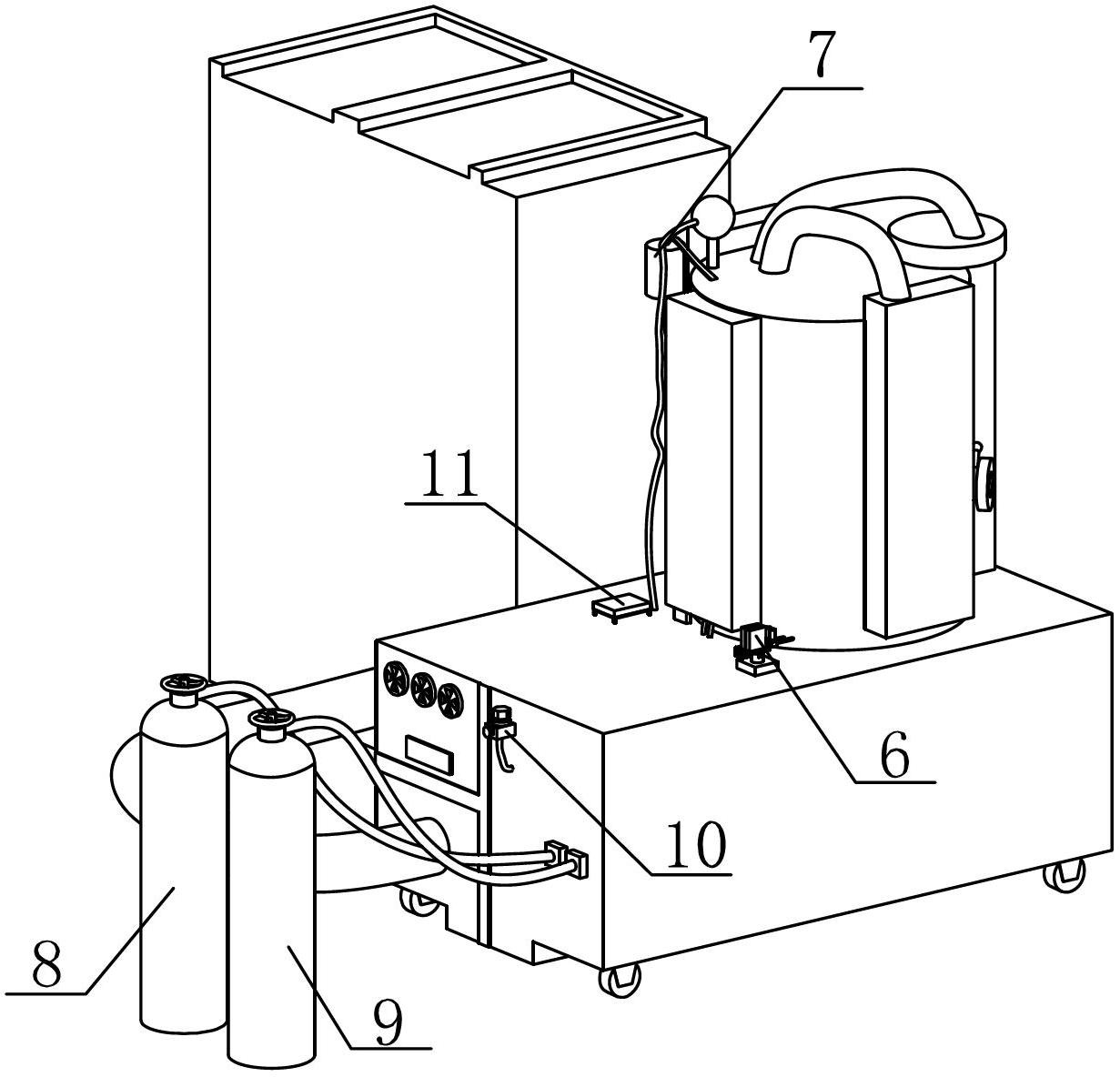

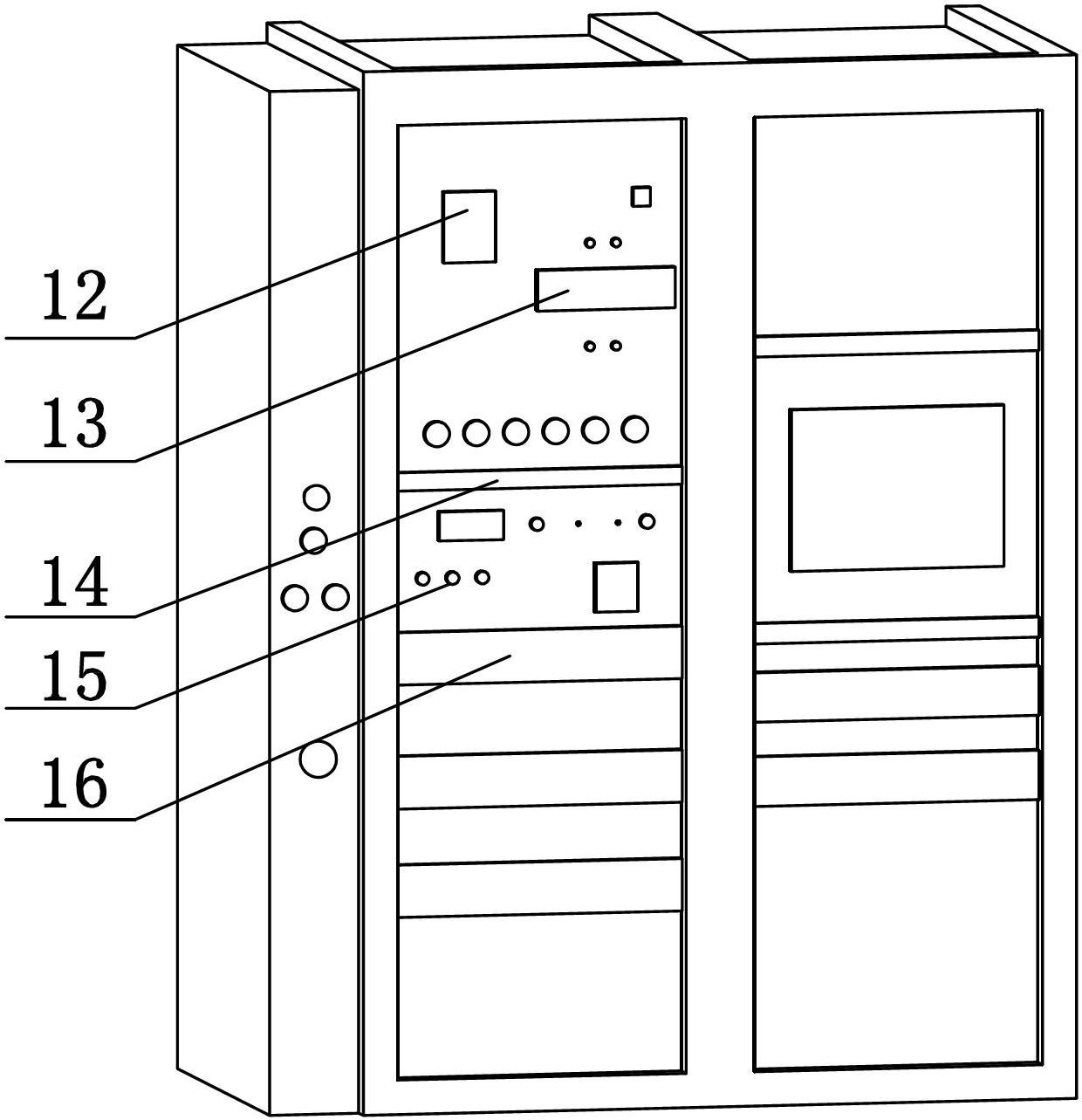

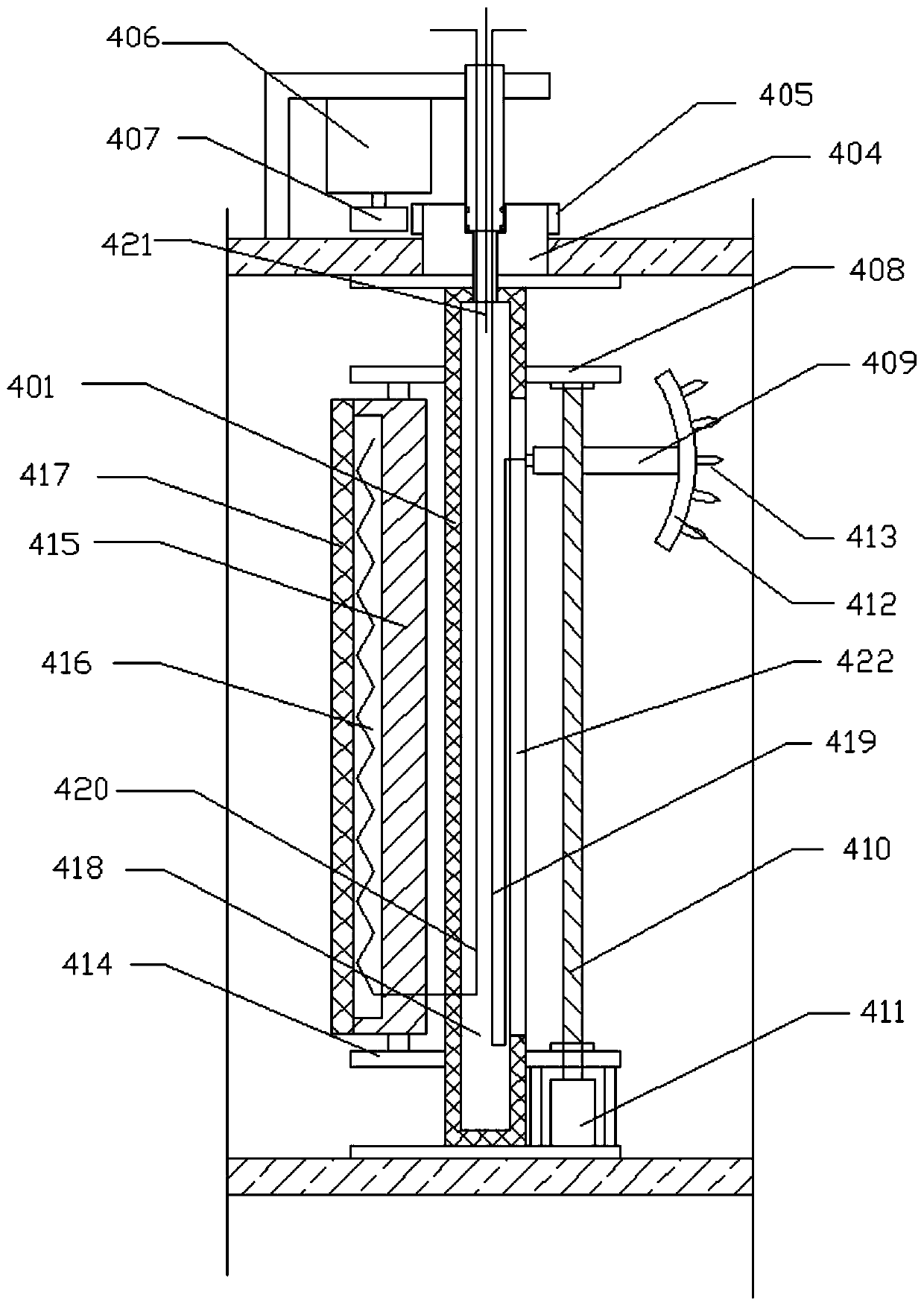

Non-balanced closed field magnetron sputtering ion plating equipment

ActiveCN102677011AGuaranteed compactnessGuaranteed adhesion effectVacuum evaporation coatingSputtering coatingProcess engineeringVolumetric Mass Density

The invention discloses non-balanced closed field magnetron sputtering ion plating equipment comprising a vacuum cavity (1) and a control cabinet (3), wherein a vacuum control cabinet (2) is arranged below the vacuum cavity (1), a manual operation interface (4) and a full-automatic operation interface (5) are arranged on the control cabinet (3), a side-open furnace door (18) is arranged on the vacuum cavity (1), an argon cylinder (8) and a nitrogen cylinder (9) are arranged behind the vacuum control cabinet (2), a gas pressure gauge (10) is arranged on the back surface of the vacuum control cabinet (2), and the equipment is also provided with a gas flow rate feedback system (16) to be connected with the gas pressure gauge (10). The non-balanced closed field magnetron sputtering ion plating equipment disclosed by the invention is provided with the gas flow rate feedback system to determine the concentration of the reaction gas through a glow discharge spectral signal, analyze and judge the regulation range of the gas flow rate and accurately regulate a gas flow rate controller to keep the pressure of the filled gas at the optimal state so as to guarantee the density and adhesiveness of a thin film.

Owner:SHENZHEN KINGMAG PRECISION TECH

Road marking construction process

InactiveCN105839556AImprove adhesionInhibit sheddingTraffic signalsRoad signsRoad engineeringRoad surface

The invention discloses a road marking construction process method, which relates to the technical field of road engineering. The method comprises the following steps: blowing the road surface to make the road surface clean and dust-free, and ensuring that the road surface is dry; dotting the required marking line according to the design Marking, spray primer, spraying amount is 150 ~ 180g / m 2 ; Use a hot-melt kettle to melt the marking paint, apply the hot-melt marking paint within 5 to 8 minutes after the primer is sprayed, apply two layers of marking paint, and apply the second layer after the first layer of paint is dry Coating, before the second layer of coating is not dry, spread glass beads evenly, the spreading amount is 350~500kg / m 2 , dry naturally, and the thickness of the road markings formed is 2-4.5mm. The invention solves the problem that road markings are easy to crack and fall off.

Owner:韦积分

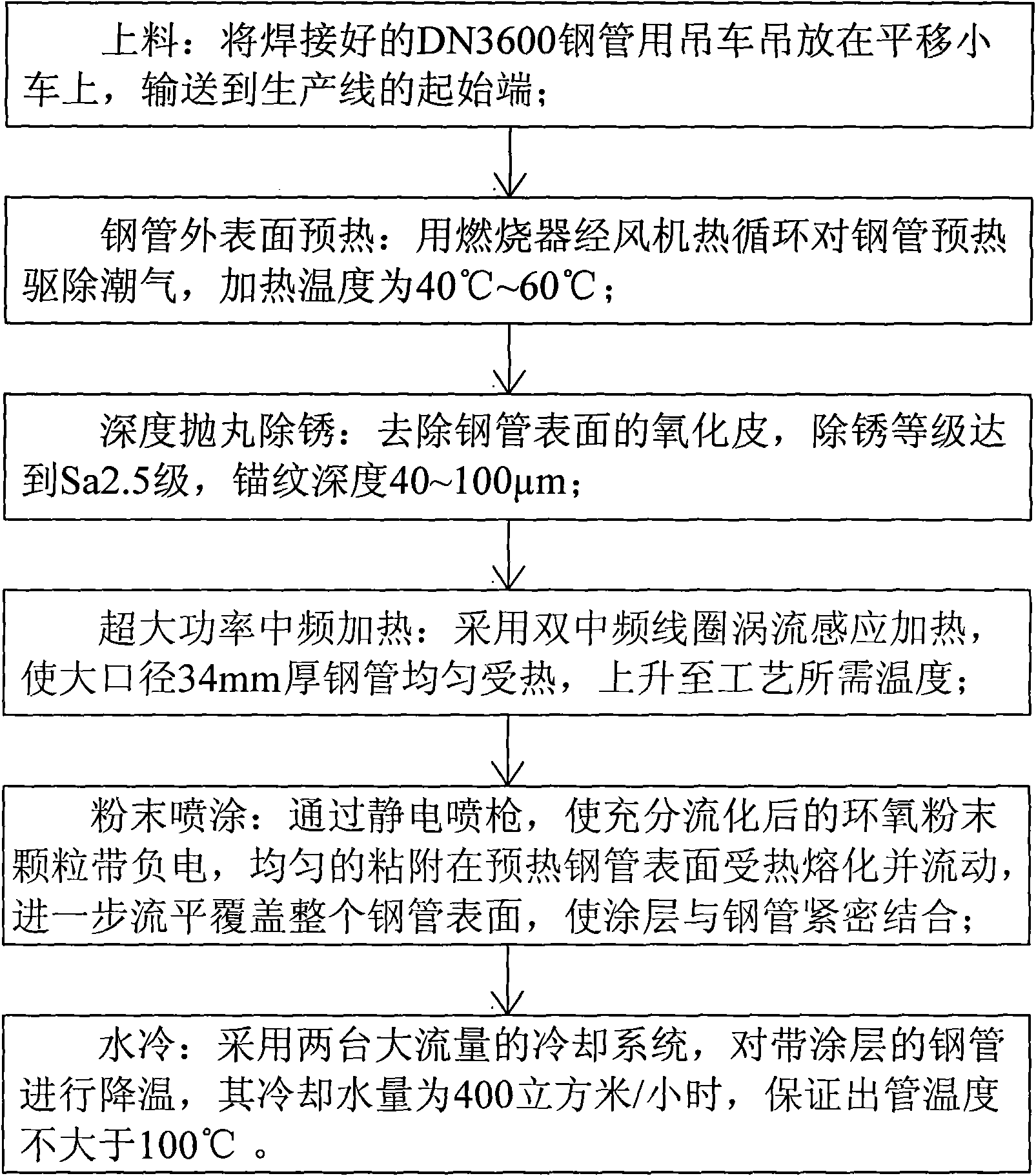

Method for carrying out outer anticorrosion on DN3600 buried steel tube by adopting molten epoxy powder

InactiveCN101602043AGuaranteed coating environmentGuaranteed coating effectPretreated surfacesCoatingsEpoxyMetallurgy

The invention relates to a method for carrying out outer anticorrosion on a DN3600 buried steel tube by adopting molten epoxy powder, and belongs to the field of anticorrosion of tube materials. A coating process comprises material loading, preheating of the outer surface of the steel tube, deep shot blasting and derusting, superlarge power medium-frequency heating, powder spraying and coating and water cooling. Aiming at the characteristics of large diameter and extremely-small rate of the wall thickness to the diameter of a large-diameter buried steel tube with DN3600 millimeter and more than DN3600 millimeter, the method optimizes the whole machining process, controls the velocity of temperature rising, heating and cooling through the control of a moving speed of the steel tube, ensures the coating environment and the coating effect of the steel tube and the adhesion effect of a coating layer and ensures that the quality of an outer anticorrosive coating layer of the large-diameter buried steel tube meets the relevant quality acceptance standards of the state.

Owner:SHANGHAI JIANZHIZHEN ANTI CORROSION TECH DEV

Honeycomb plate machining process

InactiveCN102001211AImprove adhesion strengthGuaranteed adhesion effectLaminationLamination apparatusHoneycombMachining process

The invention discloses a honeycomb plate machining process which comprises the following steps of: stretching a honeycomb core; then, coating glue on the honeycomb core and panels, and sticking the panels on both sides of the honeycomb core; subsequently, applying pressure on the panels so as to firmly stick the panels to the honeycomb core; and finally, cutting and forming the stuck honeycomb plate. The process is characterized by firstly sealing a glued plate by using a flexible sealing cover and then vaccumizing the plate in the procedure of applying pressure on the panels. The honeycomb plate machining process pressurizes the glued workpiece by using a vaccumizing mode and maintains a long period of time, the adhesion strength of glue is increased, and the adhesion effect is ensured. The invention has the advantages of easy operation, uniform pressure, good implementation effect and the like.

Owner:SUZHOU SHIJIA SCI & TECH

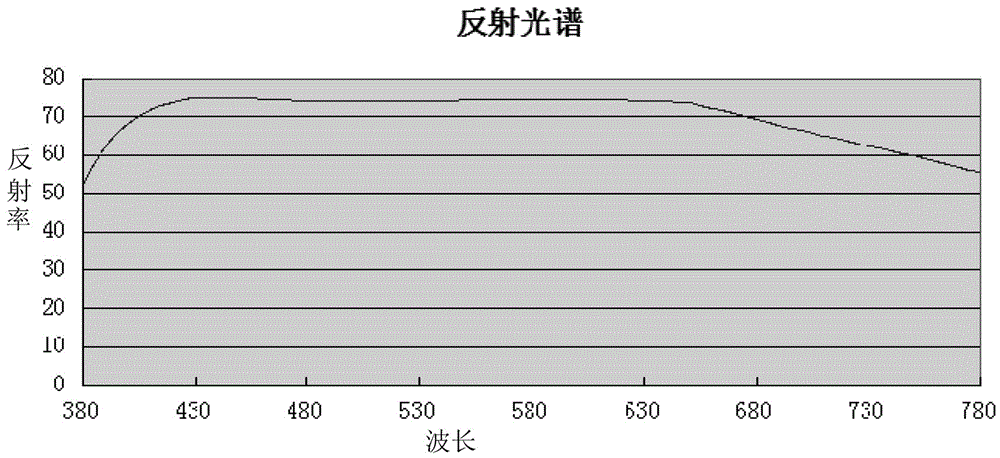

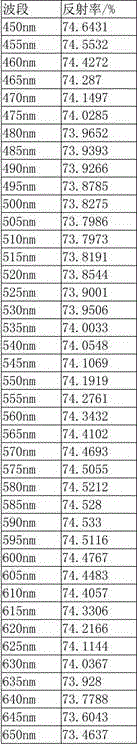

Multi-functional reflective film of on-board exterior mirror and preparation method

The invention discloses a multi-functional reflective film of on-board exterior mirror and the preparation method. The reflective film comprises glass substrates piled in sequence, the first high refractive layer, the first low refractive layer, the second high refractive layer, the second low refractive layer, metal material layer, the third low refractive layer and conducting layer. The first high refractive layer and second high refractive layer are made from Ta2O5, TiO2 and Nb2O5, the first low refractive layer, the second low refractive layer and the third low refractive layer are made from MgF2, SiOxNy and SiO2, the metal material is made from Al and Ag, and the conducting layer is made from ITO and graphene. Inorganic material and conductive material are mixed reasonably. Vacuum magnetron sputtering deposition is used to produce adjustable reflective film used for on-board exterior mirror. Based on this, the film is connected with the heating system through the conductive coating. The mirror will be clean even in the Frost and snow weather, providing safety guarantee during driving.

Owner:YICHANG NANBO DISPLAY

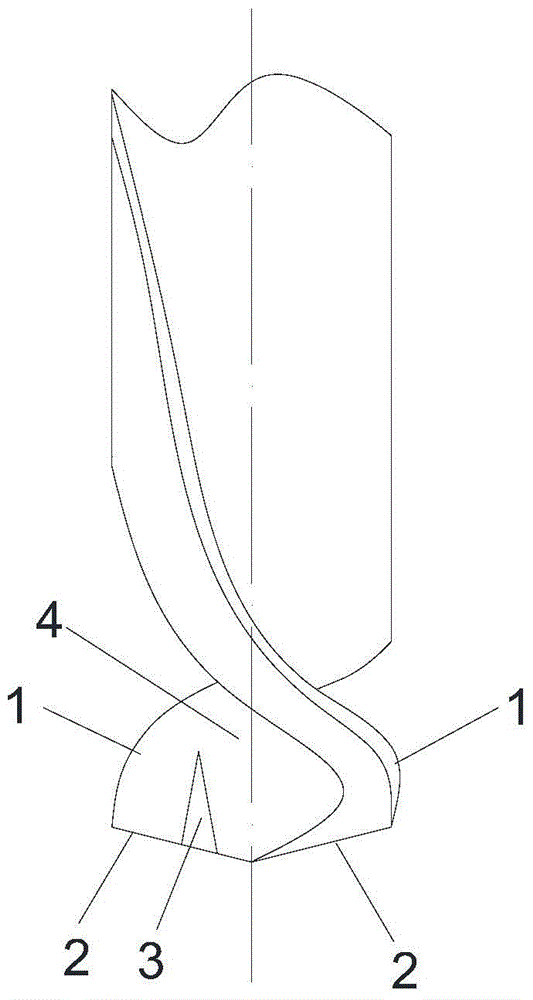

Drilling method of thick copper circuit board

InactiveCN104874826AEasy dischargeDischarge in timeTransportation and packagingTrepanning drillsCopper wirePetroleum engineering

The invention discloses a drilling method of a thick copper circuit board and relates to the technical field of circuit board manufacturing. The drilling method uses a drill with the rotation speed of 20-30krmp, tool feeding speed of 20-30mm / s and tool retracting speed of 220-300mm / s to drill holes. The drill comprises a drill stem and a drill bit. The drill bit comprises a cutting blade and a chip groove. The chip groove is axially provided with a groove at the drilling end of the drill bit. The thickness of copper of the inner circuit of the circuit board is not smaller than 3OZ. The method has the advantages that the drill with the groove notch is used, the groove notch in the drilling end of the3 drill bit can cut off a drilling copper wire, the cut-off copper wire can be discharge timely through the groove during drilling, and problems such as hole blocking and drilling copper wire drawing are avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

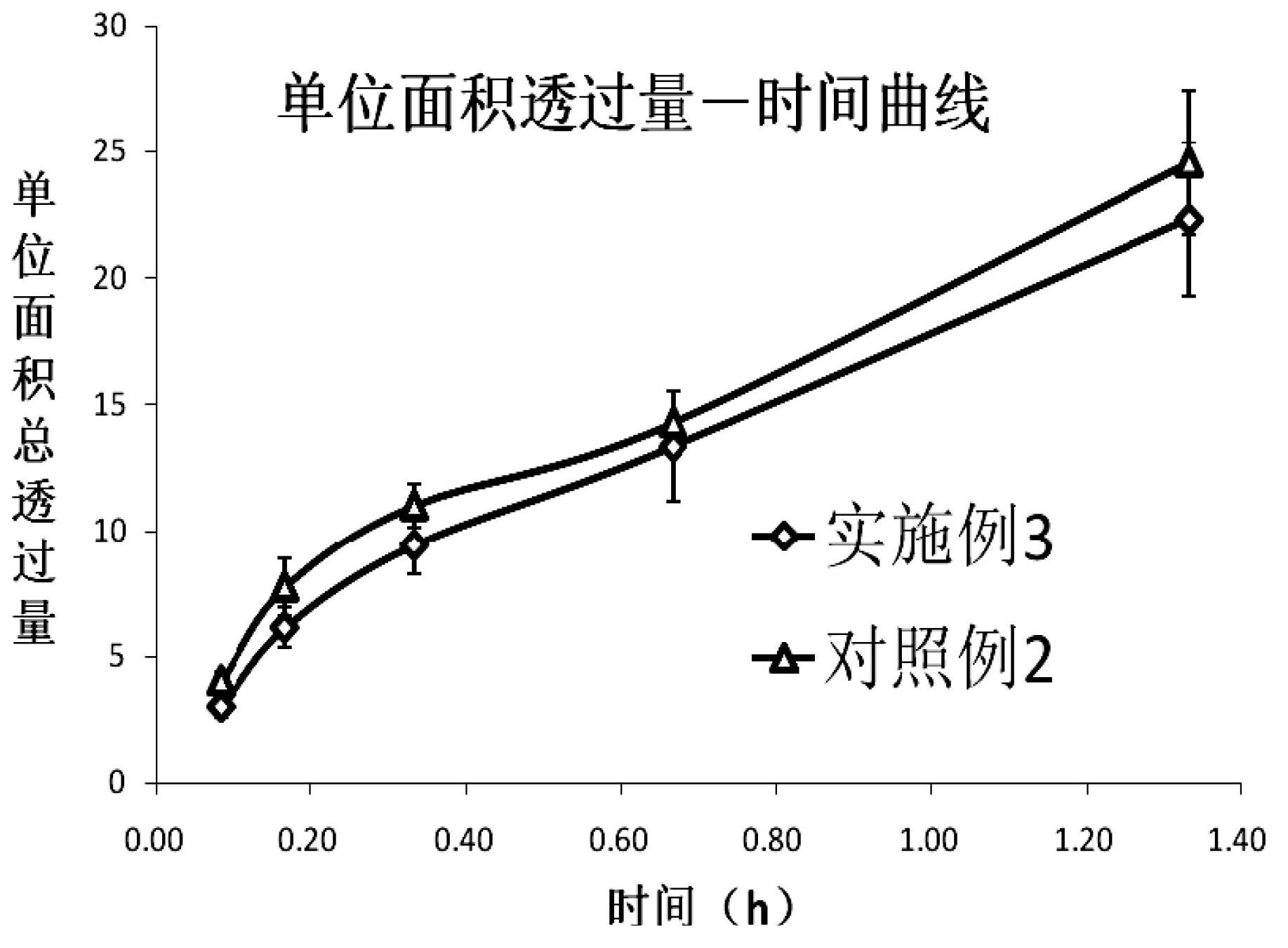

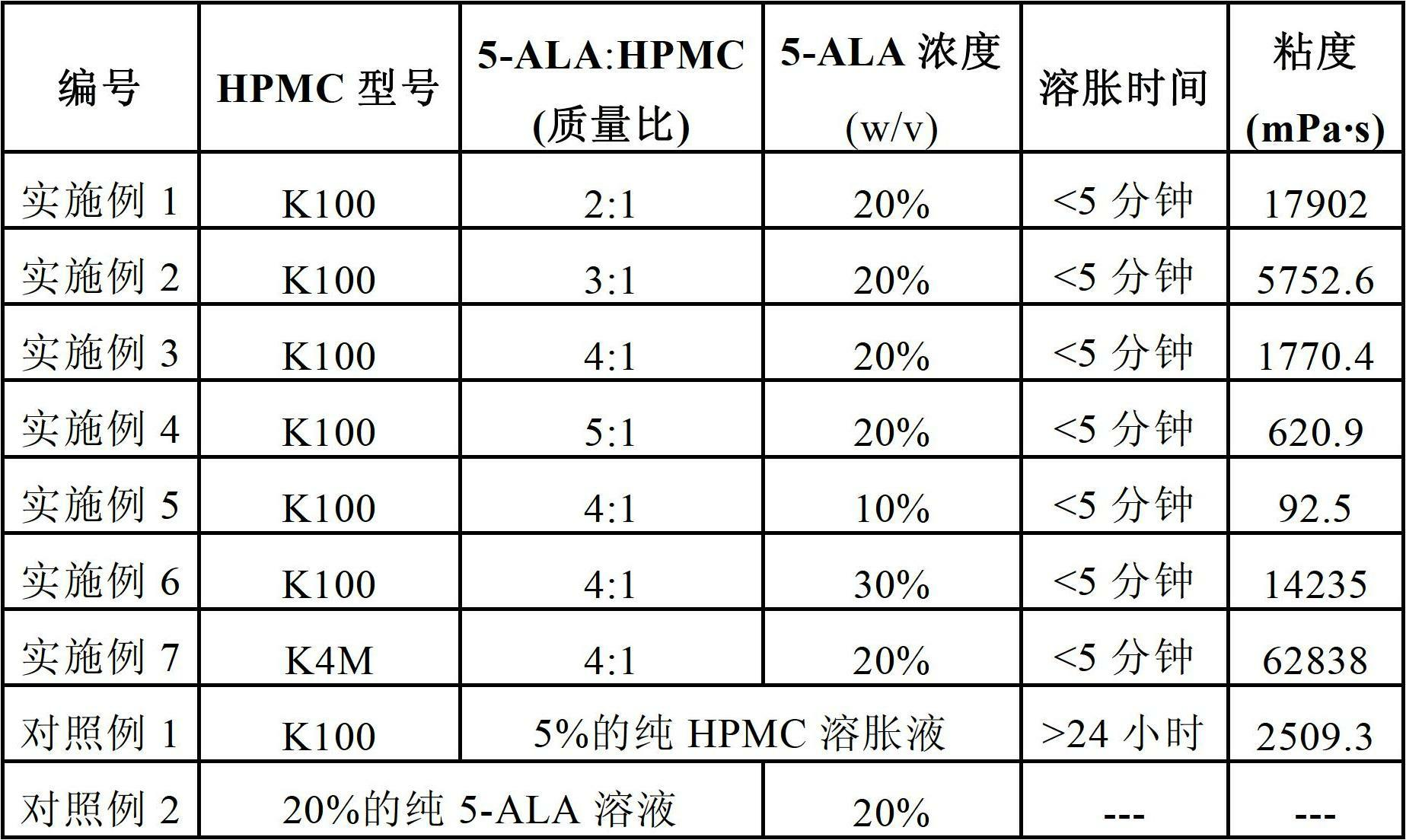

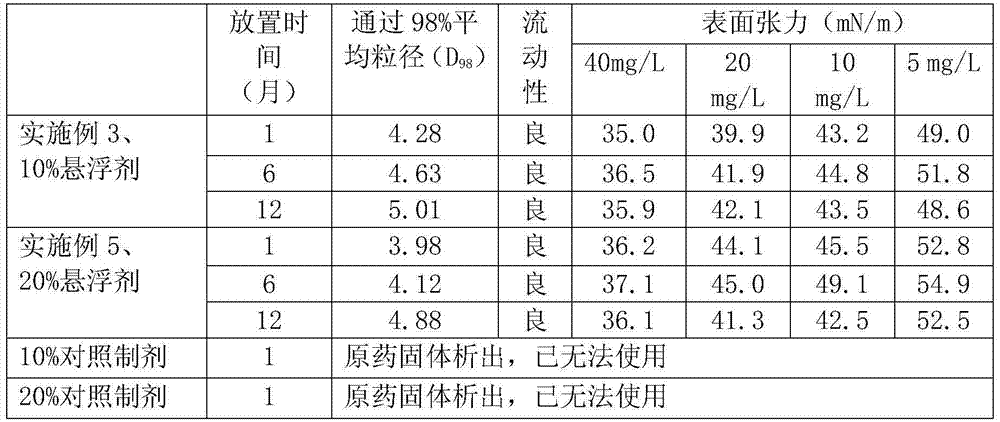

Photo-sensitizer composition, and using method and application thereof

ActiveCN102670577ASimple recipeNo incompatibilityPeptide/protein ingredientsEnergy modified materialsAmino-Levulinic AcidDisease

The invention discloses a photo-sensitizer composition, and a using method and application thereof. The photo-sensitizer composition contains an active ingredient consisting of 5-aminolevulinic acid (5-ALA) or derivative thereof and hydroxypropyl methyl cellulose (HPMC), wherein, the mass ratio of the active ingredient to HPMC is 2:1-5:1. The composition is simple in formula, and a gelatinous swelling body can be quickly formed by mixing the composition and water in a certain ratio. Because the 5-ALA does not react with HPMC, incompatibility is not produced; and two main components can be stored in the same container, so that the production, packing and storage costs are reduced. The invention also discloses application of the composition in preparation of medicaments for diagnosing or treating mucosal part diseases.

Owner:上海复旦张江生物医药股份有限公司

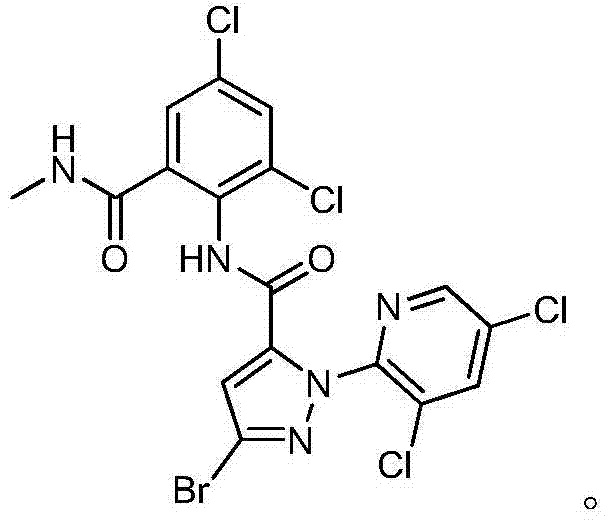

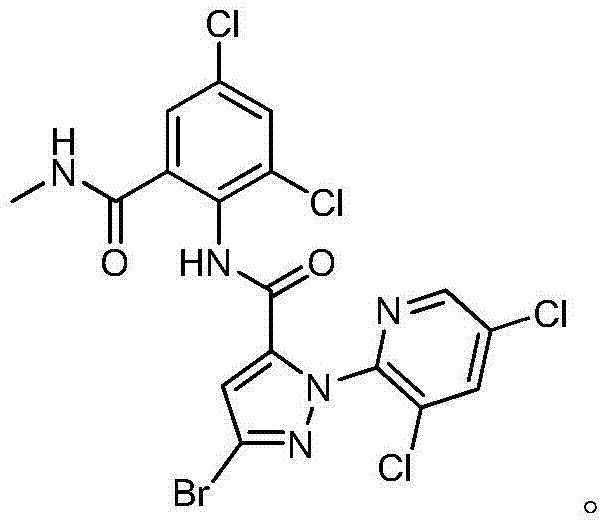

Insect disinfestation preparation and use method thereof

InactiveCN104705295AImprove retentionExtended stayBiocideAnimal repellantsEffervescent granulesUltra-low volume

The invention belongs to the field of insecticides, specifically to an anthranilamide compound insect disinfestation preparation and a use method thereof, wherein the active component in the insect disinfestation preparation is the compound having the structure represented by the following figure, the active component, at least a carrier and at least a surfactant are mixed to prepare emulsifiable concentrate, aqueous emulsion, microemulsion, soluble liquid agent, dispersible oil agent, ultra-low volume agent, powder, wettable powder, suspension, dispersible oil suspension, seed treatment agent, granules, water dispersible granules, emulsifiable powder, emulsifiable granules, effervescent granules, effervescent tablets, microcapsule granules, microcapsule suspension, sustained-release granules, ointments, aerosol or smoke agent, and in any case, the selection of the type of the preparation depends on the physical, chemical and biological properties of the active component. According to the present invention, with the preparation type, Chilo suppressalis, Ostrinia nubilalis, Mythimna separata, Plutella xylostella, Spodoptera exigua Hiibner larva and other pests can be efficiently prevented and controlled.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

Stichopus japonicus and abalone integrated-breeding method

InactiveCN104126531AGuaranteed adhesion effectNo need to add weightClimate change adaptationPisciculture and aquariaFecesShallow sea

The invention aims to provide a stichopus japonicus and abalone integrated-breeding method. In other words, both abalone and stichopus japonicus are put into abalone breeding cages and are bred in a shallow sea raft mode, and the stichopus japonicus and abalone integrated-breeding method is free of pollution and ecological and environmentally friendly. According to the method, the stichopus japonicus is bred in abalone breeding cages, the characteristic of deposition feeding habits of the stichopus japonicus is fully utilized, feces of the abalone in the breeding cages are removed, and the pollution of the organic matter in the feces of the abalone to the seabed is reduced. Meanwhile, the stichopus japonicus feeds organic detritus, benthic diatom and the like which are attached on the breeding cages so that the breeding environment can be cleaned, and flow inside and outside the breeding cages is smooth.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Heat-dissipating spraying powder for household electrical appliances

InactiveCN108300121AGuaranteed spraying effectGuaranteed cooling effectPowdery paintsEpoxy resin coatingsGrapheneMaterials science

The invention especially relates to a heat-dissipating spraying powder for household electrical appliances, belonging to the field of powdery paints. The heat-dissipating spraying powder comprises, byweight, 50 to 70% of resin, 3 to 7% of a curing agent, 2 to 4% of auxiliary agents, 15 to 25% of a pigment and 10 to 15% of a filler, wherein the auxiliary agents are composed of, by weight, 40 to 60% of graphene, 10 to 15% of a charge increasing agent, 10 to 15% of a flowing agent and 15 to 20% of a loosening agent. To guarantee the spraying effect and heat-dissipating effect of the powder, thecharge increasing agent, the flowing agent, the loosening agent and graphene are used as the auxiliary agents, and graphene facilitates heat dissipation in virtue of its excellent performance and improves the shock strength of the powder.

Owner:ZHENJIANG MEIXIN PLASTIC POWDER CO LTD

Preparation method of interior wall putty with dehumidification and humidification functions

The invention discloses a preparation method of interior wall putty with dehumidification and humidification functions. The preparation method comprises the following steps of: S1, adding one third of 20-24 parts of water to a stirrer, then adding 2-4 parts of carboxy methyl cellulose and 0.3-0.4 part of carbon fiber with the length of 3-5mm, mixing uniformly, weighing diatomite and sepiolite in 20-24 parts of humidifying material at a ratio of 5:(2-3), adding the weighed diatomite and sepiolite to the mixture, controlling the stirring speed at 100-200r / m, and stirring for 10-15 minutes to obtain a mixture A; step two, adding another one third of water to another stirrer, adding 26-28 parts of light weight calcium, 32-34 parts of heavy calcium, 8-10 parts of puffed corn starch and 3-5 parts of sodium gluconate to the stirrer, and stirring for 10-15 minutes to obtain a mixture B; step three. adding the mixture A to the mixture B, then adding 7-9 parts of white cement and the balance of water, and stirring for 15-25 minutes to obtain the putty. The putty prepared by the method can absorb moisture in air so as to reduce the humidity during high air humidity and release moisture so as to increase the humidity during low air humidity.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Solvent-free modified epoxy wear-resistant weather-resistant paint

InactiveCN105482624AGuaranteed adhesion effectGuaranteed weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses solvent-free modified epoxy wear-resistant weather-resistant paint, comprising composite slurry and a curing agent; the composite slurry is prepared from the components in percent by weight: 5-8% of active diluent, 20-30% of silicon carbon, 30-40% of epoxy resin, 10-15% of titanium white powder, 0.1-1% of defoaming agent, 0.1-1% of dispersing agent, 0.1-1% of flatting agent and the balance of mica powder; the curing agent adopts a solvent-free amino organic silicon curing agent with an amine value of 180mg of KOH / g; a weight ratio of the composite slurry to the curing agent is 2:1. The paint has the anticorrosion and chemical resistant protection functions of common epoxy paint and also has anti-ageing and wear-resistant functions, can be painted at a surface irradiated by ultraviolet, and has the characteristic of excellent weather resistance. The paint is environment-friendly, weather-resistant and wear-resistant and can meet requirements of anticorrosive and antiskid fields.

Owner:天津米一科技有限公司

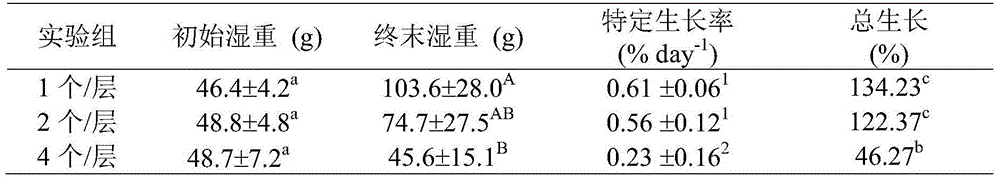

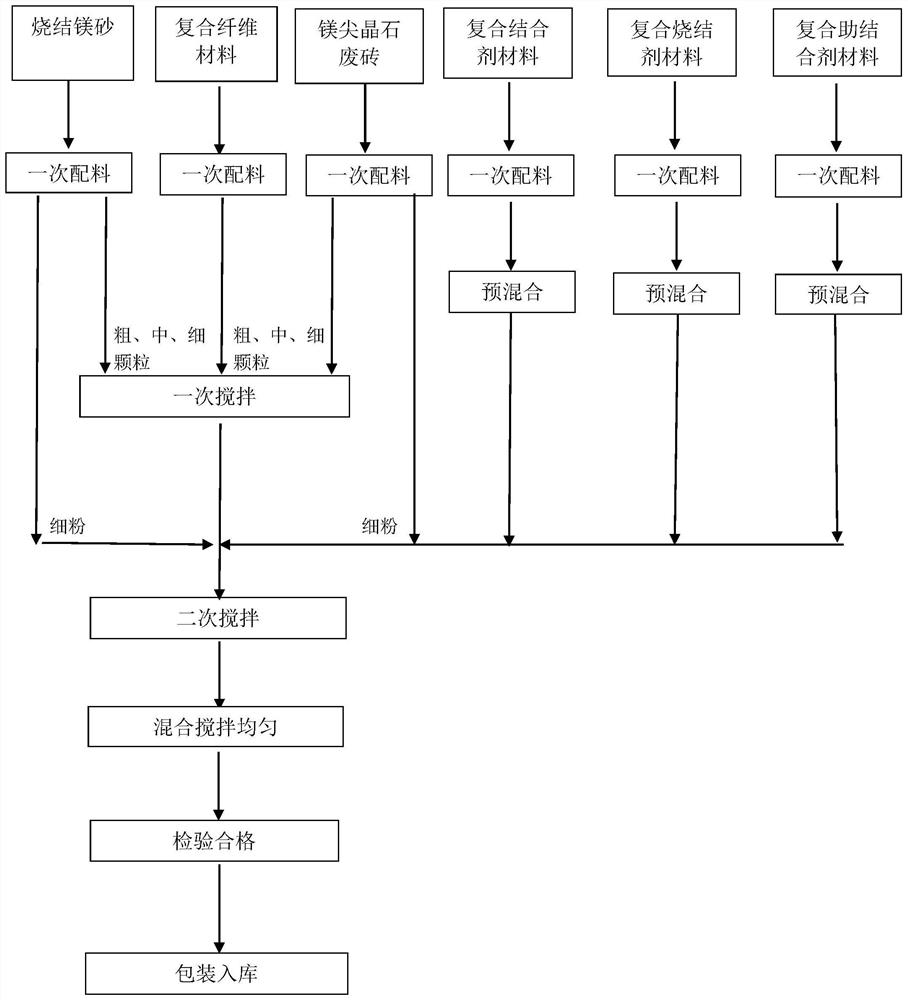

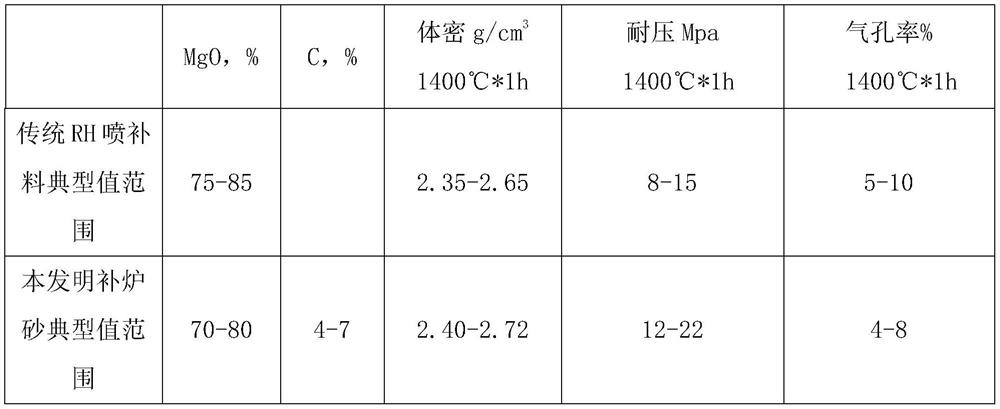

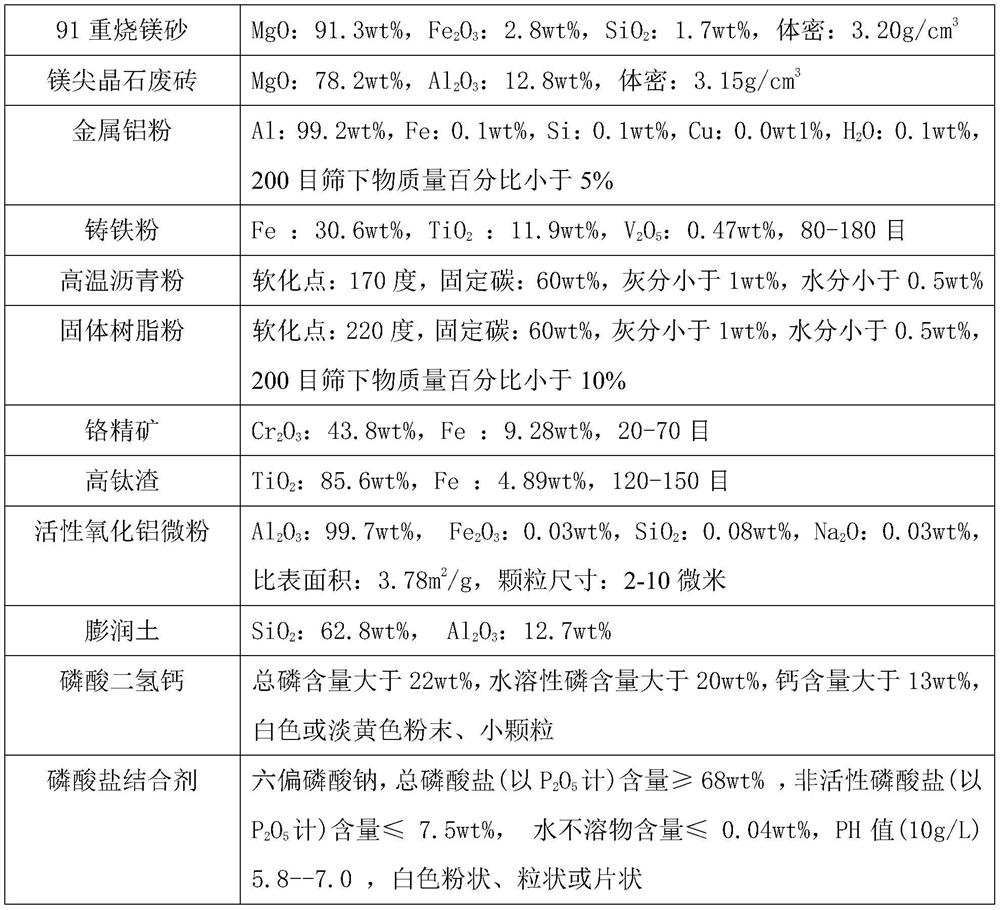

High-quality RH gunning mix added with large amount of cast iron powder and production method thereof

ActiveCN112479685AFully sinteredPromote sinteringProcess efficiency improvementCeramic materials productionFiberManufactured material

The invention relates to a high-quality RH gunning mix added with a large amount of cast iron powder and a production method thereof. The high-quality RH gunning mix is prepared from the following rawmaterials by weight: 35-60 parts of sintered magnesia, 10-30 parts of magnesia spinel waste bricks, 12-22 parts of a composite binding agent, 5-20 parts of a composite sintering agent, 3-10 parts ofa composite auxiliary binding agent and 0.1-2.0 parts of composite fibers. Compared with the prior art, the RH gunning mix has the beneficial effects that: the proportion of an existing RH gunning mixis optimally designed and improved, a large amount of cast iron powder is added for the first time in the domestic range, the sintering performance of the gunning mix is improved, so that the gunningmix meets the requirement for on-site rapid gunning maintenance of an RH dip pipe, the sintering speed is fast, the sintering strength is high, the adhesiveness is good, no resilience exists, the erosion resistance is good, meanwhile, the production method is simple and the raw material cost is lowered.

Owner:鞍山市和丰耐火材料有限公司

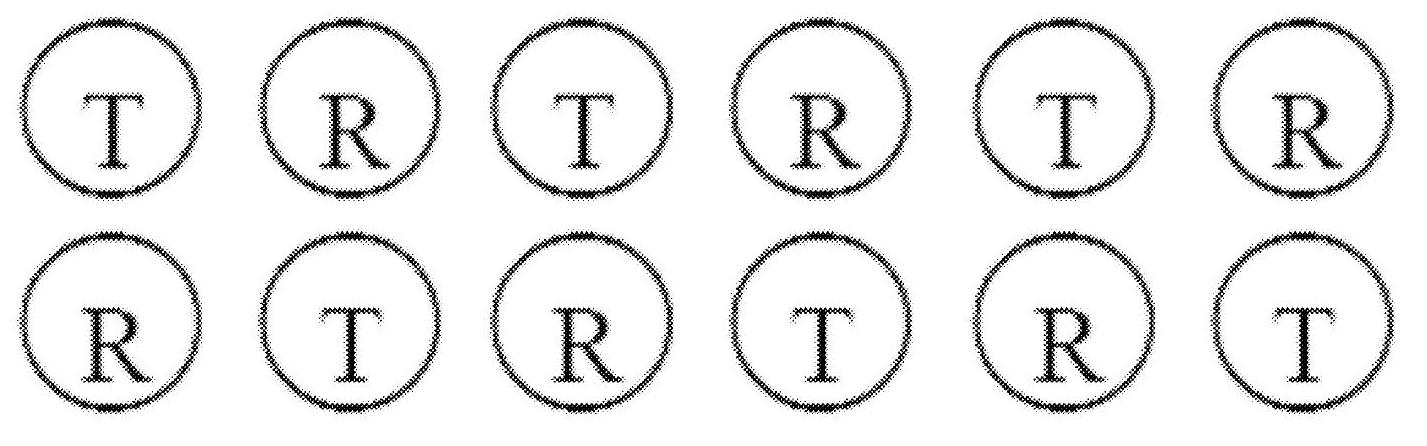

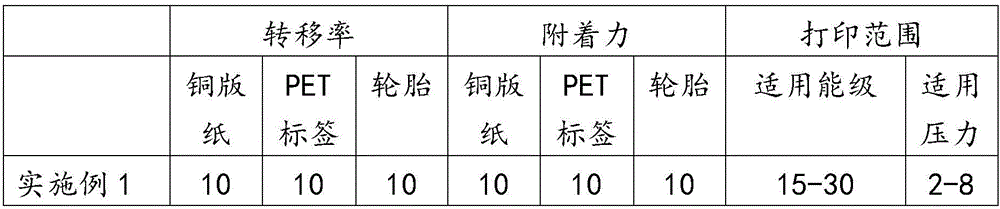

Thermal transfer ribbon

The invention relates to a thermal transfer ribbon, which consists of a bottom layer coated on a substrate, a color layer coated on the bottom layer, an adhesive layer coated on the color layer, and a color layer coated on the substrate surface. The composition of the back coating, the weight percentage of the bottom layer is composed of: silicone grease or silicone oil 100%; the weight percentage of the color layer is composed of: SEBS or EVA 20-70%, pigment 30%-70%; the adhesive layer The weight percent composition is as follows: 5-20% of fumed silicon dioxide, 80-95% of silane-modified cyclized rubber resin or 10-40% of titanium dioxide, and 60-90% of silane-modified cyclized rubber resin. The thermal transfer printing ribbon of the invention has excellent transfer rate and adhesion performance index, wide applicable energy level and pressure range, can be used not only for bar code ribbons, but also for tire dotting ribbons, and is convenient to use.

Owner:杭州兴甬复合材料有限公司

Sealant for antibacterial flame-retardant hollow glass, and preparation method thereof

InactiveCN107254291AImprove heat resistanceImprove flame retardant high temperature resistance and mechanical strengthNon-macromolecular adhesive additivesOther chemical processesChemistryPlasticizer

The invention discloses a sealant for antibacterial flame-retardant hollow glass, belonging to the technical field of sealants. The sealant contains the following raw materials in parts by weight: 55-60 parts of organic hydroxyl silicone, 14-16 parts of organic methyl silicone, 7-13 parts of methyl silane, 12-14 parts of fumed silica, 8-10 parts of zinc borate, 2-4 parts of zirconium dioxide, 6-8 parts of calcium carbonate, 1-5 parts of titanium dioxide, 6-8 parts of decabromodiphenyl ethane, 1-2 parts of dibutyltin dilaurate, 3-5 parts of amino silane, 15-17 parts of ethylene-propylene- diene-terpolymer rubber, 1-2 parts of acetic acid, 1-3 parts of olive oil, a proper amount of water, 1-3 parts of antibacterial agent, 9-11 parts of plasticizer, and 1-2 parts of bonding agent. The invention further discloses a preparation method of the sealant for antibacterial flame-retardant hollow glass. The sealant is flame-retardant and high-temperature-resistant, antibacterial and long in service, excellent in bonding capacity, and excellent in mechanical strength.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Production method for UV resistant unstretched polypropylene metalized film

InactiveCN104986437AGood compatibilityExtended service lifeFlexible coversWrappersMasterbatchAntistatic agent

The invention discloses a production method for a UV resistant unstretched polypropylene metalized film. Materials of a corona layer comprise: 92-94% of ternary polypropylene random copolymer, 4.5-5.5% of abherent, 1.5-2.5% of zeolite master batch. Materials of a core layer comprise 100% ternary co-polypropylene. Materials of a heat-seal layer comprise 92.9-93.9% of homo-polypropylene, 3% of abherent, 2.5-3.5% of slipping agent, 0.6% of antistatic agent, and 0.1-0.3% of ultraviolet light absorber. The method comprises the following steps: batching, mixing, plasticizing, forming, casting sheet, measuring thickness, performing corona, rolling up, curing, and aluminizing. Through adding the ultraviolet light absorber UV531, the film can strongly absorb ultraviolet rays in wavelength of 270-330 nm. The corona layer uses the abherent in specific proportion, so an aluminum coated layer is not easy to fall off. The corona layer is added with natural zeolite powders. Since the zeolite powders have strong adsorbability, the aluminum coated layer can maintain relatively high surface tension. The core layer is not added with a thermal synthesis additive, so that the core layer would not generate any precipitate in a reaction process, thereby ensuring adhesion effect of aluminizing.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

Production method for high-adhesion high-surface-tension CPP aluminum-plating film

ActiveCN104647849AGuaranteed adhesion effectNot easy to fall offFlexible coversWrappersMasterbatchAntistatic agent

The invention discloses a production method for a high-adhesion high-surface-tension CPP aluminum-plating film. The high-adhesion high-surface-tension CPP aluminum-plating film comprises a corona layer comprising 92-94% of ternary polypropylene randon copolymer, 4.5-5.5% of an anti-sticking agent and 1.5-2.5% of zeolite master batch, a core layer comprising 100% of ternary co-polypropylene, a heat-seal layer comprising 92.9-93.9% of homo-polypropylene, 3% of an anti-sticking agent, 2.5-3.5% of a slipping agent and 0.6% of an antistatic agent. The production method comprises the following steps: preparing materials, mixing, plastifying, molding, performing sheet casting, measuring thickness, performing corona, rolling, curing and plating aluminum. According to the production method disclosed by the invention, the corona layer selects polypropylene randon copolymer as a main material which is matched with the anti-sticking agent in specific proportion, and the core layer only adopts the ternary polypropylene randon copolymer as the raw material, so that an aluminum plating layer cannot drop easily; a certain amount of natural zeolite powder is added into the corona layer, so that parts of low-molecule polymers are prevented from rushing out of a surface layer, the aluminum-plating layer can be kept in relatively high in surface tension; meanwhile, no precipitate is separated out of the core layer in a reaction process, so that the wetting tension of the lower surface is further guaranteed, and further the adhesion effect of aluminum plating is guaranteed.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

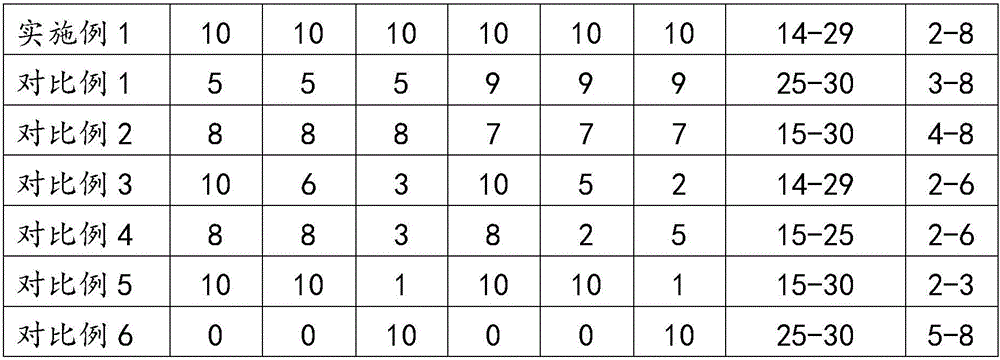

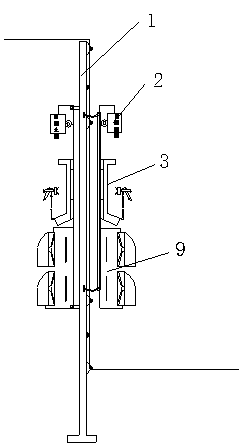

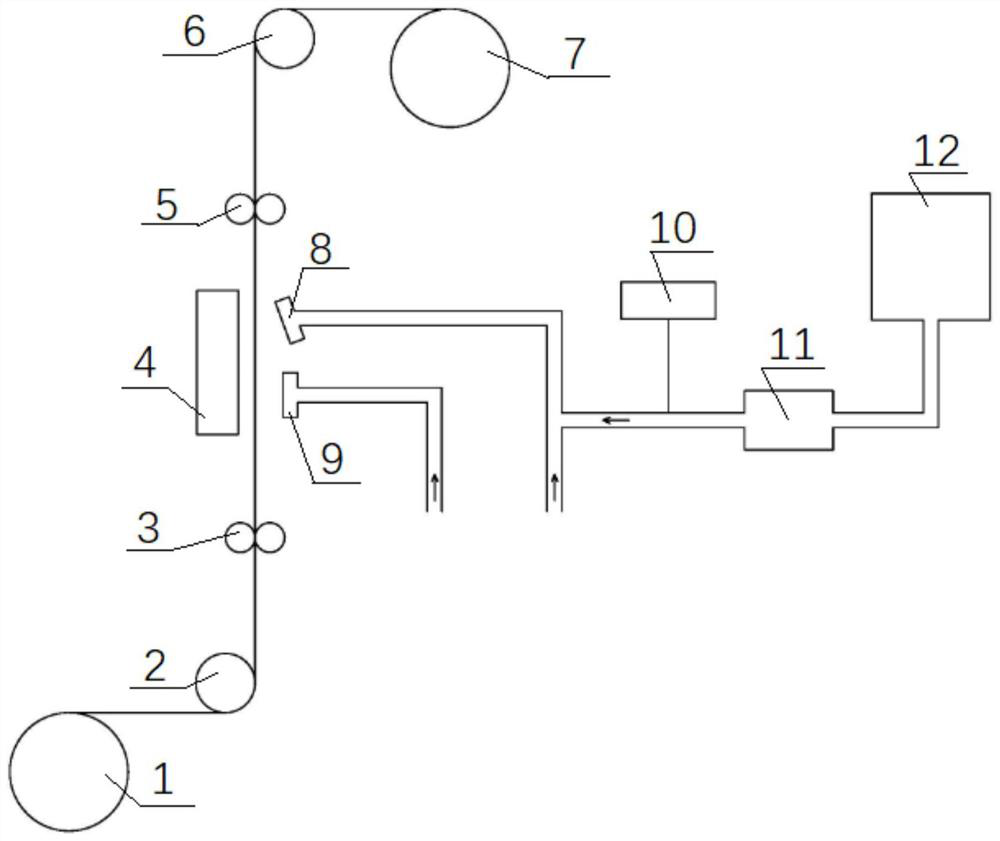

Double-rib film spraying equipment

InactiveCN102921584ALow investment costEasy to operateSpraying apparatusPretreated surfacesAgricultural engineeringCorona treatment

The invention provides the technical field of double-rib film spraying equipment. The technical scheme is as follows: the double-rib film spraying equipment comprises an equipment bracket; a corona treatment part is fixedly arranged at the upper part of the bracket; an automatic spraying part is fixedly arranged in the middle of the bracket; a drying part is fixedly arranged at the lower part of the bracket; a guide rail is transversely arranged in the middle of the bracket; and the automatic spraying part comprises a spraying gin which can slide on the guide rail and a shielding curtain fixed on the bracket. The scheme disclosed by the invention can solve the problems that a double-rib film deforms in the coating process and the spraying device is difficultly fused with the previous equipment.

Owner:CHENGDU BAOXINRONGKE

Environment-friendly weatherproof waterproof coating and preparation method thereof

InactiveCN107337967AEasy to makeLittle environmental pollutionFireproof paintsAnti-corrosive paintsFiberCarbon fibers

The invention discloses an environment-friendly weatherproof waterproof coating, belonging to the technical field of coatings. The environment-friendly weatherproof waterproof coating comprises the following raw materials by weight: 50-55 parts of an EVA emulsion, 10-15 parts of carbon fibers, 12-14 parts of quartz powder, 6-8 parts of kaolin, 10-12 parts of talcum powder, 3-5 parts of hydrophobic organosilicon powder, 5-7 parts of aluminum powder, 2-4 parts of zirconium dioxide, 4-6 parts of titanium dioxide, 18-20 parts of cement, 1 to 3 parts of carboxymethyl cellulose, 4-5 parts of stearic acid, 2-4 parts of paraffin, 5-7 parts of sodium phosphate, 2-4 parts of dodecanol ester, 1-3 parts of a wetting agent, 6-9 parts of a plasticizer, 3-5 parts of an antifoaming agent, 1-2 parts of a preservative, 2-4 parts of a dispersant and 35-40 parts of water. The invention also discloses a preparation method for the environment-friendly weatherproof waterproof coating. The weatherproof waterproof coating provided by the invention has the advantages of simple preparation, low environmental pollution, strong adhesion and good water resisnce, acid and alkali resistance and high-temperature resistance.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

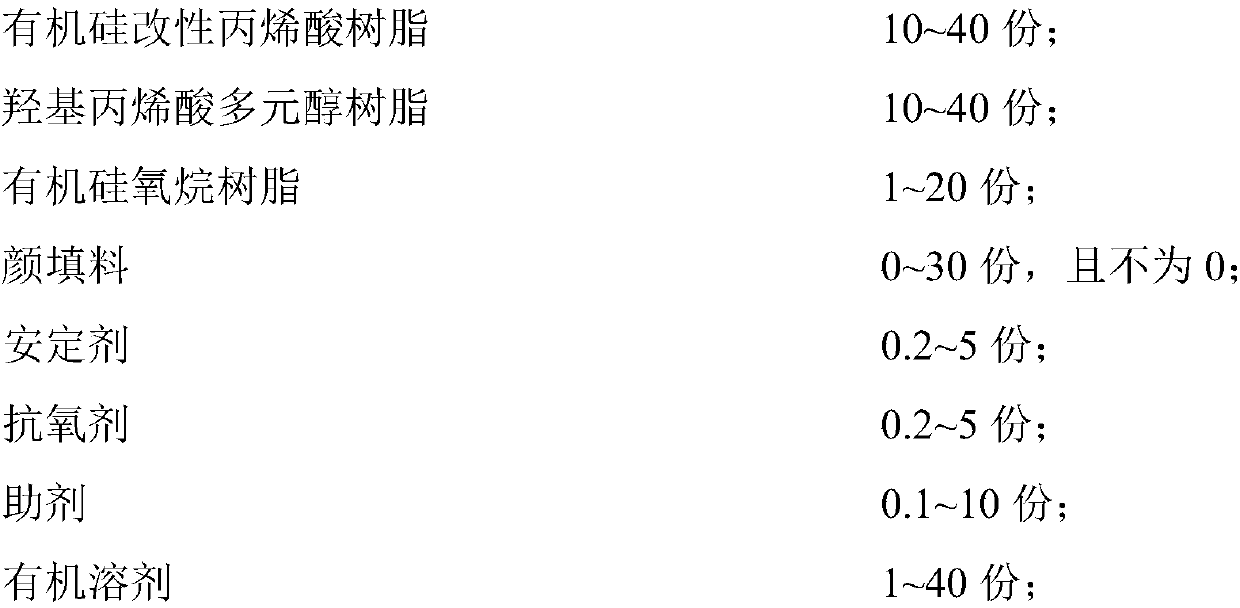

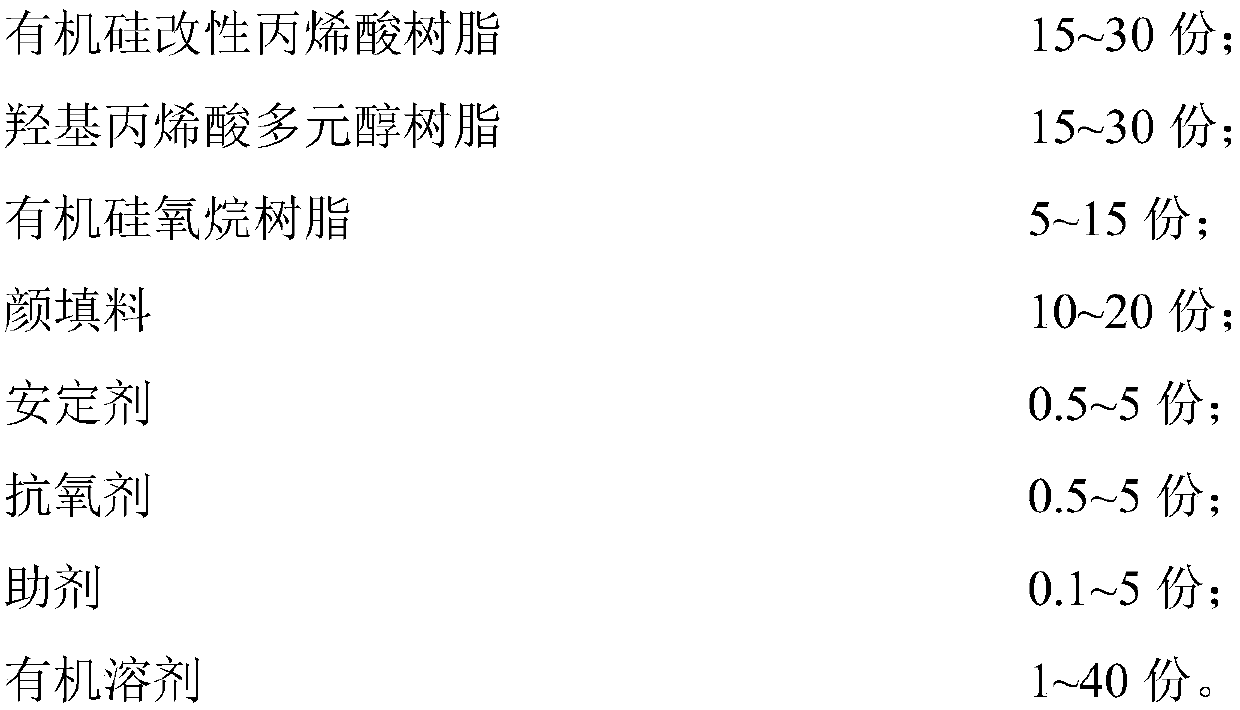

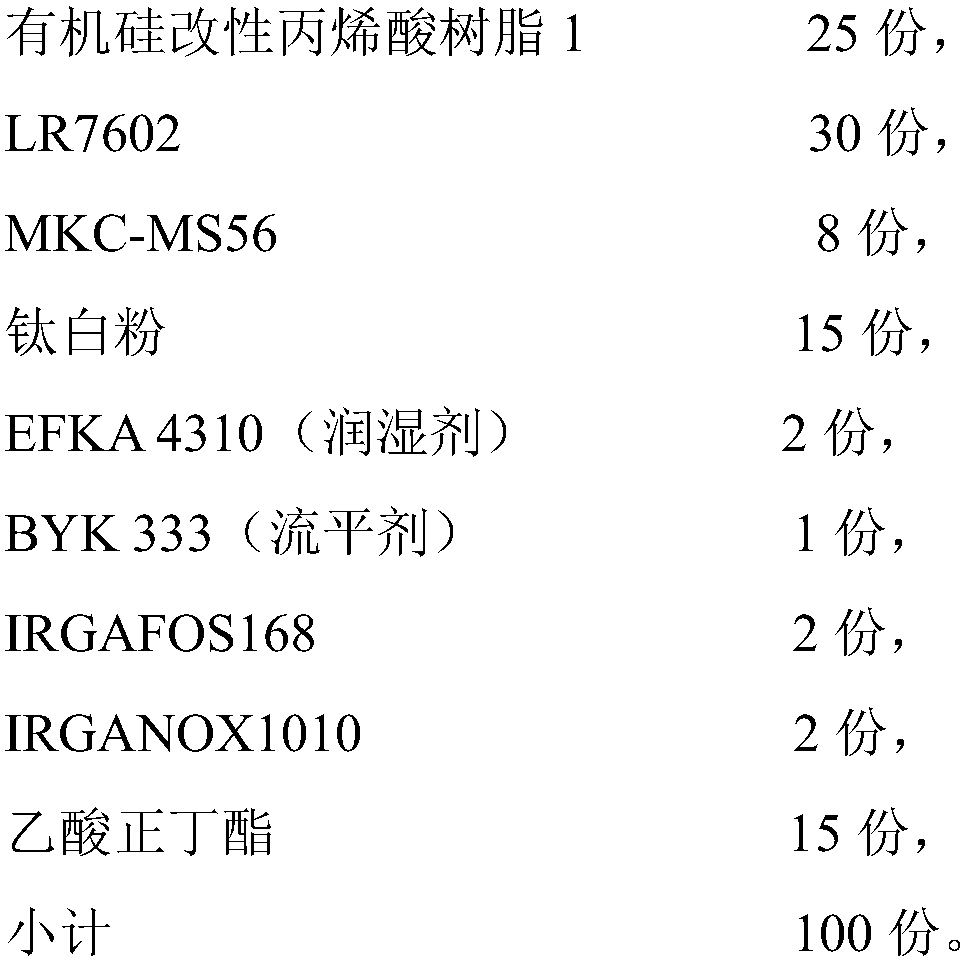

High pressure steam impact resistant coating for metal materials and preparation method of coating

ActiveCN109679478AImprove curing effectIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

The invention relates to a high pressure steam impact resistant coating for metal materials and a preparation method of the coating. The coating is prepared from the following components in parts by weight: A) 10-40 parts of silicone-modified acrylic resin, B) 10-40 parts of hydroxy acrylic polyol resin, C) 1-20 parts of hydrolyzable organosiloxane resin, D) 0-30 parts of pigments and fillers, E)0.1-10 parts of an organophosphorus compound stabilizer, F) 0.1-10 parts of an organic phenolic antioxidant, G) 0.1-10 parts of additives such as a wetting leveling agent and the like, H) 1-40 parts of an organic solvent and I) a cross-linking agent. Compared with the prior art, the coating has excellent adhesion, water resistance, high pressure steam washing resistance and other film forming properties to metal materials. According to the needs of model design, the glossiness of a coating film is adjustable, and the coating is excellent in resistance to various chemicals, has an adjustable design appearance, is especially suitable for automotive exterior parts used in cold areas, and has the advantages of corrosion resistance, warm water resistance, high pressure steam impact resistance and the like.

Owner:DONGLAI COATING TECH SHANGHAI

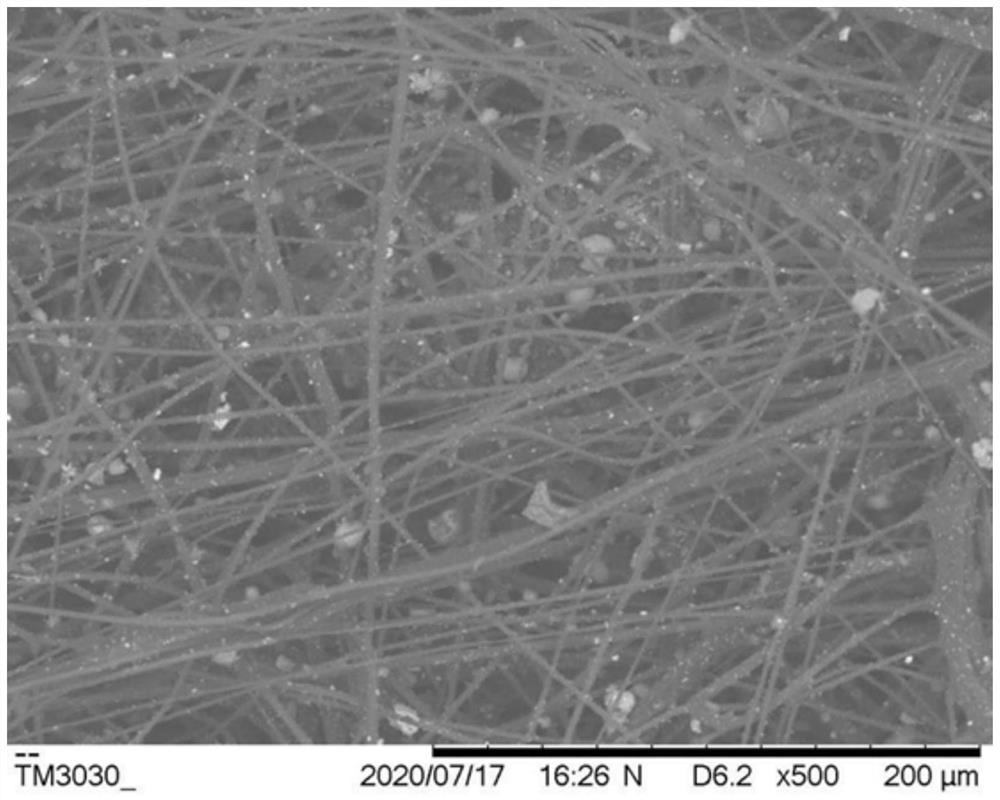

Melt-blown cloth capable of inactivating virus, steam spraying method, production line and application

PendingCN112482017ASolve for uniformitySolve the adhesionBiochemical fibre treatmentHeating/cooling textile fabricsProcess engineeringMechanical engineering

The invention provides melt-blown cloth capable of inactivating virus, a steam spraying method, a production line and application. The steam spraying method of the melt-blown cloth capable of inactivating the virus comprises the following steps of 1, mixing powder capable of inactivating the virus with water, and carrying out heating to generate high-temperature steam; 2, uniformly spraying the high-temperature steam on the surface of the preheated melt-blown cloth, and enabling the powder capable of inactivating the virus to permeate into the melt-blown cloth through the hot melting principle; and 3, performing high-temperature extrusion drying on the melt-blown cloth, and finally carrying out coiling and packaging. The invention further discloses the steam spraying production line of themelt-blown cloth capable of inactivating the virus. The steam spraying production line comprises a suction fan, a high-temperature compression roller, a drying guide shaft, a material receiving roller, a steam nozzle, a high-temperature gas nozzle, a flow powder concentration monitoring instrument, a steam generator and a liquid stirring machine. According to the steam spraying method of the melt-blown cloth capable of inactivating the virus, effective combination of the powder capable of inactivating the virus and the melt-blown cloth can be achieved.

Owner:大连医博仕医疗器械有限公司

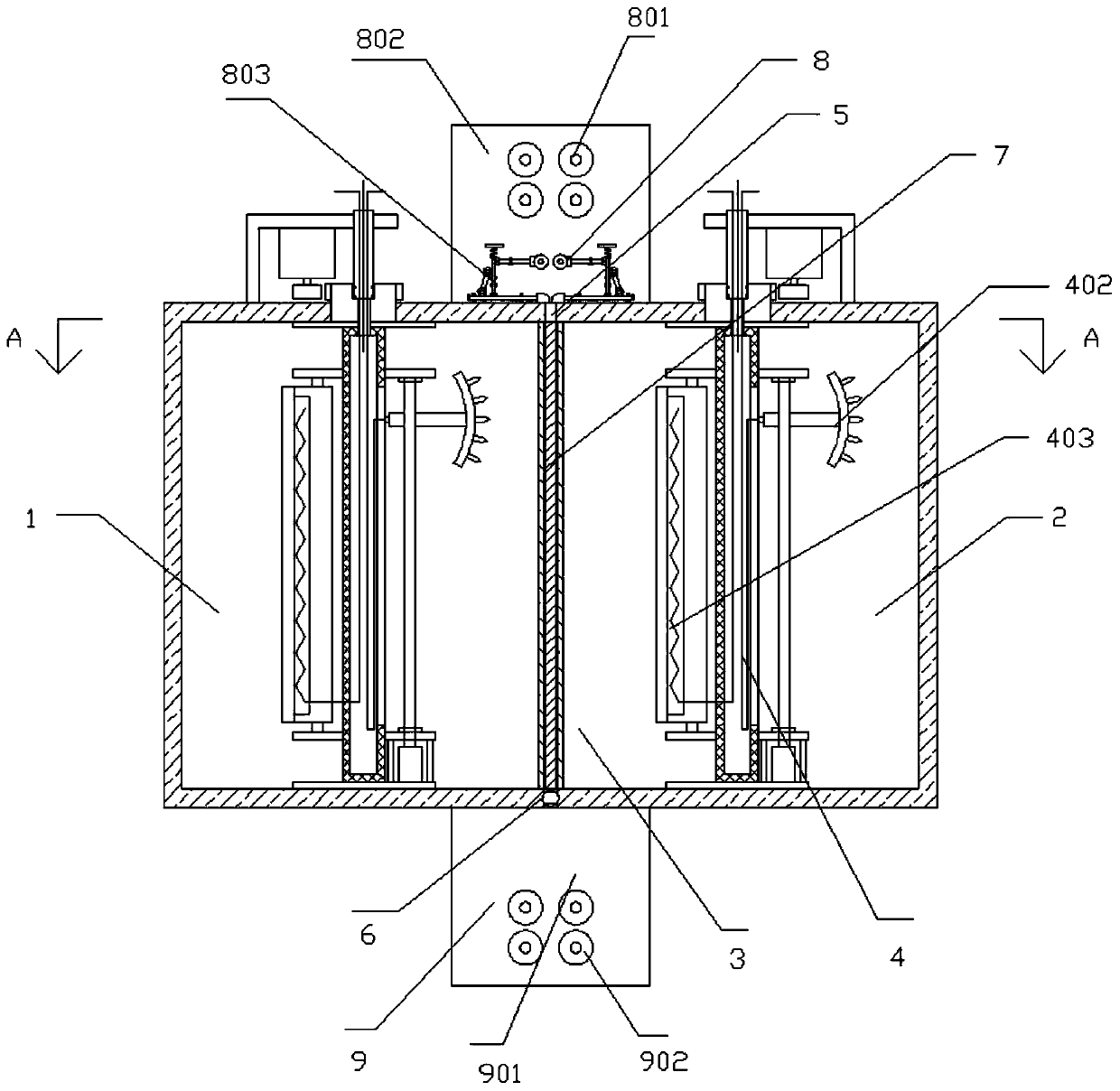

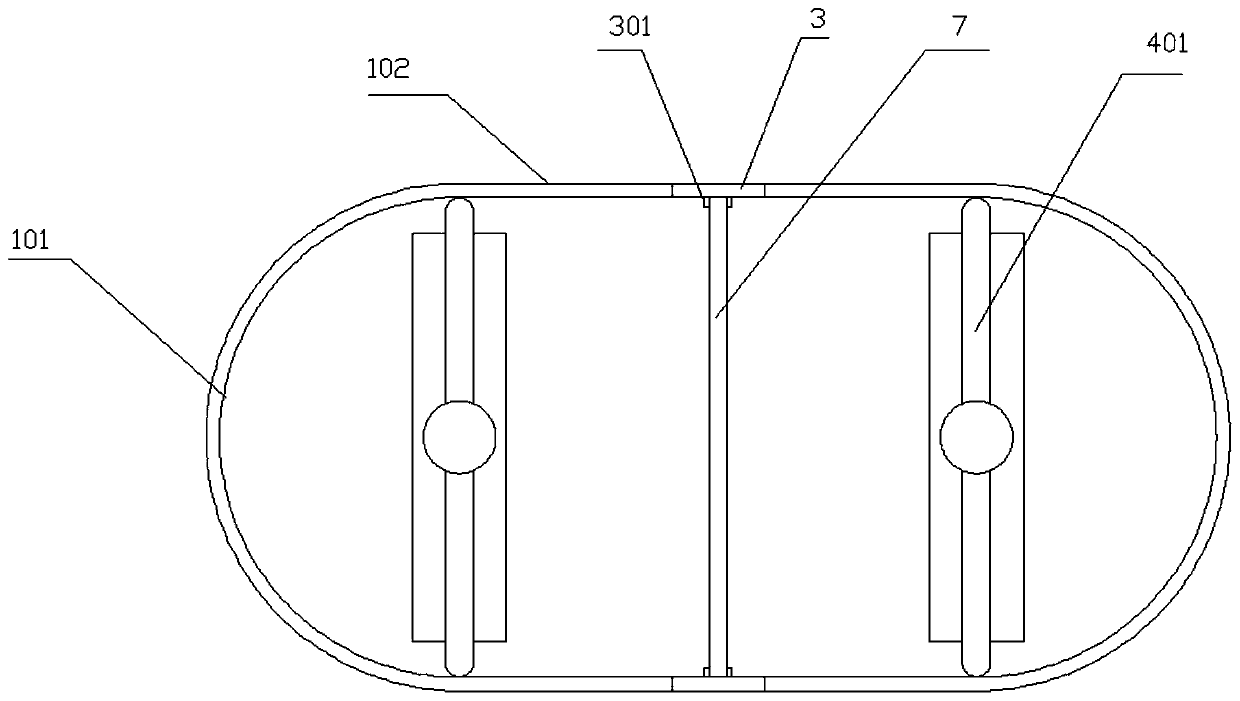

Spraying device for metal display rack machining

ActiveCN111111991AImprove efficiencySave resourcesPretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention discloses a spraying device for metal display rack machining. The spraying device comprises a left spraying chamber, a right spraying chamber and a connection cavity arranged between theleft spraying chamber and the right spraying chamber; the interiors of the left spraying chamber and the right spraying chamber are each provided with a spraying drying mechanism; the top of the connection cavity is provided with a first opening, and the bottom of the connection cavity is provided with a second opening; a display plate can be inserted into the connection cavity from the first opening and then moved out through the second opening; and the spraying drying mechanism is used for conducting spraying and drying operation on the two end surfaces of the display plate moved into the connection cavity. The spraying device is used for conducting spraying and drying operation on the display plate, the efficiency is improved, and resources are saved.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com