Multi-functional reflective film of on-board exterior mirror and preparation method

A reflective film and multi-functional technology, which is applied in the field of automotive mirrors, can solve the problems of film erosion, film corrosion and peeling, and non-adjustment, so as to improve mirror reflectivity, break through the bottleneck of coating, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The material with high refractive index is Nb 2 o 5 , the refractive index at 550nm is 2.32, the low refractive index material is SiO2, the refractive index at 550nm is 1.46, the metal material is Al, the refractive index at 550nm is 0.82, the conductive material is ITO, the refractive index at 550nm is 1.92, the film thickness as follows:

[0021] The material of the first high refractive index layer is Nb 2 o 5 , the thickness is 13±0.5nm; the material of the first low refractive index layer is SiO 2 , the thickness is 78±2nm; the material of the second high refractive index layer is Nb 2 o 5 , the thickness is 32±1nm; the material of the second low refractive index layer is SiO 2 , the thickness is 20±2nm; the metal material layer is Al, the thickness is 11±1nm; the material of the third low refractive index layer is SiO 2 , the thickness is 125±5nm; the conductive layer is ITO, the thickness is 25nm;

[0022] According to the above film structure and corresp...

Embodiment 2

[0024] The high refractive index material used is TiO2, the refractive index at 550nm is 2.38, the low refractive index material is SiO2, the refractive index at 550nm is 1.46, the metal material is Al, the refractive index at 550nm is 0.82, the conductive material is ITO, the refractive index at 550nm The refractive index is 1.92, and the film thickness is as follows:

[0025] The material of the first high refractive index layer is TiO2 with a thickness of 13±1nm; the material of the first low refractive index layer is SiO 2 , the thickness is 78±2nm; the material of the second high refractive index layer is TiO2, the thickness is 32±1nm; the material of the second low refractive index layer is SiO 2 , the thickness is 20±2nm; the metal material layer is Al, the thickness is 11±1nm; the material of the third low refractive index layer is SiO 2 , the thickness is 125±5nm; the conductive layer is ITO, the thickness is 25nm;

[0026] According to the above film structure and ...

Embodiment 3

[0027] Embodiment 3: In the film layer design process, the first high refractive index is TiO2, the second high refractive index is Nb2O5; the first low refractive index material is SiO2, and the second low refractive index material is SiOxNy, arranged by the listed materials All combinations can achieve the same reflectivity requirements.

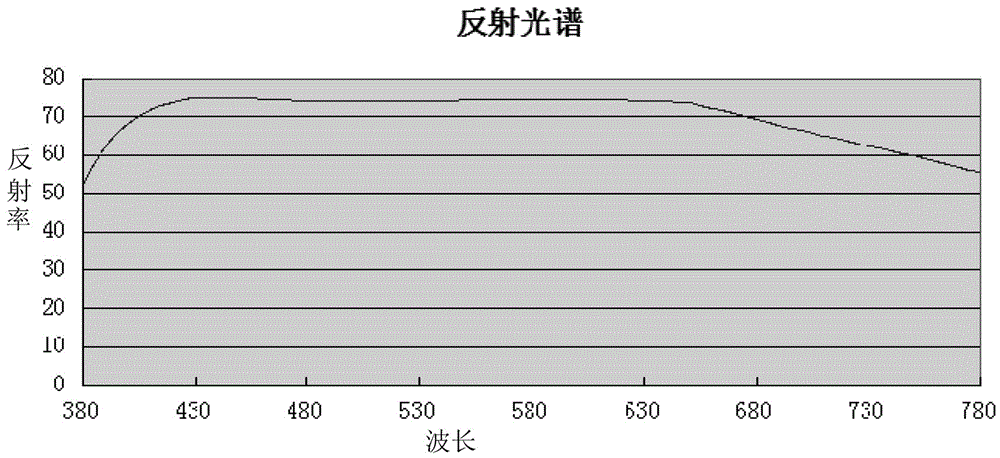

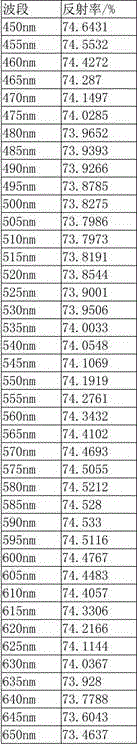

[0028] The actual measurement data of the multifunctional reflective film data of the vehicle exterior mirror obtained in Example 1 is shown in Table 1 below.

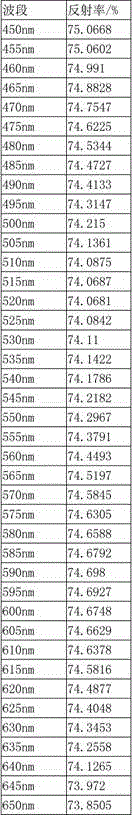

[0029] The actual measurement data of the multifunctional reflective film data of the vehicle exterior mirror obtained in Example 2 are shown in Table 2 below.

[0030] When preparing the multifunctional reflective film for vehicle-mounted exterior mirrors described in the above embodiments, the first high-refractive index layer, the first low-refractive-index layer, and the second high-refractive-index layer are sequentially deposited on the glass substrate by magnetron sputtering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com