Anhydrite-based light plastering mortar and preparation method thereof

A plastering mortar and anhydrite technology, which is applied in the field of lightweight gypsum plastering materials and its preparation, can solve the problems of affecting the quality of gypsum products and large-scale application, the high content of by-product gypsum impurities, and the lack of energy-saving effects. Achieve superior market competitiveness, suitable setting time, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

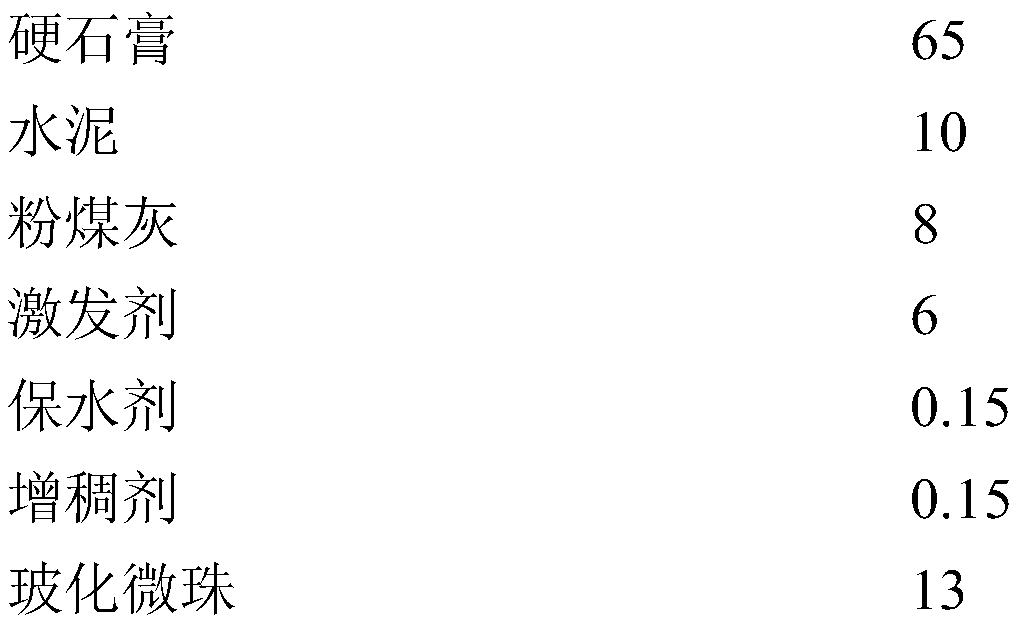

Embodiment 1

[0022]

[0023] The anhydrite-based lightweight plastering mortar material composed in this embodiment has a short setting time, the initial setting time is greater than or equal to 3h, the final setting time is greater than or equal to 3.5h, and the initial and final setting time interval is short; the strength is high: the flexural strength is greater than Or equal to 2.5MPa, and the compressive strength is greater than or equal to 5MPa. Suitable for winter construction.

Embodiment 2

[0025]

[0026] The anhydrite-based lightweight plastering mortar material composed in this embodiment has a slightly longer setting time, the initial setting time is greater than or equal to 4h, the final setting time is greater than or equal to 4.5h, and the initial and final setting time interval is slightly longer; moderate strength: flexural strength Greater than or equal to 1.8MPa, compressive strength greater than or equal to 3.5MPa; small bulk density, less than or equal to 820kg / m 3 , the unit plastering area increases, showing a light effect. It is suitable for construction in high temperature environments less than or equal to 35°C in summer.

Embodiment 3

[0028]

[0029]

[0030] The anhydrite-based lightweight plastering mortar material composed in this embodiment has moderate setting, the initial setting time is greater than or equal to 3.5h, and the final setting time is greater than or equal to 4h; the strength is moderate: the flexural strength is greater than or equal to 2MPa, and the compressive strength is greater than or equal to Equal to 4MPa; the workability of the slurry is good, which is conducive to improving the construction efficiency; the bulk density is small, less than or equal to 850kg / m 3 '. Suitable for mechanized construction.

[0031] The preparation method of anhydrite-based lightweight plastering mortar in each embodiment is realized by the following steps:

[0032] 1) Grinding anhydrite to obtain anhydrite powder; the fineness of anhydrite powder is greater than or equal to 200 mesh, and the specific surface area is greater than or equal to 4000cm 2 / g.

[0033] 2) Weigh anhydrite powder, cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com