Sealing device

A sealing device and coating technology, applied in the direction of engine sealing, machine/engine, leakage prevention, etc., can solve the problem of low adhesion strength of the base material, and achieve the effect of preventing fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the sealing device of the present invention will be described below with reference to the accompanying drawings.

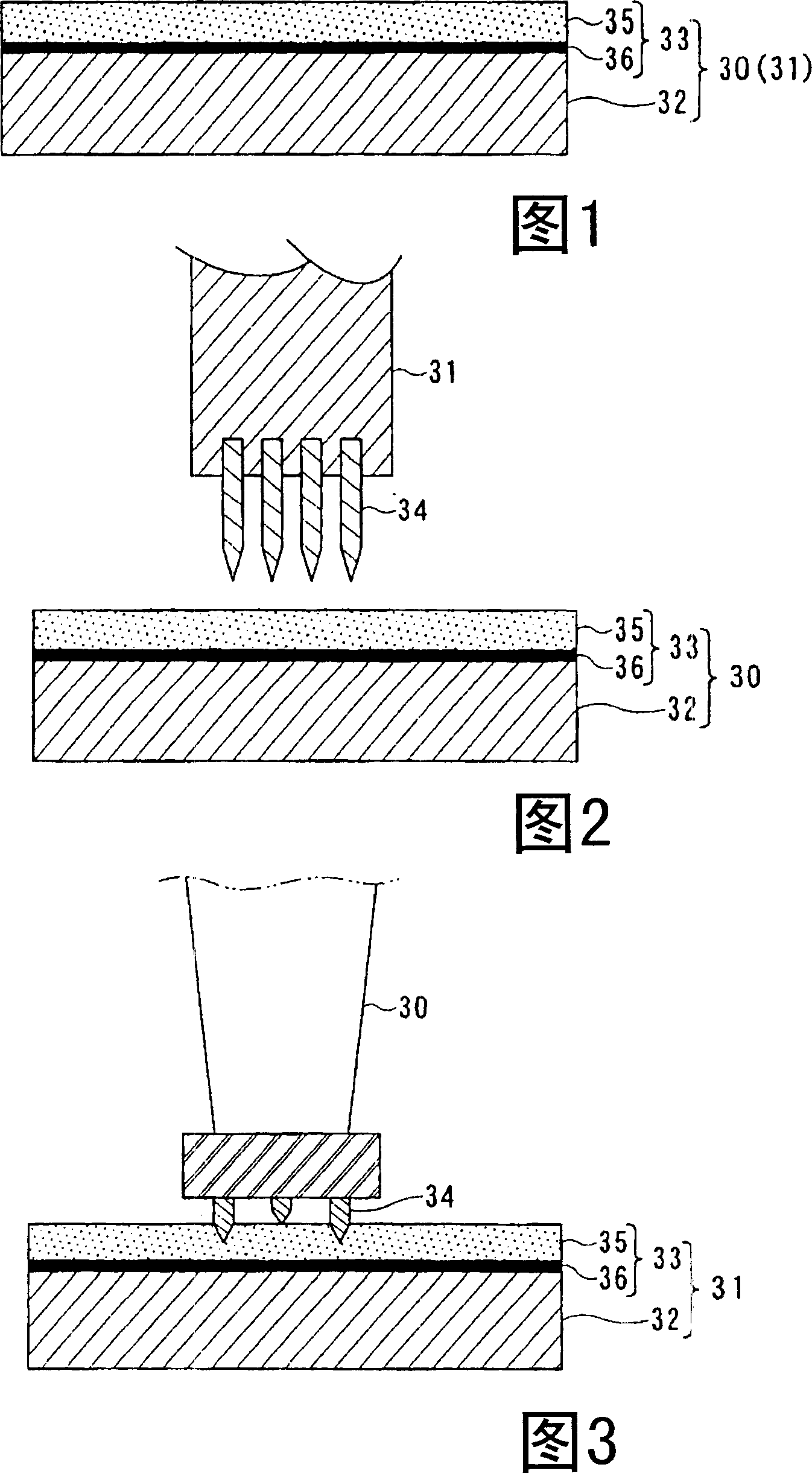

[0042] First, referring to FIG. 1 showing a sealing device according to an embodiment of the present invention, this sealing device is applied to a fluid machine having a rotating part 31 and a stationary (or fixed) part 30, wherein the rotating part 31 is, for example, a turbine rotor and a turbine The movable vanes, the stationary part 30 are for example inner and outer diaphragm rings supporting the turbine nozzle. The coating layer 33 is formed on the base material 32 of either the rotating part 31 or the stationary part 30 . The coating 33 includes a wear-resistant layer (upper layer) 35 and an adhesive layer (lower layer) 36 as a binder (bonding agent).

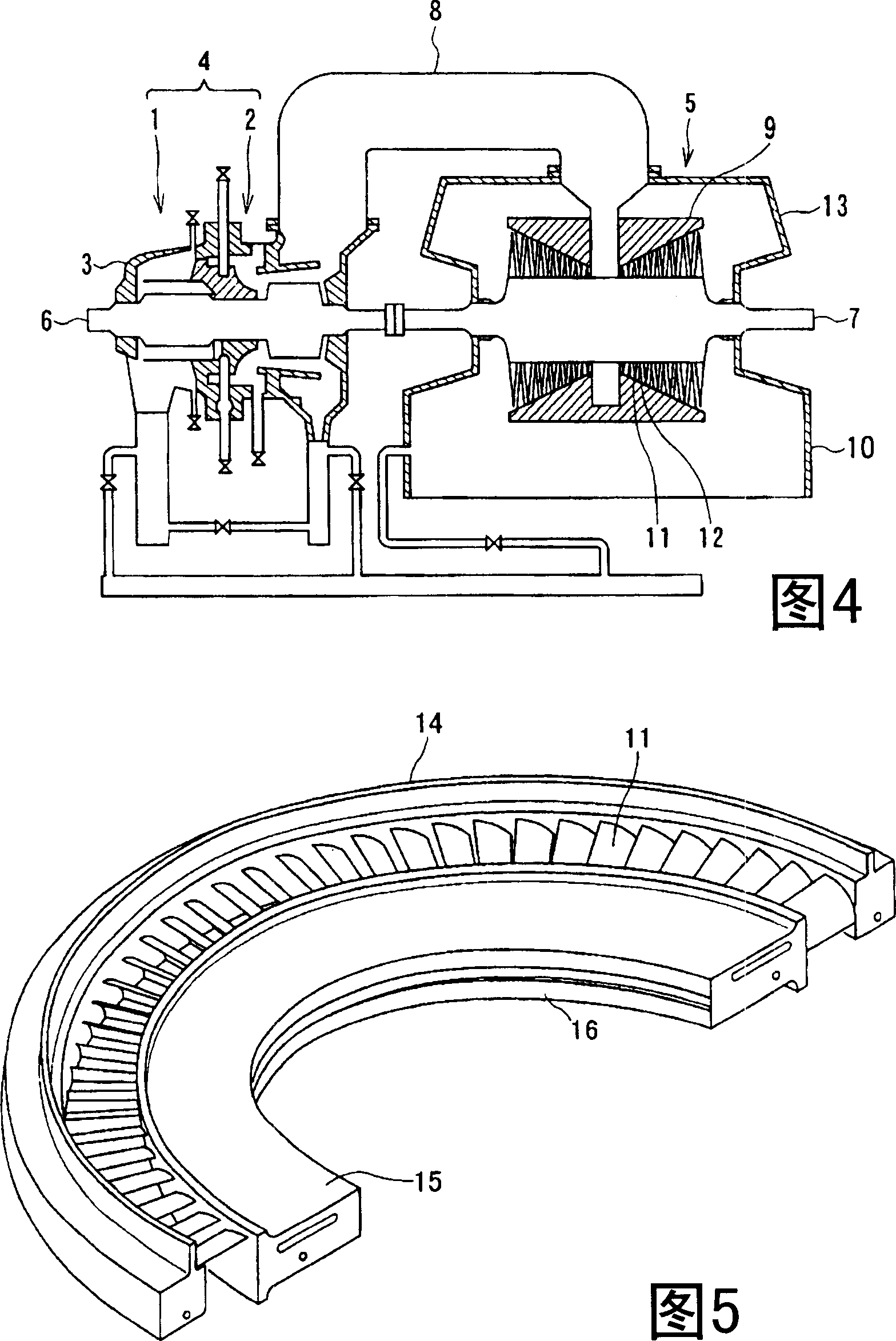

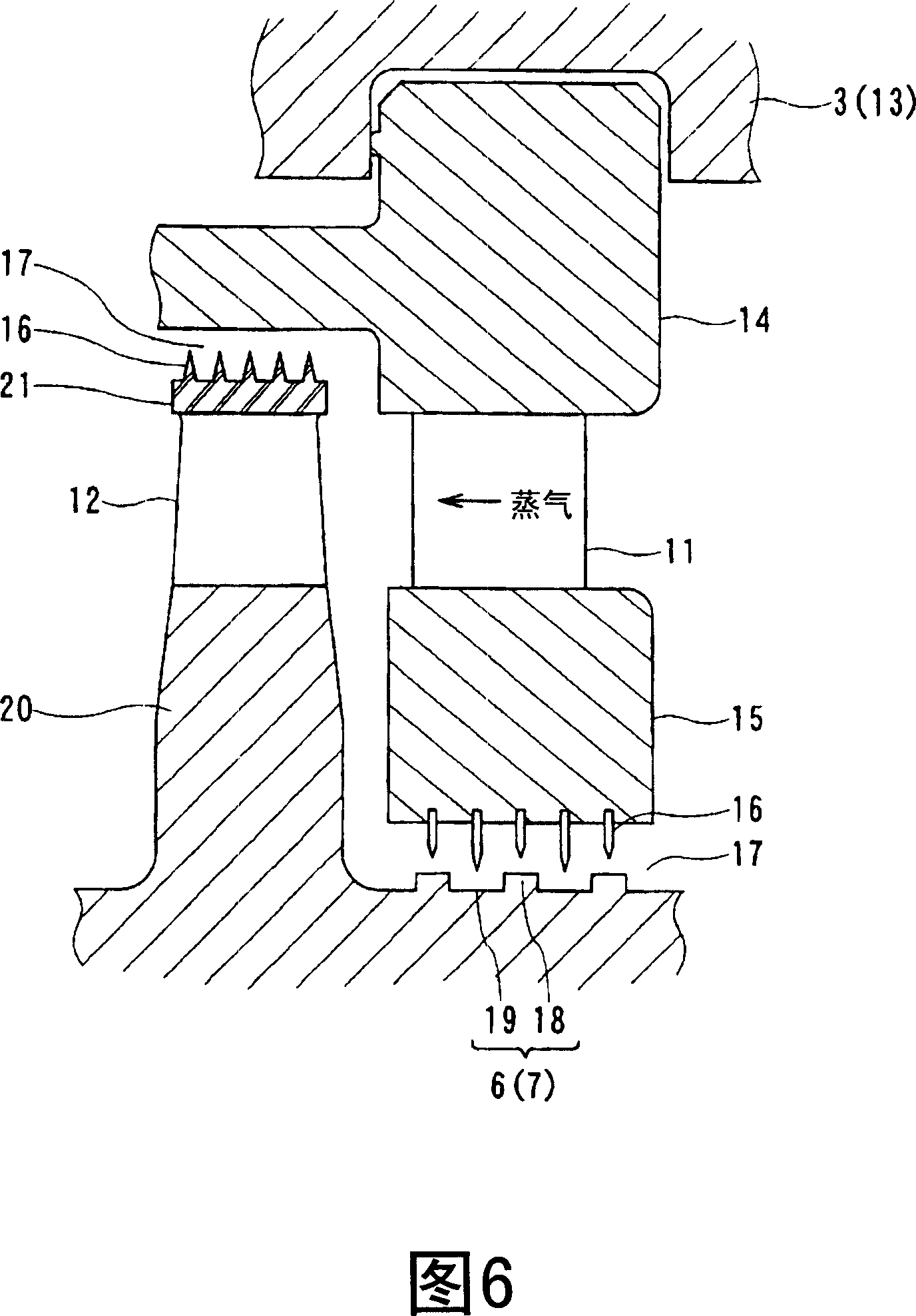

[0043] In particular, as shown in FIG. 2 , the cover of the movable blade of the turbine is an example of the rotating portion 31 and is provided with sealing fins 34 . The outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com