Polycarboxylic acid water reducing agent and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, applied in the field of polycarboxylic acid water reducing agent and its preparation, can solve the problems of poor fluidity, poor impermeability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

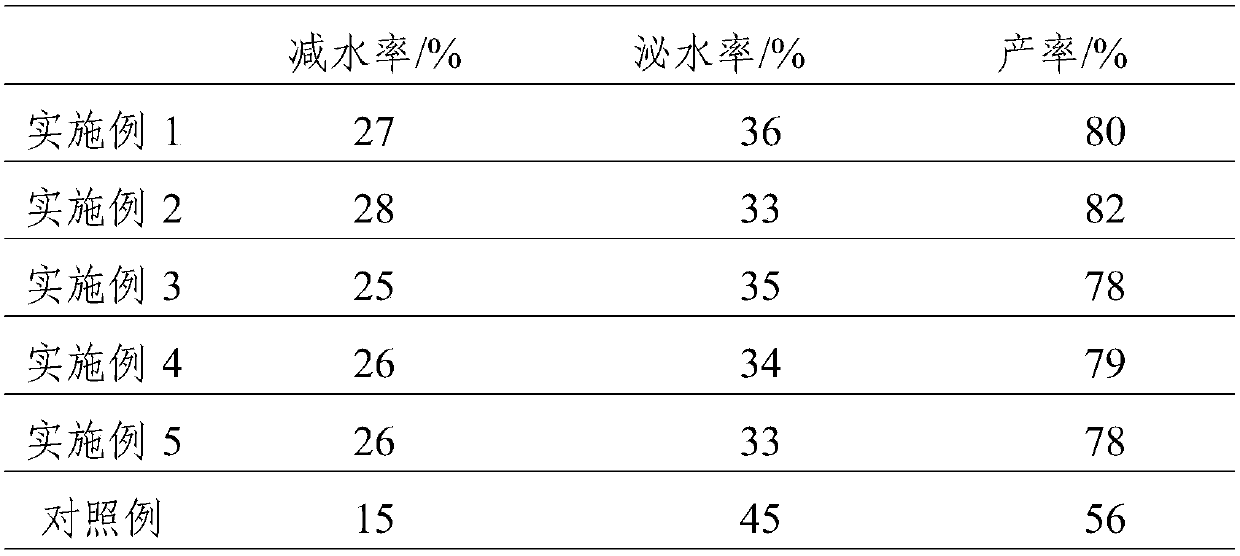

Examples

Embodiment 1

[0019] A polycarboxylate water reducer, the water reducer is made of the following raw materials in parts by weight: 35 parts of polyethylene glycol, 10 parts of methacrylic acid, 0.1 part of hydroquinone, 0.1 part of phenothiazine, ammonium persulfate 4 parts, 1 part of concentrated sulfuric acid, 1 part of calcium hydroxide, 1 part of lithium carbonate, 2 parts of sodium bisulfite, 0.5 part of sulfomethyl phenolic resin, 0.5 part of fulvic acid, appropriate amount of water.

[0020] The preparation method of this water reducer comprises the following steps:

[0021] (1) Put polyethylene glycol in the reaction pot, dissolve it under water bath conditions, add methacrylic acid, hydroquinone and phenothiazine into the reaction pot, raise the temperature to 90°C, and add concentrated sulfuric acid under the condition of stirring , continue to heat up to 120°C, keep warm for 4h, and fill with nitrogen for 2h to obtain macromonomer polyethylene glycol monomethacrylate;

[0022] (...

Embodiment 2

[0025] A polycarboxylate water reducer, the water reducer is made of the following raw materials in parts by weight: 40 parts of polyethylene glycol, 15 parts of methacrylic acid, 1 part of hydroquinone, 0.5 parts of phenothiazine, ammonium persulfate 9 parts, 5 parts of concentrated sulfuric acid, 20 parts of calcium hydroxide, 7 parts of lithium carbonate, 5 parts of sodium bisulfite, 1.5 parts of sulfomethyl phenolic resin, 1 part of fulvic acid, appropriate amount of water.

[0026] The preparation method of this water reducer comprises the following steps:

[0027] (1) Put polyethylene glycol in the reaction pot, melt it under the condition of water bath, add methacrylic acid, hydroquinone and phenothiazine into the reaction pot, raise the temperature to 95°C, add concentrated sulfuric acid under the condition of stirring , continue to heat up to 125 ° C, keep warm for 5 hours, and fill with nitrogen for 2 hours to obtain macromonomer polyethylene glycol monomethacrylate;...

Embodiment 3

[0031] A polycarboxylate water reducer, the water reducer is made of the following raw materials in parts by weight: 36 parts of polyethylene glycol, 11 parts of methacrylic acid, 0.2 parts of hydroquinone, 0.2 parts of phenothiazine, ammonium persulfate 5 parts, 2 parts of concentrated sulfuric acid, 2 parts of calcium hydroxide, 2 parts of lithium carbonate, 3 parts of sodium bisulfite, 0.8 parts of sulfomethyl phenolic resin, 0.8 parts of fulvic acid, appropriate amount of water.

[0032] The preparation method of this water reducer comprises the following steps:

[0033] (1) Put polyethylene glycol in the reaction pot, dissolve it under water bath conditions, add methacrylic acid, hydroquinone and phenothiazine into the reaction pot, raise the temperature to 90°C, and add concentrated sulfuric acid under the condition of stirring , continue to heat up to 120 ° C, keep warm for 4.5 hours, and fill with nitrogen for 2 hours to obtain macromonomer polyethylene glycol monometh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com