Multifunctional sealing and hardening prime coat, and preparation method and application thereof

A multi-functional, sealant technology, applied in coatings, antifouling/underwater coatings, conjugated diene coatings, etc., can solve problems such as weak penetration of the base, indoor environmental pollution, and no antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] According to one aspect of the present invention, a kind of preparation method of above-mentioned multifunctional seal hardening primer, described preparation method comprises the following steps:

[0071] First, mix and stir acrylic emulsion, styrene-butadiene emulsion, sealant, antiseptic and bactericide and water for 5-10 minutes, then add defoamer, thickener and acid-base regulator and mix and stir for 20-30 minutes, and finally add color paste Mix well to make a multi-purpose sealing and hardening primer.

[0072] The preparation method of the multifunctional sealing and hardening primer provided by the present invention, the above method first mixes acrylic acid emulsion, styrene-butadiene emulsion, sealant, antiseptic and bactericide and water for 5-10 minutes, then adds defoamer, thickener and acid The alkali conditioner is mixed and stirred for 20-30 minutes, and finally the color paste is optionally added and mixed evenly to prepare a multi-functional sealing ...

Embodiment 1~5

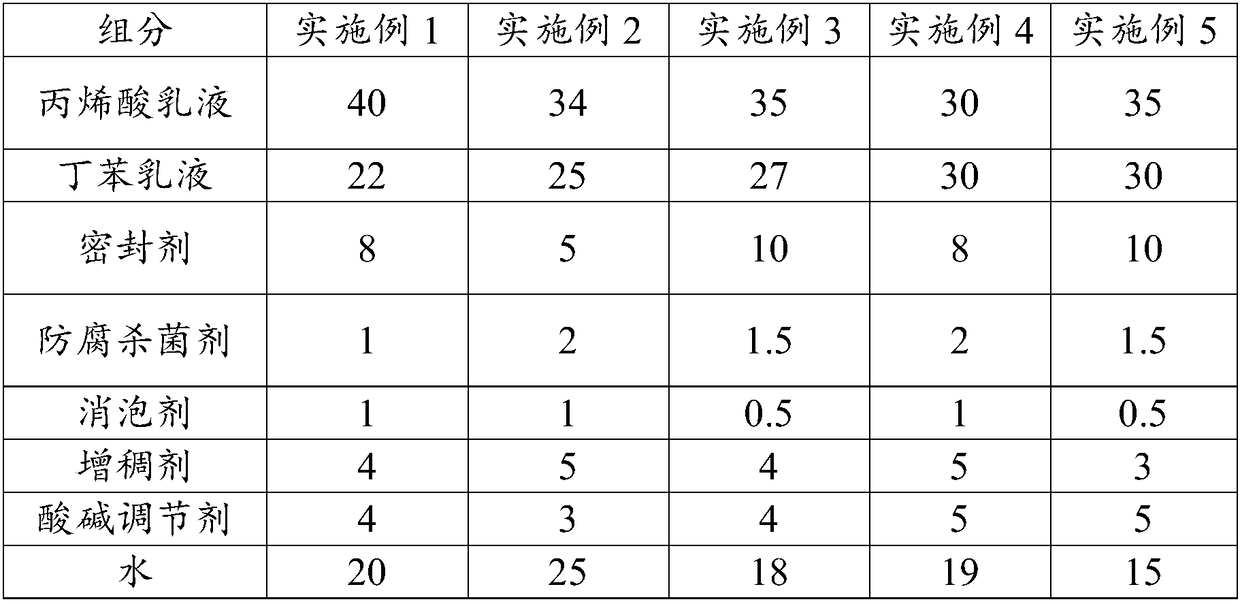

[0092] A multifunctional sealing and hardening primer, according to the parts by weight in the following Table 1, the raw material components are weighed to obtain the component formula of Examples 1 to 5 of the present invention. Multifunctional sealing and hardening primer:

[0093] Table 1: Formulas of multifunctional sealing and hardening primers of Examples 1 to 5

[0094]

[0095] Note: In the above-mentioned Examples 1 to 5 of the present invention, the acrylic emulsion is AXILAT PR 3500 produced by HEXION; the styrene-butadiene emulsion is LIPATON SB30Y160 produced by SYNTHOMER; the sealant is DURAMUL 2428F produced by DURAMUL; Preventol D7 produced by Sheng Company; the defoamer is Dehydran 1620 produced by BASF; the thickener is ROHAGIT SD15 produced by Roehm GmbH; the acid-base regulator is ammonia solution containing 25% ammonia.

[0096] Then, according to the following steps, the multifunctional sealing and hardening primers of Examples 1 to 5 of the present i...

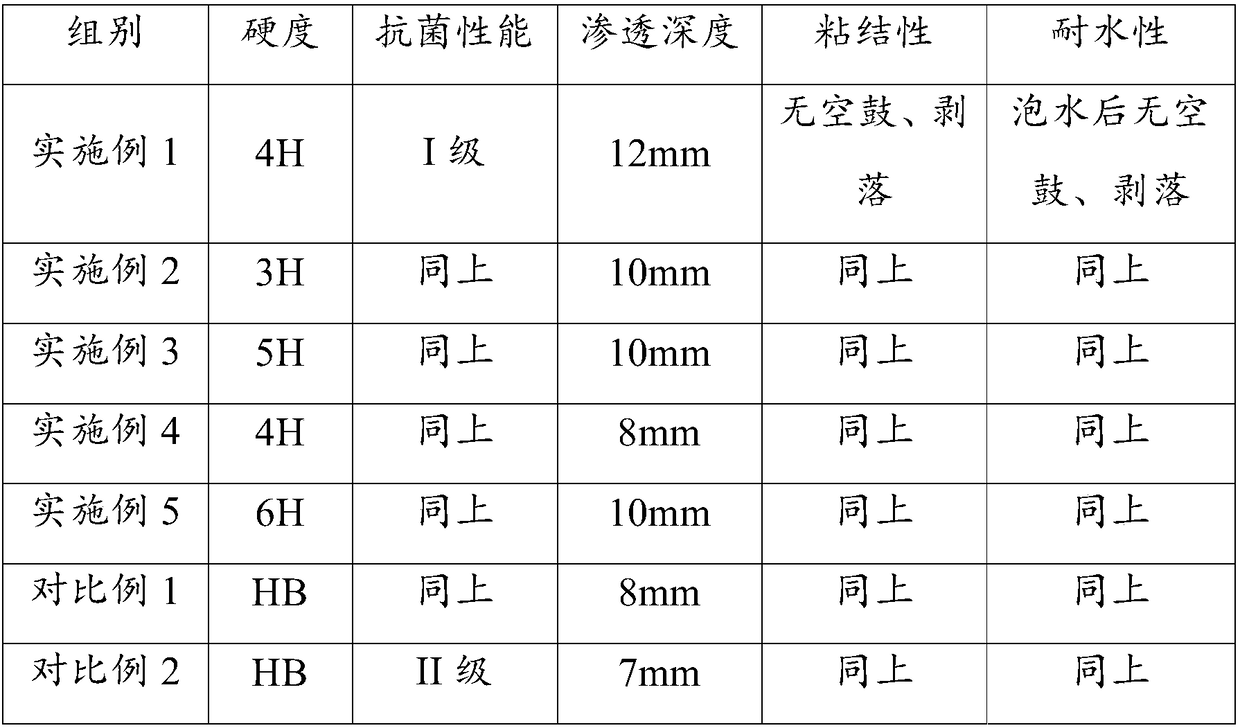

experiment example 1

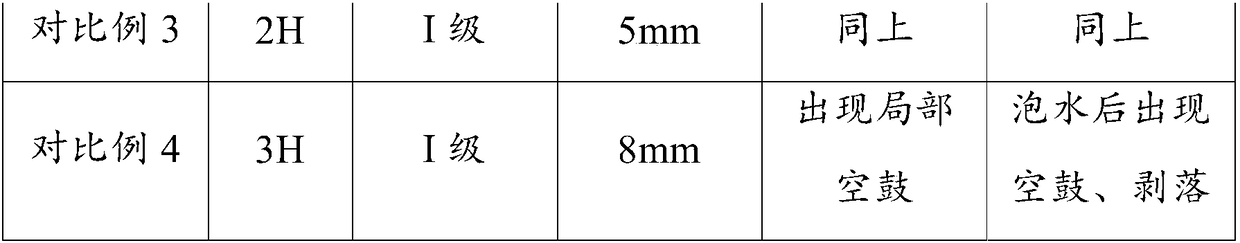

[0106] In order to show that the multifunctional sealing and hardening primer of the present invention has the characteristics of super strong permeability, high hardening strength, high sealing performance and environmental protection, the multifunctional sealing and hardening primers prepared in Examples 1 to 5 and Comparative Examples 1 to 4 are now respectively tested. The primer was tested for hardness, antibacterial performance, penetration performance, adhesion and water resistance, and the results are shown in Table 3.

[0107] Table 3: Performance test results of multifunctional seal hardening primer

[0108]

[0109]

[0110] Note: The above hardness test is carried out according to the method specified in GB / T6739-2006 "Paint and Varnish Pencil Method", where B stands for blackness, and the more B number means the darker the color and the lower the hardness; H stands for hardness, H More numbers mean greater hardness and lighter color; HB means medium hardness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com