Environment-friendly interior wall putty and preparation method thereof

An interior wall putty and environmental protection technology, applied in the direction of filling slurry, etc., can solve the problems of easy damage, poor water resistance, easy damping of putty, etc., and achieve the effect of increasing the hardening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

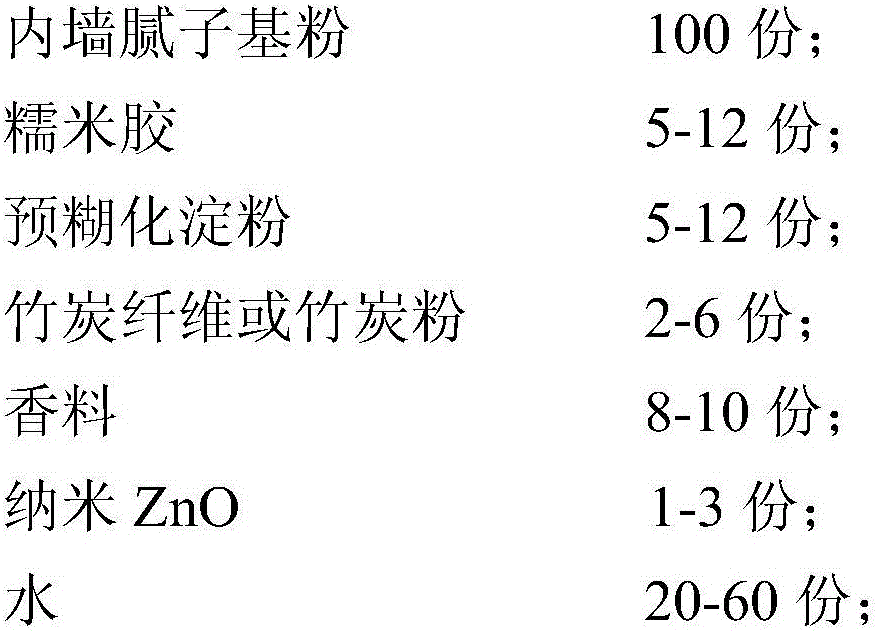

[0059] Environmentally friendly interior wall putty, the parts by weight are as follows:

[0060]

[0061] The length of the bamboo charcoal fiber is 0.5-5 millimeters, and the diameter is 10-20 microns; the diameter of the nano-ZnO is 10-20 nanometers.

[0062] The interior wall putty base powder includes heavy calcium, gray calcium and white cement, and the weight ratio of heavy calcium, gray calcium and white cement is 620:75:140.

[0063] The fineness of heavy calcium is 350 mesh, and the whiteness is 90.

[0064] The white cement has a fineness of 0.080 mm and a square hole sieve with a residue of less than 10%, and a whiteness higher than 87.

[0065] The viscosity of pregelatinized starch is 2000mpa.

[0066] The pepper powder has a fineness of 300 mesh.

[0067] Specifically prepared by the following steps:

[0068] Step (1): Prepare bamboo charcoal glutinous rice glue:

[0069] Grind the glutinous rice finely, add water and boil until gelatinous, stir the prep...

Embodiment 2

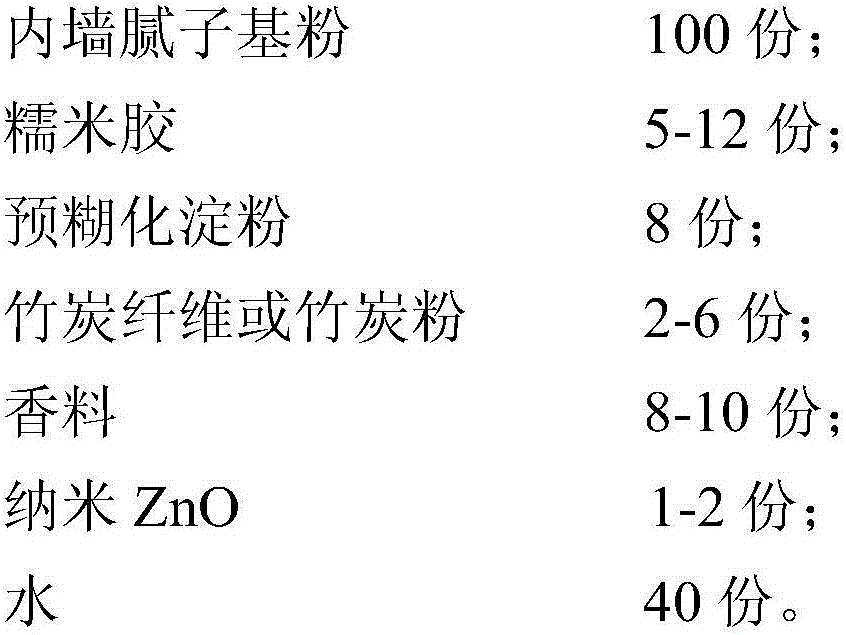

[0075] Compared with Example 1, the difference is that the environmental protection interior wall putty consists of:

[0076]

Embodiment 3

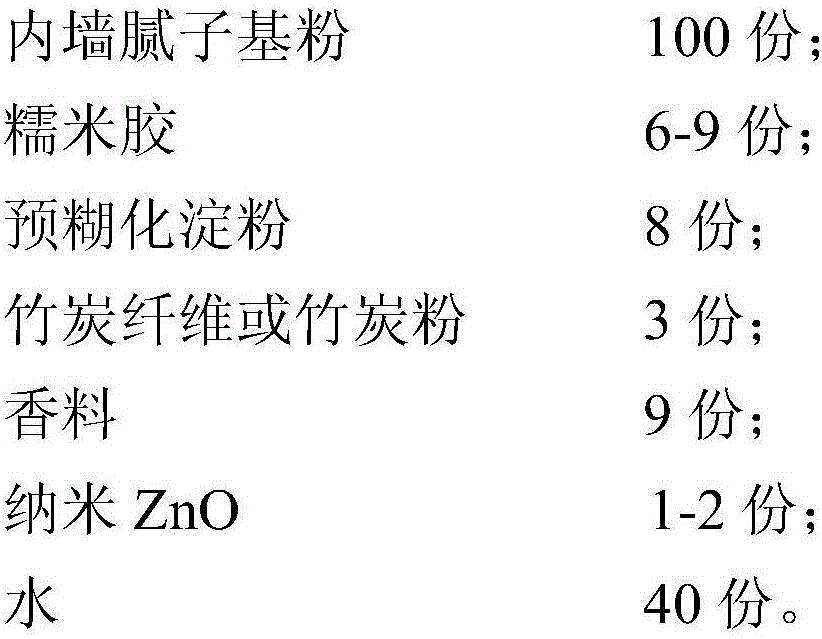

[0078] Compared with Example 1, the difference is that the environmental protection interior wall putty consists of:

[0079]

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com