Water glass sand hardener

A technology of water glass sand and hardener, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of insufficient research on the properties of ester hardeners, high residual strength of water glass sand, and expensive ester hardeners, etc., to achieve Reduction of residual strength, good hardening effect, and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The water glass sand hardening agent is formulated according to the components listed in the weight percentage in Table 1.

[0024] The preparation steps of above-mentioned water glass sand hardening agent:

[0025] ① Mix and dissolve soluble acid phosphate and urea in water according to the weight percentage in Table 1 to obtain solution A;

[0026] 2. In the solution A described in step 1., add the phosphoric acid and organic esters with a mass concentration of 80% of the above-mentioned weight percentage respectively, and mix evenly to obtain the water glass sand hardening agent.

[0027] When the above water glass sand hardener is used, the proportion of water glass sand is: 100% of quartz sand, water glass (modulus 2.43, density 1.48) is 4% of the weight of quartz sand, and the amount of hardener is 100% of water glass weight. 10% of. First, mix the curing agent of the present invention directly with quartz sand according to the above proportion, and then add wat...

Embodiment 2 Embodiment 5

[0029] The components and contents of the water glass sand hardener are shown in Table 1, and the test results are shown in Tables 2 to 4.

[0030] The compound method and application of described water glass sand hardening agent are the same as embodiment one.

[0031] Table 1 Components and content of water glass sand hardener

[0032]

[0033] Note: 1) The soluble acid phosphate is aluminum dihydrogen phosphate or sodium dihydrogen phosphate.

[0034] 2) The organic ester is glycerol diacetate, ethylene glycol monoacetate or diethylene glycol monoacetate.

[0035] Table 2 adopts the test results of the present invention at 0~5°C

[0036]

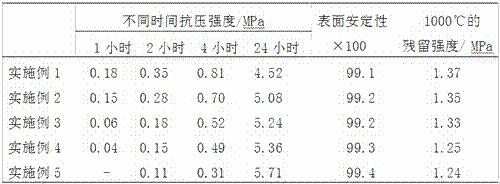

[0037] Table 3 adopts the test result of the present invention at 12~18 ℃

[0038]

[0039] Table 4 adopts the test result of the present invention at 25~30 ℃

[0040]

[0041]The test results show that the novel curing agent of the present invention has different hardening speeds to water glass sand, and can adapt to diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com