Double-rib film spraying equipment

A technology of spraying equipment and fascia, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of double fascia deformation and difficulty in fusion, and achieve convenient operation, reduce investment cost, and significantly progressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

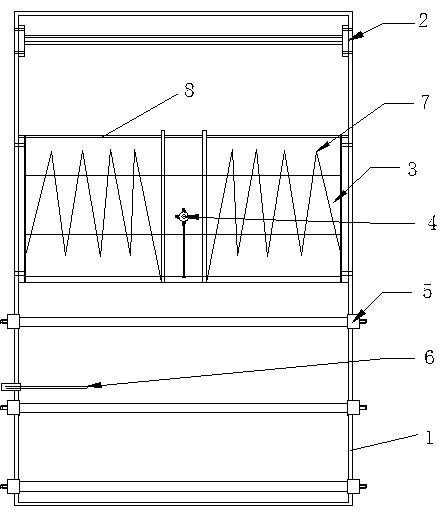

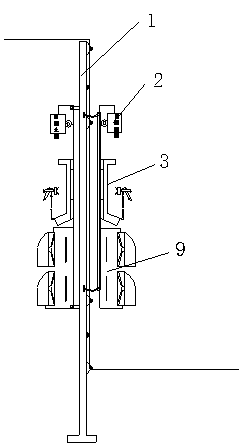

[0014] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation mode combined with its accompanying drawings.

[0015] It can be seen from the accompanying drawings that the specific embodiment of this scheme is: after the double fascia is formed by the film blowing machine, it passes through the bracket from top to bottom, and firstly corona treats the surface of the double fascia through corona treatment to remove The surface is oily to increase the surface area of paint adhesion; then the spraying operation is carried out through the automatic spraying parts; finally, the double fascia after spraying is dried through the drying parts to achieve a good adhesion effect; finally, the winding operation is carried out.

[0016] When spraying, the spray gun can evenly spray paint on the entire double fascia by sliding on the guide rail of the bracket, and the blocking curtain arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com