Thermal transfer ribbon

A thermal transfer ribbon and color layer technology, applied in printing, ink ribbons, inking devices, etc., can solve problems such as incompetent general-purpose ribbons, achieve excellent performance indicators, wide applicable energy levels and pressure ranges, and ensure integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

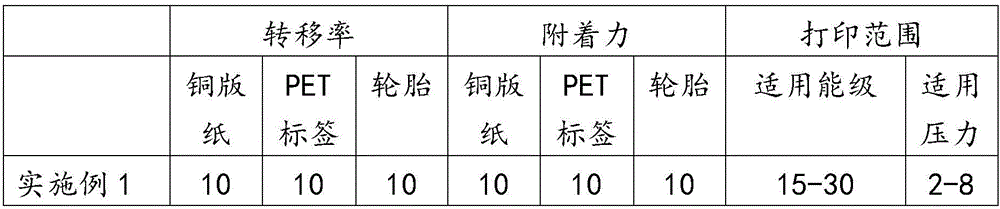

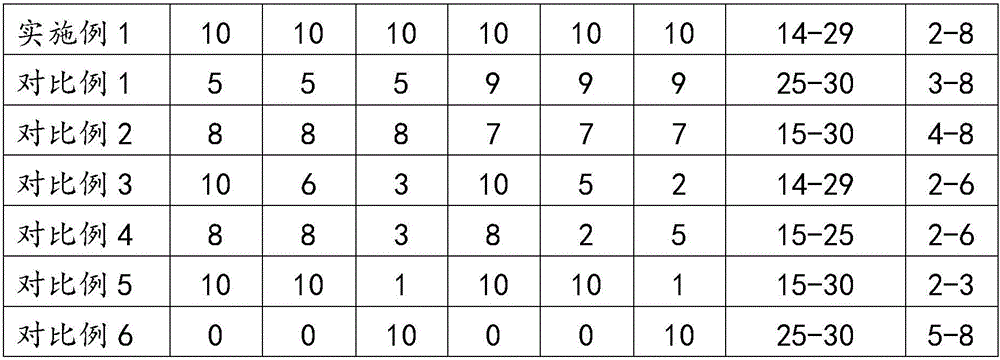

Embodiment 1

[0024] Embodiment 1: A kind of heat transfer ribbon, is coated on the base layer on the base material, the colored layer coated on the base layer, the adhesive layer coated on the colored layer, and coated on the base material quilt surface The composition of the back coating, the composition of the bottom layer, color layer and adhesive layer is as follows:

[0025] Underlying formula: 100% silicone grease;

[0026] Color layer formula: SEBS50%, pigment 50%;

[0027] Adhesive layer formula: fumed silica 10% + silane-modified cyclized rubber resin 90%.

Embodiment 2

[0028] Embodiment 2: A kind of thermal transfer ribbon, is coated on the base layer on the base material, the colored layer coated on the base layer, the adhesive layer coated on the colored layer, and coated on the substrate surface The composition of the back coating, the composition of the bottom layer, color layer and adhesive layer is as follows:

[0029] Base formula: 100% silicone oil.

[0030] Color layer formula: EVA50%, pigment 50%;

[0031] Adhesive layer formula: 20% titanium dioxide + 80% silane-modified cyclized rubber resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com