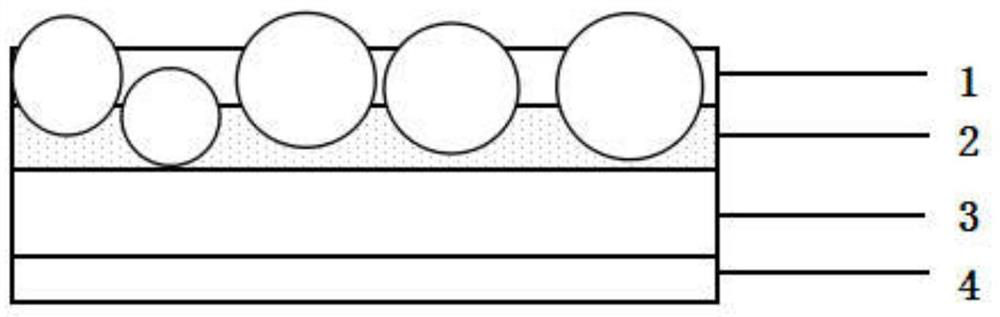

A kind of antiglare cured film and preparation method thereof

A hardened film and anti-glare technology, which is applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve problems that affect product order and appearance, cleaning work, and solar power generation effects, and achieve excellent anti-glare properties , avoid shrinkage cavity, good anti-glare performance and surface texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

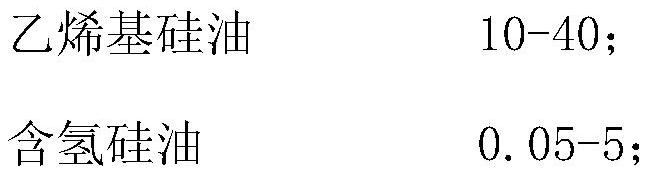

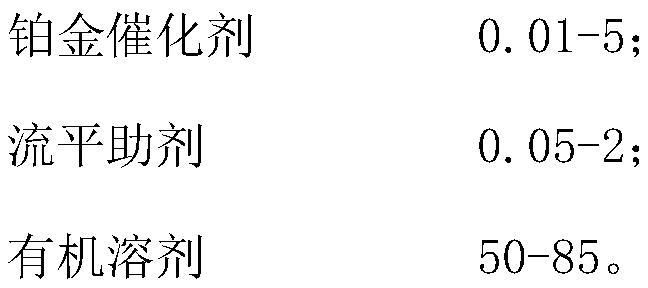

Method used

Image

Examples

Embodiment 1

[0048] Hardened layer coating solution preparation: 20g modified bisphenol A epoxy acrylate (Changxing Technology, trade name: 6231A-80), 3g polyether modified dimethyl siloxane (Bick Chemical Company, trade name: BYK-3550), 1g 1-hydroxycyclohexyl phenyl ketone (Double Bond Chemical Co., Ltd., trade name: Doublecure 184), 6g nano silicon dioxide (Nanjing Tianxing New Material Co., Ltd., trade name: TDS-A2 ), 70g butanone was placed in a stirring pot, and stirred evenly to obtain a hardened layer coating liquid.

[0049] Anti-glare hardening solution preparation: 36g aliphatic polyurethane hexaacrylate (Changxing Technology, trade name: 6149-100), 20g tridecyl acrylate (Sartomer, trade name: SR489D), 30g silica particles ( Evonik, trade name: ACEMATT3600) was placed in the container, and after stirring at a high speed, 10 g of organomodified polysiloxane (Tiger Auxiliaries, trade name: Tech-2037D), 4 g of 2,4,6-trimethylbenzene Formyl-diphenylphosphine oxide (Double Bond Chemi...

Embodiment 2

[0055] Hardened layer coating solution preparation: 29g modified hexafunctional epoxy acrylate (Changxing Technology, trade name: DR-G908), 0.05g OH group-containing polyether modified silicone (Bick Chemical Company, trade name: BYK -377), 1.55g 2-hydroxyl-2-methyl-1-phenyl-1-acetone (Double Bond Chemical Co., Ltd., trade name: Doublecure 173), 20g nano silicon dioxide (Nanjing Tianxing New Material Co., Ltd. company, trade name: TDS-C10), 49.4 methyl isobutyl ketone is placed in a stirring pot, and stirred evenly to obtain a hardened layer coating liquid.

[0056] Anti-glare hardening solution preparation: 45g aliphatic polyurethane acrylate (Double Bond Chemical, trade name: Doublemer588), 37g aliphatic polyurethane acrylate (Haohui New Materials, trade name: CR90442), 2g PMMA particles (Soken Chemical, trade name Name: MR-10HG) is placed in the container, after stirring at a high speed, add 6g polyether modified silicone containing OH groups (Byk Chemical Company, trade na...

Embodiment 3

[0062] Hardened layer coating solution preparation: 35g fatty acid modified polyester acrylate (Evergreen Technology, trade name: 6313-100), 1.5g polyether modified silicone (Byk Chemical Company, trade name: BYK-325), 1.5 g of 1-hydroxycyclohexyl phenyl ketone (Double Bond Chemical Co., Ltd., trade name: Doublecure 184), 62 g of propylene glycol monomethyl ether were placed in a stirring pot, and stirred evenly to prepare a hardened layer coating liquid.

[0063] Antiglare hardening solution preparation: 35g aliphatic hexaacrylate (Double Bond Chemicals, trade name: Doublecure 571), 11g cyclohexane dimethanol diacrylate (Sartomer, trade name: CD406), 50g PMMA particles (Comprehensive Research Chemical, trade name: MR-7GC4) is placed in the container, after high-speed stirring is uniform, add 0.5g organomodified polysiloxane (Tiger Auxiliaries, trade name: Tech-2750), 3.5g 2-hydroxyl-2-formazan Base-1-phenyl-1-acetone (Double Bond Chemical Co., Ltd., trade name: Doublecure 173...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com