High-adaptability wet-mixed mortar additive and manufacturing process thereof

A wet-mixed mortar and adaptable technology, which is applied in the field of highly adaptable wet-mixed mortar additives and its manufacturing process, can solve problems such as troublesome manufacturing of wet-mixed mortar additives, and achieve the effects of large volume, control precision, and improved hardening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

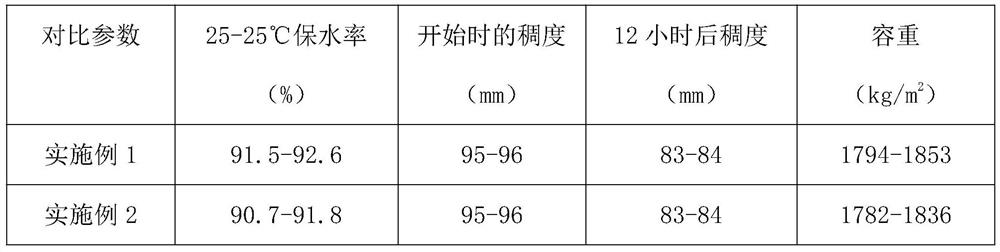

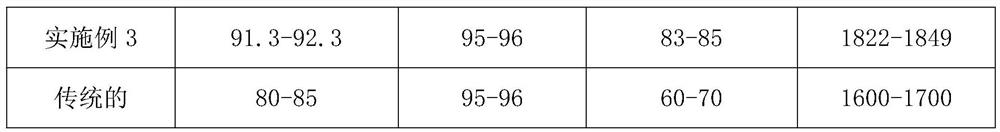

Embodiment 1

[0025] A highly adaptable wet-mix mortar additive, including the following raw materials in parts by weight: 13 parts of thickener, 7 parts of air-entraining agent, 15 parts of water reducing agent, 12 parts of water-retaining agent, 11 parts of retarder, anti-cracking agent 9 parts, 5 parts of foam stabilizer and 75 parts of water.

[0026] In this example, the thickening agent is maltose beerugin, the air-entraining agent is a mixture of sodium abietate, triterpene saponin and sodium lauryl sulfate, the water-reducing agent is prenol polyoxyethylene ether, and the water-retaining agent is hydroxy Composition of propyl methylcellulose and Wenlun glue, and the amount of hydroxypropyl methylcellulose is 10% of the amount of Wenlun glue, and the retarder is a composition of sodium citrate and sodium hexametaphosphate, anti-cracking The agent is hydroxypropyl methylcellulose, and the foam stabilizer is fatty acyldiethanolamine.

[0027] On the other hand, the present invention a...

Embodiment 2

[0033] A highly adaptable wet-mix mortar additive, including the following raw materials in parts by weight: 12 parts of thickener, 8 parts of air-entraining agent, 15 parts of water-reducing agent, 10 parts of water-retaining agent, 13 parts of retarder, anti-cracking agent 10 parts, 4 parts of foam stabilizer and 80 parts of water.

[0034] In this example, the thickener is polyacrylamide, the air-entraining agent is a mixture of sodium abietate, triterpene saponin and sodium lauryl sulfate, the water-reducing agent is an aliphatic water-reducing agent, and the water-retaining agent is hydroxypropylmethyl The combination of base cellulose and Wenlun glue, and the amount of hydroxypropyl methylcellulose is 10% of the amount of Wenlun glue, the retarder is sodium gluconate, white sugar composition, and the anti-cracking agent is hydroxypropylmethyl Cellulose and sodium alginate are mixed at a ratio of 1:1, and the foam stabilizer is fatty acyldiethanolamine.

[0035] On the o...

Embodiment 3

[0041] A highly adaptable wet-mix mortar additive, including the following raw materials in parts by weight: 15 parts of thickener, 5 parts of air-entraining agent, 13 parts of water-reducing agent, 12 parts of water-retaining agent, 15 parts of retarder, anti-cracking agent 13 parts, 6 parts of foam stabilizer and 90 parts of water.

[0042] In this example, the thickener is polyacrylamide, the air-entraining agent is a mixture of sodium abietate, triterpene saponin and sodium lauryl sulfate, the water reducing agent is a naphthalene-based superplasticizer, and the water-retaining agent is hydroxypropyl The composition of methyl cellulose and Wenlun glue, and the consumption of hydroxypropyl methylcellulose is 15% of the consumption of Wenlun glue, the retarder is sodium gluconate, and the anti-cracking agent is hydroxypropyl methylcellulose, Sodium alginate and redispersible latex powder are mixed at a ratio of 1:1:1, and the foam stabilizer is fatty acyldiethanolamine.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com