Honeycomb plate machining process

A processing technology, technology of honeycomb panels, applied in lamination devices, lamination, layered products, etc., can solve problems such as uneven surface of metal sheets, damage to honeycomb panels, uneven pressure, etc., to achieve good implementation effect and high pressure Uniform, easy-to-handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be further described in detail below.

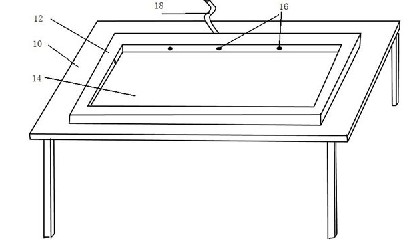

[0010] like figure 1 As shown, the pressure applying equipment for implementing the honeycomb panel processing technology of the present invention includes a table-shaped workbench 10, and the workbench 10 is provided with a rectangular area surrounded by end-to-end connection of vacuum exhaust pipes 12, that is, a workpiece platform 14. The vacuum suction pipe 12 is a hollow tube with a square cross section. The vacuum suction pipe 12 is provided with several air holes 16 on the inner side close to the workpiece platform 14 , and is connected to the vacuum suction device (not shown) through a pipe 18 on the outside. A flexible sealing film (not shown) is also provided on the workbench 10, and the sealing film seals the entire workpiece platform 14 and the vacuum exhaust pipe 12 to isolate it from the atmosphere of the environment. One side of the sealing film is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com