Patents

Literature

48results about How to "High hardening strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macromolecular adhesive cement

The invention relates to a cement-based self-leveling mortar, and more particularly relates to a macromolecular adhesive cement. The macromolecular adhesive cement comprises the components in parts by weight: 80-100 parts of water-borne epoxy resin, 16-20 parts of water-borne epoxy curing agent, 120-150 parts of complex portland cement, 30-50 parts of quartz silt powder, 10-15 parts of water, 35-50 parts of pigments and fillers, 0.3-0.5 parts of wetting dispersant, 2-6 parts of self-leveling additives, and 2-5 parts of water-borne color paste. The macromolecular adhesive cement disclosed by the invention is a single-component, dry-powder-shaped and water-borne self-leveling cement-based hard / soft type waterproof adhesion-blocking and leveling material which is processed via scientific proportioning, integrates the functions of water prevention, adhesion, blockage and leveling, as well as is non-toxic and odorless, and belongs to cement-based macromolecular polymer water-borne dry-powder waterproof mortars.

Owner:浙江西塘实业有限公司

Gypsum-base self-flatting ground making level material and preparation process thereof

A self-leveling gypsum-based floor-leveling material for building is proportionally prepared from natural anhydrous gypsum, alkaline exciter, acidic exciter, water preserving agent, water decreasing agent and defoamer through grinding anhydrous gypsum, premixing others, mixing the anhydrous gypsum powder with the premixture, and stirring.

Owner:安徽恒泰非金属材料科技有限责任公司

Whitewashing gypsum and preparing method thereof

The invention relates to a building brushing plaster and preparing method, including semiwater plaster and water retention agent, its character: also anhydrite powder and exciter is added to it, where wt% of each component: anhydrite powder 80-90, semwater plaster 3-13, exciter 1-7 and water retention agent 0.1-0.3. its preparing method: 1), milling natural anhydrite into powders by industrial ball mill, where the particle size is that the rest is less than 3% by 200 eye screen and the specific surface area is 4500-7000 sq cm / g; 2), preparing raw material: according to the demand, additionally adds in hydraulic cementitous material, which accounts for 0-15% of total weight; 3) weighing all the raw materials, mixing in the mixer to make the brushing plaster powder at once. The fine sand less than 5 mm can be added to mixed raw materials according to the demand to make the bushing substrate. It has water proofness.

Owner:WUHAN UNIV OF TECH +1

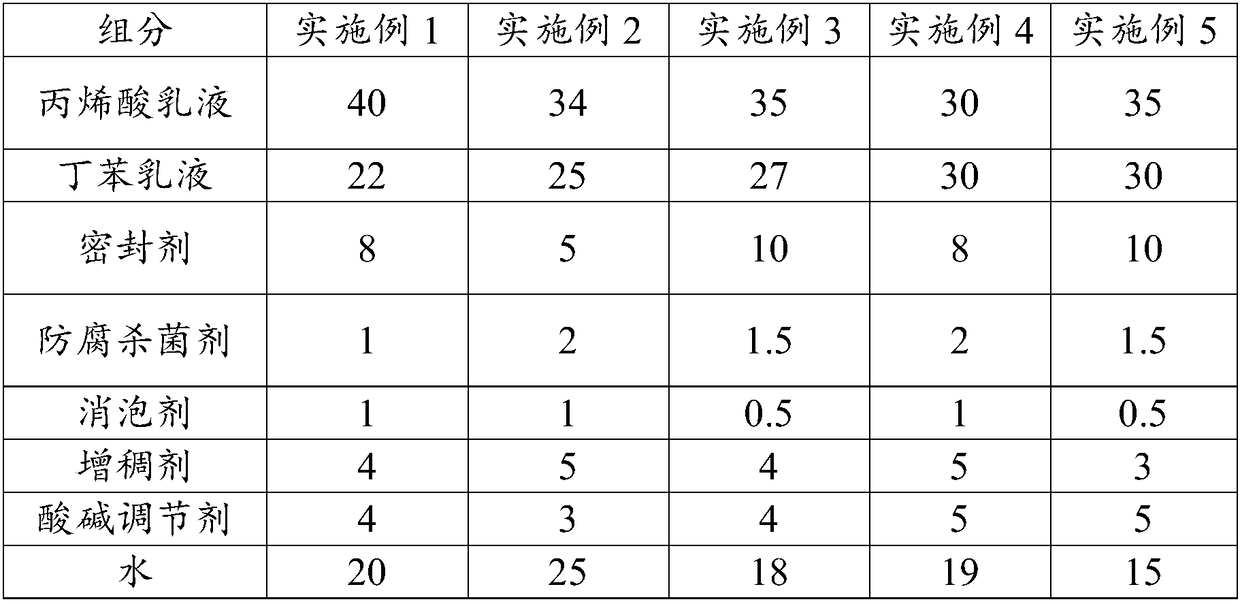

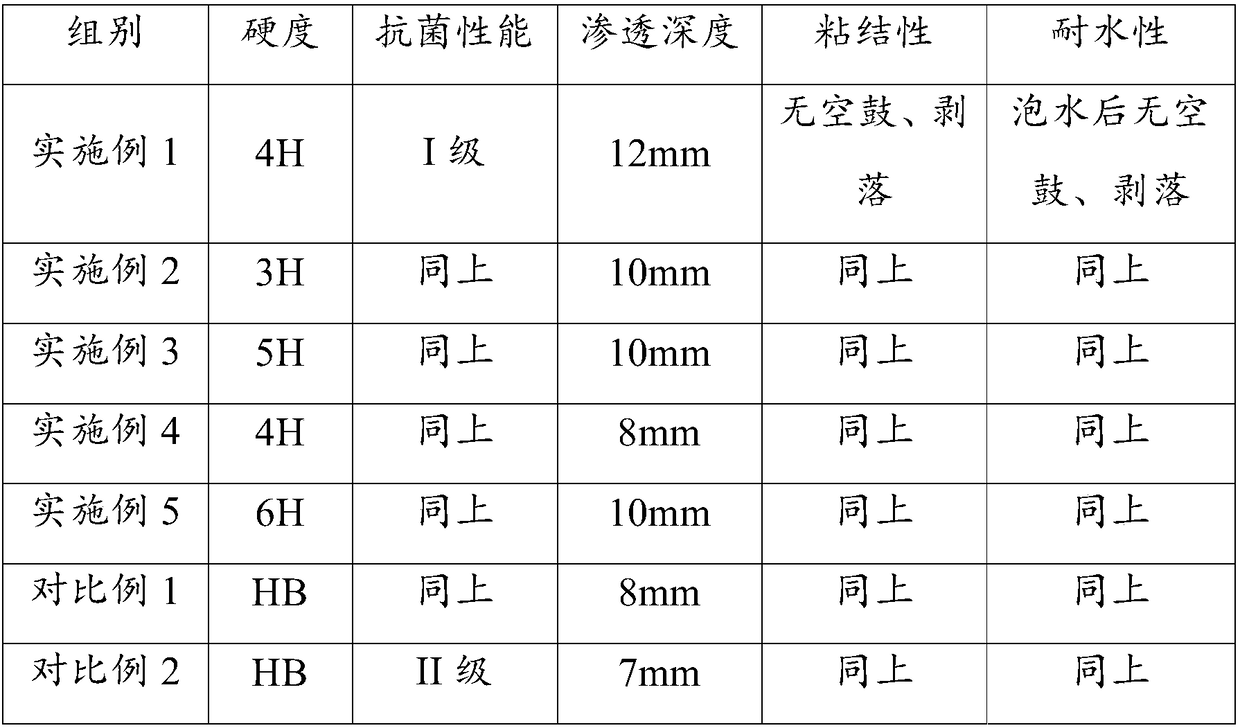

Multifunctional sealing and hardening prime coat, and preparation method and application thereof

ActiveCN108587354AImprove permeabilityImprove wettabilityAntifouling/underwater paintsConjugated diene hydrocarbon coatingsEnvironmental resistancePorosity

The invention provides a multifunctional sealing and hardening prime coat, and a preparation method and application thereof, and relates to the technical field of building operations. The multifunctional sealing and hardening prime coat mainly comprises acrylic emulsion, butylbenzene emulsion, sealants, anticorrosive bactericide, deforming agents, thickeners, acid-base regulators and water. The prime coat can have ultrahigh permeability and excellent wettability through the acrylic emulsion; bonding strength of the prime coat and a base layer can be improved through the butylbenzene emulsion;hardness of a prime coat layer can be enhanced through the sealants; bacteria growth in the prime coat can be inhibited effectively through the anticorrosive bactericide; the acid-base regulators canbe used for regulating system pH values within a required range. The multifunctional sealing and hardening prime coat obtained by compounding the components has the advantages of ultrahigh permeability, high hardness, high sealing performance, environment protection and the like, and can be widely applied to sealing and hardening treatment of high-porosity materials, concrete, wood base layers andstone surface layers.

Owner:GOLD MANTIS CONSTR DECORATION

Natural anhydrite based lightweight interior wall plastering gypsum material and preparation method thereof

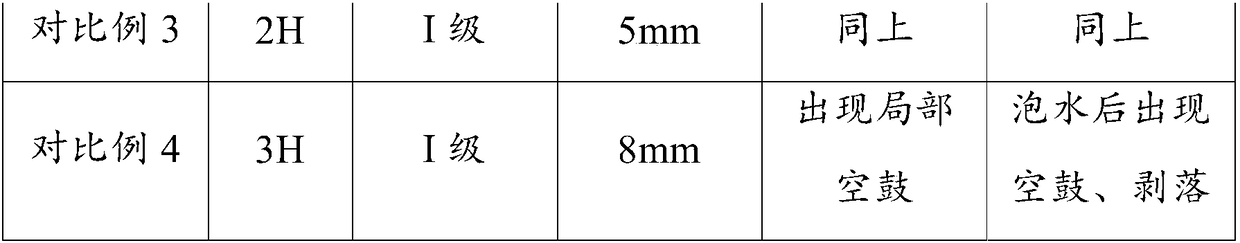

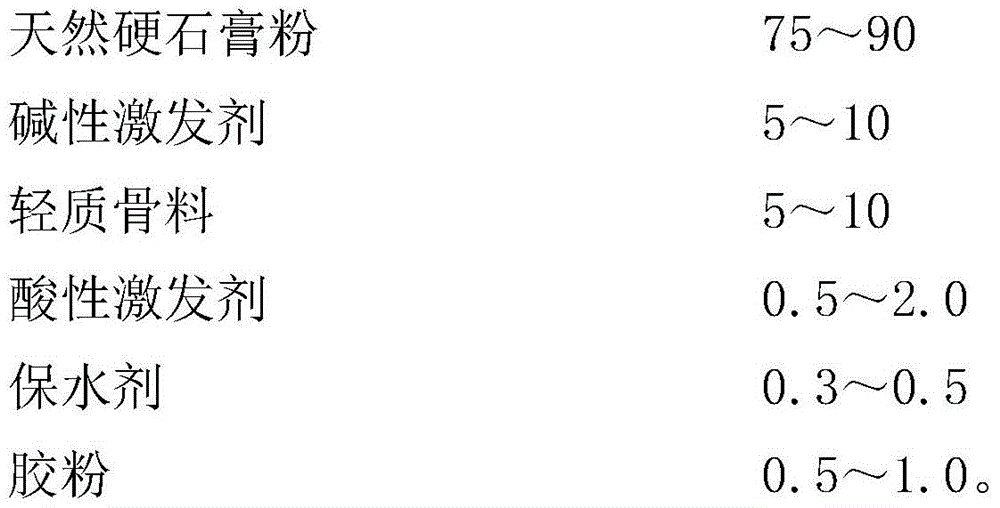

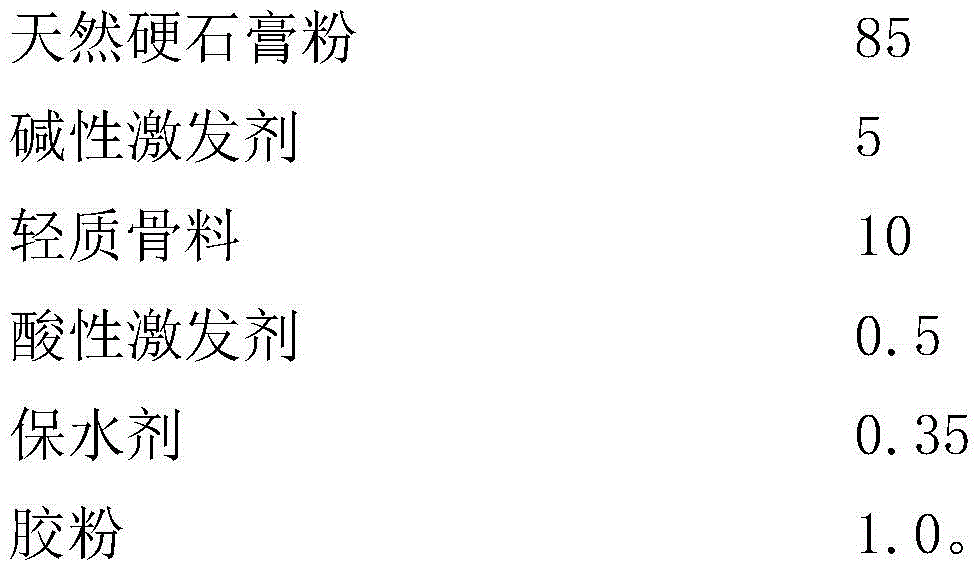

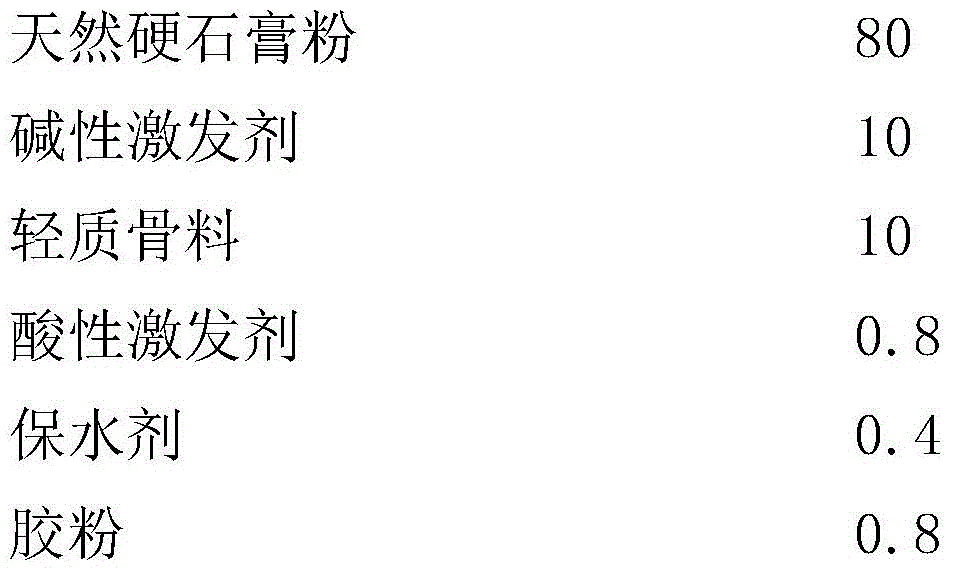

The invention discloses a natural anhydrite based lightweight interior wall plastering gypsum material used in the field of construction, and a preparation method thereof. The natural anhydrite based lightweight interior wall plastering gypsum material is prepared from the following components in percentage by weight: 75-85% of natural gypsum powder, 5-10% of alkali activator, 5-10% of lightweight aggregate, 0.5-2.0% of acidic activator, 0.3-0.5% of water-retaining agent and 0.50-1.0% of cement powder. The preparation method of the natural anhydrite based lightweight interior wall plastering gypsum material comprises the following steps: weighing well-ground gypsum powder based on the weight percentage according to claim 1; uniformly mixing the gypsum powder in a mixer to obtain the natural anhydrite based lightweight interior wall plastering gypsum material. The natural anhydrite based lightweight interior wall plastering gypsum material disclosed by the invention has the advantages of good stability, water-retaining capacity, sagging capacity, large unit plastering area, light weight, heat preservation, good adhesive performance, firm adhesiveness, slight expansibility, convenience for construction, and capabilities of greatly enhancing the adhesiveness between the product and a base material, avoiding undesirable effects such as cracks and realizing both manual construction and mechanized construction.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

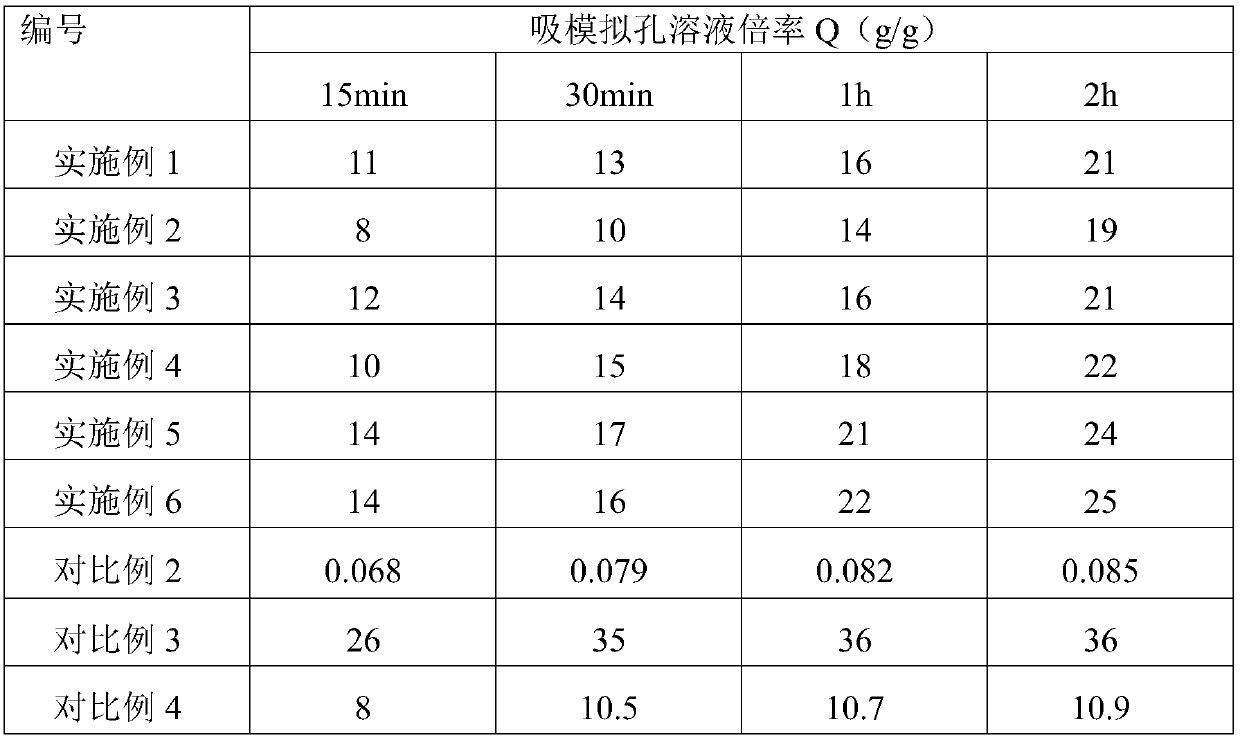

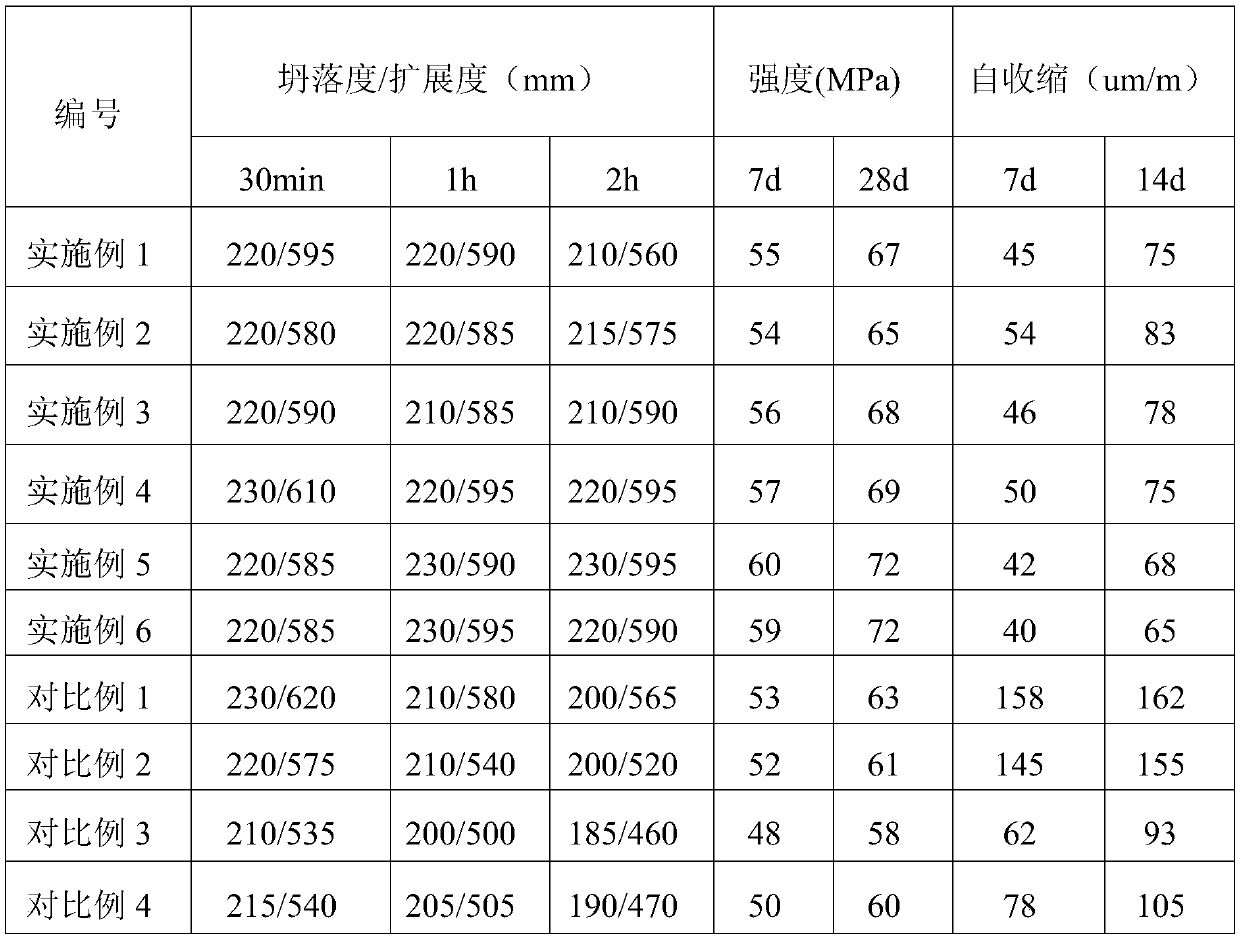

Curing agent in ceramsite carrier concrete and preparation method thereof

ActiveCN109516714AImprove water absorptionEasy to cause loss of work performanceExpanded clay aggregateAbsorption rate

The invention discloses a curing agent in ceramsite carrier concrete. A preparation method of the curing agent comprises the following steps that an acrylic acid solution, 2-acrylamide-2-methacrylic acid, initiators and crosslinking agents are uniformly mixed to prepare a reaction solution a; an etherificated sodium alginate solution, an acrylamide solution, initiators and crosslinking agents areuniformly mixed to prepare a reaction solution b; ceramsite is sequentially soaked in the reaction solution a and the reaction solution b, and is sequentially subjected to microwave treatment. Firstly, the ceramsite is used as a carrier; the polymerization of water absorption resin is performed inside and outside the ceramsite; meanwhile, a hole-inside hole-outside two-step method is used; the building of polymers with different water absorption rates inside and outside holes is realized; the prepared curing agent in the ceramsite carrier concrete can greatly improve the humidity inside the concrete; the early-period reduction and shrinkage effect of the concrete is obvious; meanwhile, the curing agent in the ceramsite carrier concrete has the advantages that the water absorption and waterrelease rate is slow; the use performance such as concrete strength is favorably guaranteed; important application and promotion values are realized.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

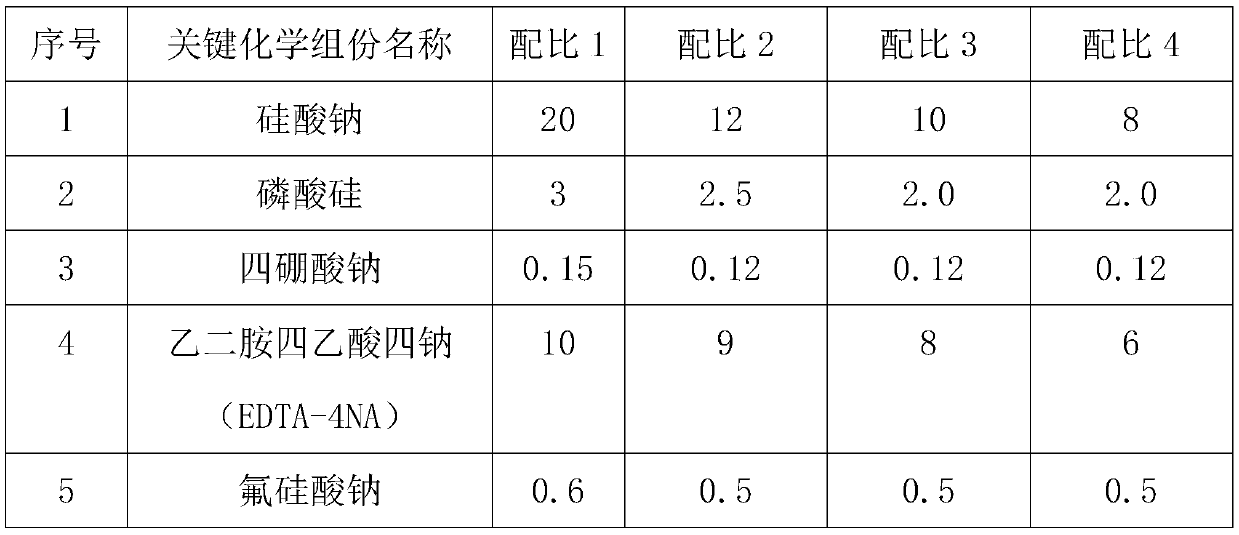

Water glass sand hardener

InactiveCN101941043ASlow down the rate of hydrolysisHigh strengthFoundry mouldsFoundry coresPhosphoric acidChemistry

The invention discloses a water glass sand hardener which is composed of the following components in percentage by weight: 20-80% of organic ester, 6-24% of phosphoric acid with the mass concentration of 80%, 2-8% of soluble acid phosphate, 1-4% of urea and 11-44% of water. The preparation method is as follows: mixing and dissolving the soluble acid phosphate and the urea into the water to form a solution; and evenly mixing with the phosphoric acid and the organic ester to obtain the water glass sand hardener. The water glass sand hardener of the invention has the advantages of convenient use, good hardening effect, low cost and controllable hardening speed, can obviously lower the water glass addition and obviously improves the moulding sand collapsibility.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Gypsum-based internal heat insulation material

ActiveCN102503342AReduce pollutionReduce consumptionSolid waste disposalUltimate tensile strengthPollution

The invention discloses a gypsum-based internal heat insulation material, which comprises, by weight, 80-90 parts of desulfurized gypsum powder, 6-10 parts of vitrified small balls, 4-6 parts of polyphenyl particles, 0.2-0.5 part of water-retaining agent, 0.1-0.4 part of retarder and 0.2-0.5 part of exciting agent. The gypsum-based internal heat insulation material has the advantages of high hardening strength, high water resistance and proper setting time, and requires no grinding but mixing. The gypsum-based internal heat insulation material is energy-saving, pollution-reducing and low in additive usage, so that production cost can be reduced.

Owner:安徽省恒泰新材料有限公司

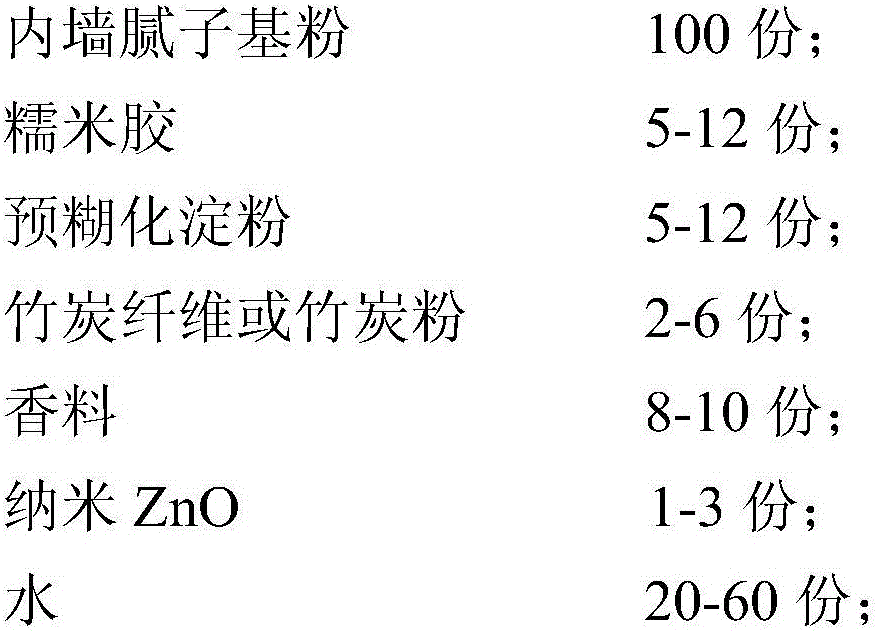

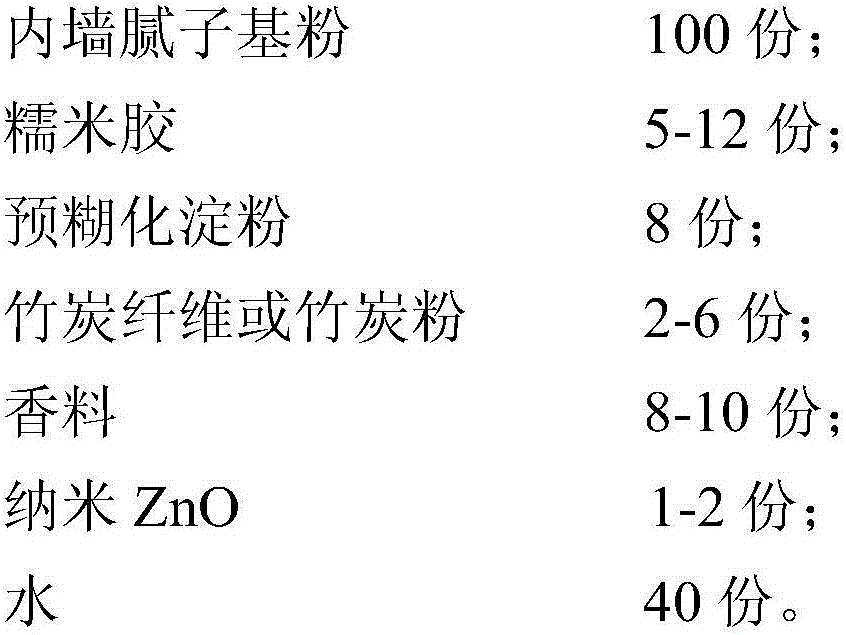

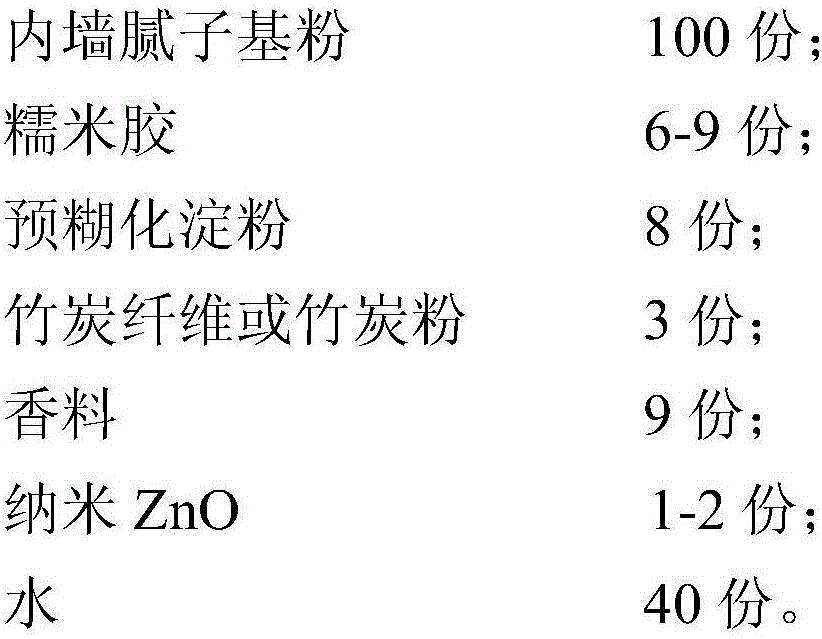

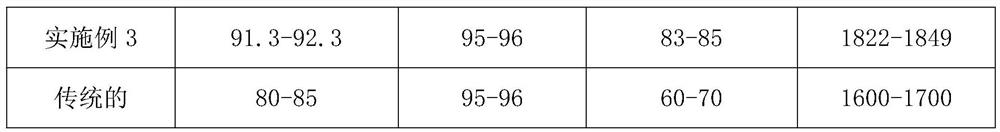

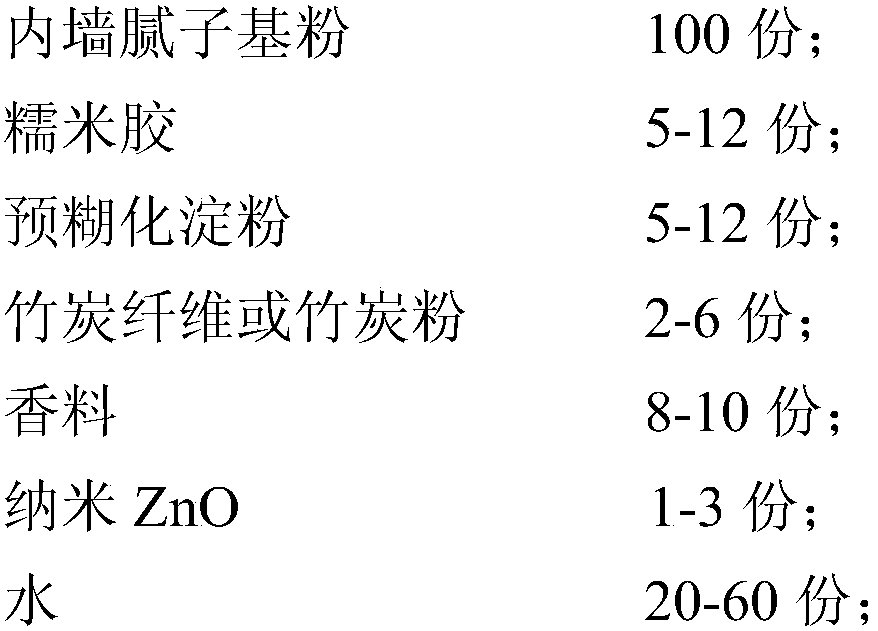

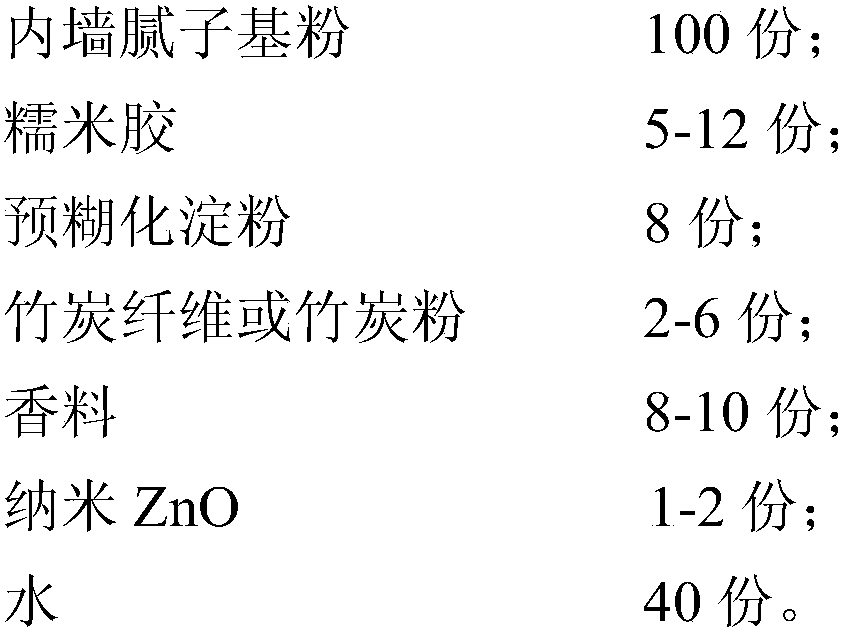

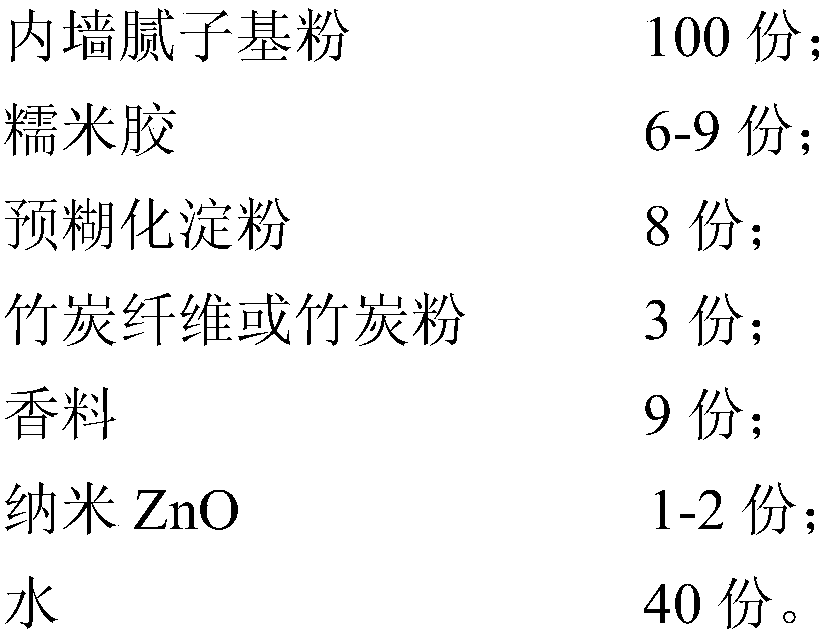

Environment-friendly interior wall putty and preparation method thereof

ActiveCN105778607AImprove crack resistanceHigh hardening strengthFilling pastesCarbon fibersCrack resistance

The invention discloses environment-friendly interior wall putty. The environment-friendly interior wall putty comprises the following components in parts by weight: 100 parts of interior wall putty base powder, 5-12 parts of sticky rice glue, 5-12 parts of pregelatinized starch, 2-6 parts of bamboo carbon fibers or bamboo carbon powder, 8-10 parts of spices, 1-3 parts of nano ZnO, and 20-60 parts of water. The interior wall putty base powder comprises ground calcium carbonate, ash calcium and white cement; the length of the bamboo carbon fibers is 0.5-5 millimeters, and the diameter of the bamboo carbon fibers is 10-20 microns; the fineness of the bamboo carbon powder is 200-300 meshes; and the diameter of the nano ZnO is 10-20 nanometers. The invention further discloses a method for preparing the environment-friendly interior wall putty. The materials are matched cooperatively in proportion, so that the crack resistance, the hardening strength, the compactness, the mildew prevention, the bacteria resistance and the probiotics environment friendliness of the environment-friendly interior wall putty can be remarkably improved.

Owner:ZHEJIANG HUMANITIES LANDSCAPE CO LTD

Energy-saving type impervious waterproof building concrete and preparation method thereof

The invention discloses an energy-saving type impervious waterproof building concrete and a preparation method thereof. The raw materials comprise, by weight part, 68-75 of Portland cement, 23-25 of black soil powder, 12-15 of graphite powder, 8-10 of aluminum nitride powder, 3-4 of iron oxide red powder, 10-15 of a mushrooms cultivation material, 0.4-0.6 of tetramethyl guanidine, 2-4 of calcium stearate, 1.5-2.0 of sodium tripolyphosphate, 0.8-1.0 of sodium tartrate, 1.2-1.5 of amino sulfonic acid, 2-4 of a milky white glue, 4-5 of zinc chloride, 1.0-1.5 of sodium alginate and a proper amount of water. The concrete provided by the invention has the characteristics of high hardening strength, good water resistance, impermeability and watertightness, and suitable setting time. The concrete provided by the invention adopts a variety of waste materials as the raw materials, saves energy, reduces pollution, and has small dosage of additives, thus reducing the production cost.

Owner:青阳县天工预拌商品砂浆有限公司

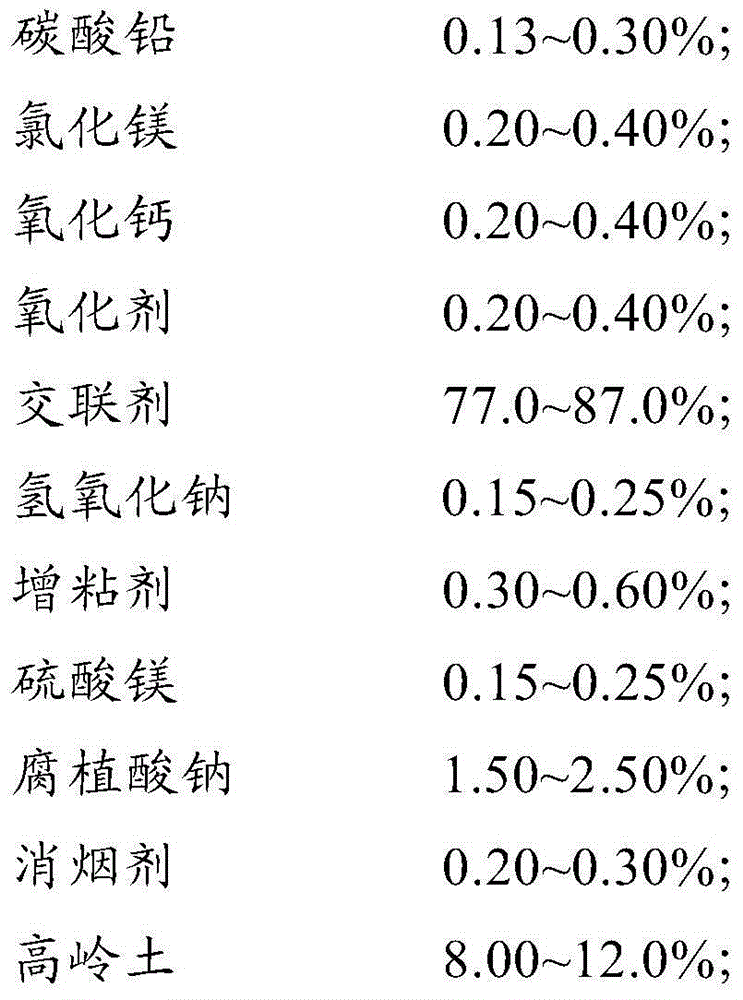

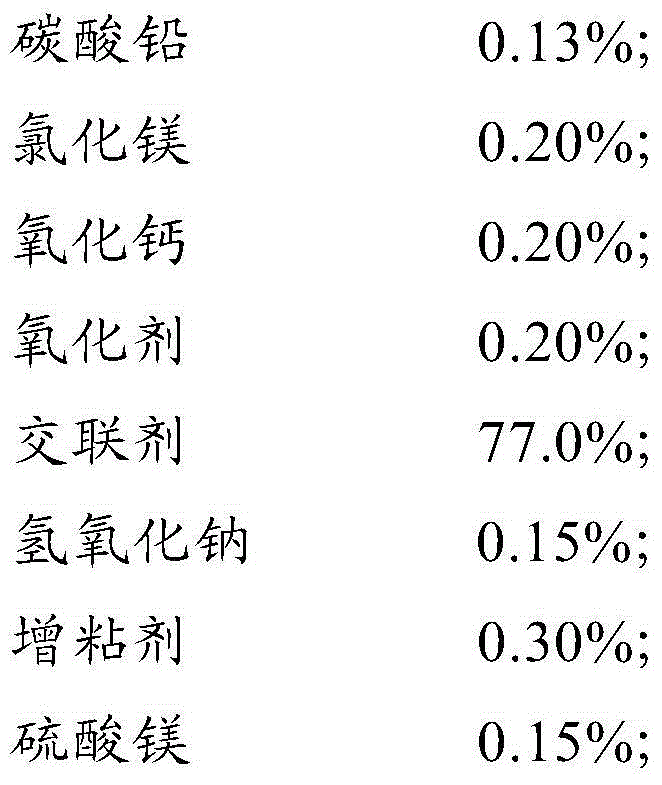

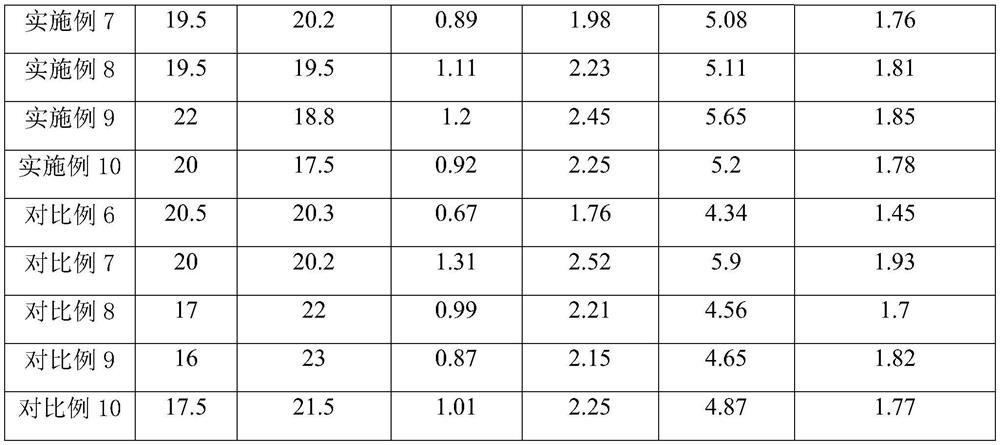

Cleaning briquette coal binder

The invention discloses a cleaning briquette coal binder. The binder comprises the following raw materials: 0.13-0.30% of lead carbonate, 0.20-0.40% of magnesium chloride, 0.20-0.40% of calcium oxide, 0.20-0.40% of an oxidizing agent, 77.0-87.0% of a crosslinking agent, 0.15%-0.25% of sodium hydroxide, 0.30-0.60% of a tackifier, 0.15%-0.25% of magnesium sulfate, 1.50-2.50% of sodium humate, 0.20-0.30% of a smoke suppressant and 8.00-12.0% of kaolin. The briquette coal binder disclosed by the invention has the effects of suppressing smoke, preventing moisture, reducing dust, fixing sulfur, inhibiting nitrogen and the like, and is developed in line with the national situation of energy conservation, emission reduction and haze treatment according to China coal energy actual application and the characteristics of the haze formation cause in recent years; the binder has prominent energy conservation and emission reduction effects and an oxidative combustion-promoting effect; and since the binder is fully burnt, the energy conservation effect is achieved.

Owner:李晓雷

Ointment pumping filler material for mine roadway support and preparation

ActiveCN101486556APotential hydration activityHigh hardening strengthSolid waste managementFilling materialsMarket competition

The invention discloses a plaster pumping filling material used for supporting mine enby left and a preparation method thereof. At first, natural anhydrite is grinded by an industrial globe mill, the fineness is controlled to be less than 1 percent in the weight of screen residue of 200 meshes, and the specific surface is between 4000 and 5000cm / g; then 0.03 to 0.08 percent of air entraining agent, 0.5 to 1.0 percent of excitant, 1.5 to 2.5 percent of early strength admixture, 0.40 to 1.2 percent of accelerating agent as well as 0.5 to 1.0 percent of water reducing agent are mixed, and then uniformly mixed with 15 to 18 percent of natural anhydrite, 15 to 25 percent of cement, 18 to 25 percent of fly ash, 20 to 25 percent of stones as well as 20 to 25 percent of river sand in a batch mixer to obtain the plaster pumping filling material used for supporting mine enby left. The invention does not need calcining and grinding during production, and can save energies and reduce pollution; moreover, as the dosage of the water reducing agent is reduced, the production cost is reduced, and the market competition is improved, thus greatly promoting the technical development for future mine production; the production technique is simple; mechanical pumping is employed for construction; the invention is simple to be operated and brings more guarantee for the safe production of the mine.

Owner:安徽省恒泰新材料有限公司

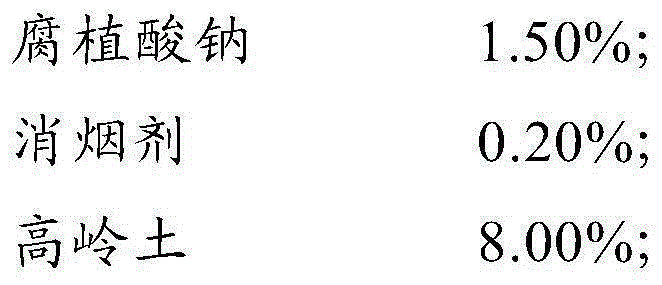

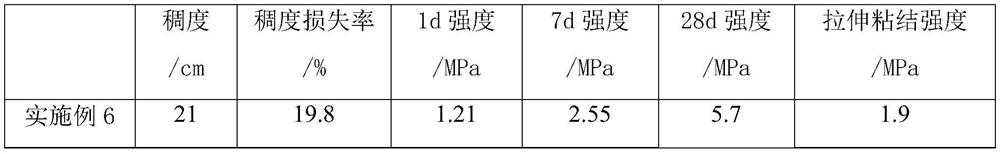

Anhydrite-based light plastering mortar and preparation method thereof

ActiveCN111410502ALow hardening strengthHigh hardening strengthSolid waste managementMining engineeringMaterials science

The invention discloses anhydrite-based light plastering mortar and a preparation method thereof. The anhydrite-based light plastering mortar which is light, energy-saving, good in comprehensive performance and simple in process and is prepared by taking anhydrite as a main material is researched and developed, and the anhydrite-based light plastering mortar has important practical significance. The anhydrite-based light plastering mortar is composed of anhydrite, cement, fly ash, an excitant, vitrified microbead, a thickening agent and a water-retaining agent. The concrete is composed of thefollowing components in parts by weight: 65-70 parts of the anhydrite, 8-10 parts of the cement, 4-8 parts of the fly ash, 4-6 parts of the excitant, 0.15-0.2 parts of the water-retaining agent, 0.1-0.15 part of the thickening agent, and 13-16 parts of vitrified microbead. The anhydrite-based light plastering mortar is prepared by adopting anhydrite associated in a pyrite production process as a main material, calcination treatment is not needed, only physical grinding and mixing are needed, the preparation process is simple, energy is saved, and pollution is reduced; and the problems of hollowing and cracking of the traditional mortar are fundamentally solved.

Owner:安徽合信大环保科技有限公司

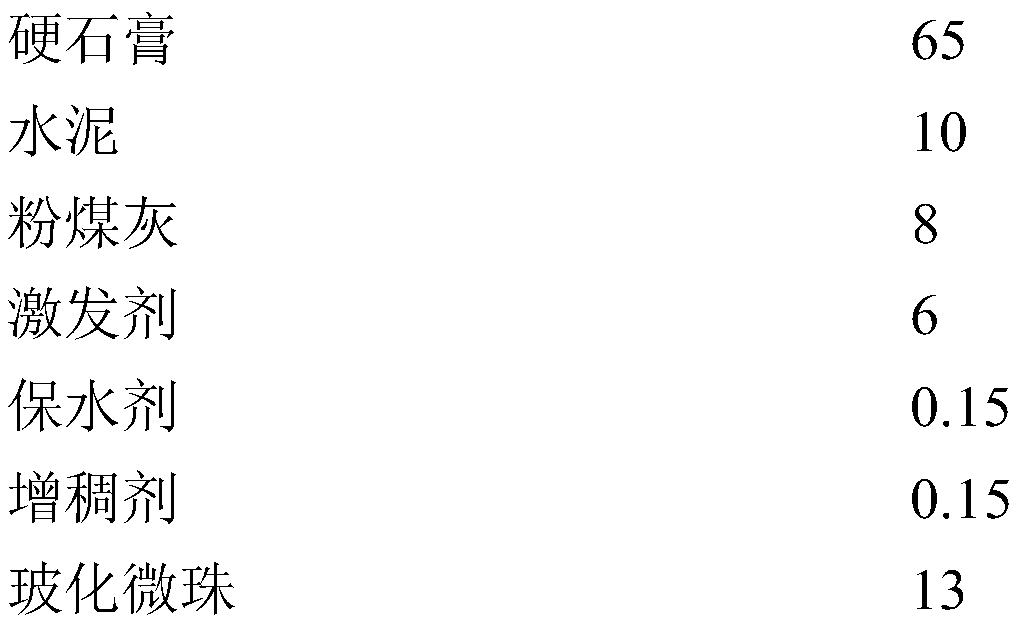

Production method of water-based capillary crystalline waterproof material convenient to produce and use

The invention discloses a production method of a water-based capillary crystalline waterproof material convenient to produce and use. An additive comprises the following components: 30 parts of a gelmaterial, 16.7 parts of a crystallization accelerator, 0.12 part of an additive, 3 parts of a cement molecule secondary reactant, 0.07 part of an anti-freezing agent, 0.15 part of a metal ion complexing agent, 0.4 part of a curing agent, 1 part of a hydrophobic agent and 48.56 parts of a diluent. The materials of the components are subjected to burdening, stirring, mixing and filtering to obtain the water-based capillary crystalline waterproof material. The invention discloses a production method of a water-based capillary crystalline waterproof material convenient to produce and use. Jelly-shaped crystals and sulphoaluminate, silicate and the like participating in the reaction thoroughly form crystals under the action of sodium fluosilicate; in addition, in order to ensure that enough waterproof agents permeate into a concrete base layer, the reaction speed needs to be controlled, flocculent crystals are prevented from appearing too early, so that a metal ion complexing agent needs tobe used for delaying the reaction speed.

Owner:苏州鼎益建筑科技有限公司

Method for producing casting cold-box resin

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

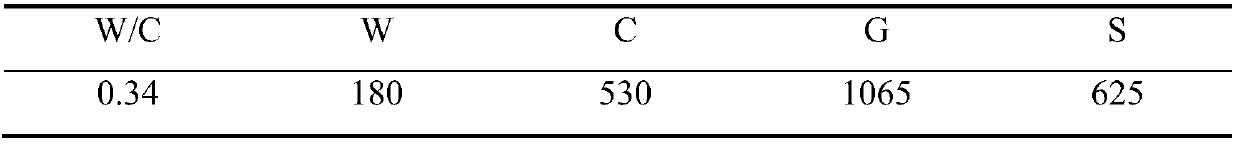

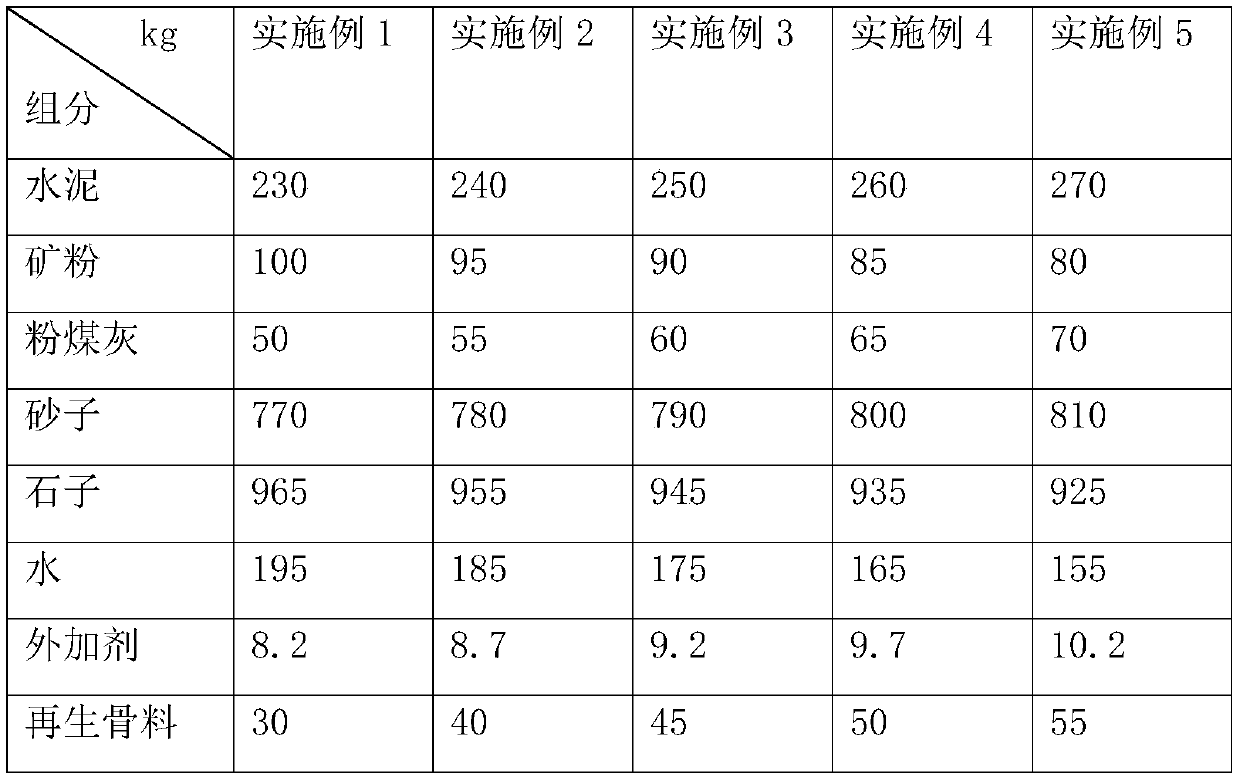

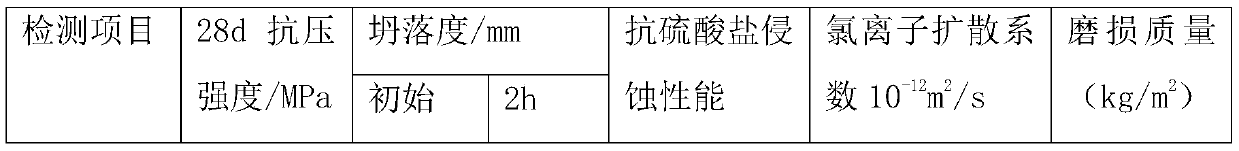

C30 regenerated aggregate concrete and preparation method thereof

InactiveCN110937865APromote environmental protectionPromote \"greening\"Solid waste managementCompressive resistanceRed mud

The invention discloses a C30 regenerated aggregate concrete and a preparation method thereof. The C30 regenerated aggregate concrete includes the following components: cement, mineral powder, fly ash, sand, cobble, water, an additive, and regenerated aggregate comprising activated iron tailing and waste slurry by the mass ratio of 1:0.3-0.6. The activated iron tailing is prepared through steps of: 1) drying iron tailing sand and red mud at 100-110 DEG C for 2-2.5 h; 2) adding sodium silicate and diatomite to the iron tailing sand and red mud, wet-milling the mixture for 10-20 min, drying themixture, calcining the mixture at 600-700 DEG C for 1-2 h, dry-milling the mixture for 10-15 min, and screening the mixture through a 200-mesh sieve to prepare the activated iron tailing. The C30 regenerated aggregate concrete is high in compressive strength, can reduce environmental pollution of the iron tailing and concrete waste slurry, saves resources and protects environment.

Owner:青岛汇鑫混凝土有限公司

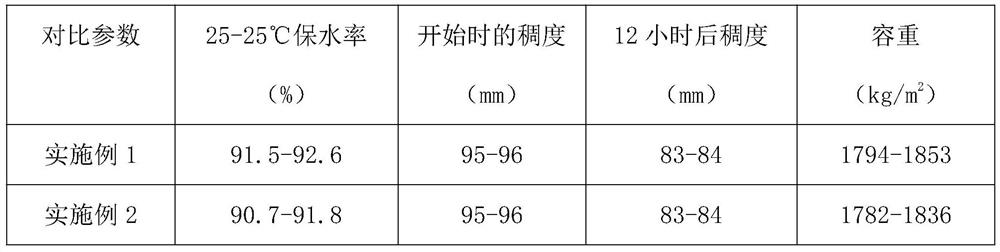

High-adaptability wet-mixed mortar additive and manufacturing process thereof

The invention relates to the technical field of building materials, in particular to a high-adaptability wet-mixed mortar additive and a manufacturing process thereof, and the high-adaptability wet-mixed mortar additive is prepared from the following raw materials in parts by weight: 12-15 parts of a thickening agent, 5-8 parts of an air entraining agent, 10-15 parts of a water reducing agent, 10-12 parts of a water-retaining agent, 10-15 parts of a retarder, 8-12 parts of an anti-cracking agent, 4-6 parts of a foam stabilizer and 70-100 parts of water. The additive is reasonable in proportion, simple and convenient in preparation process, high in water retention rate and large in volume weight, the prepared additive is used in mortar to effectively improve the hardening strength of wet-mixed mortar, the adopted water-retaining agent can enable the wet-mixed mortar to still have very good water retention at high temperature, the addition amount can be increased, pumping is convenient when the additive is added into the wet-mixed mortar, the precision of the liquid mortar consistency regulator is easier to control in production, and corresponding adjustment is easier to make according to environmental factors.

Owner:HUNAN ZHENXING BUILDING MATERIALS TECH

A kind of environment-friendly interior wall putty and preparation method thereof

ActiveCN105778607BImprove crack resistanceHigh hardening strengthFilling pastesCrack resistanceCarbon fibers

The invention discloses environment-friendly interior wall putty. The environment-friendly interior wall putty comprises the following components in parts by weight: 100 parts of interior wall putty base powder, 5-12 parts of sticky rice glue, 5-12 parts of pregelatinized starch, 2-6 parts of bamboo carbon fibers or bamboo carbon powder, 8-10 parts of spices, 1-3 parts of nano ZnO, and 20-60 parts of water. The interior wall putty base powder comprises ground calcium carbonate, ash calcium and white cement; the length of the bamboo carbon fibers is 0.5-5 millimeters, and the diameter of the bamboo carbon fibers is 10-20 microns; the fineness of the bamboo carbon powder is 200-300 meshes; and the diameter of the nano ZnO is 10-20 nanometers. The invention further discloses a method for preparing the environment-friendly interior wall putty. The materials are matched cooperatively in proportion, so that the crack resistance, the hardening strength, the compactness, the mildew prevention, the bacteria resistance and the probiotics environment friendliness of the environment-friendly interior wall putty can be remarkably improved.

Owner:ZHEJIANG HUMANITIES LANDSCAPE CO LTD

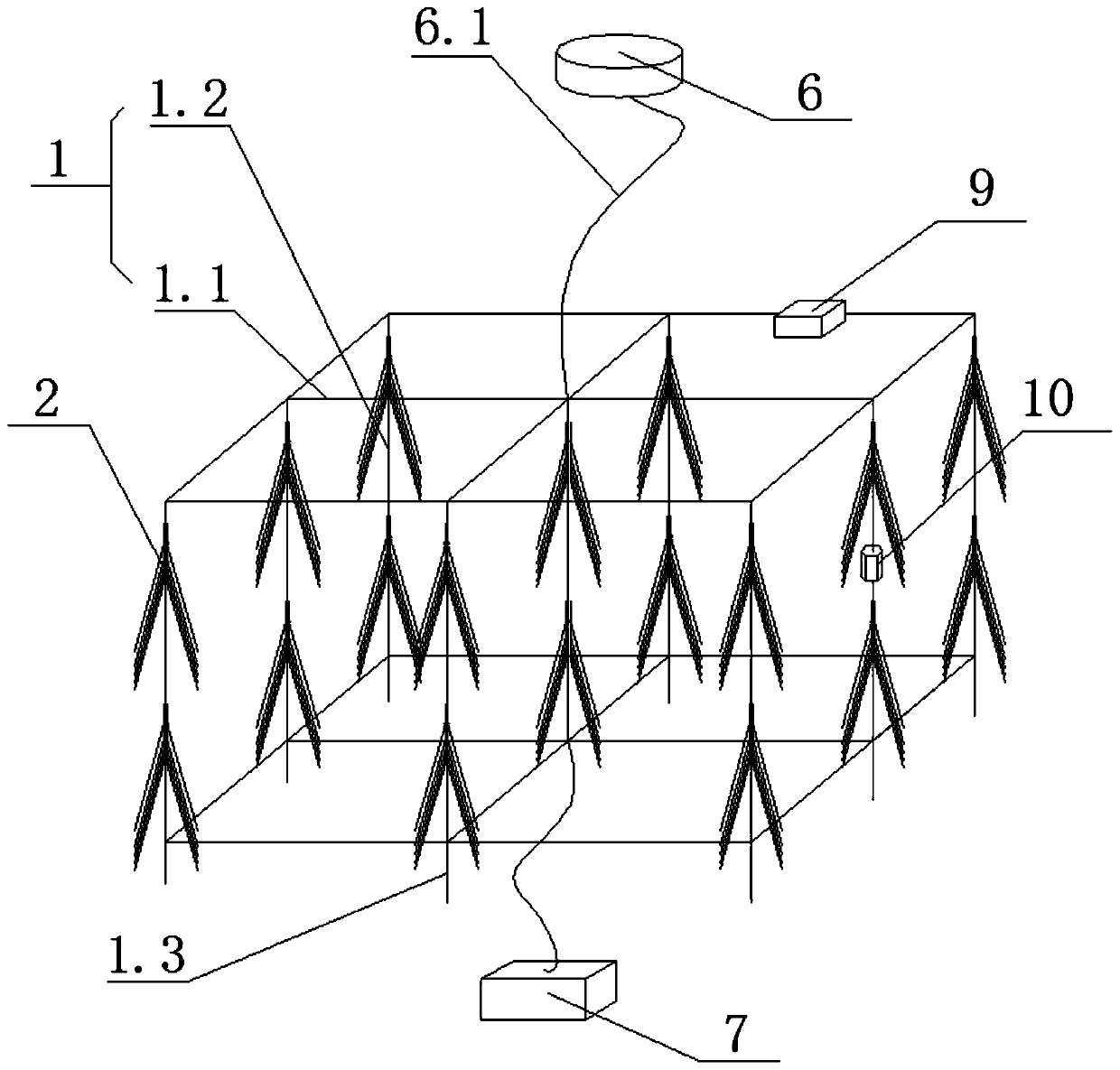

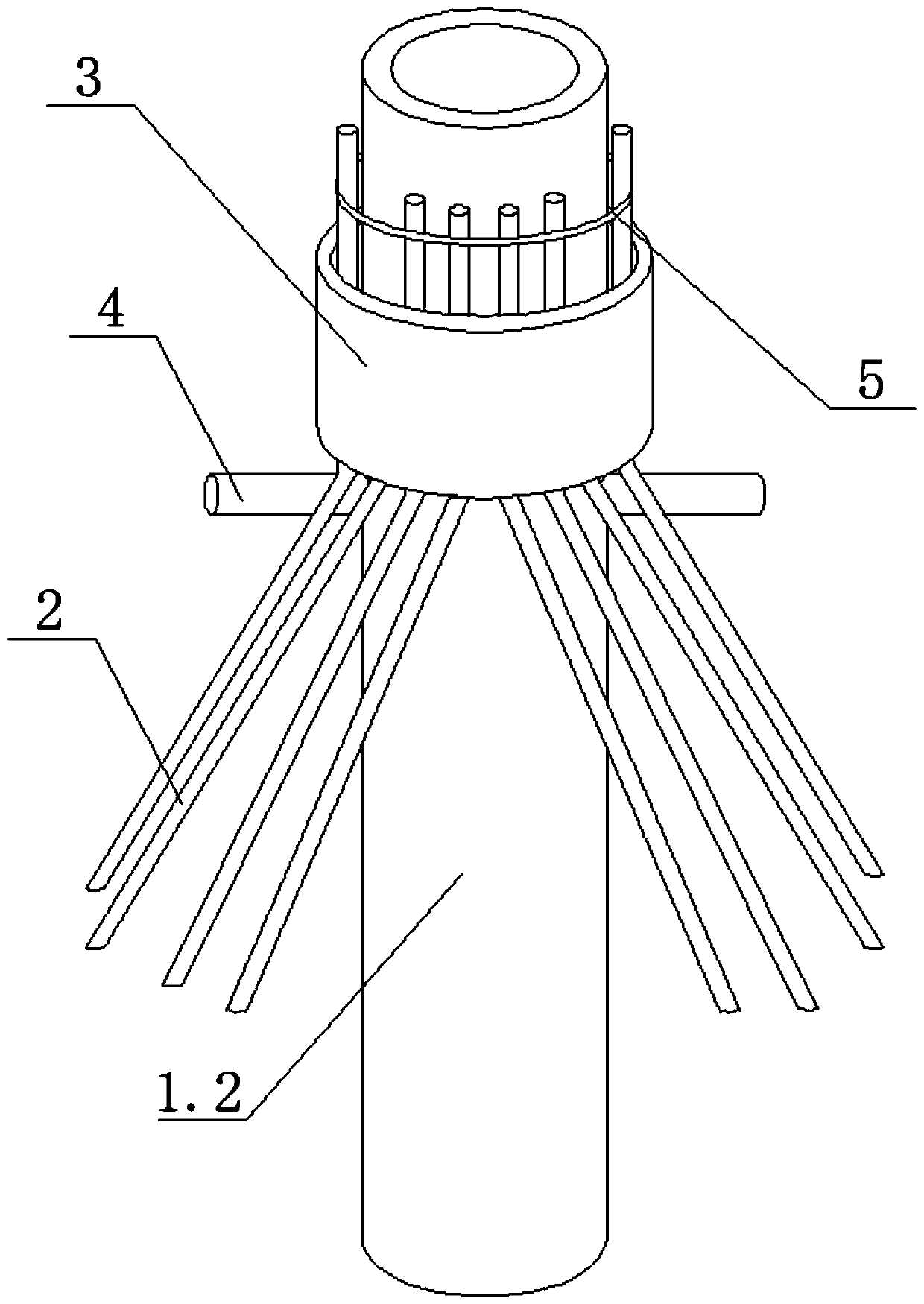

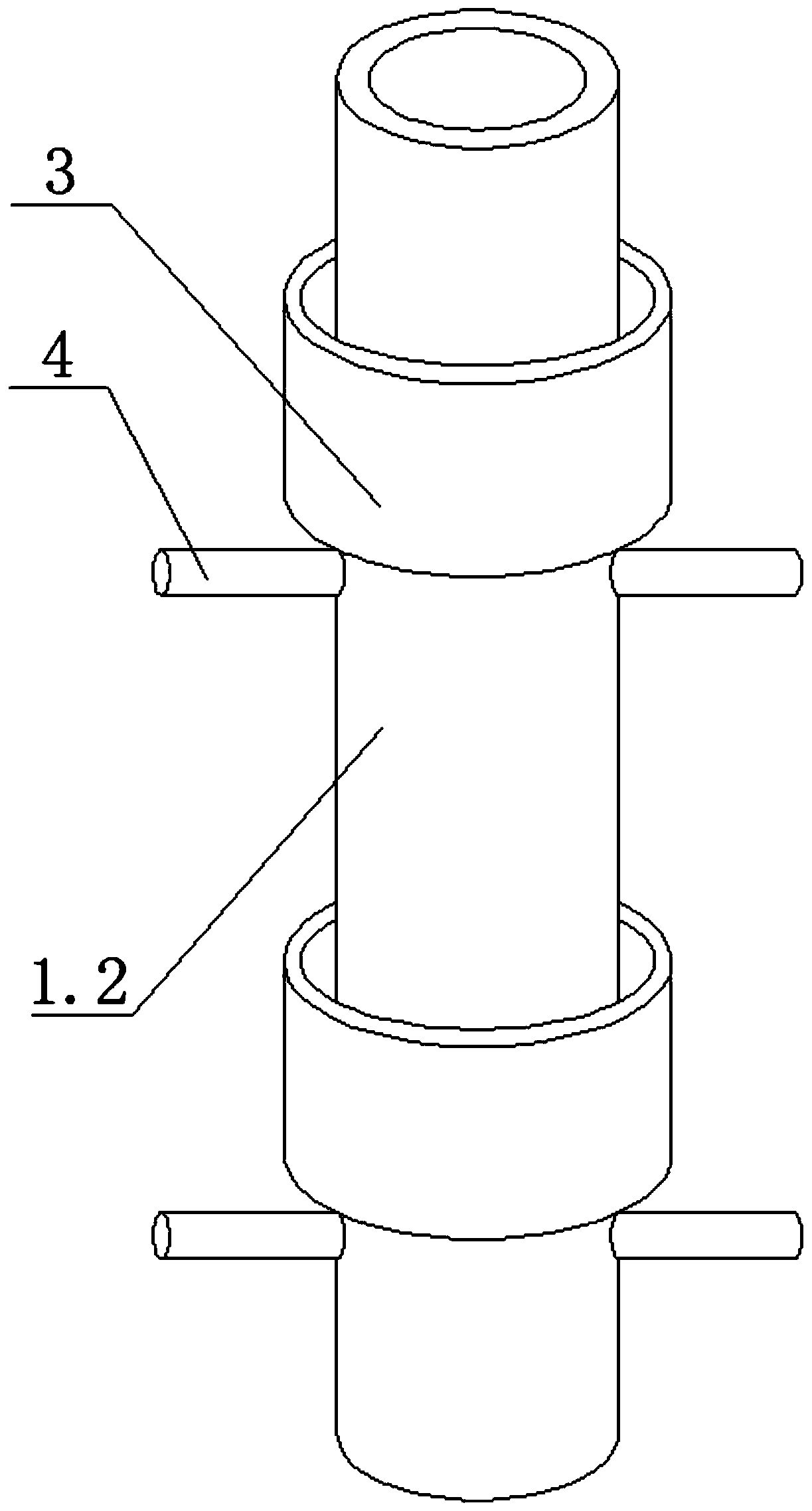

Straw fish shelter and preparing method thereof

PendingCN110250067AImprove corrosion resistanceImprove crack resistanceClimate change adaptationReed/straw treatmentContact timeEngineering

The invention discloses a straw fish shelter and a preparing method thereof. The fish shelter comprises a frame and straw arranged on the frame. The frame comprises a cuboid or cubic frame body. The frame body is composed of a plurality of beams and stand columns perpendicularly connected with one another. The straw is rolled on the stand columns. Each stand column is provided with multiple bundles of straw sequentially arrayed in the length direction of the stand column. One end of each bundle of straw is bound to the corresponding stand column, and the other end of the bundle of straw is naturally dispersed around. The nutrients and effective area of the straw are sufficiently used; since one end of each bundle of straw is dispersed in space, the occupied space is large, more algae and shells can be attached, and the unit benefits are improved; meanwhile, due to the structure, the ocean current of an ocean can be changed, the flow velocity of the ocean is reduced in the structure, and therefore the contact time between the fish shelter and the straw is prolonged, and the fish shelter is low in weight, simple in structure and easy to repair.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

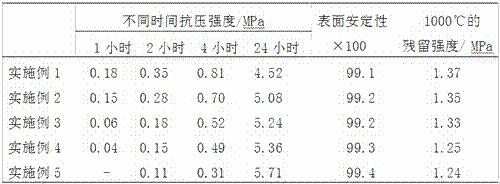

Innerlining damage small repair material recipe for aluminum electrolytic bath

The present invention relates to refractory material, and is especially recipe of material for minor repairing the damaged cathode lining of aluminum electrolytic bath. The recipe of the repair material consists of anhydrous magnesium chloride, light magnesium oxide and magnesia in the weight ratio of 1 to 2 to 3. All the anhydrous magnesium chloride, light magnesium oxide and magnesia are mixed to form the magnesia concrete.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Molding sand proportioning technology for producing large supercritical casting steel

InactiveCN102861865AImprove liquidityHigh hardening strengthFoundry mouldsFoundry coresUltimate tensile strengthMolding sand

The invention relates to a molding sand proportioning technology for producing large supercritical casting steel. The back sand in the technology adopts alkaline phenolic resin sand, and the weight ratio of alkaline phenolic resin to quartz sand is (1.5-2):100, and the weight ratio of the alkaline phenolic resin to a hardener is 100: (20-30). The face sand adopts alkaline phenolic resin chrome ores, and the weight proportion of the alkaline phenolic resin to chrome ores is (1.5-2):100, and the weight ratio of the alkaline phenolic resin to the hardener is 100: (15-25). The invention provides the sand technology for producing the large supercritical casting steel which has high proportioning and casting strength, hot deformability and good collapsibility.

Owner:SANXIN HEAVY IND MACHINERY

Preparation method of energy-saving composite refractory material

Provided is a preparation method of an energy-saving composite refractory material. The method includes the steps that a, magnesium oxide and calcium oxide are mingled, clear water is used for removing impurities in magnesium oxide and calcium oxide, and magnetic separation for removing iron is performed, then a pulverizer is adopted for smashing to obtain a first mixture after drying; b, fine serpentine powder, silicon carbide and waste tail slags are blended and disposed by a ball mill in a ball-milling mode to obtain a second mixture; c, the second mixture is added with a bonding agent, and stirred and mixed with a plasticizer after being stirred evenly to obtain a third mixture; d, the third mixture is disposed by calcination and drying to complete the whole process. Refractory materials prepared by the preparation method have the advantage of great thermal shock resistance, and meanwhile, since the silicon carbide generates a silicon dioxide layer film under a high temperature in a refractory material layer, the slags are prevented from soaking into the refractory material layer, and the corrosion caused on the refractory material layer by the slags is restrained.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Production process for separating and recycling metal smelting slag

The invention provides a production process for separating and recycling metal smelting slag, which belongs to the technical field of metal smelting solid waste utilization, and is characterized in that slag harmless treatment is carried out through sequential cooling treatment, secondary metal recovery and tailing comprehensive recovery and utilization processes, so that sustainable development of enterprises is realized; firstly, slag granulation and dehydration are carried out through a Jiaheng process to replace hydraulic conveying in a traditional process, the process is simple and reliable, environmental pollution is small, and the quality of finished slag is good; according to the invention, residual metal is removed through high-temperature reduction, and the smelting slag is activated through a modification treatment method and is used as a binding material admixture, so that the hardening strength of the binding material is improved, the slag waste is effectively utilized, and the comprehensive utilization rate of the slag waste is improved.

Owner:吴联权

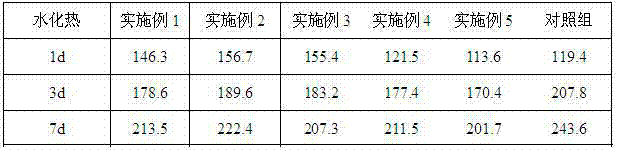

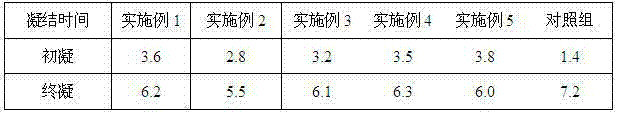

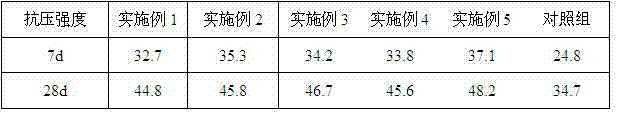

Intermediate-hydration-heat composite cement and preparation method thereof

Disclosed are intermediate-hydration-heat composite cement and a preparation method thereof, which relate to the field of a building material. The composite cement comprises the following components, by mass: (1) 40.0-55.0% of portland cement clinker, (2) 10.0-20.0% of aluminate cement clinker, (3) 2.1-8.0% of nanometer tin oxide, (4) 5.0-15.0% of glass fiber, (5) 5.0-10.0% of silica fume, (6) 5.0-10.0% of struvite, and (7) 2.5-5.0% of gypsum. The preparation method of the intermediate-hydration-heat composite cement comprises: (1) material preparation, (2) grinding, (3) pre-mixing, and (4) powder grinding. The intermediate-hydration-heat composite cement provided in the invention is prepared by utilizing both characteristics of the portland cement clinker and the aluminate cement clinker; the early strength and long-term strength of the materials are improved via a synergistic effect among each component; the hydration heat is effectively reduced; and affects of hydration heat on the molding and properties of the cement are avoided.

Owner:苏州市德莱尔建材科技有限公司

Efficient energy-saving refractory material and preparation method thereof

The invention provides an efficient energy-saving refractory material and a preparation method thereof. The efficient energy-saving refractory material is prepared from the following components: magnesium oxide, calcium oxide, modified zirconia fiber, high silicon gangue, high aluminum red mud, a binder and a plasticizer. The refractory material prepared by the method has good mechanical strengthand excellent fire resistance, and has a simple preparation method and is easy to produce on the existing equipment in large scale.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Cementing material, historic building repair mortar and preparation method of historic building repair mortar

ActiveCN114105502AWell mixedImprove adhesionSolid waste managementCement productionCompressive resistanceArchitectural engineering

The invention relates to the technical field of building materials, in particular to a cementing material, historic building repair mortar prepared from the cementing material and a preparation method of the historic building repair mortar, the historic building repair mortar is composed of the cementing material, aggregate, an additive and water, and the cementing material comprises the following components in parts by weight: 20-150 parts of slag and 250-500 parts of active iron tailings; a preparation method of the active iron tailings comprises the steps that iron tailings are dried and then subjected to first-time grinding, quicklime powder and water are added for second-time grinding, then high-temperature activation is conducted at the temperature of 700-800 DEG C, and the active iron tailings are obtained. According to the preparation method of the historic building repair mortar, provided by the invention, the active iron tailings and the slag are used for preparing the gel material for the historic building repair mortar, so that the bonding performance and the compressive strength of each age of the historic building repair mortar can be improved; the early strength is high, the cohesiveness is good, the erosion resistance is strong, and the durability is good.

Owner:UNIV OF SCI & TECH BEIJING +1

Novel composite fire-resistant material and preparation method thereof

The invention provides a novel composite fire-resistant material and a preparation method thereof. The novel composite fire-resistant material is prepared by a fire-resistant base material, silicon carbide, waste tailings slag, partially stabilized zirconia, zirconium carbide particles, acrylated amine, methylene bisacrylamide, ammonium persulfate, an organic solvent, a binding agent and a naturalplasticizer. Compare with a traditional fire-resistant material, the prepared fire-resistant material is low in pore number, high in density, small in expansion rate and linear change on reheating, good in stability, excellent in thermal shock performance and good in wear resistance.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

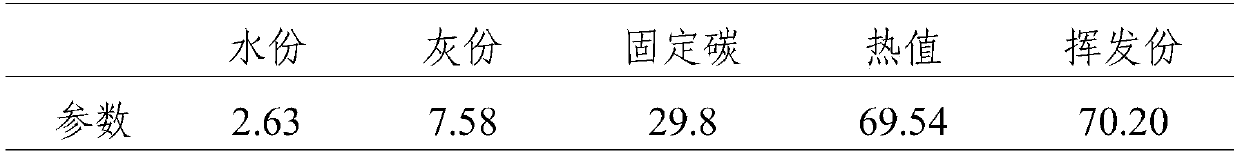

Polycarboxylic acid water reducing agent and preparation method thereof

The invention relates to the field of water reducing agents and in particular relates to a polycarboxylic acid water reducing agent and a preparation method thereof. The water reducing agent is prepared from the following raw materials in parts by weight: 35 to 40 parts of polyethylene glycol, 10 to 15 parts of acrylic acid, 0.1 to 1 part of hydroquinone, 0.1 to 0.5 part of phenothiazine, 4 to 9 parts of ammonium persulfate, 1 to 5 parts of concentrated sulfuric acid, 3 to 8 parts of calcium hydroxide, 1 to 7 parts of lithium carbonate, 2 to 5 parts of sodium hydrogen bisulfite, 0.5 to 1.5 parts of sulfonated phenolic resin, 0.5 to 1 part of fulvic acid and a proper amount of water. According to the water reducing agent provided by the invention, the defects of an existing water reducing agent that the flowability is poor and the anti-permeability is poor are effectively overcome to a certain extent.

Owner:萧县沃德化工科技有限公司

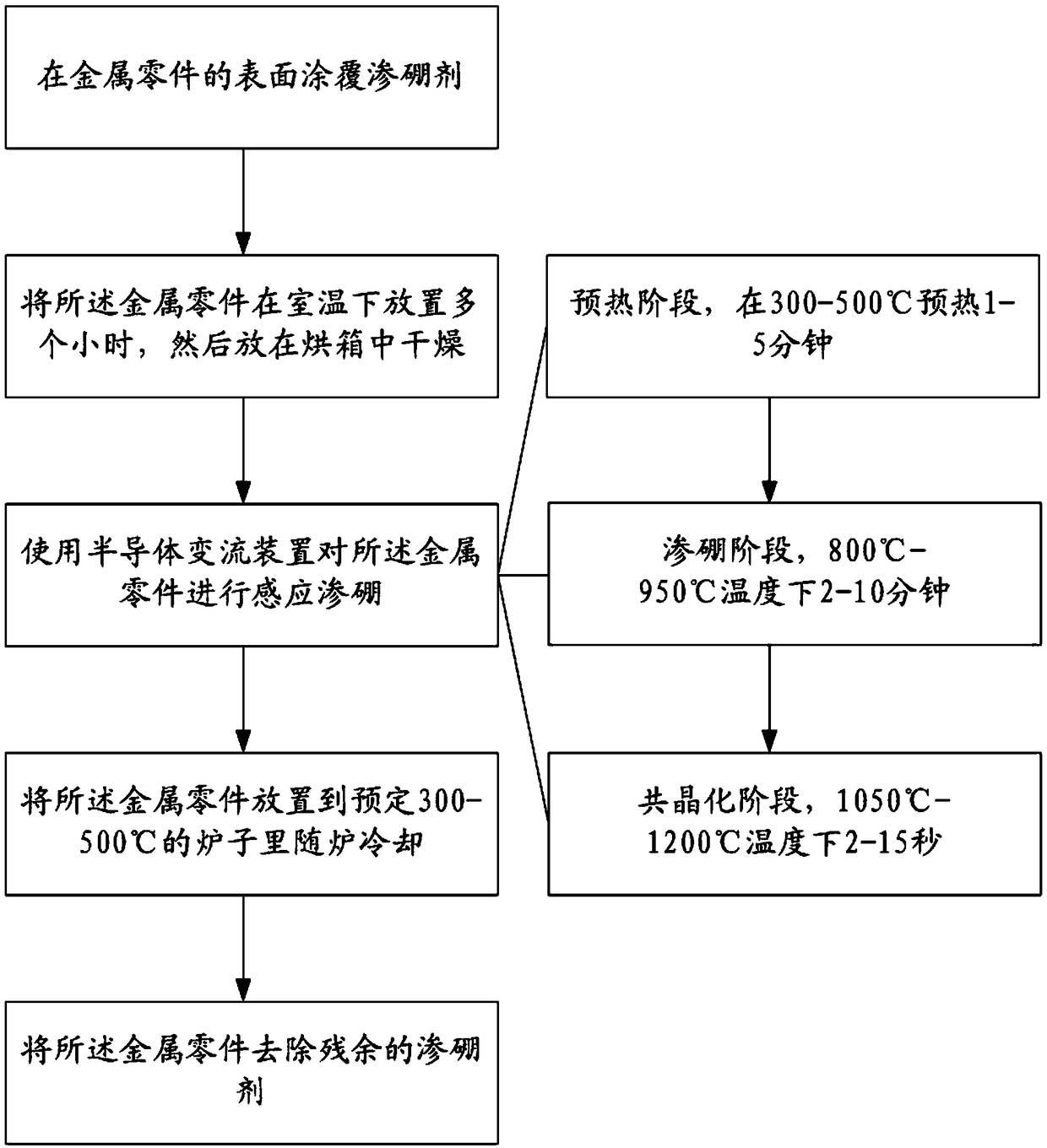

Metal part surface hardening method

InactiveCN108842132AHigh hardening strengthTo achieve the effect of wear resistance and wear reductionSolid state diffusion coatingWear resistantRoom temperature

The invention discloses a metal part surface hardening method. The metal part surface hardening method comprises the following steps: 1) a boronizing agent coats the surface of a metal part; 2) the metal part is placed at room temperature for a plurality of hours, and then put in a drying oven to be dried; 3) a semiconductor variable-flow device is used for carrying out induction carburization onthe metal part; 4) the metal part is placed in a furnace at the temperature of 300-500 DEG C for cooling along with the furnace; and 5) the metal part is removed, and the residual boronizing agent isremoved. In the step 3), the induction carburization comprises the following steps that 31) a preheating stage is carried out at the temperature of 300-500 DEG C for 1-5 minutes; 32), a boronizing stage is carried out at the temperature of 800 DEG C-950 DEG C for 2-10 minutes; and 33), a co-crystallization stage is carried out at the temperature of 1050 DEG C-1200 DEG C for 2-15 seconds. Accordingto the metal part surface hardening method, the hardening strength can be improved; and the surface super-hard layer is generated by adopting a surface induction heating boronizing process, so that the wear-resistant and anti-wear effects are achieved.

Owner:SEED TECH CORP LTD

Novel super-white water-resistant putty powder and preparation method thereof and method for manufacturing glittering and translucent white-wall carving decoration wall

InactiveCN109517423AImprove water resistanceGood viscosity stabilityCovering/liningsFilling pastesLacquerWhitening Agents

The invention discloses a novel super-white water-resistant putty powder and a preparation method thereof. The novel super-white water-resistant putty powder is prepared from the following componentsin parts by weight: 15 to 20 parts of superfine triple superphosphate, 25 to 30 parts of ash calcium powder, 0.5 to 2 parts of hydroxypropyl methyl cellulose, 40 to 50 parts of talcum powder, 0.1 to 1part of starch ether, 1 to 5 parts of latex powder, 0.51 to 2 parts of whitening agent, 7 to 15 parts of light calcium carbonate, and 2 to 3 parts of pearlescent pigment. The preparation method comprises the following steps of in the preparation process, weighing the components according to a ratio, and uniformly mixing, so as to obtain the novel super-white water-resistant putty powder. The novel super-white water-resistant putty powder has the advantages that the super-white and environment-friendly effects are realized, the paint is not used at certain degree, the technique is advanced, and the application effect is good. The invention also discloses a fully novel construction method for manufacturing the glittering and translucent white wall with similar carving effect by the super-white putty powder; the application prospect is broad.

Owner:定州康丽水性涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com