Production method of water-based capillary crystalline waterproof material convenient to produce and use

A waterproof material and permeable crystallization technology, applied in the field of water-based permeable crystalline waterproof materials, can solve the problems of reduced practicability, poor penetration effect, reduced overall practicability, etc., to achieve convenient production and use, high density and strength, increase Effect of hardening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

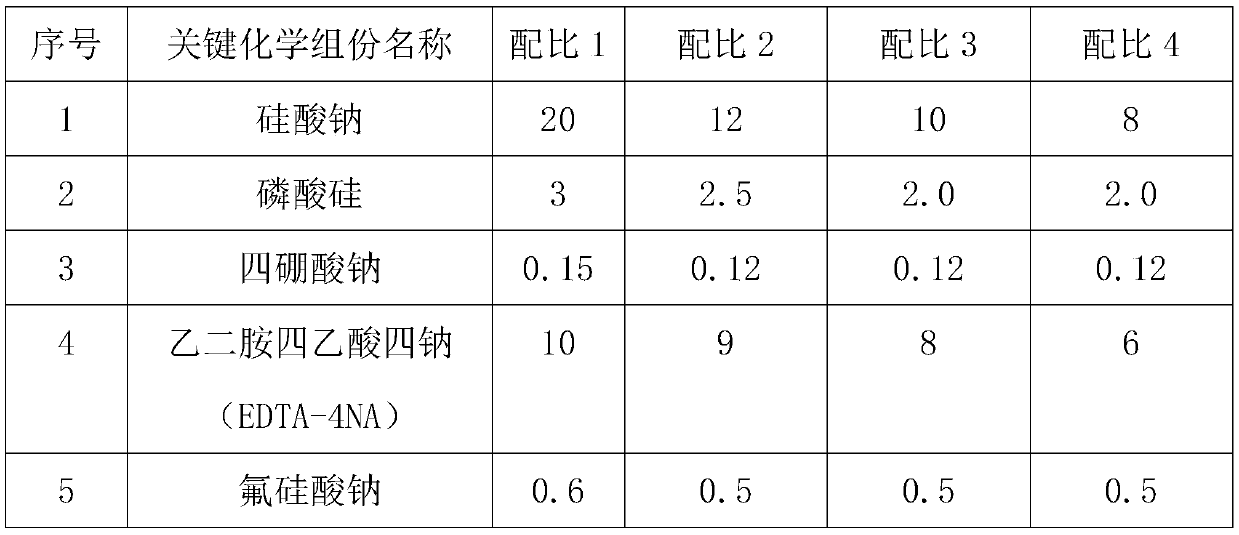

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of this waterproof material is prepared through the following steps:

[0026] Step 1: batching, take 30 parts of gel material sodium silicate, stand-by, and weigh each component according to the formula ratio, 16.7 parts of crystallization coagulant (4 parts of silicon phosphate, 0.7 part of sodium tetraborate and ethylenediamine Tetrasodium tetraacetate (EDTA-4Na) 12 parts), admixture carboxylic acid 0.12 parts, cement molecular secondary reaction agent triethanolamine 3 parts, antifreeze agent potassium carbonate 0.07 parts, metal ion complexing agent sodium hexametaphosphate 0.15 parts, 0.4 parts of curing agent sodium fluorosilicate, 1 part of hydrophobic agent potassium methyl silicate, 48.56 parts of diluent deionized water, a total of 100 parts;

[0027] Step 2: Preparation, place 48.56 parts of ionized water inside the reactor, ensure that the temperature inside the reactor is 15°C to 35°C, and ensure that the relative humidity of the envi...

Embodiment 2

[0032] The preparation method of this waterproof material is prepared through the following steps:

[0033] Step 1: batching, take 30 parts of gel material sodium silicate, stand-by, and weigh each component according to the formula ratio, 16.7 parts of crystallization coagulant (4 parts of silicon phosphate, 0.7 part of sodium tetraborate and ethylenediamine Tetrasodium tetraacetate (EDTA-4Na) 12 parts), admixture carboxylic acid 0.12 parts, cement molecular secondary reaction agent triethanolamine 3 parts, antifreeze agent potassium carbonate 0.07 parts, metal ion complexing agent sodium hexametaphosphate 0.15 parts, 0.4 parts of curing agent sodium fluorosilicate, 1 part of hydrophobic agent potassium methyl silicate, 48.56 parts of diluent deionized water, a total of 100 parts;

[0034] Step 2: Preparation, place 48.56 parts of ionized water and 30 parts of gel material sodium silicate inside the reactor, ensure that the temperature inside the reactor is 15°C-35°C, and ens...

Embodiment 3

[0038] The preparation method of this waterproof material is prepared through the following steps:

[0039] Batching, take 30 parts of gel material sodium silicate, stand-by, and weigh each component according to the formula ratio, 16.7 parts of crystallization coagulant (4 parts of silicon phosphate, 0.7 part of sodium tetraborate and ethylenediaminetetraacetic acid tetra Sodium (EDTA-4Na) 12 parts), admixture carboxylic acid 0.12 parts, cement molecular secondary reaction agent triethanolamine 3 parts, antifreeze agent potassium carbonate 0.07 parts, metal ion complexing agent sodium hexametaphosphate 0.15 parts, curing agent fluorine 0.4 parts of sodium silicate, 1 part of potassium methyl silicate as hydrophobic agent, 48.56 parts of diluent deionized water, 100 parts in total;

[0040] Step 2: Preparation, place 48.56 parts of ionized water and 30 parts of gel material sodium silicate inside the reactor, ensure that the temperature inside the reactor is 15°C-35°C, and ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com