Cleaning briquette coal binder

A binder and clean technology, applied in the field of clean briquette binder, can solve the problems of reducing the effect of clean emissions, difficult waste gas treatment, and high economic costs, and achieves reduced emissions, reduced haze formation probability, and sufficient combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

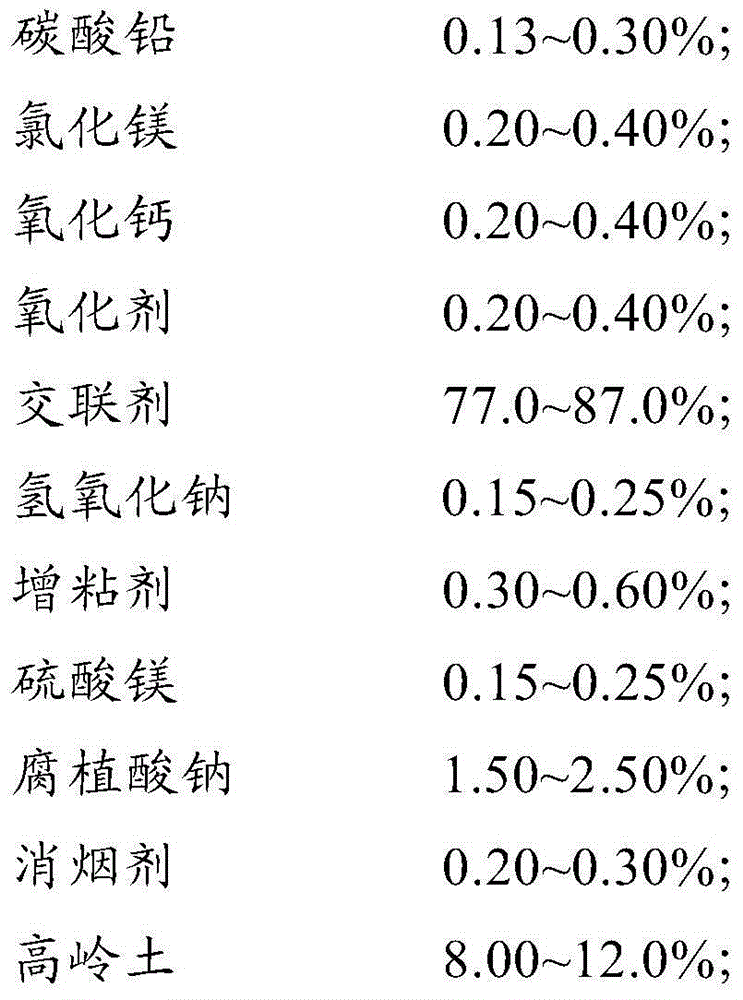

[0019] Embodiment 1, a kind of clean briquette binder described in the embodiment of the present invention, use this binder to add into briquette and produce briquette, briquette comprises solid waste particle or powder 500kg, lignite 200kg, straw Coal 300kg, this binding agent comprises the raw material of following weight component:

[0020]

[0021]

[0022] The above percentages are all mass percentages based on the total mass of the binder.

[0023] In this technical solution, it is further stated that the binder also includes ferric oxide, propane, and ammonium nitrate, and the mass percentages of the three components in the binder are: 0.25% of ferric oxide, 0.4% of propane, and ammonium nitrate 0.2%. In this technical solution, the oxidizing agent is further prepared by mixing 0.1% potassium permanganate and 0.1% manganese dioxide, and the above percentages are all mass percentages of the total mass of the binder. In the technical solution, further, the crossli...

Embodiment 2

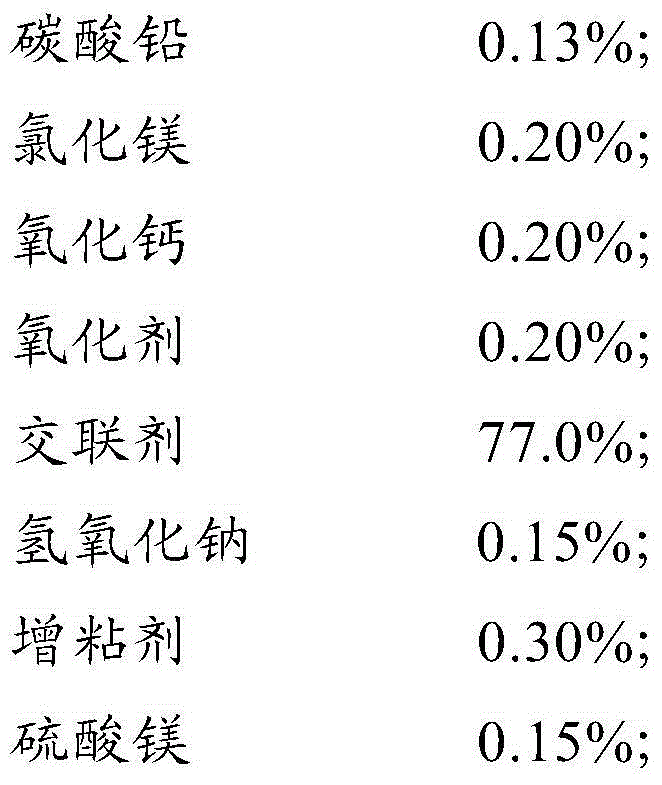

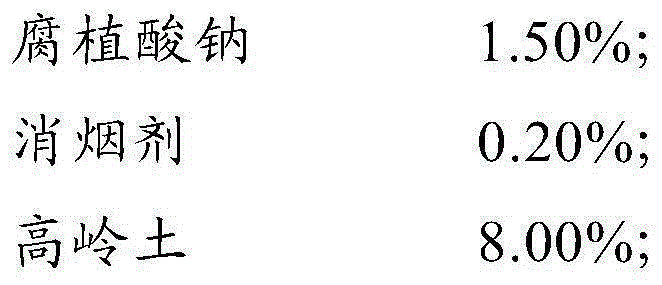

[0025] Embodiment 2, a kind of clean briquette binder described in the embodiment of the present invention, use this binder to add into briquette and produce briquette, briquette comprises solid waste particle or powder 400kg, lignite 300kg, straw Coal 300kg, this binding agent comprises the raw material of following weight component:

[0026]

[0027]

[0028] The above percentages are all mass percentages based on the total mass of the binder.

[0029] Further, the binder also includes ferric oxide, propane, and ammonium nitrate, and the mass percentages of the three components in the binder are: 0.28% of ferric oxide, 0.46% of propane, and 0.26% of ammonium nitrate. Further, the oxidizing agent is made by mixing 0.13% potassium permanganate and 0.15% manganese dioxide, and the above percentages are all mass percentages of the total mass of the binder. Further, the crosslinking agent is made by mixing 71% of starch, 6% of sodium silicate, and 3% of isoprene, and the a...

Embodiment 3

[0031] Embodiment 3, a kind of clean briquette binder described in the embodiment of the present invention, use this binder to add into briquette and produce briquette, briquette includes 400kg of solid waste particles or powder, 100kg of anthracite, straw Coal 400kg, biomass 100kg, this binding agent comprises the raw material of following weight component:

[0032]

[0033]

[0034] The above percentages are all mass percentages based on the total mass of the binder.

[0035] Further, the binder also includes ferric oxide, propane, and ammonium nitrate, and the mass percentages of the three components in the binder are: 0.30% ferric oxide, 0.50% propane, and 0.30% ammonium nitrate. Further, the oxidizing agent is made by mixing 0.15% potassium permanganate and 0.17% manganese dioxide, and the above percentages are all mass percentages of the total mass of the binder. Further, the crosslinking agent is made by mixing 72% of starch, 6.5% of sodium silicate and 3.5% of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com