Non-balanced closed field magnetron sputtering ion plating equipment

A technology of magnetron sputtering and closed field, which is applied in the direction of sputtering plating, ion implantation plating, vacuum evaporation plating, etc., to achieve the effects of easy observation, guaranteed density and adhesion, and convenient opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

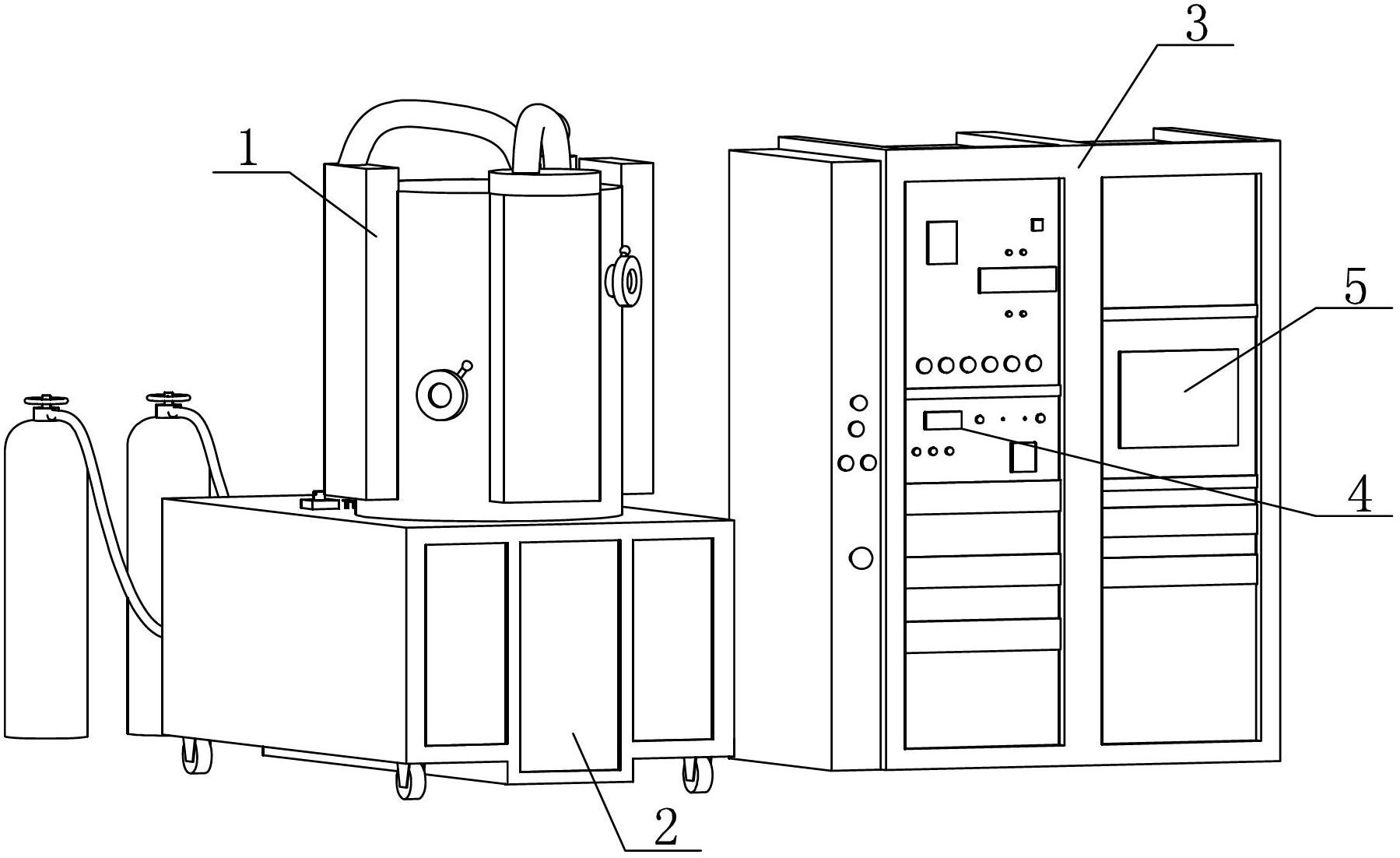

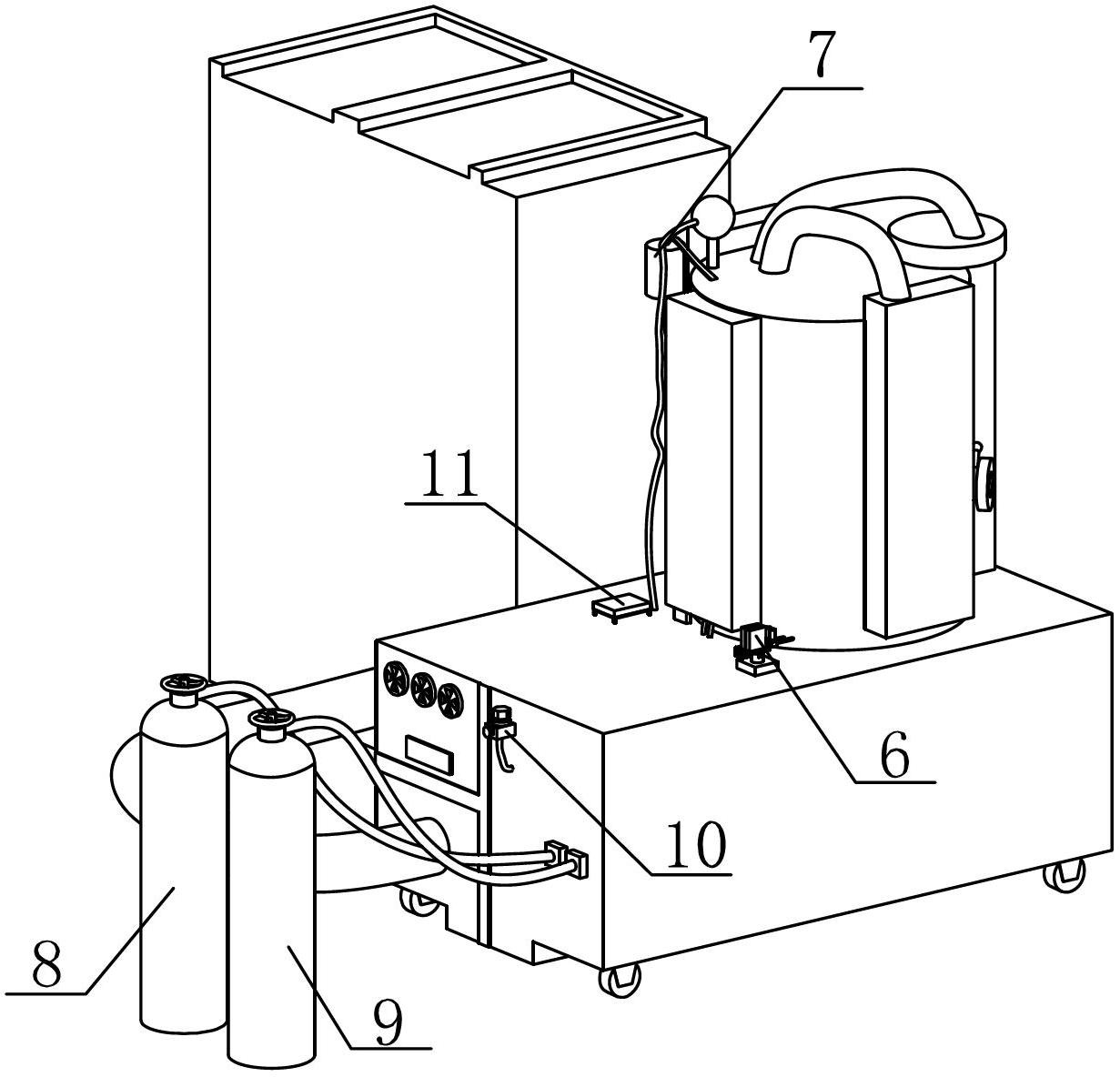

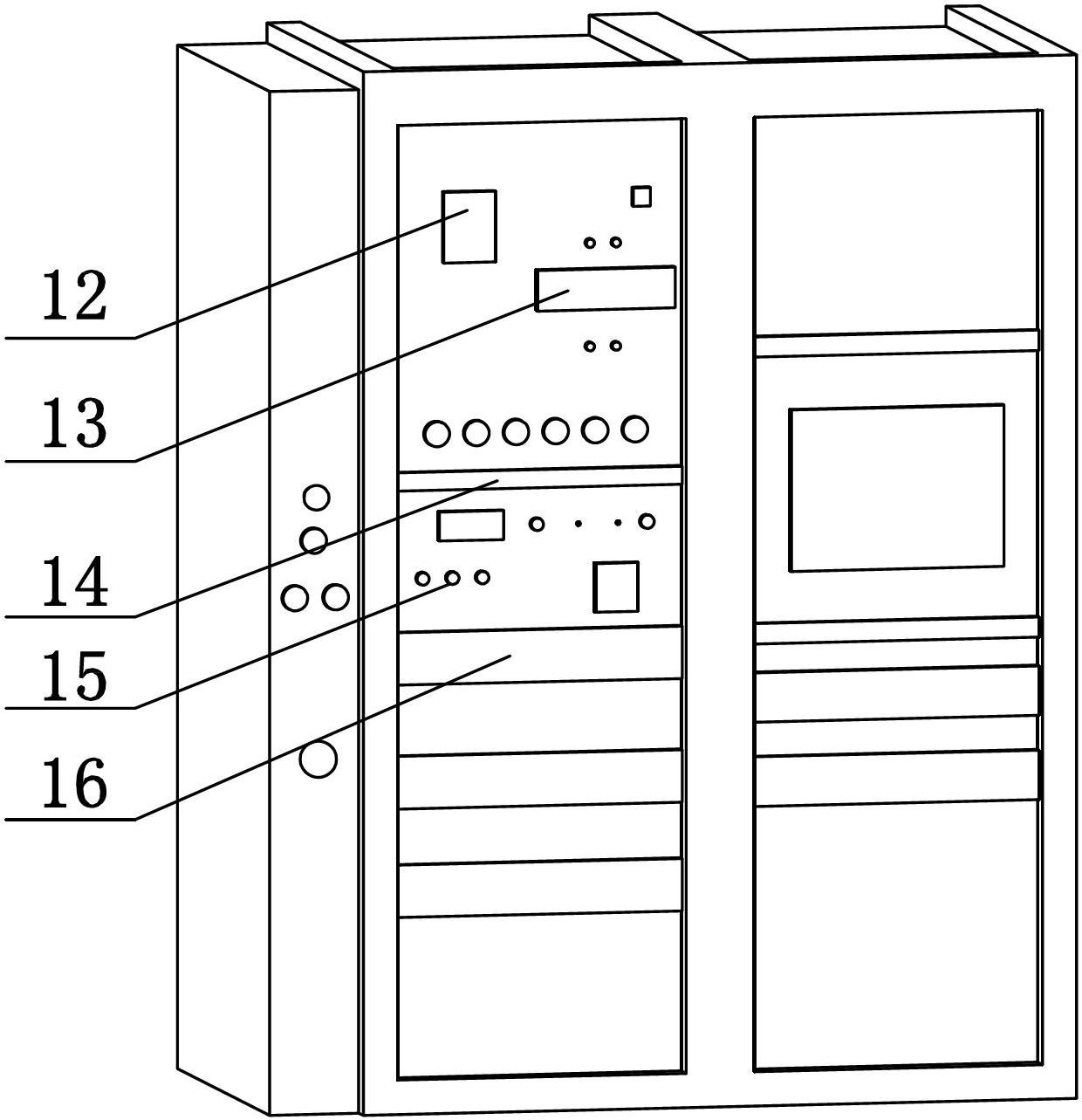

[0028] Embodiment 1 of the present invention: as figure 1 , figure 2 As shown, an unbalanced closed-field magnetron sputtering ion plating equipment includes a vacuum chamber 1 and a control cabinet 3, a vacuum control cabinet 2 is provided below the vacuum chamber 1, a manual operation interface 4 and a fully automatic An operation interface 5, a side-opening furnace door 23 is provided on the vacuum chamber 1, an argon gas cylinder 8 and a nitrogen gas cylinder 9 are provided behind the vacuum control cabinet 2, a gas pressure gauge 10 is provided behind the vacuum control cabinet 2, and a gas The flow feedback system 16 is connected with the gas pressure gauge 10 . The vacuum control cabinet 2 includes a diffusion pump, a Roots pump and a mechanical pump; the vacuum control cabinet 2 is provided with an inert gas flowmeter 11 and a monochromator 6 ; and a vacuum gauge 7 is provided above the vacuum chamber 1 . The vacuum degree in the vacuum chamber 1 is 10-1Pa.

[0029...

Embodiment 2

[0035] Embodiment 2 of the present invention: as figure 1 , figure 2 As shown, an unbalanced closed-field magnetron sputtering ion plating equipment includes a vacuum chamber 1 and a control cabinet 3, a vacuum control cabinet 2 is provided below the vacuum chamber 1, a manual operation interface 4 and a fully automatic An operation interface 5, a side-opening furnace door 23 is provided on the vacuum chamber 1, an argon gas cylinder 8 and a nitrogen gas cylinder 9 are provided behind the vacuum control cabinet 2, a gas pressure gauge 10 is provided behind the vacuum control cabinet 2, and a gas The flow feedback system 16 is connected with the gas pressure gauge 10 . The vacuum control cabinet 2 includes a diffusion pump, a Roots pump and a mechanical pump; the vacuum control cabinet 2 is provided with an inert gas flowmeter 11 and a monochromator 6 ; and a vacuum gauge 7 is provided above the vacuum chamber 1 . The vacuum degree in the vacuum chamber 1 is 10-1Pa.

[0036...

Embodiment 3

[0042] Embodiment 3 of the present invention: as figure 1 , figure 2 As shown, an unbalanced closed-field magnetron sputtering ion plating equipment includes a vacuum chamber 1 and a control cabinet 3, a vacuum control cabinet 2 is provided below the vacuum chamber 1, a manual operation interface 4 and a fully automatic An operation interface 5, a side-opening furnace door 23 is provided on the vacuum chamber 1, an argon gas cylinder 8 and a nitrogen gas cylinder 9 are provided behind the vacuum control cabinet 2, a gas pressure gauge 10 is provided behind the vacuum control cabinet 2, and a gas The flow feedback system 16 is connected with the gas pressure gauge 10 . The vacuum control cabinet 2 includes a diffusion pump, a Roots pump and a mechanical pump; the vacuum control cabinet 2 is provided with an inert gas flowmeter 11 and a monochromator 6 ; and a vacuum gauge 7 is provided above the vacuum chamber 1 . The vacuum degree in the vacuum chamber 1 is 10-2Pa.

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com