Macromolecular adhesive cement

A technology of polymer glue and quartz powder is applied in the field of cement-based self-leveling mortar, which can solve the problems of affecting the appearance and use effect of the building surface, difficult to guarantee the quality, and not being effectively cured, and achieve good construction adaptability and construction. The effect of good quality and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the quartz powder sand filler is as follows: using a dry powder mortar mixer, under the condition of cutting off air or inert gas protection, mixing 100-120 mesh quartz sand and quartz powder, adding additives, and fully mixing and stirring.

[0032] Water-based epoxy resin and water-based epoxy curing agent are prepared according to the patent (CN 100532480C A kind of water-based epoxy resin coating and its preparation method).

[0033] The self-leveling additives include retarders, coagulation accelerators, leveling agents, defoamers, and early strength agents.

[0034] The auxiliary additives used in the present invention are all general-purpose additives for coatings.

[0035] The preparation method of described polymer cement is as follows:

[0036] First disperse a part of water, additives and all pigments and fillers at a speed of 900-1200r / min for 8-30 minutes, then reduce the speed, then add a water-based epoxy curing agent, mix a...

Embodiment 1

[0040] The polymer cement of the present invention, in parts by weight: 80 parts of water-based epoxy resin, 16 parts of water-based epoxy curing agent, 120 parts of composite Portland cement, 30 parts of quartz silt filler, 10 parts of water, 35 parts of pigment and filler 0.3 parts of wetting and dispersing agent, 2 parts of self-leveling additive, 2 parts of water-based color paste.

[0041]The silica silt filler is, by weight percentage: 90% a mixture of quartz sand and quartz powder, and 10% additives. The additive is a lubricant.

[0042] The preparation method of the quartz powder sand filler is as follows: using a dry powder mortar mixer, under the condition of cutting off air or inert gas protection, mixing 100-120 mesh quartz sand and quartz powder, adding additives, and fully mixing and stirring.

[0043] Water-based epoxy resin and water-based epoxy curing agent are prepared according to the patent (CN 100532480C A kind of water-based epoxy resin coating and its p...

Embodiment 2

[0048] The polymer cement of the present invention, in parts by weight: 100 parts of water-based epoxy resin, 20 parts of water-based epoxy curing agent, 150 parts of composite Portland cement, 50 parts of quartz silt filler, 15 parts of water, 50 parts of pigment and filler 0.5 parts of wetting and dispersing agent, 6 parts of self-leveling additive, 5 parts of water-based color paste.

[0049] The quartz silt filler is: 80% mixture of quartz sand and quartz powder, 20% lubricant.

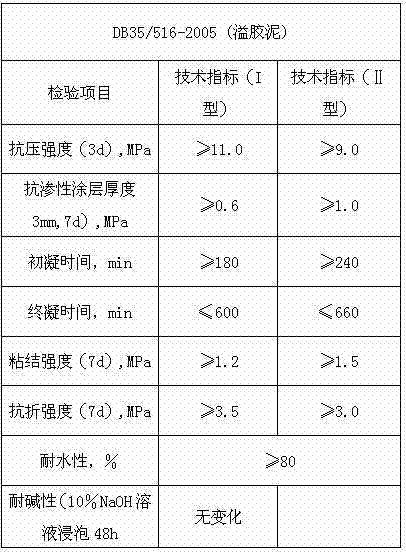

[0050] All the other preparations were as in Example 1. The product complies with DB35 / 516-2005.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com