C30 regenerated aggregate concrete and preparation method thereof

A recycled aggregate and concrete technology, applied in the field of building materials, can solve problems such as poor workability, large concrete slump loss, and large porosity, and achieve the effects of reducing interaction force, promoting environmental protection, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

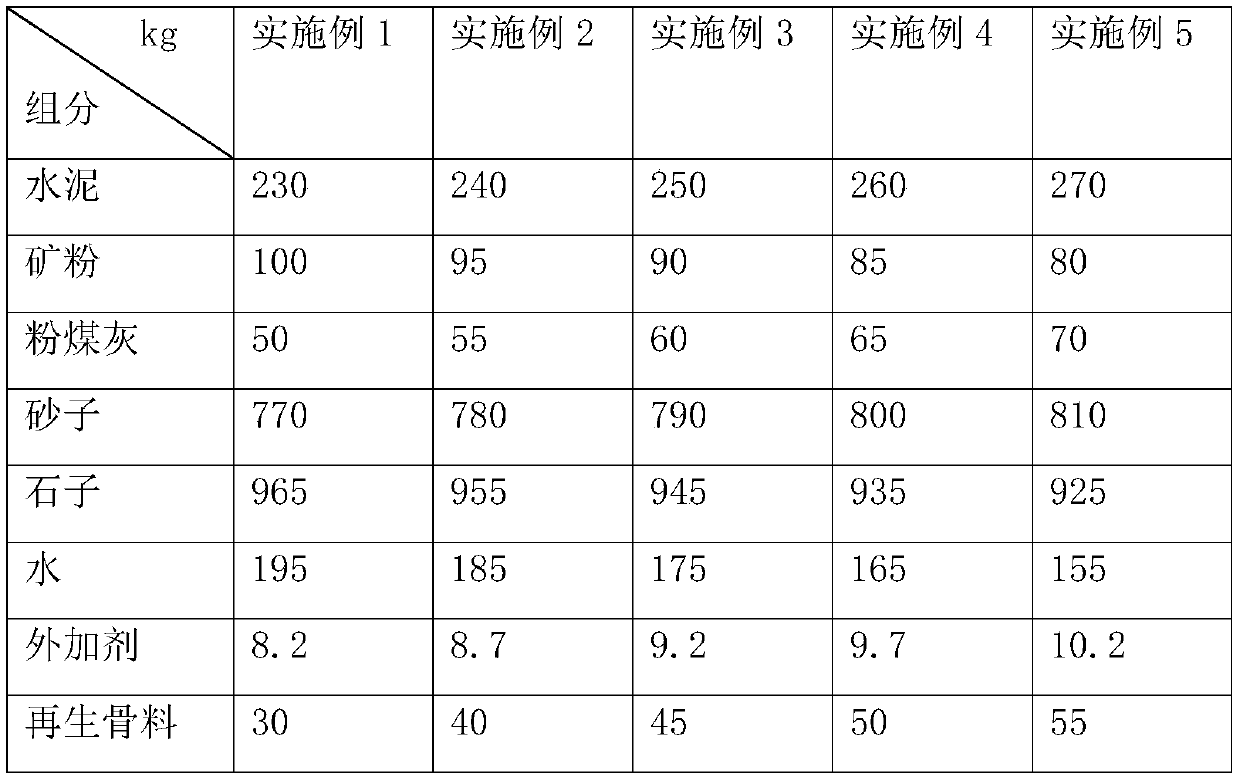

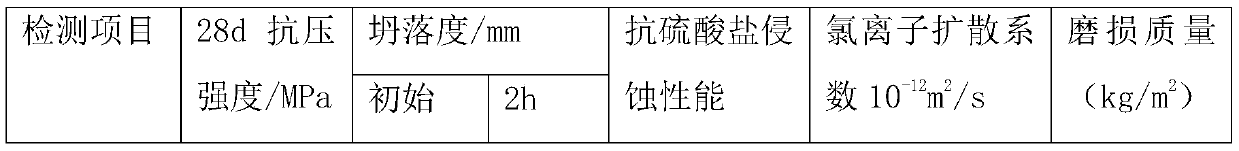

Examples

preparation example 1

[0044] Preparation Example 1: (1) Dry the iron tailings and red mud at 100°C for 2.5 hours. The composition analysis of the iron tailings and red mud is shown in Table 1; Add sodium silicate and diatomaceous earth to tailings sand and red mud, wet grind at 67% concentration for 20 minutes, dry at 100°C after wet grinding, then calcinate at 600°C for 2 hours, dry grind for 10 minutes, and pass through 200 mesh Sieve to obtain activated iron tailings, the mass ratio of iron tailings sand to red mud is 2:0.9, and the mass ratio of iron tailings sand to sodium silicate and diatomite is 1:0.3:0.5.

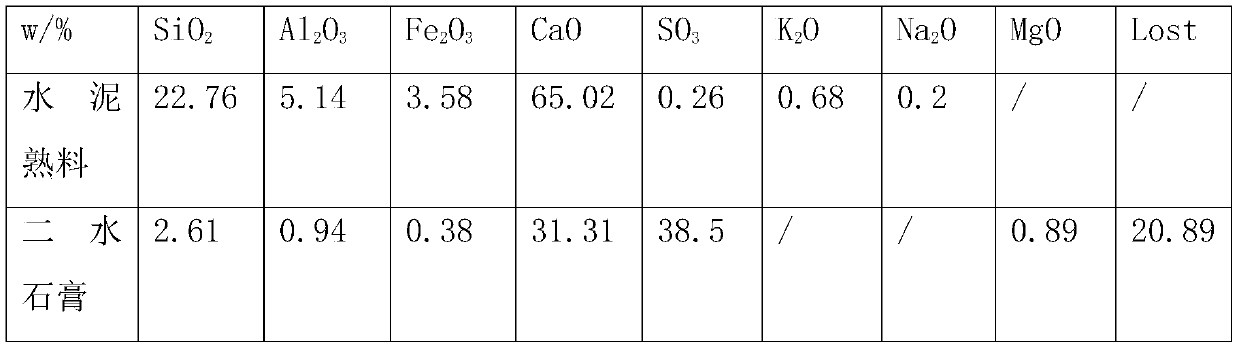

[0045] The main chemical composition of iron tailings sand and red mud in table 1 preparation example 1-3

[0046] Element Fe 2 o 3

preparation example 2

[0047] Preparation Example 2: (1) Dry the iron tailings and red mud at 105°C for 2.3 hours. The composition analysis of the iron tailings and red mud is shown in Table 1; Add sodium silicate and diatomaceous earth to tailings sand and red mud, wet grind at 68% concentration for 15 minutes, dry at 110°C after wet grinding, then calcinate at 650°C for 1.5h, dry grind for 15 minutes, pass 200 mesh sieve to obtain activated iron tailings, the mass ratio of iron tailings sand to red mud is 2:1, and the mass ratio of iron tailings sand to sodium silicate and diatomite is 1:0.4:0.6.

preparation example 3

[0048] Preparation Example 3: (1) Dry the iron tailings and red mud at 110°C for 2 hours, and the composition analysis of the iron tailings and red mud is shown in Table 1; (2) add the iron tailings prepared in step (1) Add sodium silicate and diatomite to the ore sand and red mud, wet grind at 70% concentration for 10 minutes, dry at 120°C after wet grinding, then calcinate at 700°C for 1 hour, dry grind for 20 minutes, and pass through a 200-mesh sieve , to prepare activated iron tailings, the mass ratio of iron tailings sand to red mud is 2:1.1, and the mass ratio of iron tailings sand to sodium silicate and diatomite is 1:0.5:0.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com