Patents

Literature

65results about How to "Excellent anti-glare" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard-coated antiglare film, method of manufacturing the same, optical device, polarizing plate, and image display

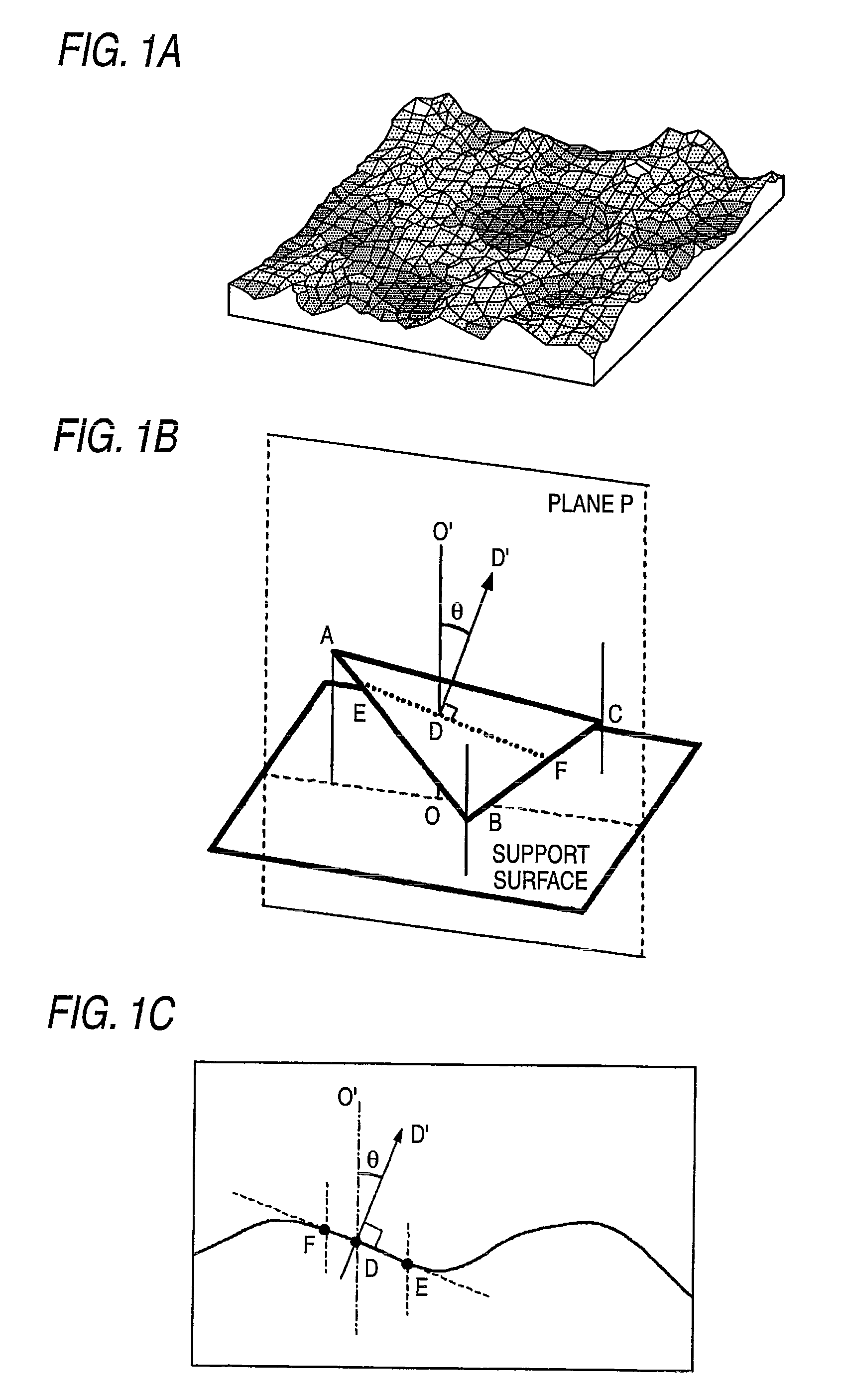

InactiveCN101046520ASolve the lack of hardnessHigh hardnessSynthetic resin layered productsPolarising elementsCoated surfaceHardness

A hard-coated antiglare film is provided that has high hardness, high scratch resistance, and good antiglare properties. In the hard-coated antiglare film of the present invention including a transparent plastic film substrate, a hard-coating layer containing fine particles is formed on at least one surface of the transparent plastic film substrate, the hard-coating layer has a thickness in the range of 15 to 30 mum, the fine particles have a weight average particle size of 30 to 75% of a thickness of the hard-coating layer, the average tilt angle thetaa of the unevenness of the hard-coating layer surface is in the range of 0.4 DEG to 1.5 DEG , and the hard-coating layer is formed using a resin for forming the hard-coating layer containing three specific resin components.

Owner:NITTO DENKO CORP

Ultraviolet curing nano transparent heat-insulation composite coating

InactiveCN101760110AImprove aging resistanceExcellent stain resistance and self-cleaningAntifouling/underwater paintsPaints with biocidesUltravioletContamination

The invention discloses an ultraviolet curing nano transparent heat-insulation composite coating belonging to the field of ultraviolet curing coatings and containing the following substances in percentage by weight: 30-75 percent of oilopolymer, 0.01-15 percent of photosensitive curing agent and 10-55 percent of activated monomer, as well as 0.1-15 percent of stannic oxide. The transparent heat-insulation coating can be prepared in 1 minute under ultraviolet irradiation at room temperature, and the curing speed is high and the cost is low. The coating has selectivity to a solar spectrum, and a coating film which is about 5-70 micrometers is formed on the material surface. When the coating is used for glass, the visible light transmissivity of the glass is still higher than 75 percent, and the infrared thermal screening factor is higher than 70 percent, thereby not only keeping the transparency of the original glass, but also effectively isolating the infrared thermal radiation of sunlight. The coating has good ageing resistance, contamination resistance, anti-static performance, anti-dazzle performance, radiation protection, quick curing, environmental protection and the like.

Owner:南京海泰纳米材料有限公司

Dazzling-proof hard coating material and high hardness hard coating film using same

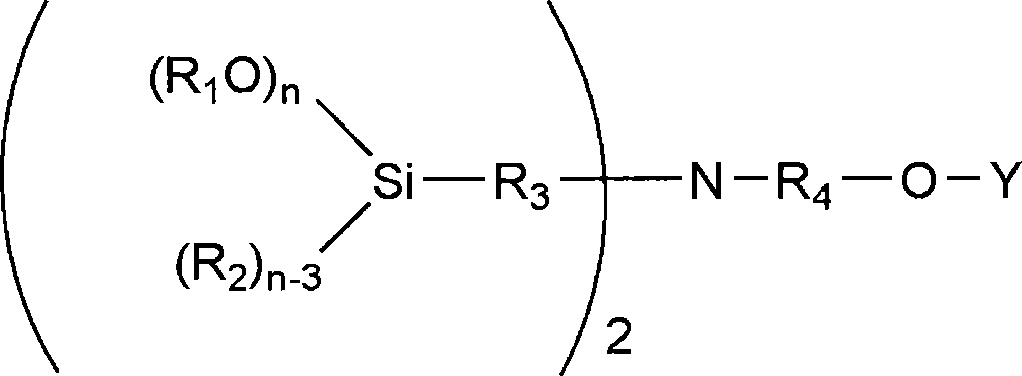

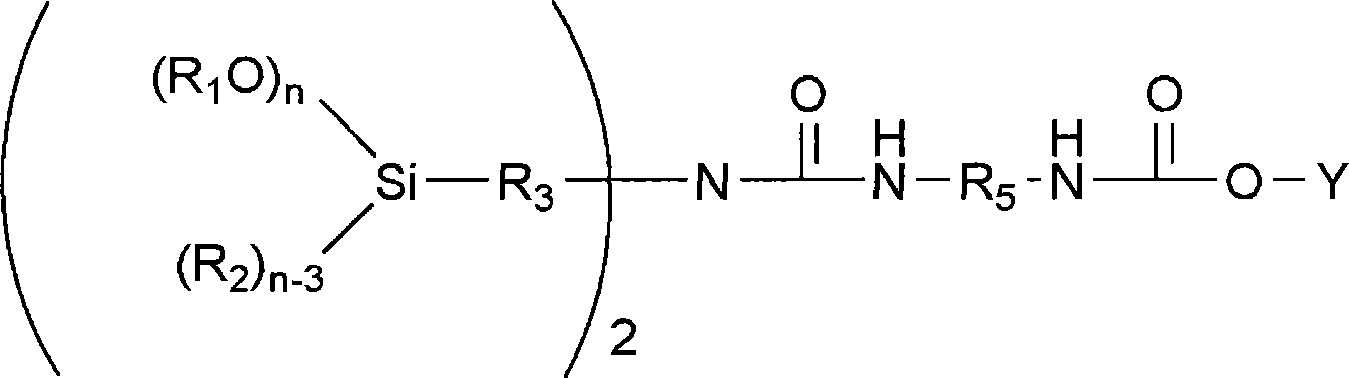

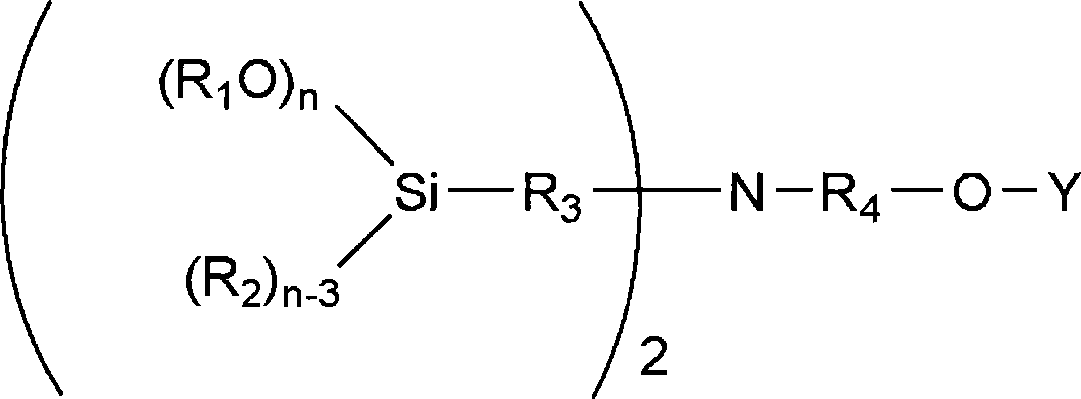

InactiveCN101235244AImprove aging resistanceFast curingLiquid surface applicatorsAntifouling/underwater paintsSilane compoundsSilica particle

An anti-glare hard coating solution is provided to retain good physical properties needed for hard coating films, and to suppress a peeling-off or curling phenomenon of a hard coating layer. An anti-glare hard coating solution includes (A) 5-50wt% of organic-inorganic silica particles in which a multi-functional silane compound comprising multi-functional (meth)acrylate represented by the following formula 1 is chemically bound to hydroxyl groups on the surface of the silica particle, (B) 5-40wt% of multi-functional (meth)acrylate, (C) 0.1-10wt% of an initiator, and (D) 1-20wt% of silicon fine particles, based on 100wt% of the hard coating solution.

Owner:DONGWOO FINE CHEM CO LTD

Ultraviolet curing nano transparent heat-insulating composite coating

InactiveCN102120900AHigh visible light transmittanceHigh infrared heat shielding rateCoatingsUltravioletMaterials science

The invention relates to an ultraviolet curing nano transparent heat-insulating composite coating. The ultraviolet curing nano transparent heat-insulating composite coating mainly comprises the following substances in percentage by weight: 30 to 75 percent of oligomer, 0.01 to 15 percent of photoinitiator, 10 to 55 percent of activated monomer, 0.1 to 15 percent of tin stibium oxide and 0.01 to 10 percent of nano material. The ultraviolet curing nano transparent heat-insulating composite coating can be prepared into a transparent heat-insulating coating within one minute through ultraviolet irradiation at normal temperature, so the curing speed is high and the cost is low. The coating has selectivity on solar spectrum and forms a coating film of about 2 to 7 mu m on the surface of a material. When the coating is applied to glass, visible light transmissivity of the glass is still more than 75 percent and the infrared heat shielding rate is more than 70 percent, so the coating maintains the transparency of the original glass, can effectively isolate infrared heat radiation of sunlight, and has the advantages of excellent aging resistance, stain resistance, self cleaning, static resistance, glare resistance, radiation resistance, high curing speed, environmental friendliness and the like.

Owner:高建宾

Method for preparing multifunctional automobile glass window film

InactiveCN103964705AGood explosion-proofImprove wear resistanceThermal insulationUltraviolet resistance

The invention discloses a method for preparing a multifunctional automobile glass window film. The method comprises the whole process of preparing specific components of the glass window film into the glass window film by using a specific method. In such a mode, by adopting the method for preparing the multifunctional automobile glass window film, the automobile glass window not only has various characteristics of explosion resistance, abrasion resistance, ultraviolet resistance, privacy, glare resistance, thermal insulation, sun blocking and the like, but also automobile owners can select and manufacture exclusive automobile window films according to personality and favor of self, and thus requirements of people can be better met.

Owner:WUXI HAITE NEW MATERIAL RES INST

Antiglare film, antireflective film, polarizing plate and image display device

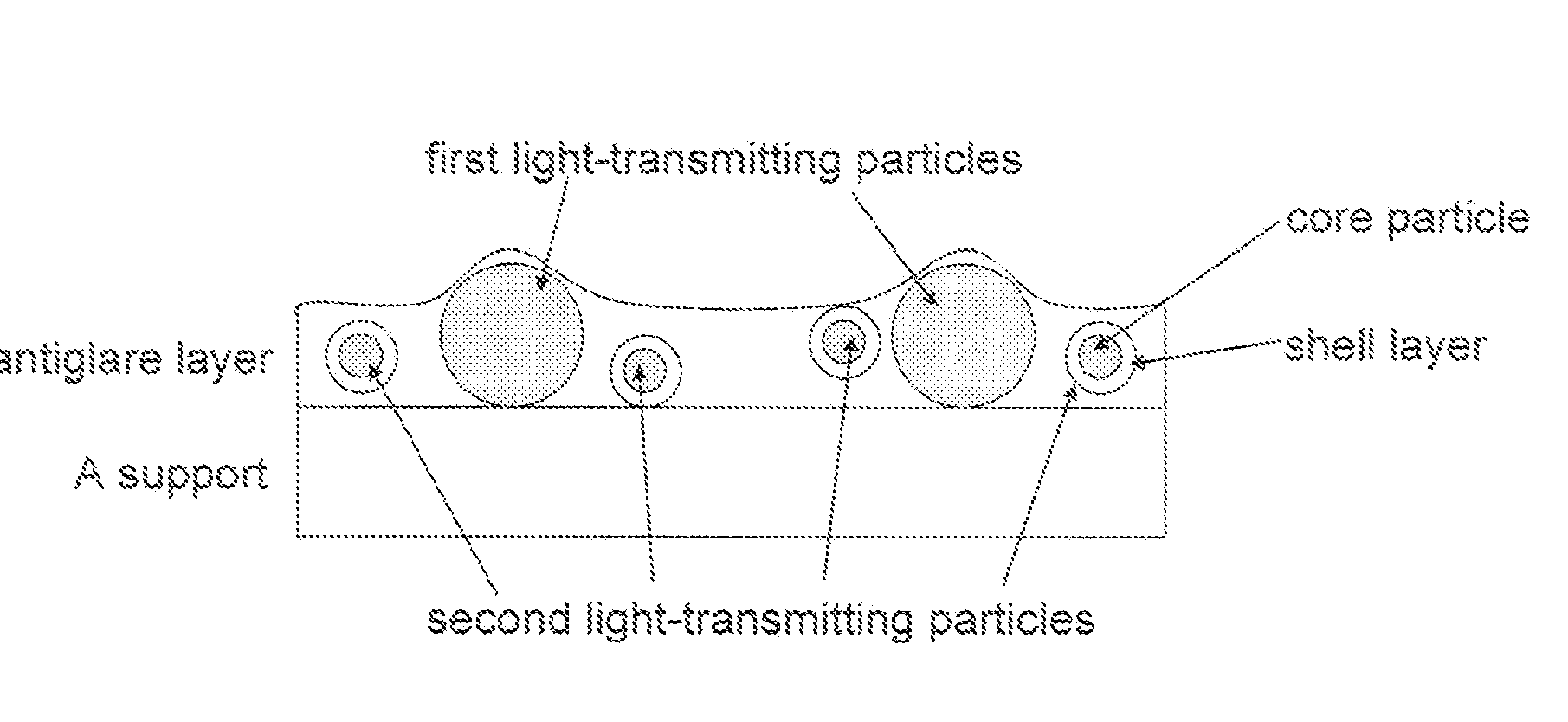

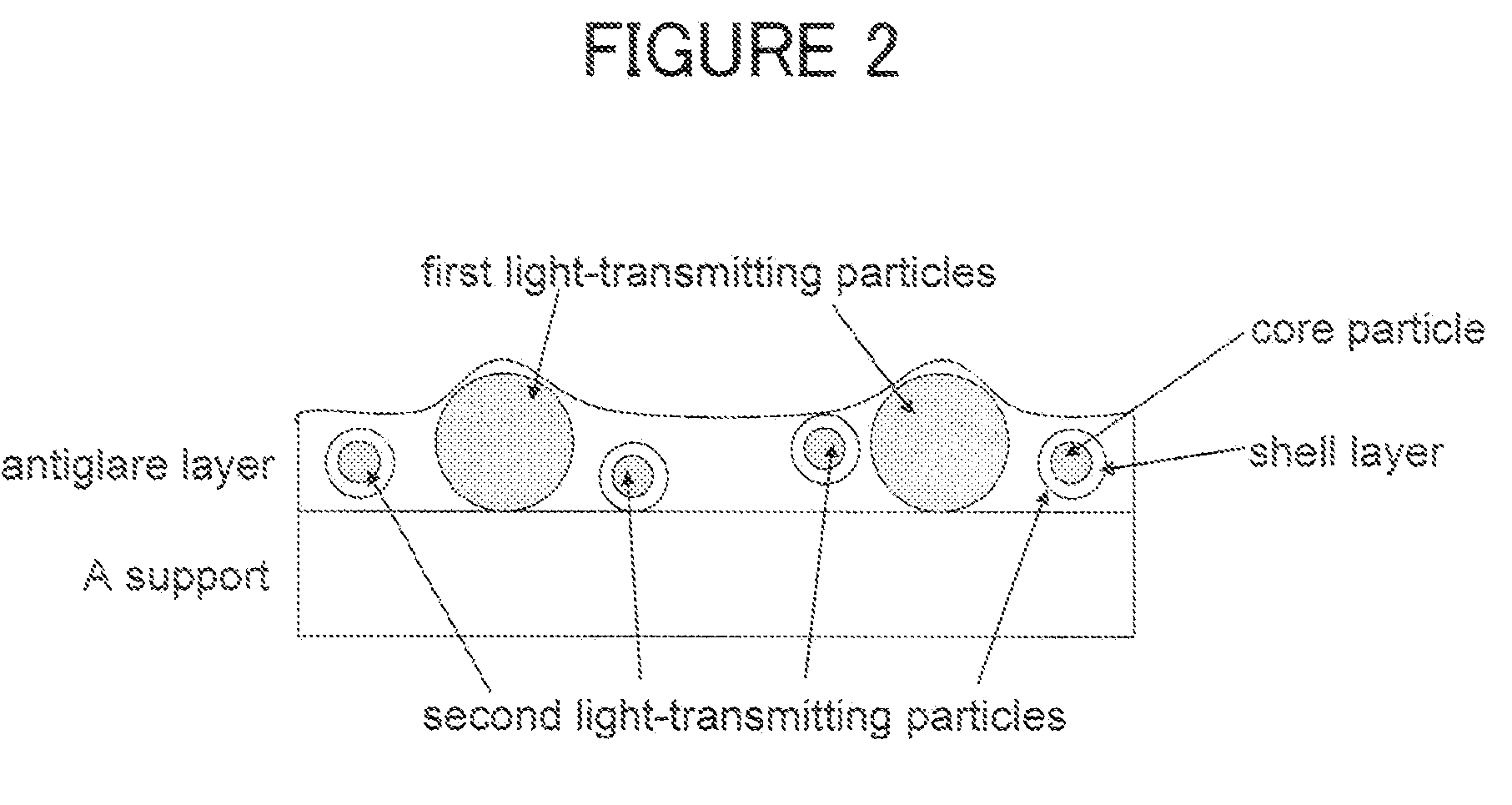

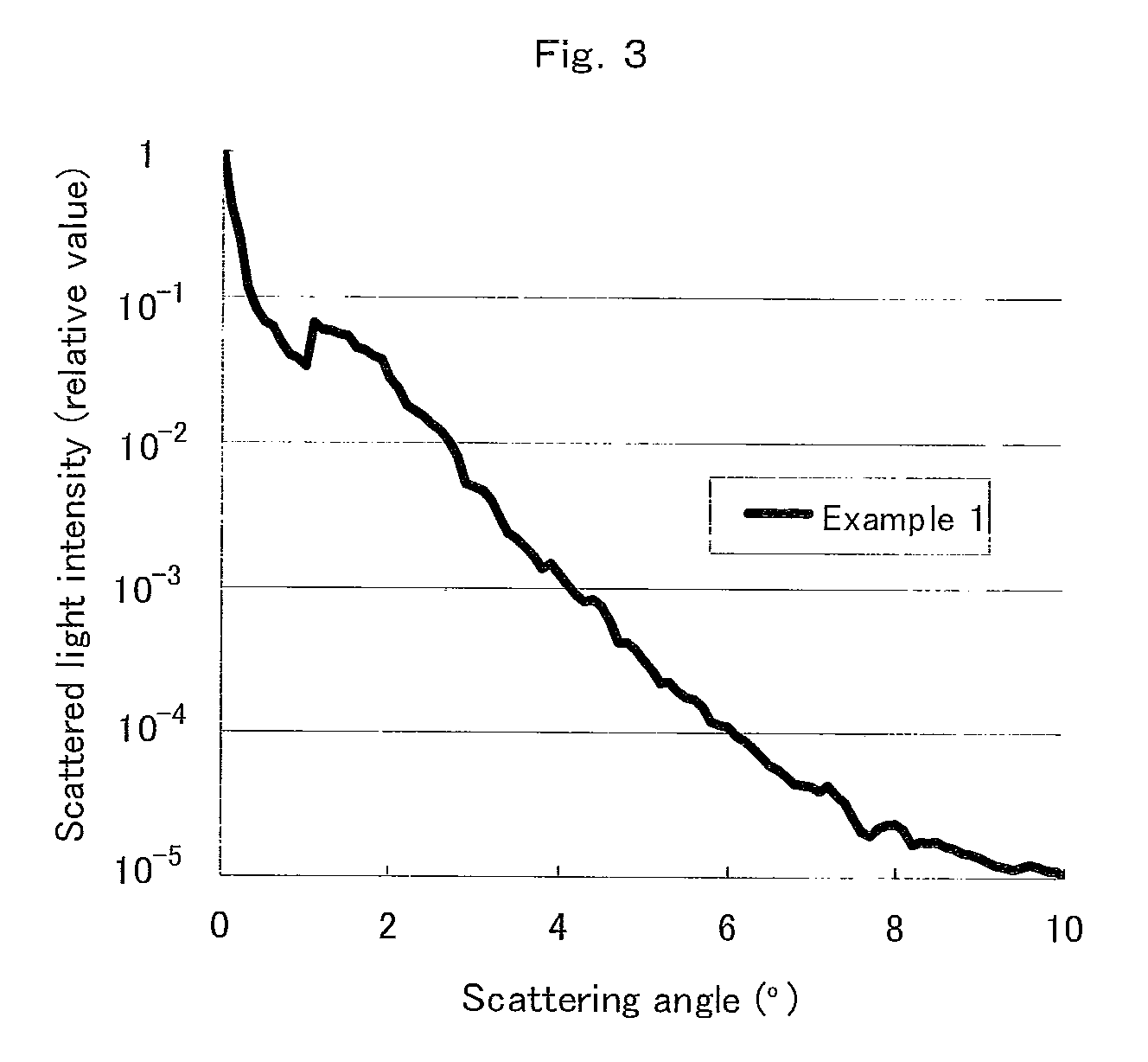

ActiveUS8256908B2Excellent anti-glareReduce reflectivityDiffusing elementsTotal solid contentOragene

An antiglare film is provided, the antiglare film including: a support; and an antiglare layer including a surface that has asperities, wherein the antiglare layer contains at least first light-transmitting particles and second light-transmitting particles, the first light-transmitting particles have an average particle size that is 0.01 to 2.5 μm greater than an average thickness of the antiglare layer, the second light-transmitting particles have an average particle size that is at least 0.1 μm smaller than the average thickness of the antiglare layer, the first light-transmitting particles are contained in an amount of 0.1 to 2 mass % based on a total solid content in the antiglare layer, the second light-transmitting particles are contained in an amount of 2 to 30 mass % based on the total solid content in the antiglare layer, and the second light-transmitting particles include organic polymer-containing particles each of which has a core particle / shell layer structure.

Owner:FUJIFILM CORP

Anti-glare film and process for producing the same

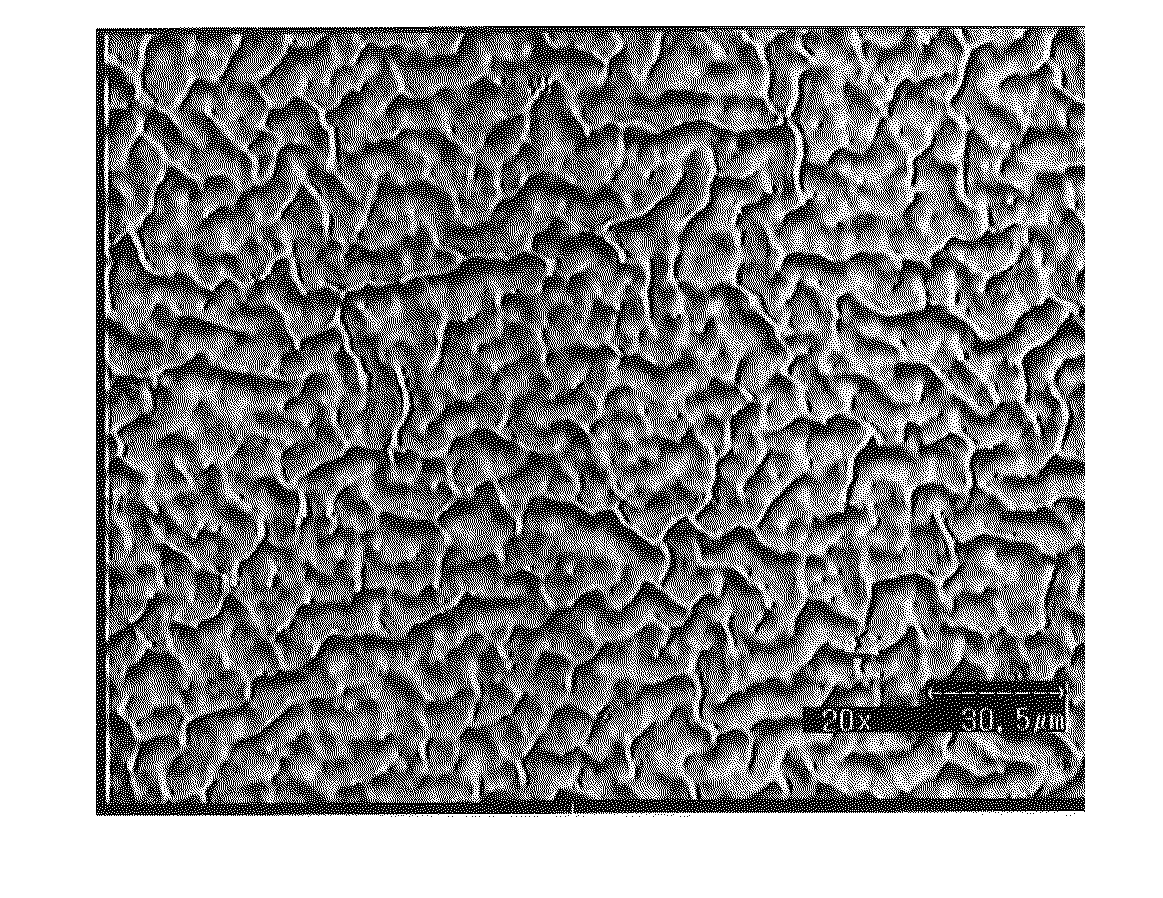

ActiveUS20150301237A1Well-balanced hazeWell-balanced clarityDiffusing elementsSolid-state devicesSquare MillimeterPhase splitting

An anti-glare film comprises an anti-glare layer having a ridge on a surface thereof. The ridge is formed by phase separation of a plurality of resin components, and the ridge has a branched structure and a total length of not less than 100 pl, and one or more of the ridges per square millimeter exist on the surface of the anti-glare layer.

Owner:DAICEL CHEM IND LTD

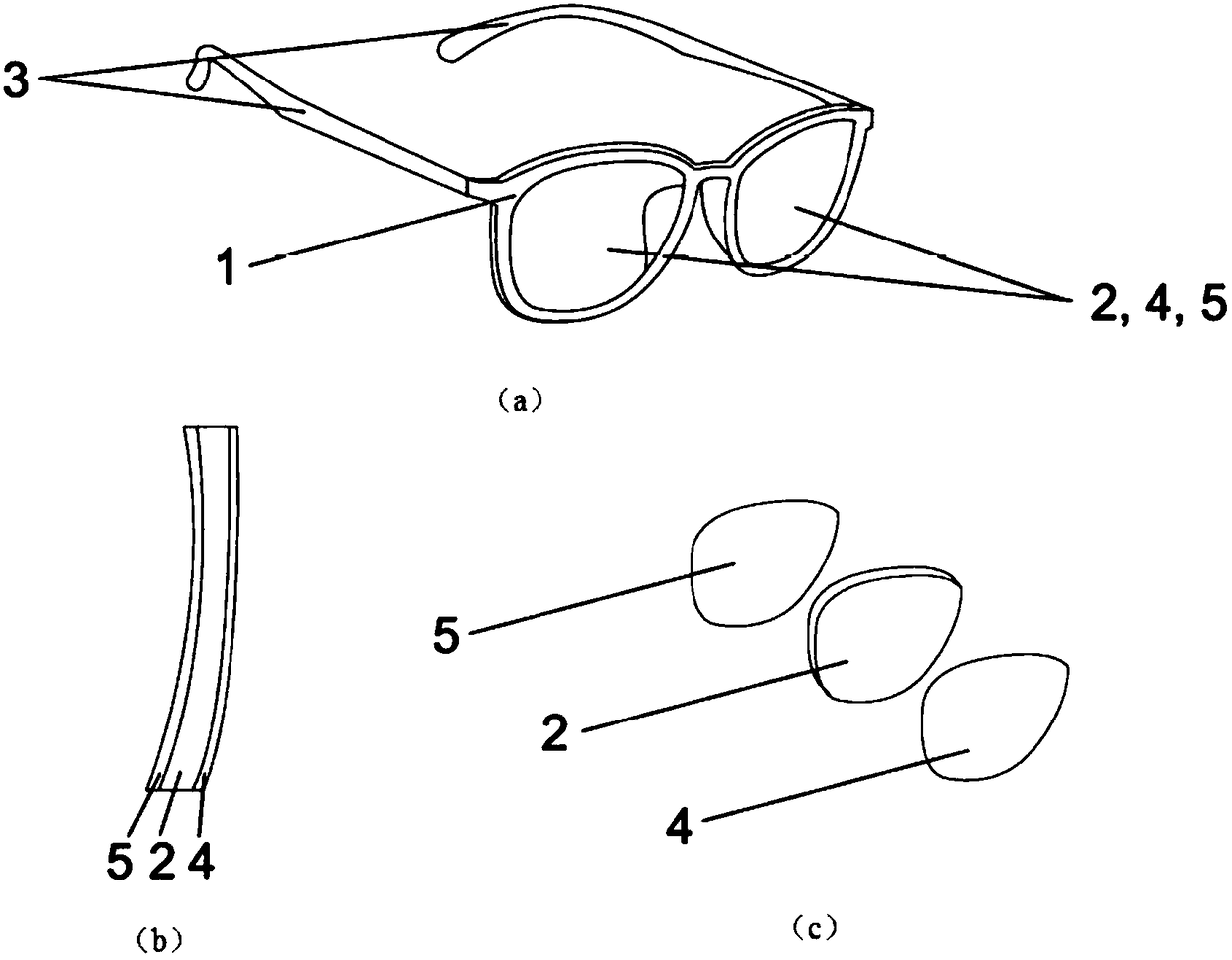

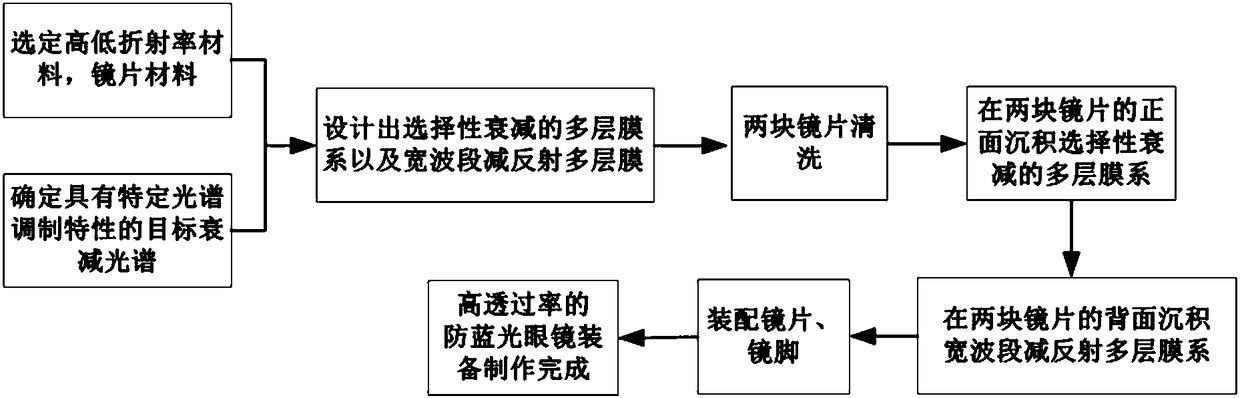

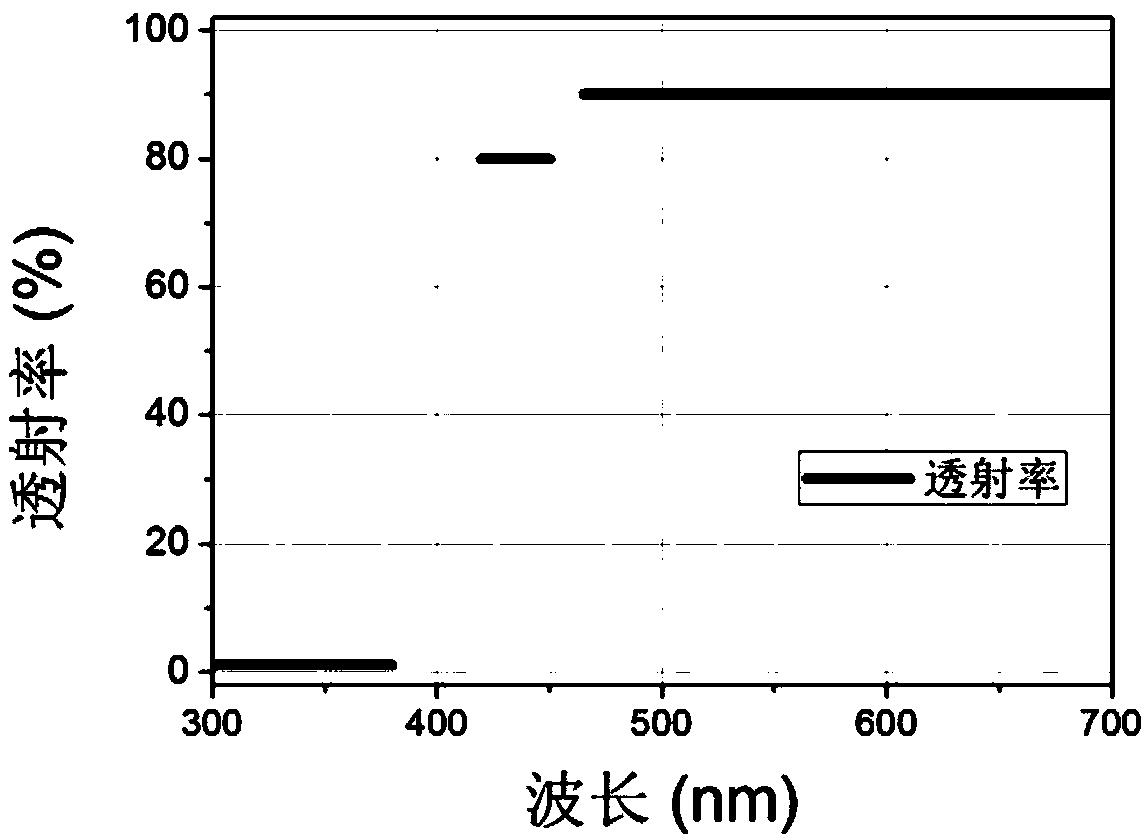

High-transmittance anti blue-ray lens, eyeglasses and device and manufacturing method thereof

ActiveCN108132545AAvoid harmGuaranteed indistortionOptical partsOptical elementsUltrasound attenuationHigh energy

The invention discloses a high-transmittance anti blue-ray lens, eyeglasses and device, and a manufacturing method thereof. The front face of a lens body is deposited with a full-medium multilayer film stack with the characteristic of a selective transmission attenuation band, and a back face is deposited with a wide-wave-band anti-reflection multilayer film stack at a visible light band; the high-transmittance anti blue-ray lens needs to meet the conditions: the transmittance at the wave band of 420 nm-450 nm is less than or equal to 80%, the transmittance at the wave band of 465 nm-700 nm ismore than or equal to 90%, and the transmittance at the wave band of 300 nm-380 nm is less than or equal to 1%. Through selection of the appropriate high and low refractive index film layer design, the attenuation transmission is achieved in a specific high-energy blue ray wave band, and high transmittance is achieved in the rest of wave bands, so the anti-blue protection with basic color balanceis achieved. The lens has the advantages of compact structure, simple manufacturing process and low cost, and is convenient for large-scale production.

Owner:HANGZHOU DENGZHITA TECH CO LTD

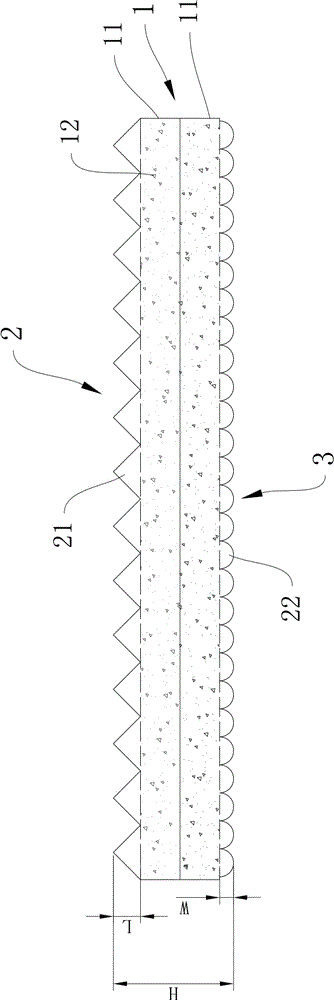

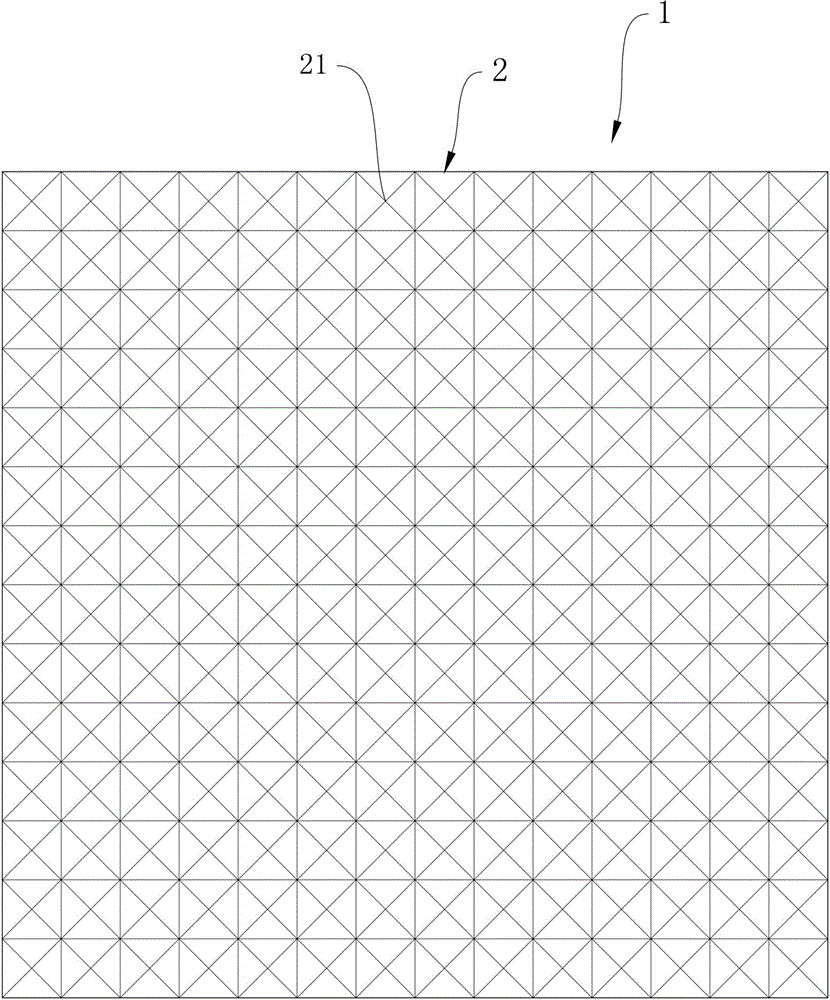

Multilayer integrally-formed anti-dazzle optical diffuser plate

InactiveCN105974500AExcellent performanceGood weather resistanceDiffusing elementsCo extrusionOptoelectronics

The invention relates to a multilayer integrally-formed anti-dazzle optical diffuser plate which comprises an optical diffuser plate body. The multilayer integrally-formed anti-dazzle optical diffuser plate is characterized in that the optical diffuser plate body is composed of light-penetrating optical scattering layers which are obtained through integral co-extrusion and extension and have different optical performances; the top surface of the optical diffuser plate body is a light outlet surface; the light outlet surface is also provided with a light outlet diffusion structure layer which is obtained through integral co-extrusion and extension with the optical diffuser plate body; the bottom surface of the optical diffuser plate body is a light inlet surface; and each light-penetrating optical scattering layer is provided with an optical scattering particle structure. The optical diffuser plate has a multilayer structure and is obtained through integral forming. Simple structure and low production cost are realized. Debugging and manufacture of optical boards which are in different optical grades and have different optical performances by an optical board manufacturer can be greatly facilitated, thereby realizing selection and application by each industry. The multilayer integrally-formed anti-dazzle optical diffuser plate has advantages of uniform and soft illumination, high illumination brightness, small light loss, and high anti-dazzle effect.

Owner:钟莉

Anti-ultraviolet anti-glare coating film and applications thereof

InactiveCN108690209AExcellent anti-glareHigh hardnessCoatingsOptical elementsUltraviolet lightsSolvent

The invention belongs to the field of optical materials, and particularly relates to an anti-ultraviolet anti-glare coating film and applications thereof. In the prior art, the irradiation of the light source onto the screen surface can produce glare. A purpose of the present invention is to solve the technical problem in the prior art. The invention provides an anti-ultraviolet anti-glare coatingfilm, which comprises a base material layer and at least a hard coating positioned on the surface of the base material layer, and a coating liquid is prepared from the raw materials of the hard coating during the preparation, and comprises, by weight, 40-80 parts of acrylic oligomer, 15-35 parts of an acrylic monomer, 3-12 parts of organic particles or inorganic particles, 2-7 parts of a photoinitiator, 0.1-1 part of a wetting and dispersing agent, 0.1-1 part of a leveling agent, 0.1-1 part of an ultraviolet light absorber, and 120-180 parts of a solvent. The anti-ultraviolet anti-glare coating film of the present invention has excellent anti-glare performance.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

Anti-glare film and process for producing the same

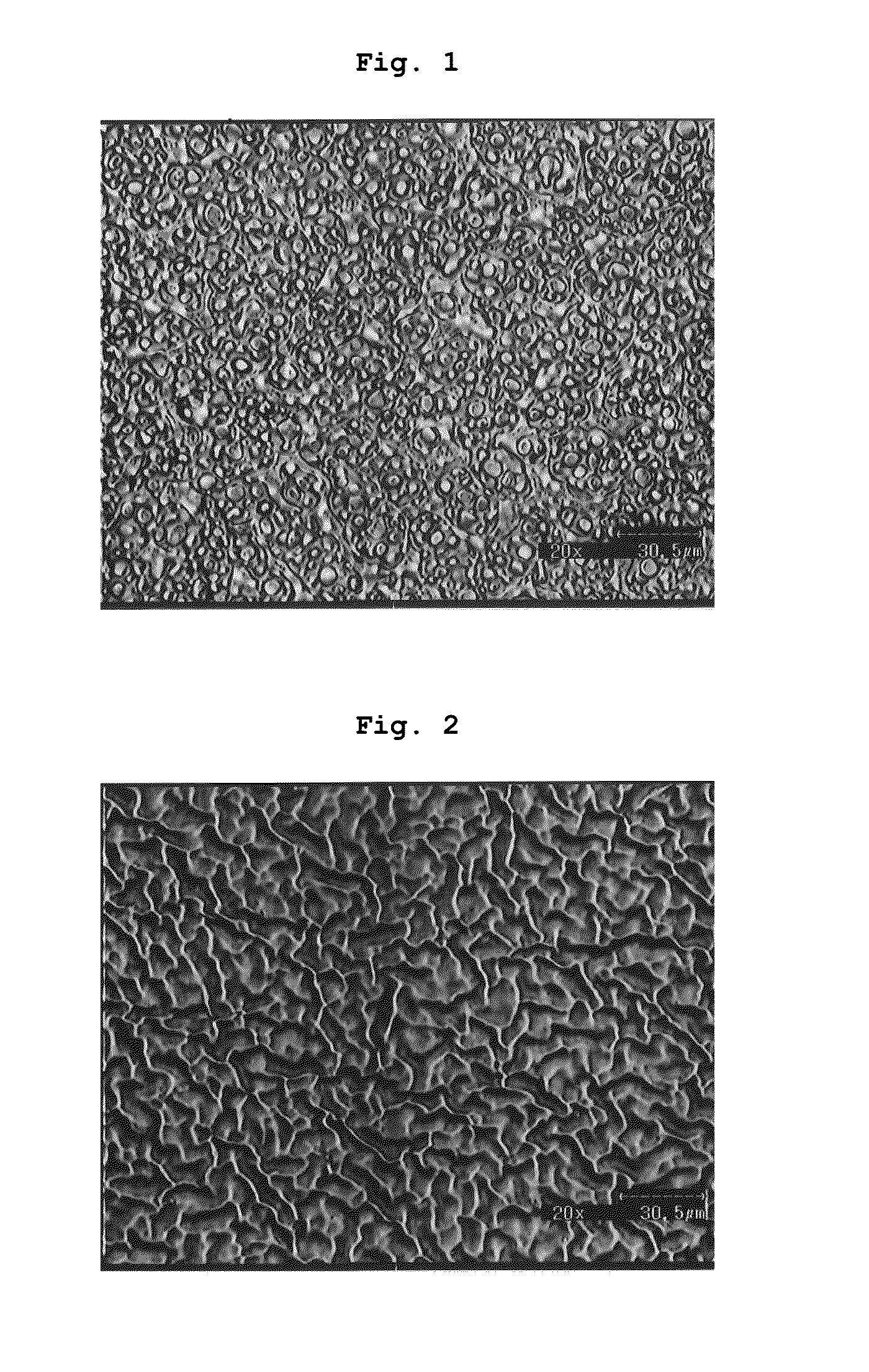

InactiveUS20100062225A1Increase stickinessAvoid reflectionsDiffusing elementsSynthetic resin layered productsCyclo olefin polymerSurface structure

An anti-glare film comprises a substrate film comprising a cycloolefinic polymer and an anti-glare layer formed on the substrate film. In the anti-glare film, the anti-glare layer is a cured layer of a curable resin composition and has a phase separation structure and an uneven surface structure, and the curable resin composition comprises a plurality of components being capable of phase separation and containing at least one curable component.

Owner:DAICEL CHEM IND LTD

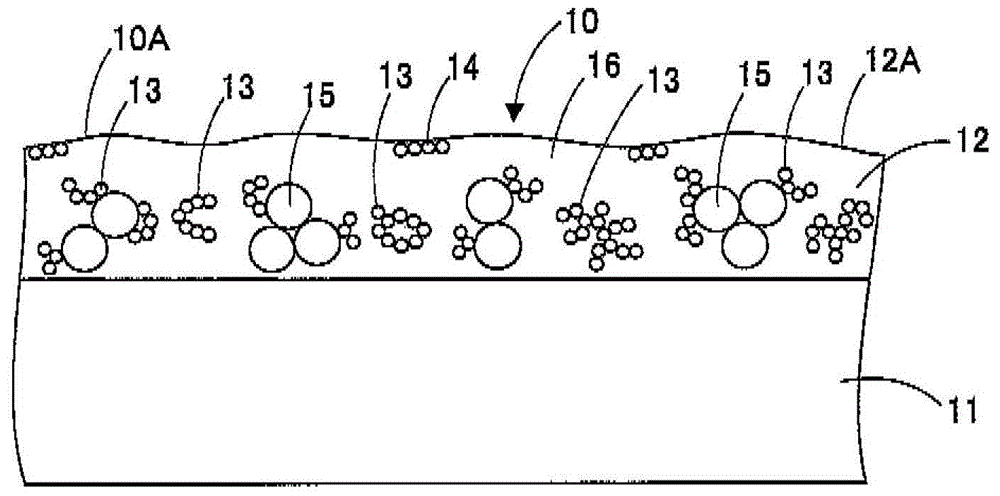

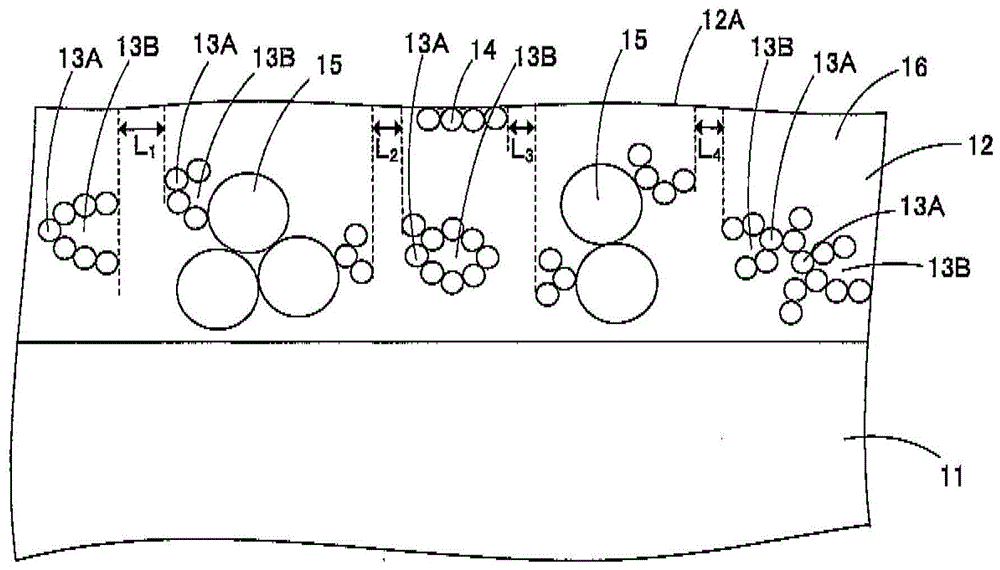

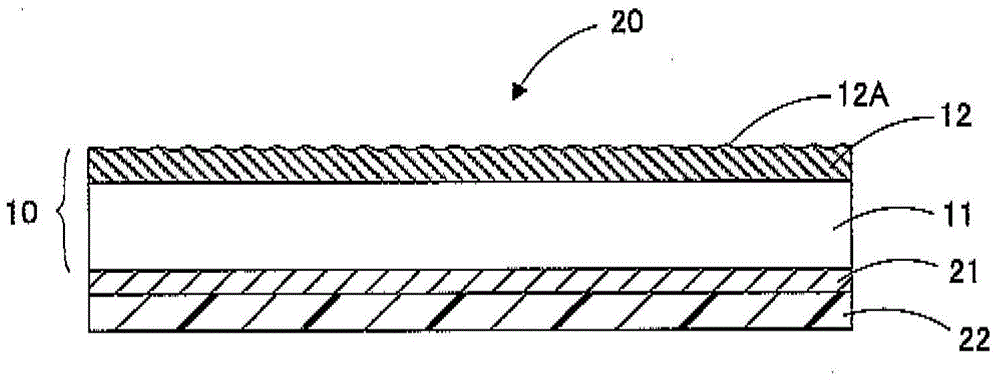

Anti-glare film, polarizing plate, liquid crystal panel, and image display device

ActiveCN105005104AGood anti-glareGood black colorDiffusing elementsSynthetic resin layered productsInorganic particleLiquid-crystal display

The invention relates to an anti-glare film, a polarizing plate, a liquid crystal panel, and an image display device, and aims at providing an anti-glare film, a polarizing plate, a liquid crystal panel, and an image display device which have the anti-glare performance that people do not mind incident light, and has good anti-blinding performance and good black colour feeling. An anti-glare film (10) is provided with a light-transmitting base material (11) and an anti-glare layer (12) arranged on the light-transmitting base material (11). The surface of the anti-glare layer (12) is an uneven surface (12A); the anti-glare layer (12) comprises adhesive resin (16) and more than two first inorganic particle condensates (13), each first inorganic particle condensate (13) is arranged in the adhesive resin (16), and is condensed by more than three inorganic particles; each first inorganic particle condensate (13) comprises a bending part (13A), the inorganic particles are connected to form the bending part (13A), and the bending part (13A) is provided with an inside area (13B) which is filled with the adhesive resin (16).

Owner:DAI NIPPON PRINTING CO LTD

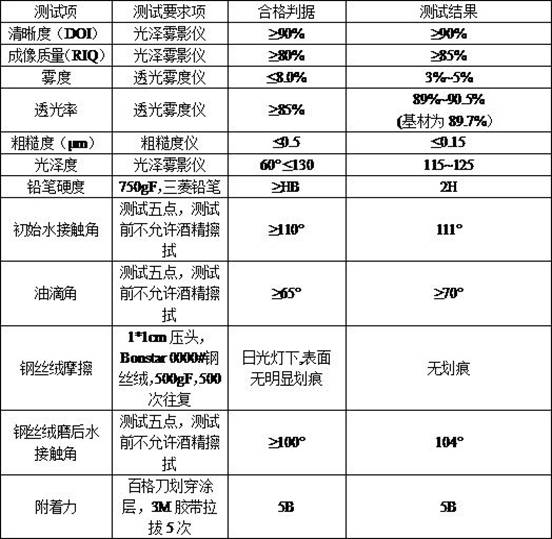

Anti-fingerprint and anti-glare coating, protective film containing same and preparation method of protective film

ActiveCN112094588AExcellent anti-fingerprint and anti-glare functionImprove clarityFireproof paintsAntifouling/underwater paintsFunctional monomerImaging quality

The invention discloses an anti-fingerprint and anti-glare coating, a protective film containing the same and a preparation method of the protective film. The protective film comprises the anti-fingerprint and anti-glare coating and a base material layer which are sequentially stacked from top to bottom. The anti-fingerprint and anti-glare coating comprises the following components in percentage by weight: 10-15% of urethane acrylate, 5-8% of fluorine-containing acrylate, 3-5% of six-functional monomer, 2-3% of low-functionality monomer, 1-2% of fluorine-containing functional monomer, 0.5-0.8%of inorganic filler, 0.5-2% of POSS monomer, 2-3% of assistant, 0.5-1% of photoinitiator and 65-75% of composite solvent, totaling 100%. The coating disclosed by the invention has the characteristicsof low haze, high light transmittance, high definition, good imaging quality, high visual visibility and the like, and can be used for a long time in a relatively complex and harsh environment.

Owner:NINGBO FUNA NEW MATERIALS TECH CO LTD

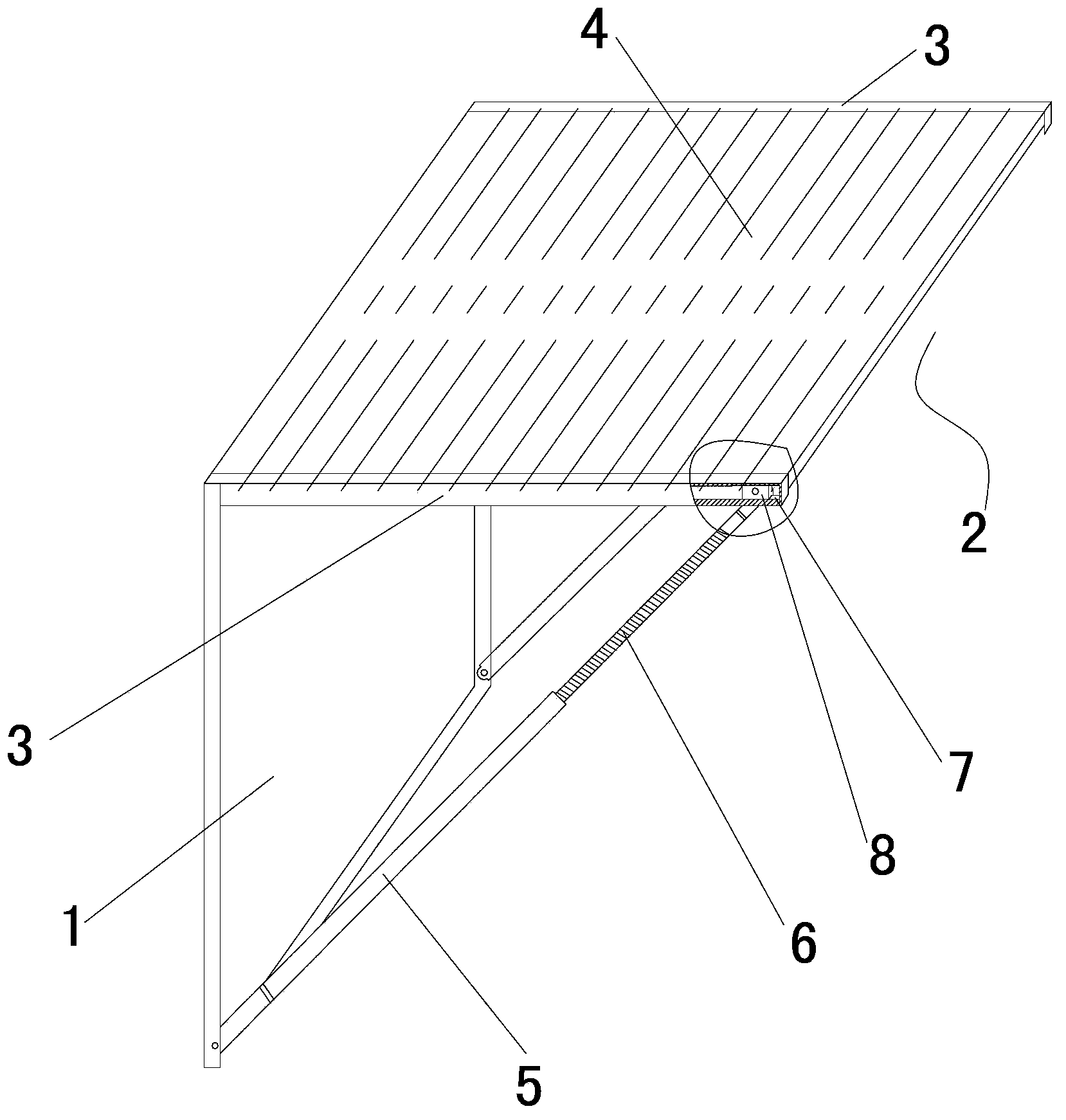

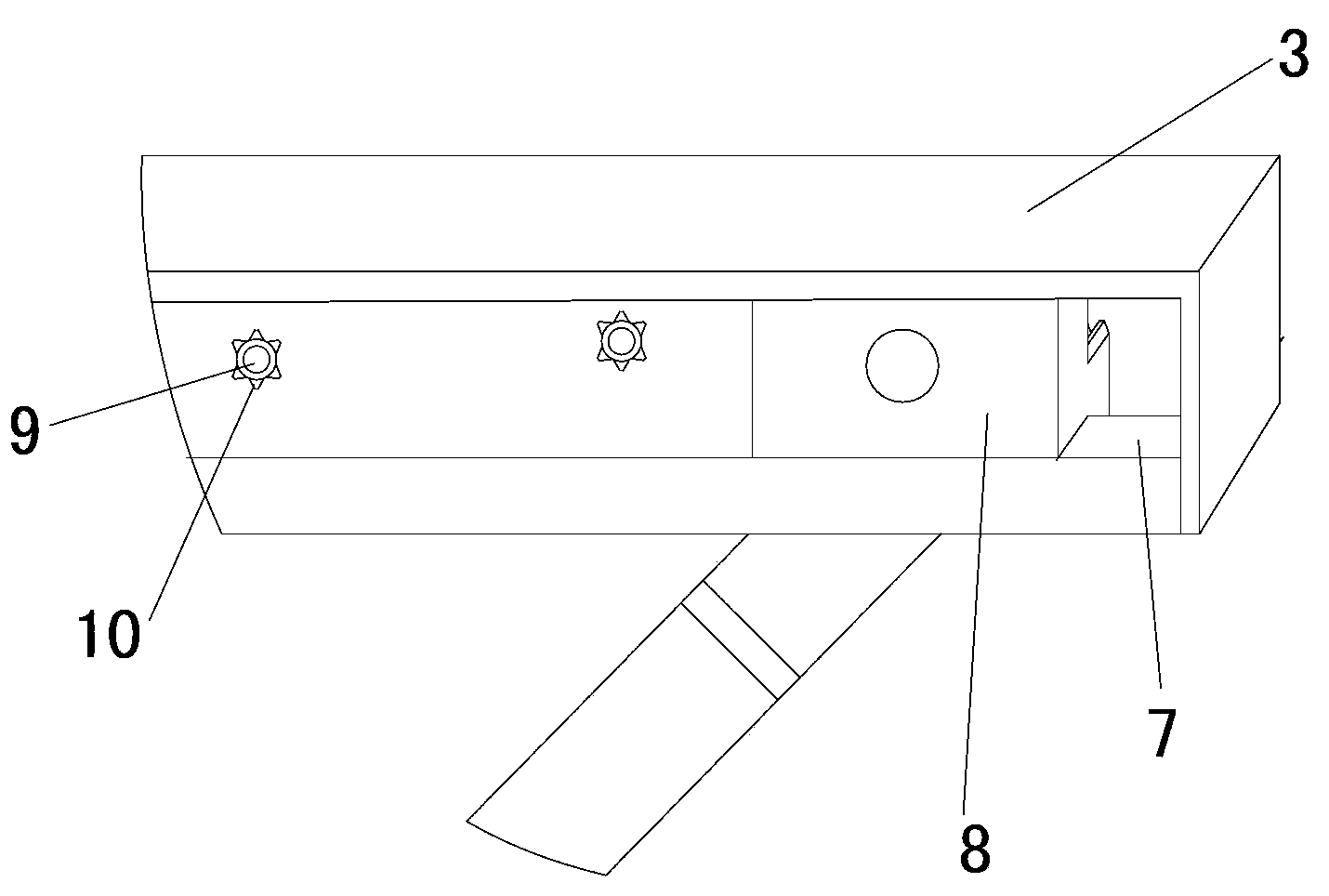

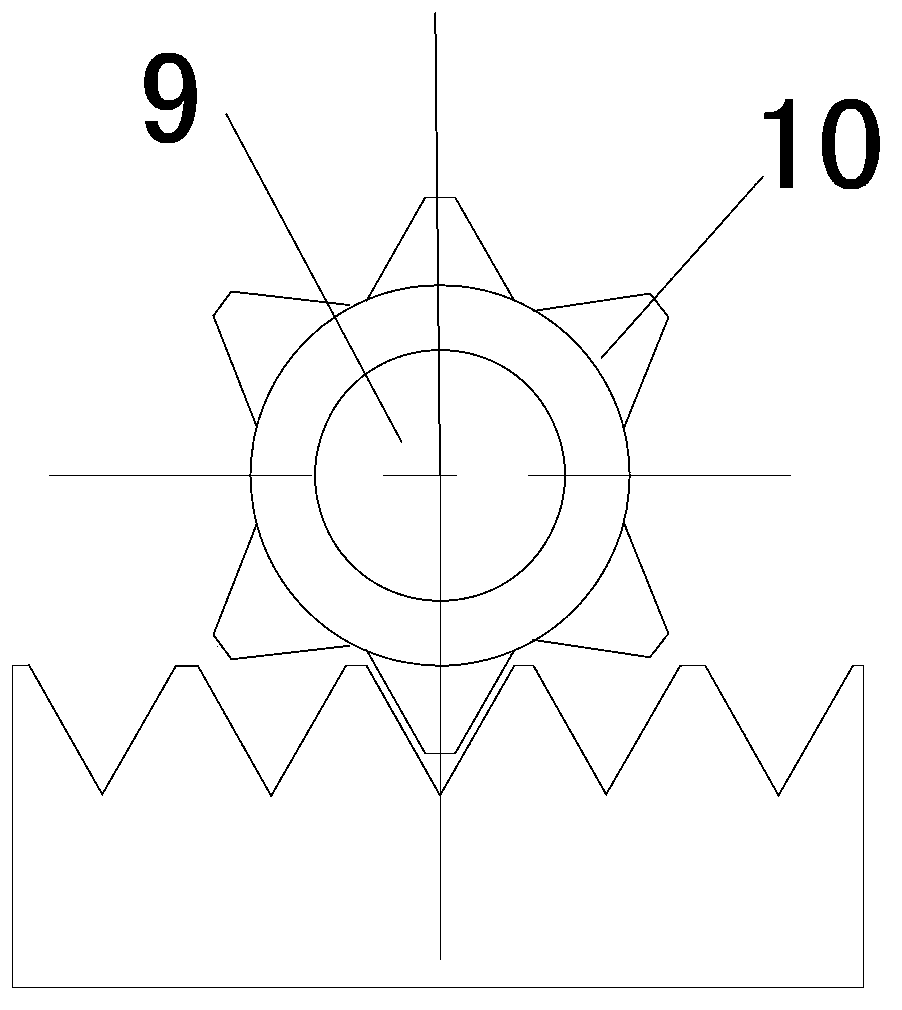

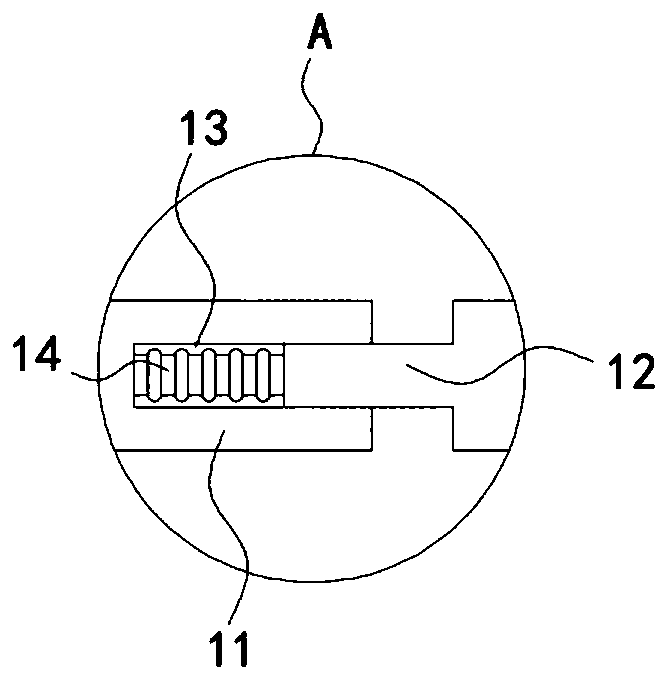

Shutter sunshading device capable of being packed up

The invention discloses a shutter sunshading device capable of being packed up. The shutter sunshading device comprises louvre blades, a support and a louvre blade opening device, wherein the support is hinged to the upper portion of a window or a glass curtain wall and can extend outwards. Hollow struts are arranged on the two sides of the support. Guiding rails are arranged inside the struts, sliding blocks capable of sliding along the guiding rails are arranged on the guiding rails. The sliding blocks are connected with a driving device which is used for driving the sliding blocks to slide up and down along the guiding rails and for supporting the struts. The driving device comprises a supporting rod I and a supporting rod II, wherein the supporting rod I is hinged to the lower portion of the window or the glass curtain wall, and the supporting rod II is movably connected with the sliding blocks. The supporting rod II is arranged inside the supporting rod I in a sleeved mode through a thread, and a rotating device for driving the supporting rod II to rotate and capable of extending outwards is arranged inside the supporting rod I. The shutter sunshading device capable of being packed up is simple in structure and light in weight and can be opened and packed up by the manner that the shutter sunshading device capable of being packed up is installed on the upper portion of the window or the glass curtain wall, and sunshading and dazzle prevention are convenient while indoor ventilation and natural lighting are not affected.

Owner:CHONGQING UNIV

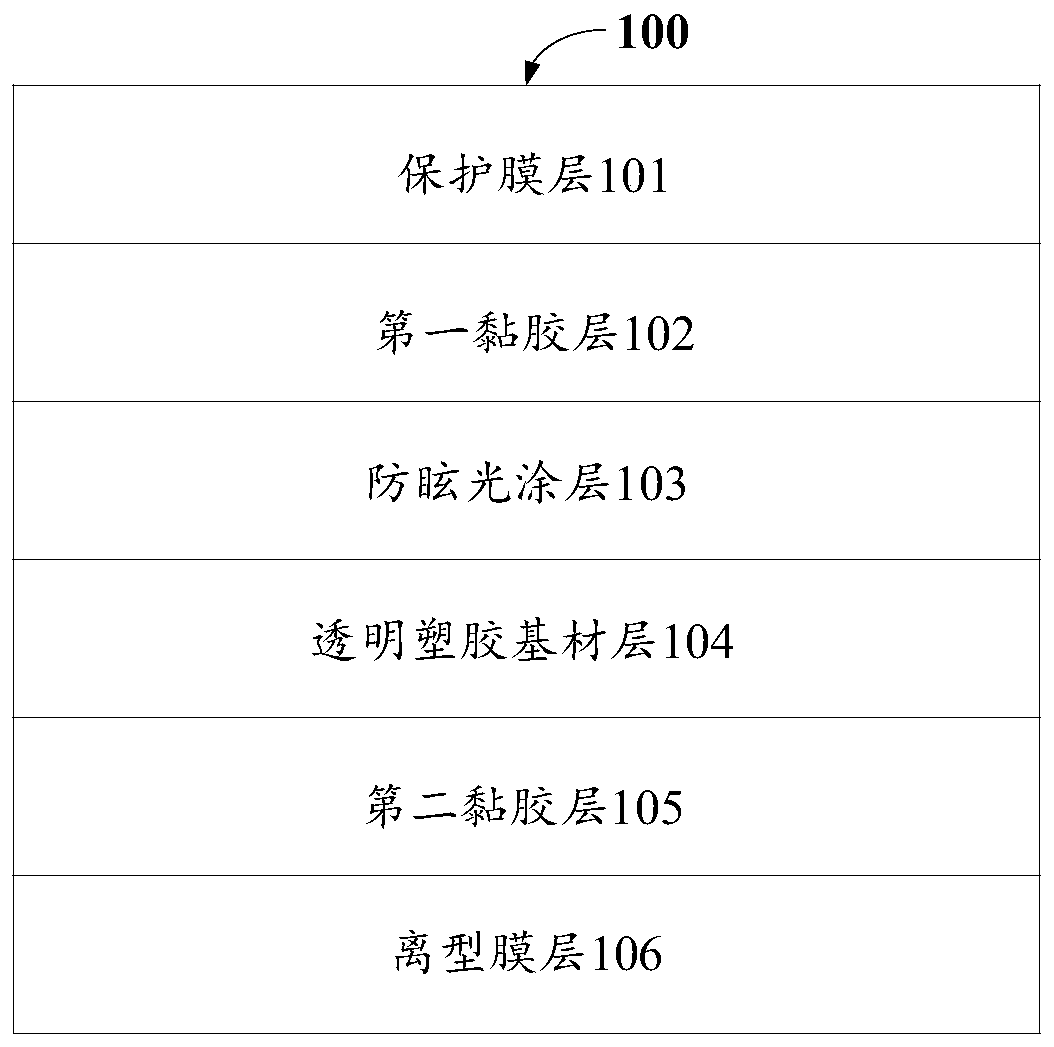

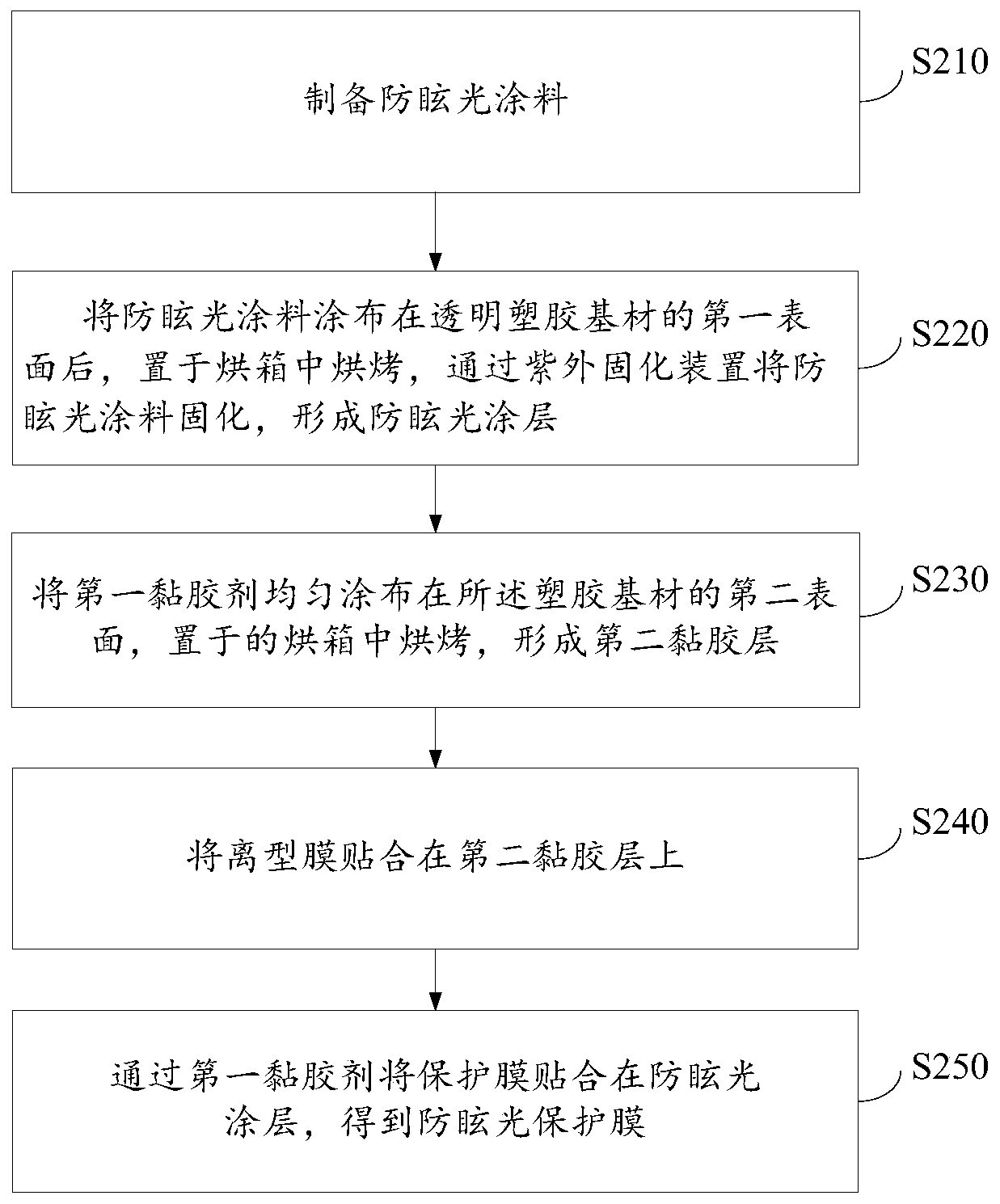

Anti-glare protective film and preparation method thereof

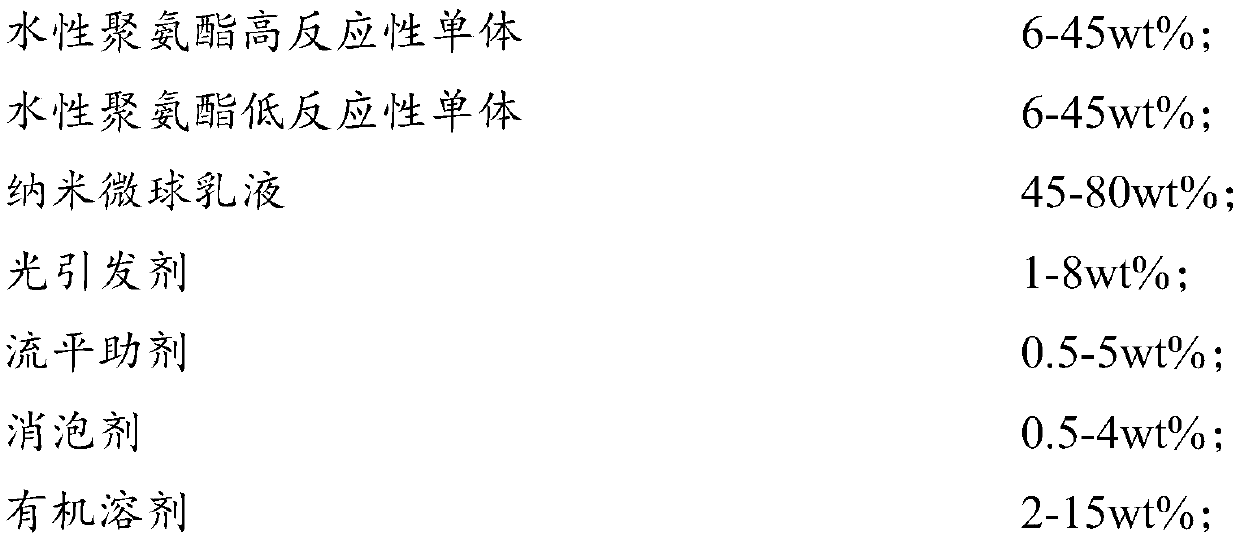

ActiveCN110531447AExcellent anti-glarePolyurea/polyurethane coatingsOptical elementsCooking & bakingTectorial membrane

The invention relates to the technical field of a film material, and particularly relates to an anti-glare protective film and a preparation method thereof. The anti-glare protective film sequentiallycomprises a protective film layer, a first adhesive layer, an anti-glare coating, a transparent plastic base material layer, a second adhesive layer and a release liner layer. The anti-glare coatingcomprises the following components in parts by weight: 6 weight percent to 45 weight percent of waterborne polyurethane hyper-responsiveness monomer, 6 weight percent to 45 weight percent of waterborne polyurethane hypoergia monomer, 45 weight percent to 80 weight percent of nanosphere emulsion, 1 weight percent to 8 weight percent of photoinitiator, 0.5 weight percent to 5 weight percent of leveling agent, 0.5 weight percent to 4 weight percent of defoaming agent and 2 weight percent to 15 weight percent of organic solvent. An anti-glare paint and an adhesive are coated at both sides of the transparent plastic base material layer, the transparent plastic base material layer is placed in a baking oven with a temperature of 60 DEG C to 130 DEG C to be baked for 1.5min to 2min, and then thetransparent plastic base material layer is attached to a protective film and a release liner to prepare the anti-glare protective film. The anti-glare protective film prepared by the invention has good anti-glare and scratch-proof performance, is simple in preparation process and has no pollution to the environment.

Owner:SHENZHEN MOMA TECH CO LTD

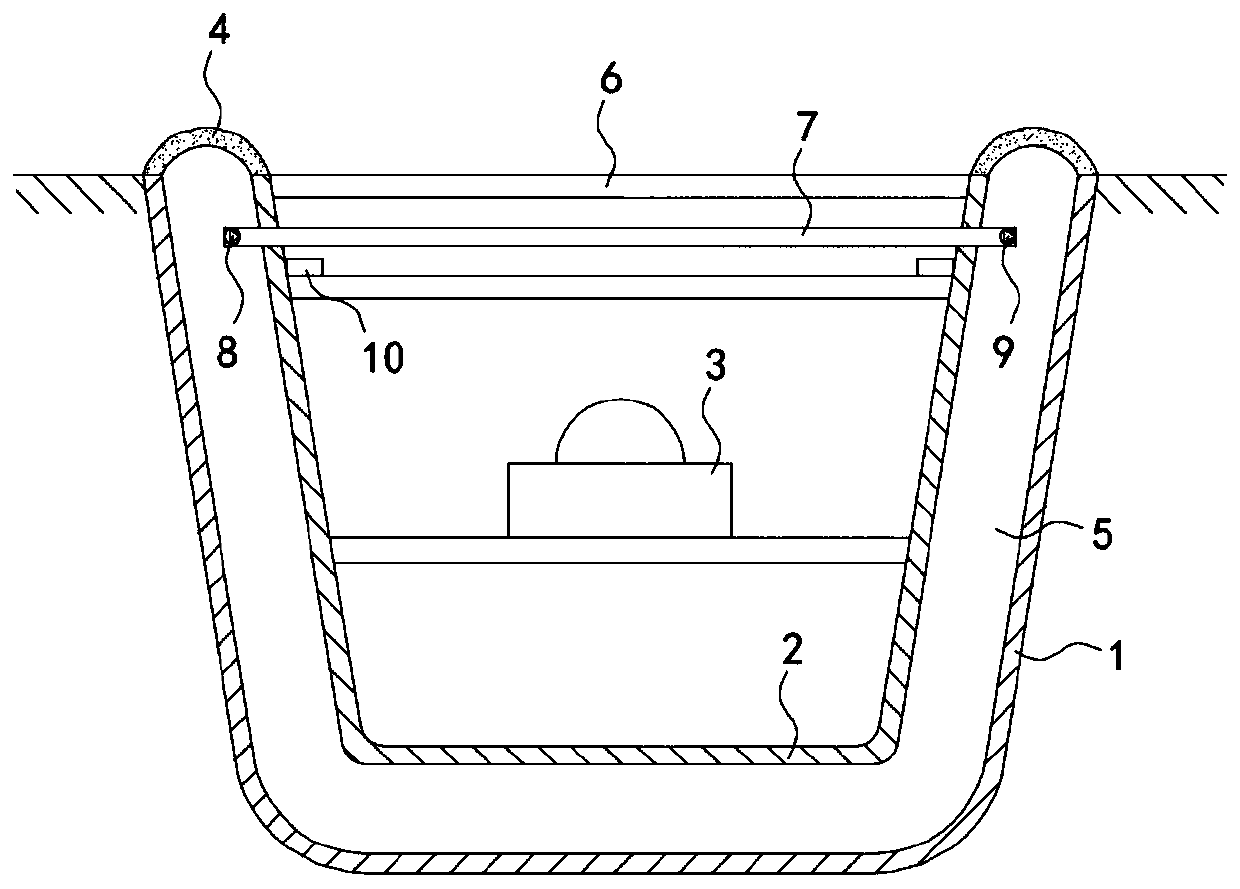

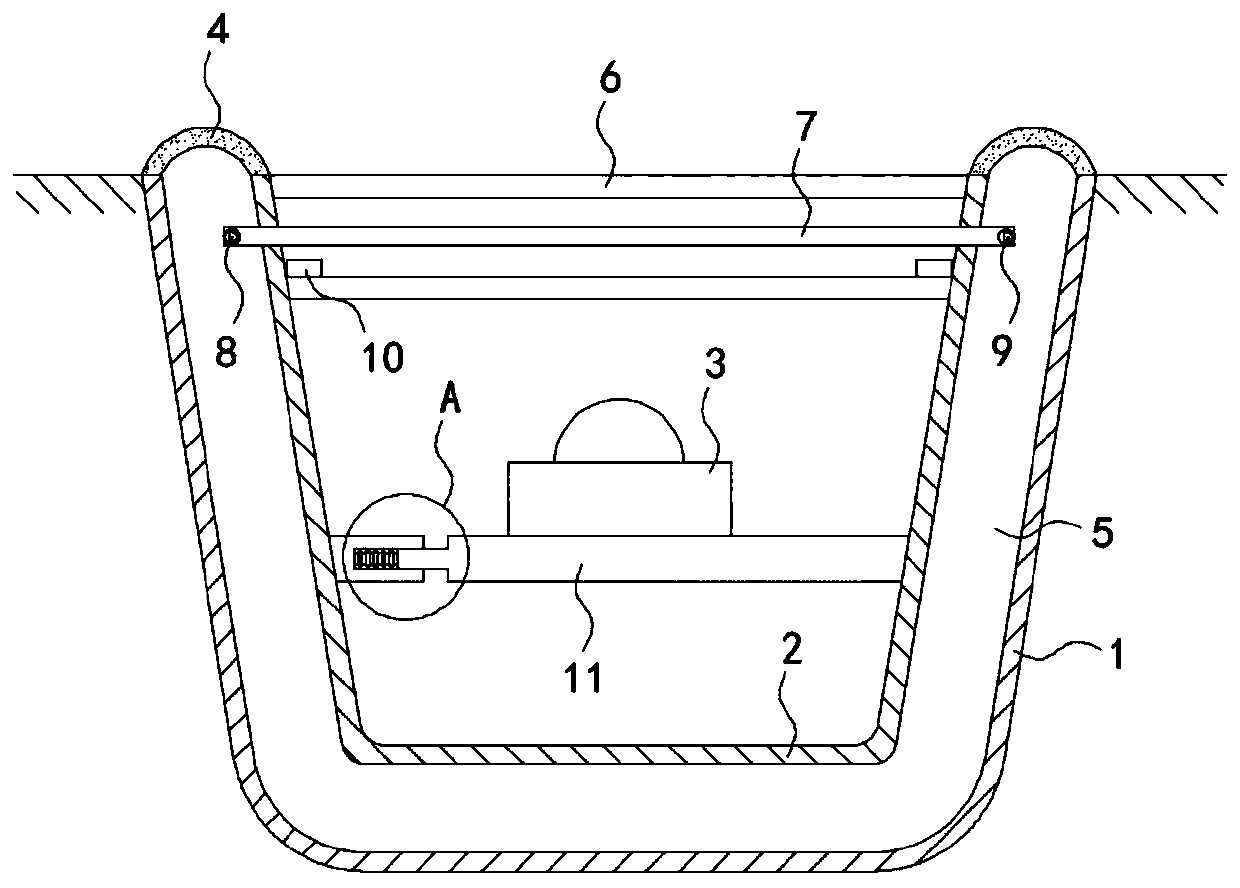

Anti-dazzle type high-heat-dissipation LED underground lamp

ActiveCN110906217AImprove cooling effectReduce light transmittanceNon-electric lightingPoint-like light sourceEngineeringLED lamp

The invention belongs to the field of LED lamps, in particular to an anti-dazzle high-heat-dissipation LED underground lamp. The anti-dazzle high-heat-dissipation LED underground lamp comprises an outer shell and an inner shell, an LED lamp set is arranged in the inner shell. The upper end of the inner shell and the upper end of the outer shell are both provided with openings. The inner shell is arranged in an inverted circular truncated cone shape; a flexible annular plate is arranged above the inner shell and the outer shell; an inner ring and an outer ring of the flexible annular plate arefixedly connected with the inner shell and the outer shell respectively; the cross section of the flexible annular plate is arranged in a convex surface shape which is arched upwards; a sealed coolingliquid cavity is formed among the inner shell, the outer shell and the flexible annular plate, the cooling liquid cavity is filled with cooling liquid, two light-transmitting plates are fixedly connected to the inner side wall of the inner shell, the space between the two light-transmitting plates is filled with opacifier, and a cooling liquid pipe is arranged between the two light-transmitting plates. Pedestrians can tread the flexible annular plate to cool the opacifying agent, so that the opacifying effect is achieved, and glare is prevented from being generated to affect safe passage of the pedestrians.

Owner:湖南凌特科技有限公司

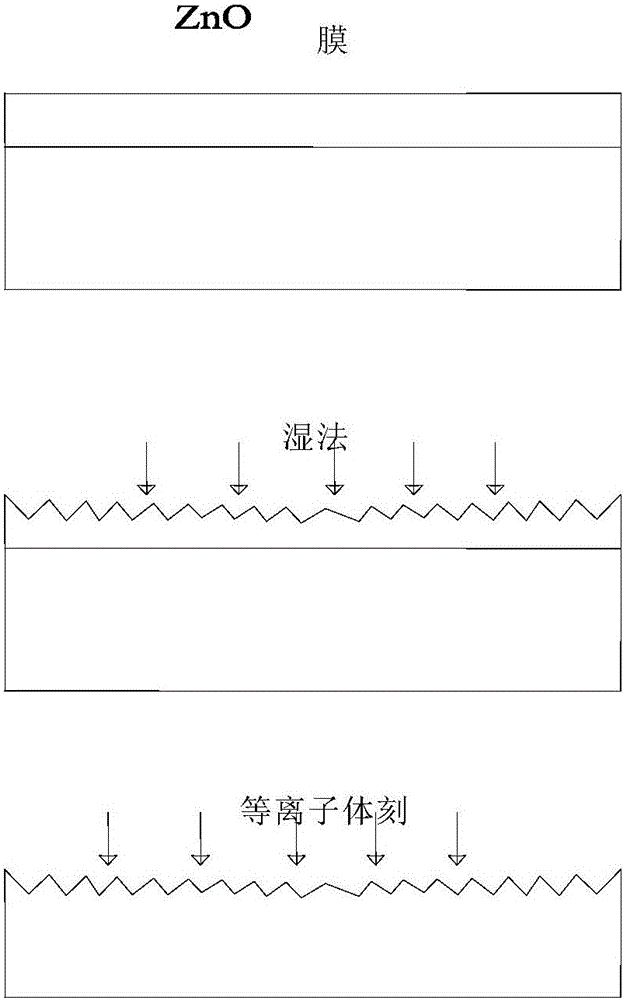

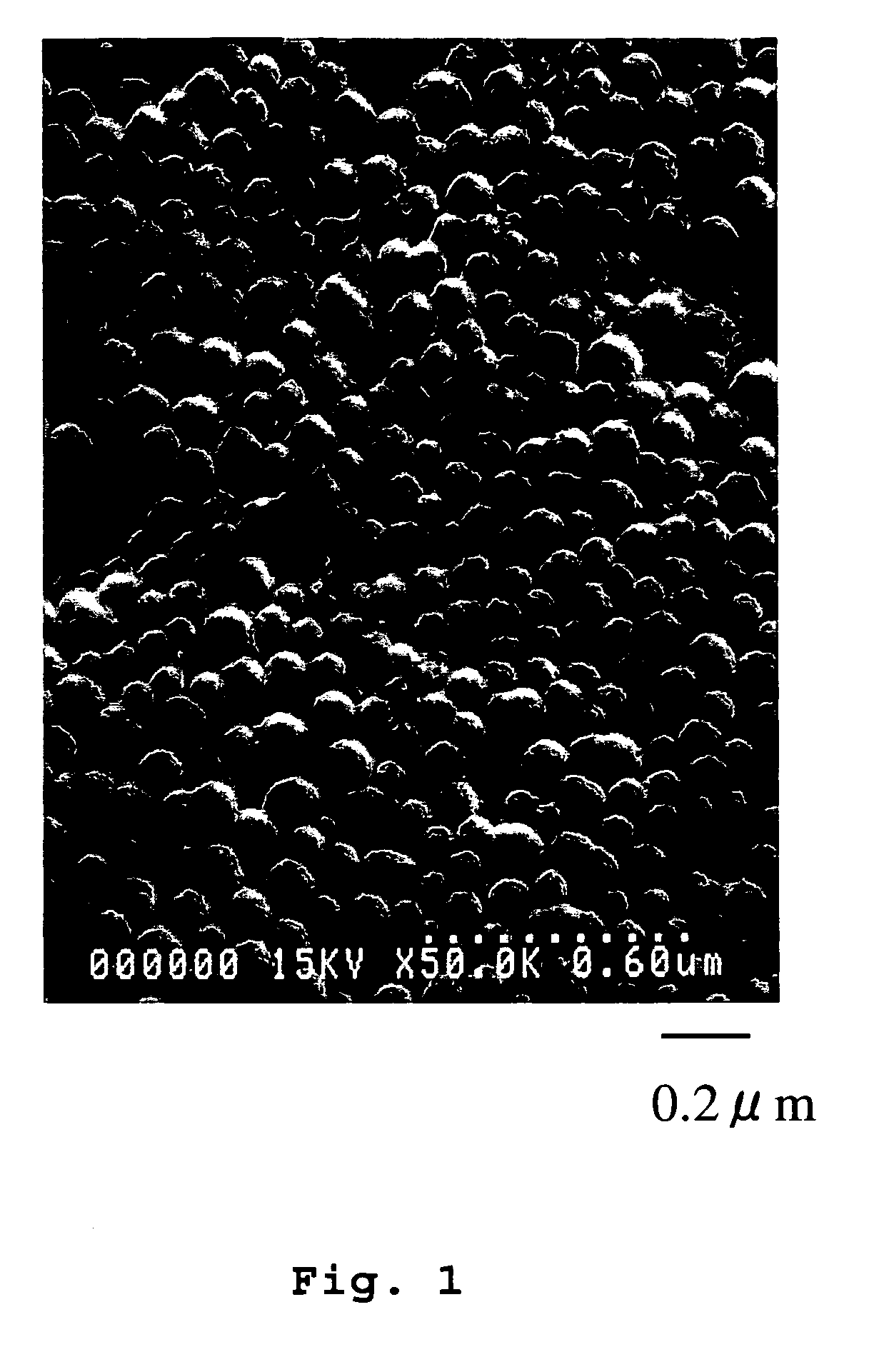

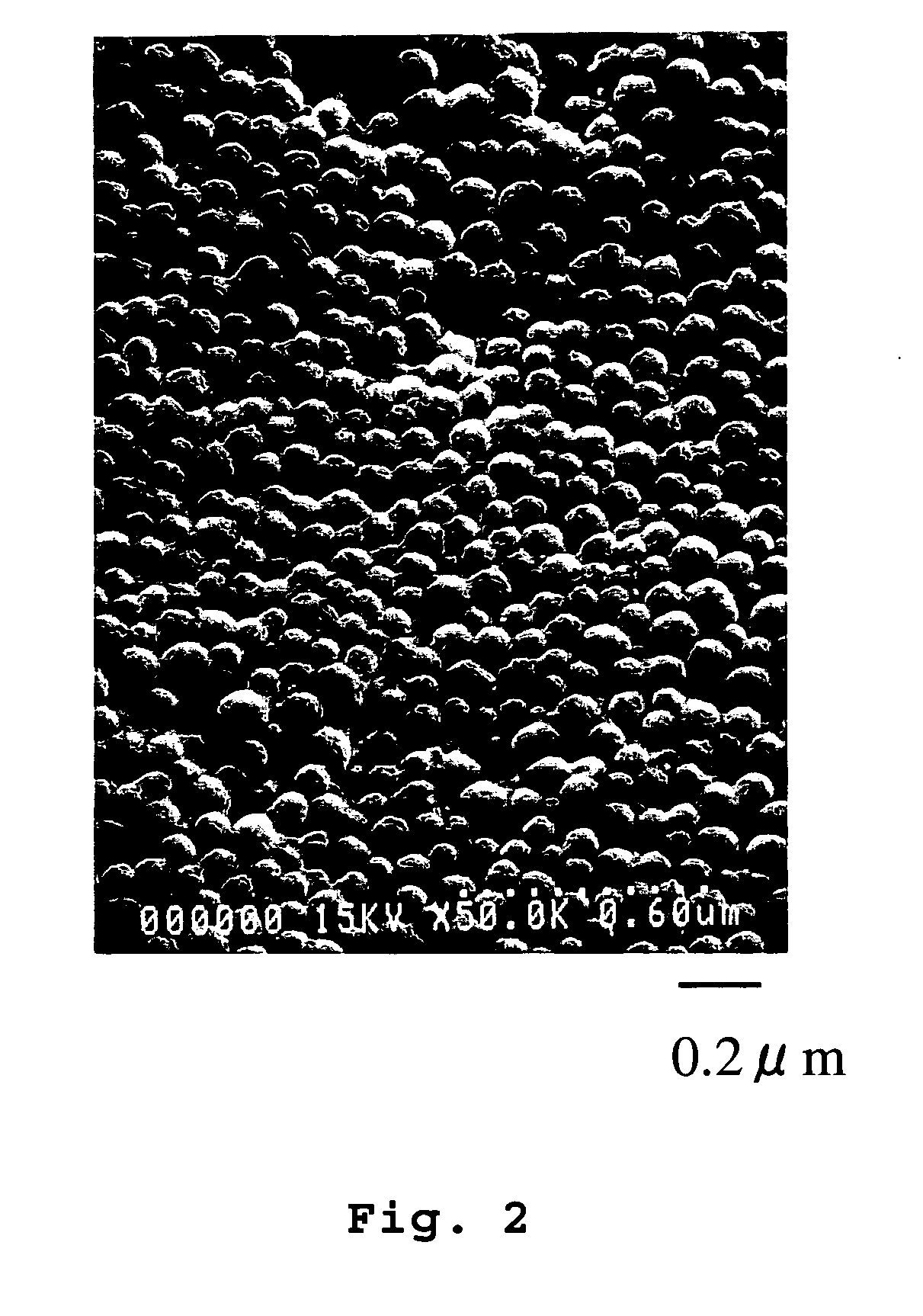

Preparation method of anti-dazzle glass

A preparation method of anti-dazzle glass includes the steps of: (a) depositing a layer of ZnO thin film on a surface of a glass substrate; (b) etching the ZnO thin film with an acid solution or an alkaline solution in low concentration to form a three-dimension mask plate; and (c) etching the glass with the three-dimension mask plate ZnO thin film formed thereon with plasma to prepare the glass having an uneven structure. In the method, the anti-dazzle glass is prepared by pre-preparing the three-dimension mask plate and then performing plasma etching. The method has high etching speed and uniform etching pattern and can be used for forming a uniform uneven structure. The anti-dazzle glass has excellent anti-dazzle performance, has low damage on human body and is suitable for a high-grade display panel.

Owner:CHINA TRIUMPH INT ENG

Process for producing a layered article

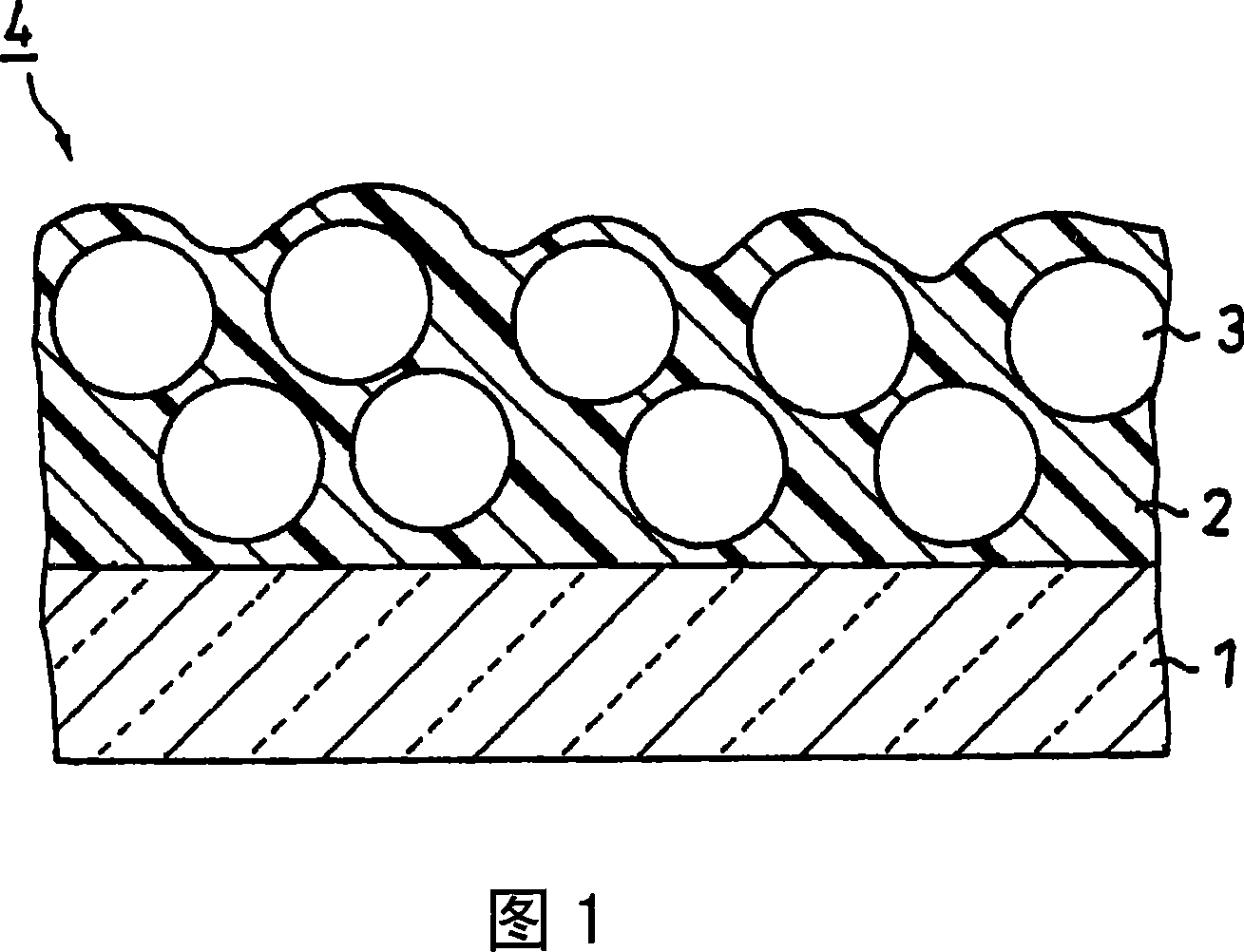

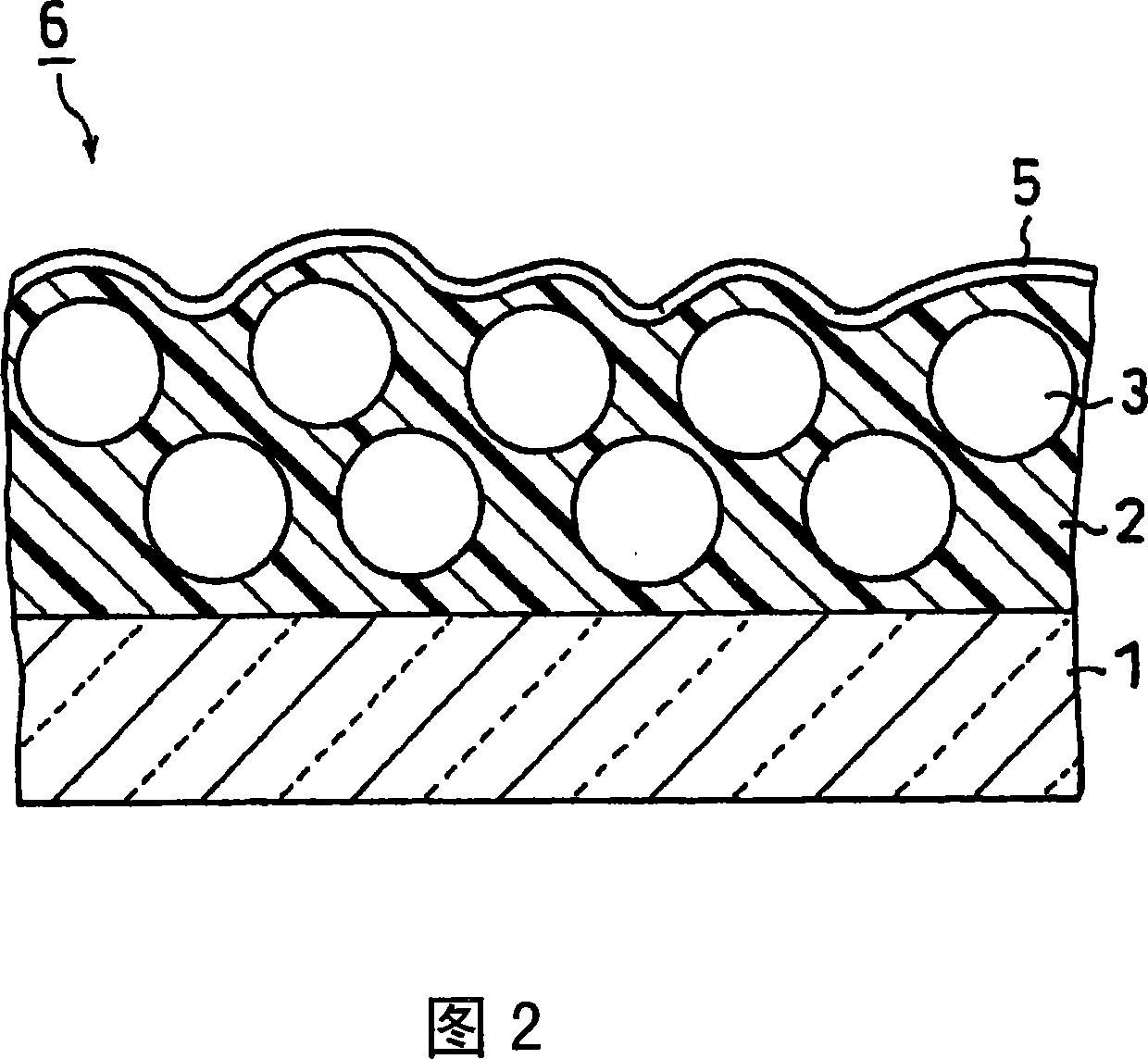

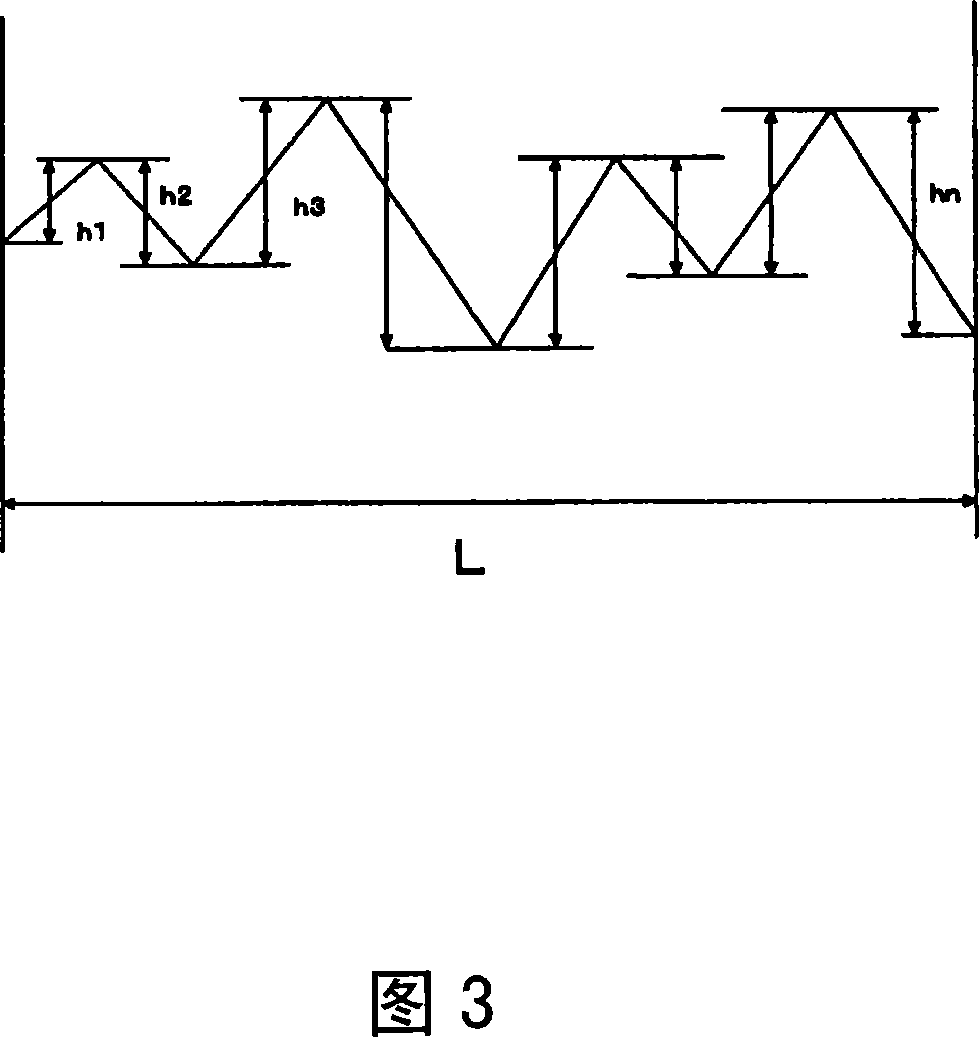

ActiveUS20060193987A1High strengthExcellent anti-glareSynthetic resin layered productsPretreated surfacesInorganic particleInorganic particles

Disclosed is a process for producing a layered article including a substrate and an inorganic particle layer formed thereon, the process including: preparing a mixed inorganic particle dispersion comprising a liquid dispersion medium containing inorganic particles (A) and inorganic particles (B), the mixed inorganic particle dispersion being characterized by conditions (1) regarding particle size, (2) regarding volume fraction of inorganic particles and (3) regarding weight fraction; applying the mixed inorganic particle dispersion to a substrate, and removing the liquid dispersion medium from the mixed inorganic particle dispersion applied to form an inorganic particle layer on the substrate.

Owner:SUMITOMO CHEM CO LTD

Hyperbranched structured anti-dazzle polyurethane acrylate UV cured resin and preparation method therefor

ActiveCN108659192AFlexibleBoth hardnessPolyurea/polyurethane coatingsHyperbranched polyesterTransmittance

The invention discloses a hyperbranched structured anti-dazzle polyurethane acrylate UV cured resin composition and a preparation method therefor. The hyperbranched structured anti-dazzle polyurethaneacrylate UV cured resin composition disclosed by the invention contains the following ingredients in percentage by weight: 10-80% of polyurethane acrylate with hyperbranched polyester as a core and 20-90% of polyurethane acrylate with hyperbranched polyether as a core. The hyperbranched structured anti-dazzle polyurethane acrylate UV cured resin composition disclosed by the invention can achievean excellent anti-dazzle effect without additionally adding auxiliaries or carrying out surface treatment, has good light transmittance and has both hardness and flexibility.

Owner:无锡博加电子新材料有限公司 +1

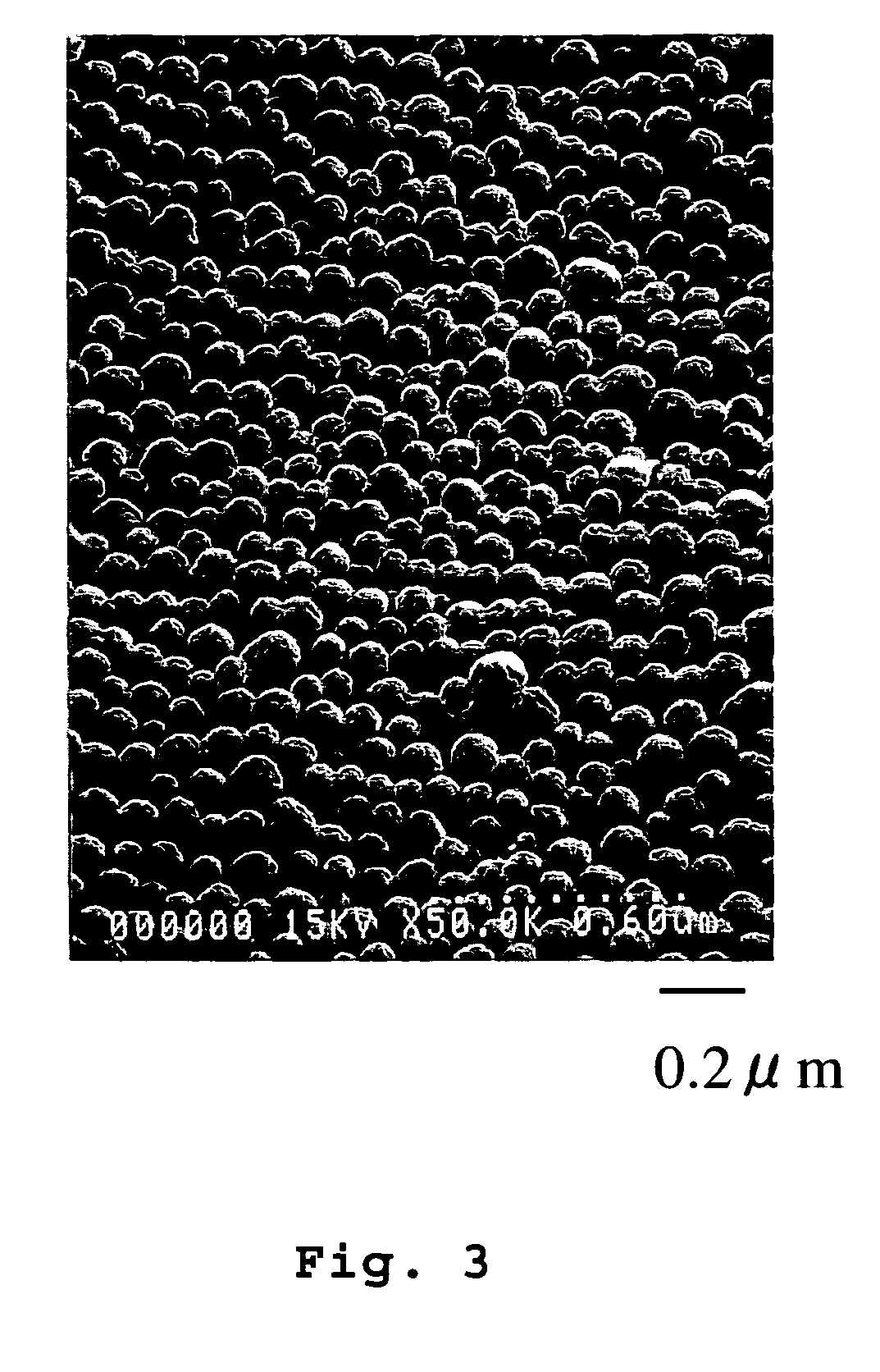

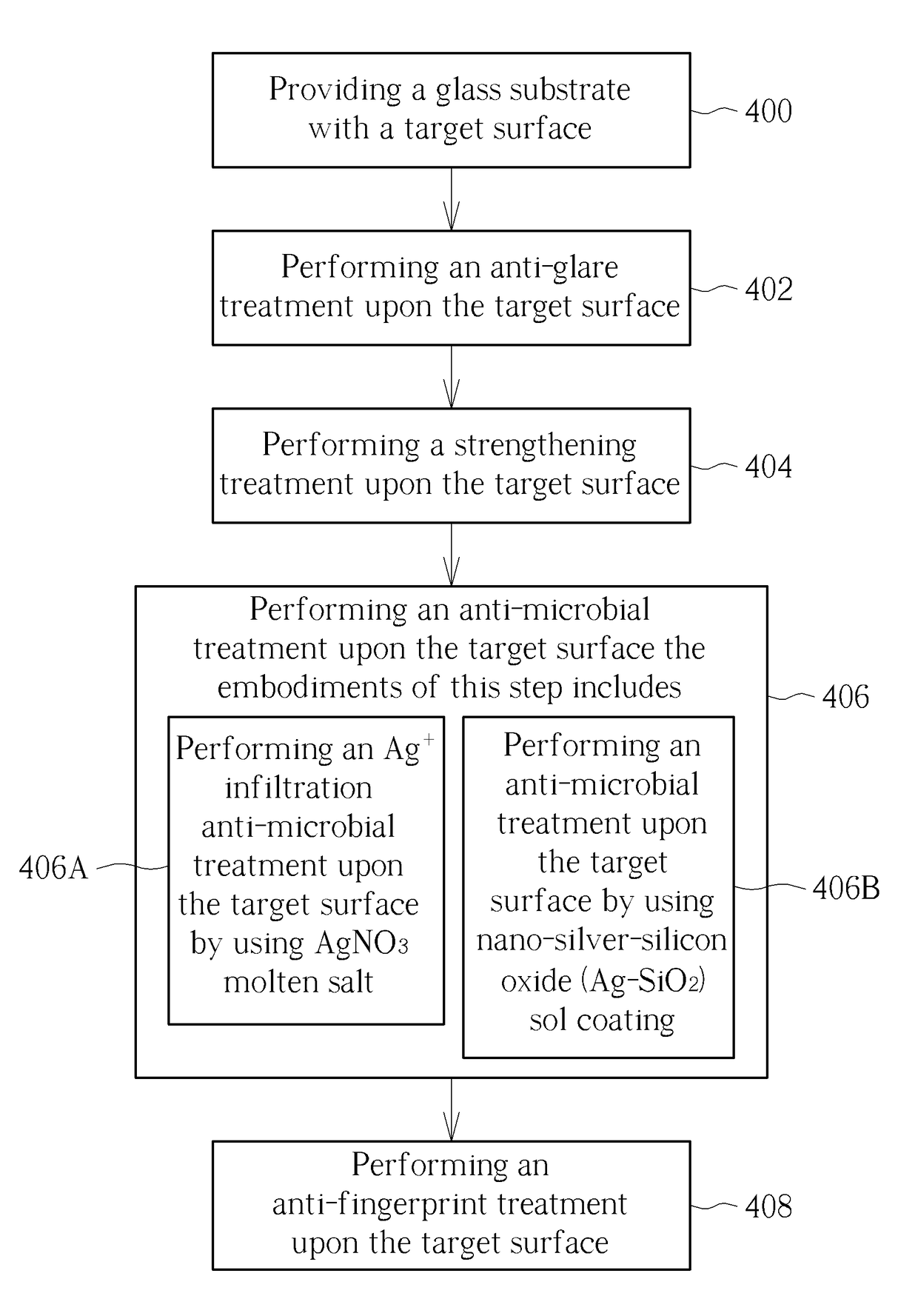

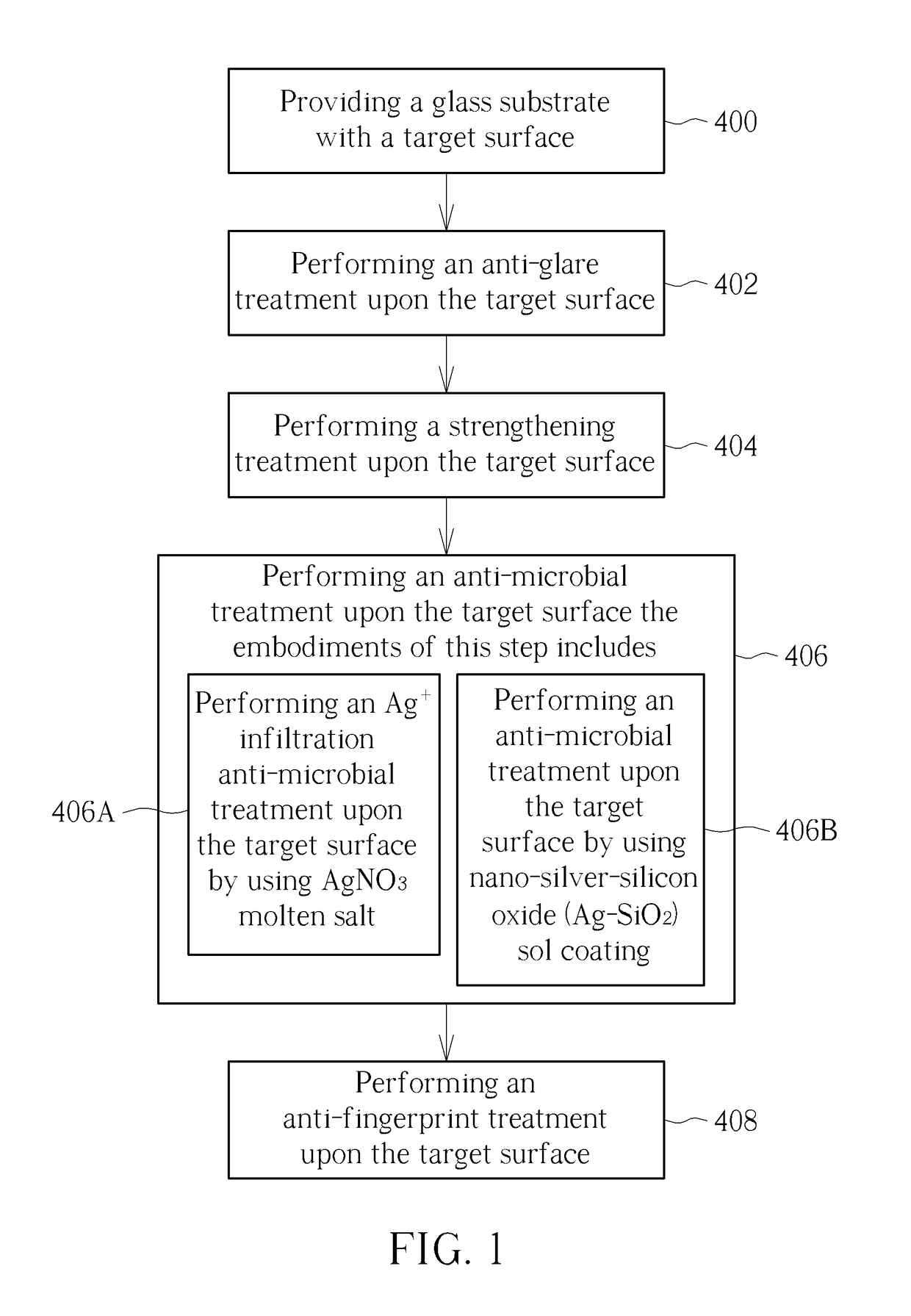

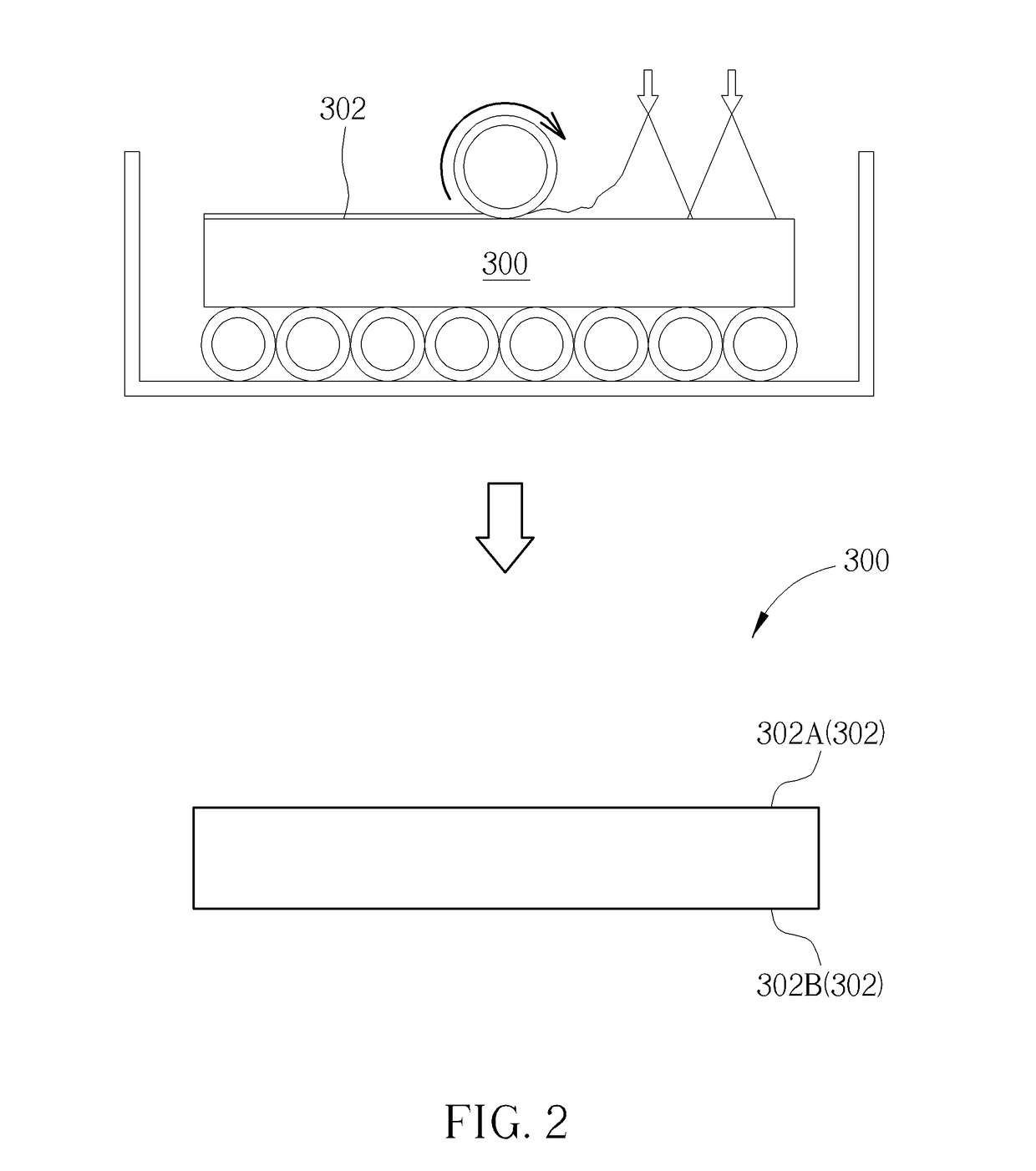

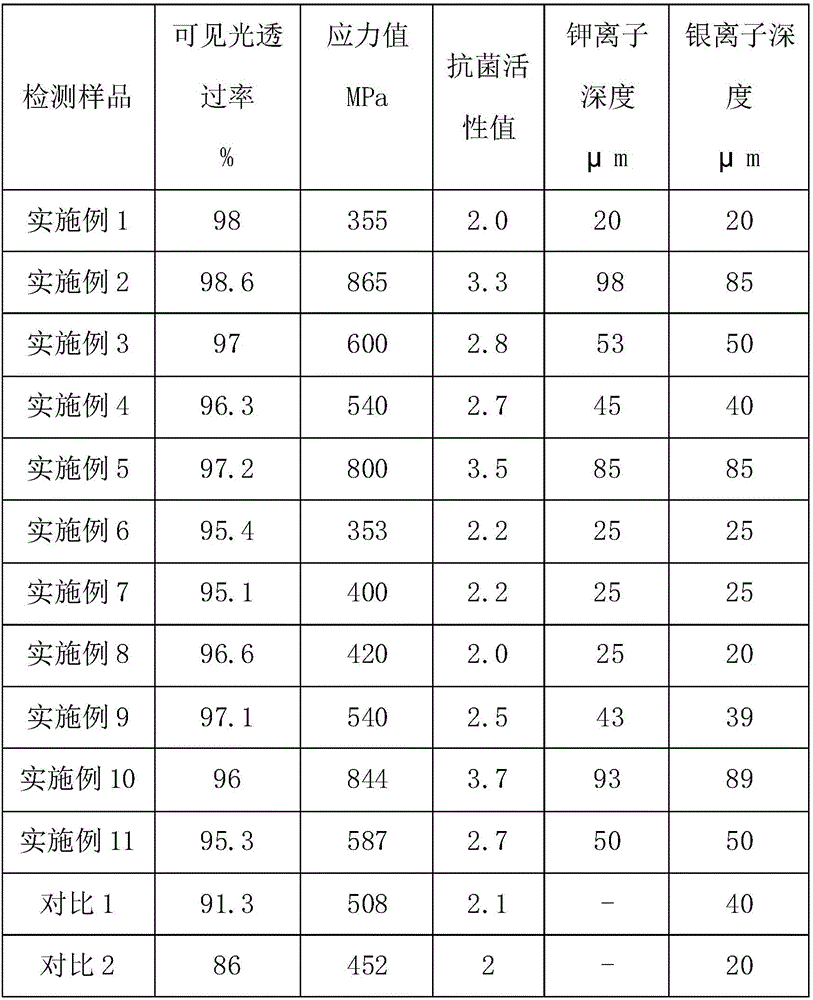

Method of fabricating an Anti-glare, strengthened, Anti-microbial and antifingerprint strengthened glass

InactiveUS20180141854A1Strengthened, anti-microbialExcellent anti-glareCoatingsTarget surfaceFluorocarbon

The present invention provides a method of manufacturing a glass with anti-glare, strengthened, anti-microbial and anti-fingerprint capabilities. A glass substrate is provided with a target surface. Plural treatments are carried out, including: performing an anti-glare treatment upon the target surface by using a mixed acid solution; performing a strengthening treatment by using KNO3; performing an anti-microbial treatment by using a silver-containing fluid; and performing an anti-fingerprint treatment by forming a fluorocarbon siloxane layer on the target surface.

Owner:HONY GLASS TECH

High performance antiglare film

InactiveCN105062328AStrong adhesionGood weather resistancePolyurea/polyurethane coatingsEpoxy resin coatingsALUMINUM STEARATESPolymer science

The invention discloses a high performance antiglare film. The raw materials include: a fluorine-containing epoxy acrylate oligomer, a fluorine-containing polyurethane acrylate oligomer, polycarbonate, styrene, hydroxyethyl methacrylate, N-vinyl pyrrolidone, pentaerythritol triarylate, glycerol monostearate, sorbitol, polyethylene glycol, nano-titanium dioxide, nano-silica, aluminum stearate, aluminum-doped zinc oxide, vinyl-tri(2-methoxyethoxy)silane, sodium dodecyl benzene sulfonate, 1-hydroxycyclohexyl phenyl ketone, triphenylphosphine oxide, phenolic resin, amino resin, an additive, and a solvent. The high performance antiglare film provided by the invention has high adhesion with the substrate, good scratch resistance, and excellent anti-static, antiglare and anti-radiation effects.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

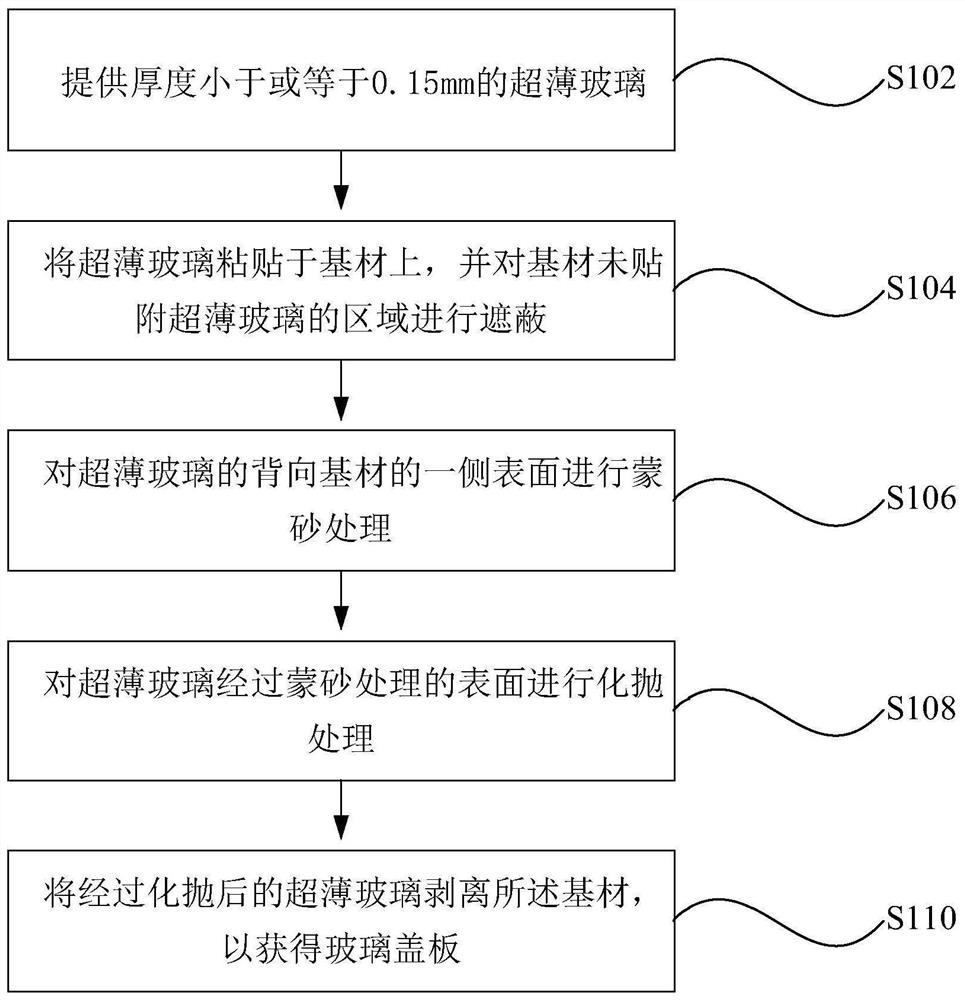

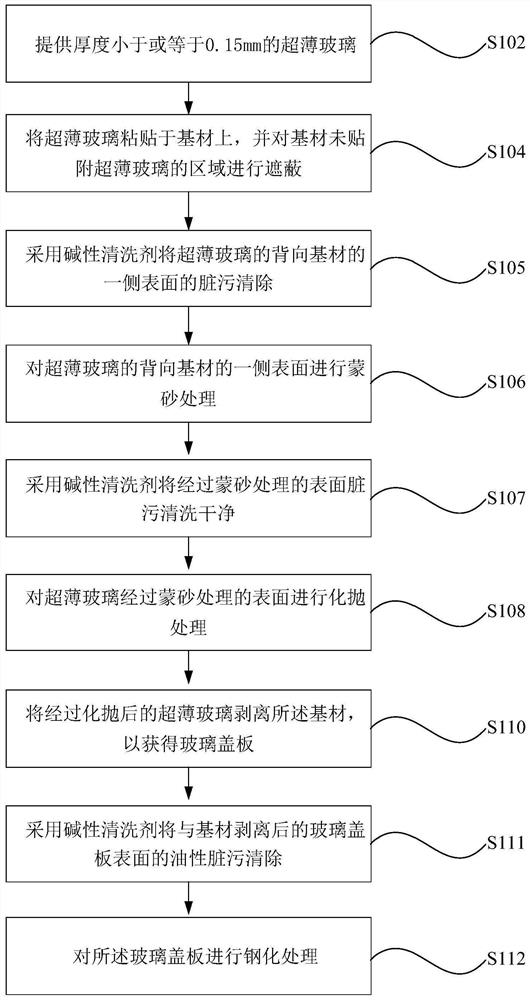

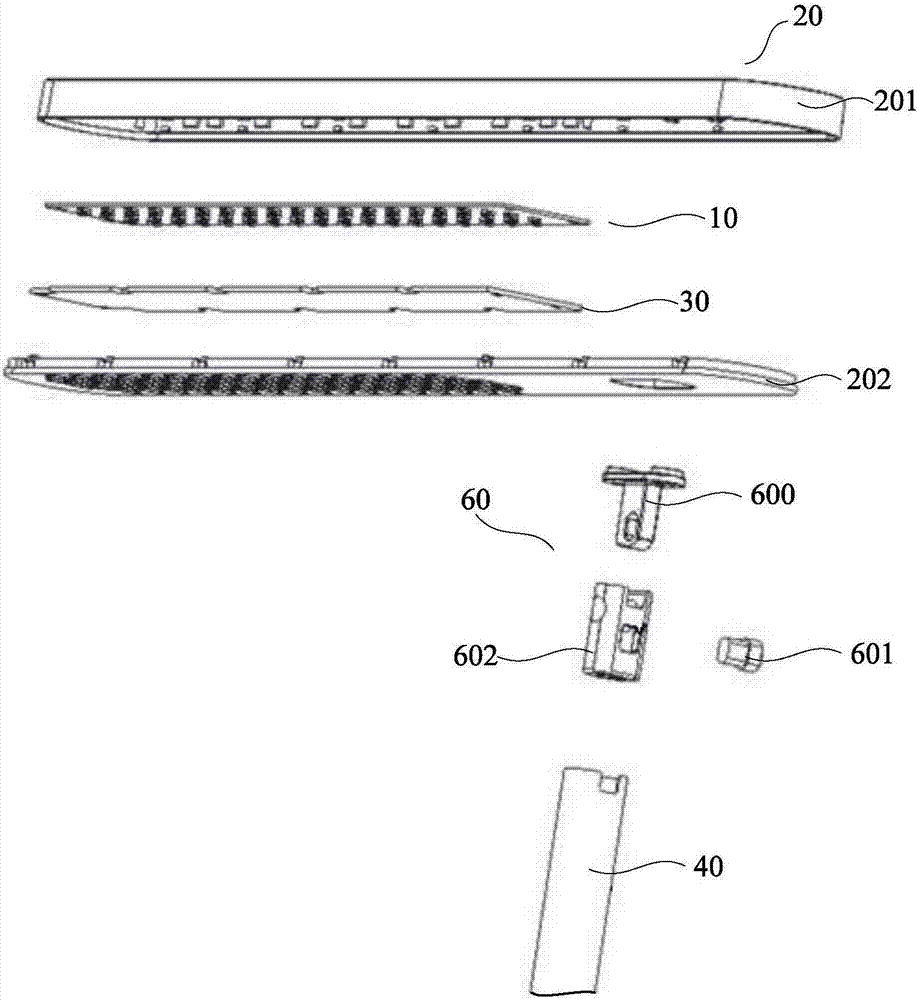

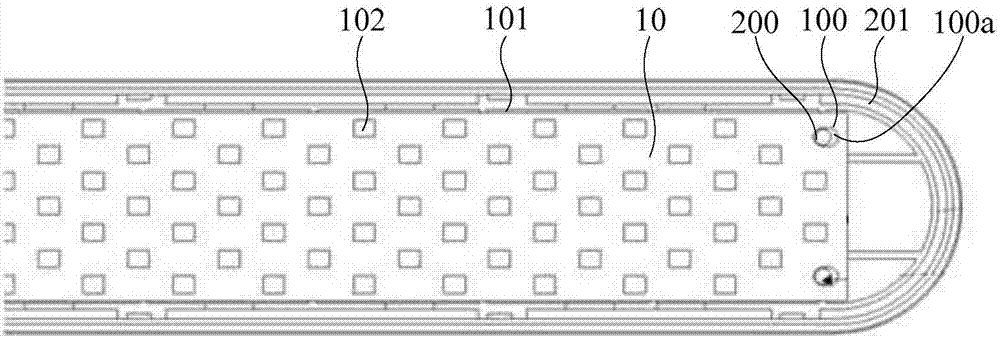

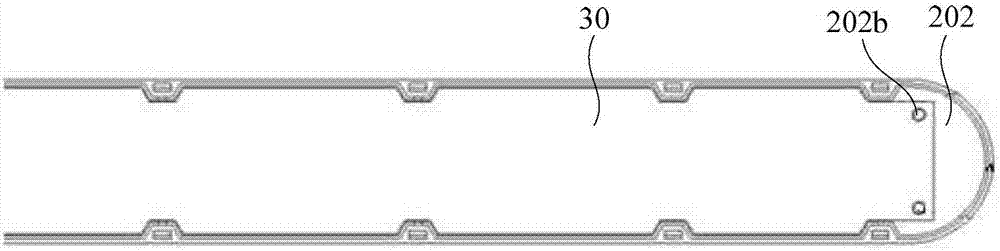

Mobile terminal, flexible display screen, glass cover plate and processing method thereof

PendingCN113121121AGood bending propertiesGood displayTelephone set constructionsIdentification meansEngineeringFlexible display

The invention relates to a mobile terminal, a flexible display screen, a glass cover plate and a processing method thereof. The processing method of the glass cover plate comprises the following steps: providing ultra-thin glass; pasting the ultra-thin glass on the base material, and shielding the area, where the ultra-thin glass is not attached, of the base material; frosting the surface of one side, back to the base material, of the ultra-thin glass; carrying out polishing treatment on the frosted surface of the ultra-thin glass; and stripping the polished ultrathin glass from the base material to obtain the glass cover plate. According to the mobile terminal, the flexible display screen, the glass cover plate and the processing method thereof, the glass cover plate prepared by utilizing the processing method of the glass cover plate not only has good bending performance, but also has a relatively good anti-dazzle effect, so that the folding performance and the display effect can be effectively ensured when the glass cover plate is applied to the flexible display screen and the mobile terminal.

Owner:WGTECH JIANGXI

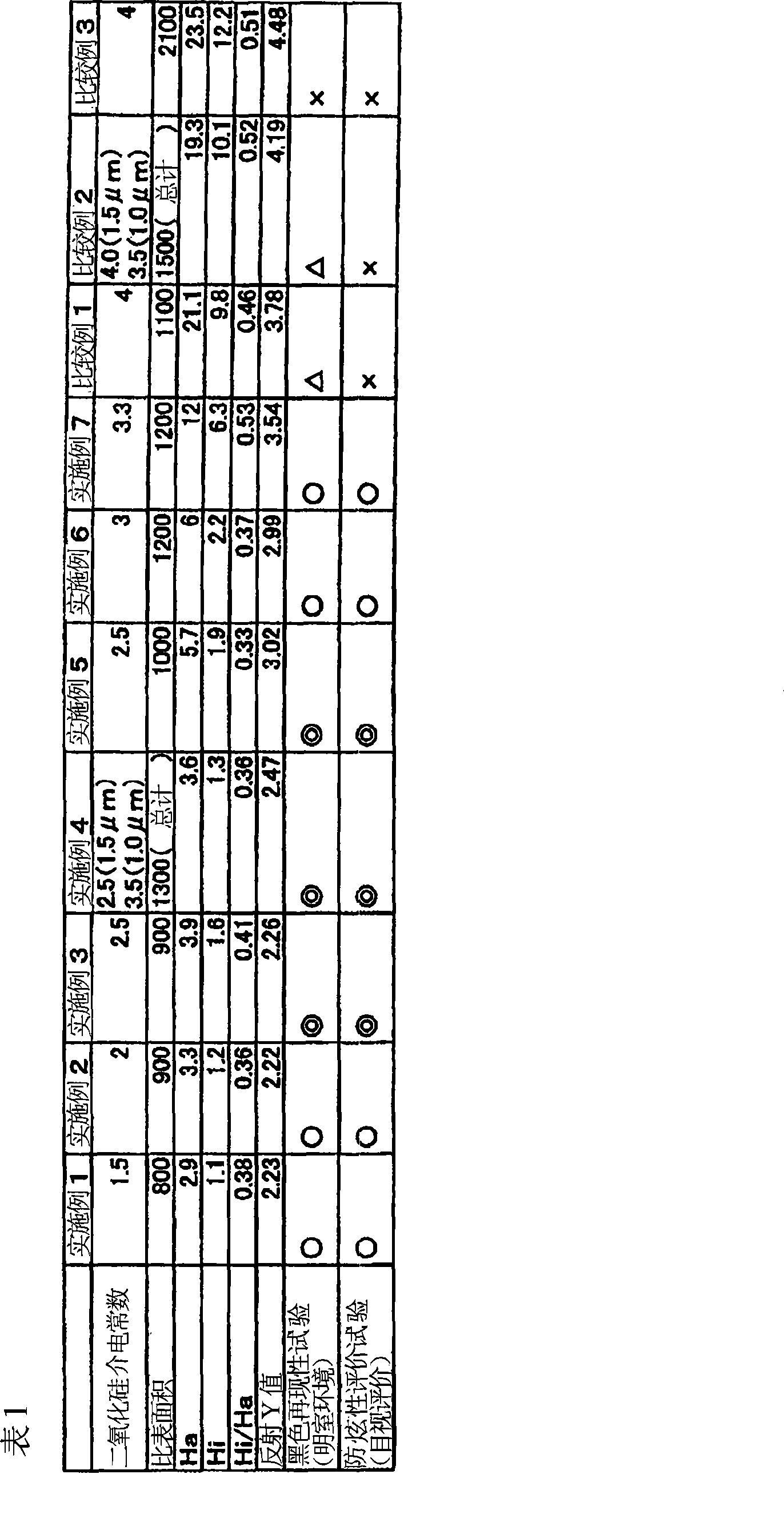

Optical laminates, polarizing paltes and image display devices

ActiveCN101458343AExcellent anti-glareImprove antifouling performanceDiffusing elementsLayered productsOptical propertyDisplay device

The invention relates to an optical lamination body, a polarization plate and an image displaying device. Even thought an anti-glaring layer contains silicon dioxide particles, the optical lamination body has good optical character with reasonable agglutinated silicon dioxide particles. The optical lamination body comprises a transparent substrate and the anti-glaring layer containing the silicondioxide particles, wherein the dielectric constant of the silicon dioxide particles is less than 4.0.

Owner:DAI NIPPON PRINTING CO LTD

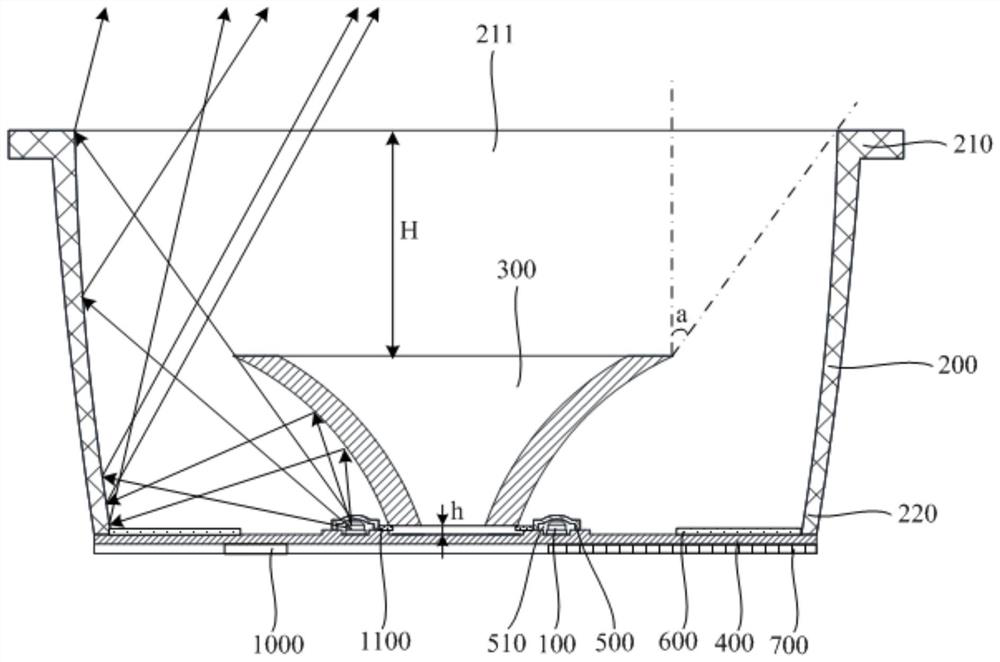

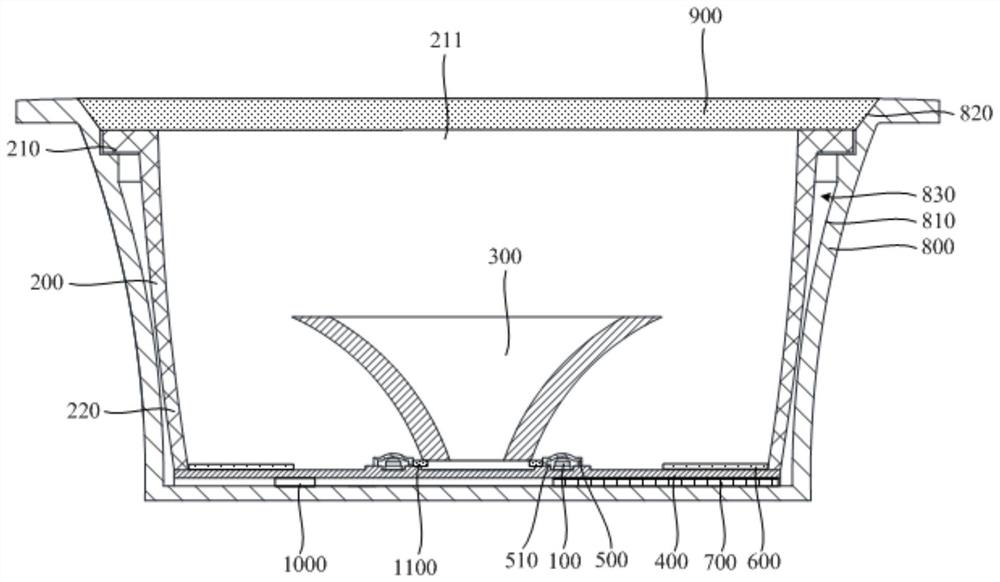

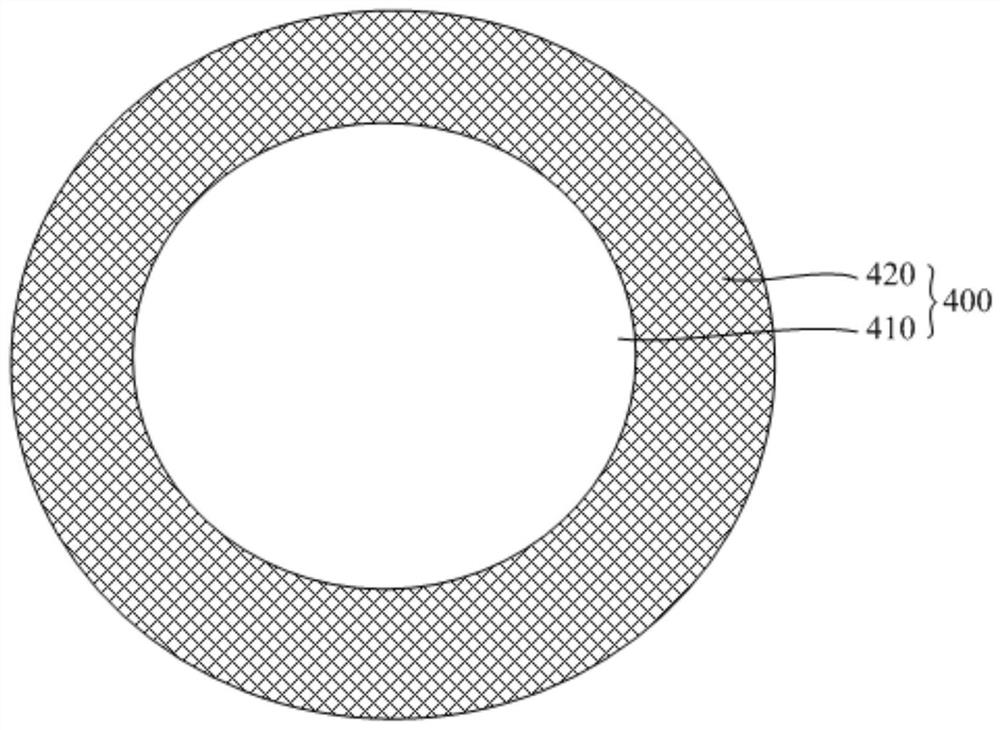

Illuminating lamp and light source system thereof

PendingCN111998243AAchieve hiddenAchieve lightingSemiconductor devices for light sourcesReflectorsEngineeringMaterials science

The invention discloses an illuminating lamp and a light source system thereof. At least part of a luminous body (100) is arranged in a first reflector (200); the first end (210) of the first reflector (200) is provided with a light outlet (211); at least part of a second reflector (300) is arranged in the first reflector (200); the upward projection of the luminous body (100) at the light outlet(211) is a first projection; the upward projection of the end part, facing the light outlet (211), of the second reflector (300) on the light outlet (211) is a second projection; wherein the second projection covers the first projection, a part of light emitted by the light-emitting body (100) is reflected by the second reflector (300) and the first reflector (200) in sequence and is projected outfrom the light outlet (211), and the other part of light emitted by the light-emitting body (100) is reflected by the first reflector (200) and is projected out from the light outlet (211). Accordingto the scheme, the problem that an illuminating lamp is serious in glare can be solved.

Owner:SUZHOU OPPLE LIGHTING +1

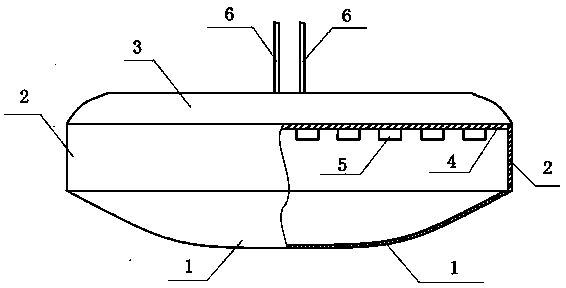

Anti-dazzle LED illuminating lamp

InactiveCN103398302ASimple structureLow costPoint-like light sourceElectric lightingFresnel lensEngineering

The invention provides an anti-dazzle LED illuminating lamp which solves the problems that in the prior art, an anti-dazzle light-transmitting screen is comparatively complex in structure, high in cost, low in light-transmitting efficiency and the like. The anti-dazzle LED illuminating lamp comprises an LED lamp umbrella formed by an umbrella film, a power source wire and a plurality of LED illuminating components and an anti-dazzle light-transmitting screen with a light-transmitting thin film. The anti-dazzle LED illuminating lamp is characterized in that the anti-dazzle light-transmitting screen is made of Fresnel lens array light-transmitting films, and the LED lamp umbrella is connected together with the anti-dazzle light-transmitting screen through an insulating supporting frame. The anti-dazzle LED illuminating lamp is reasonable in design, and the anti-dazzle light-transmitting screen is simple in structure, low in cost, and capable of meeting the anti-dazzle function, and meanwhile has the good light-transmitting performance.

Owner:刘军

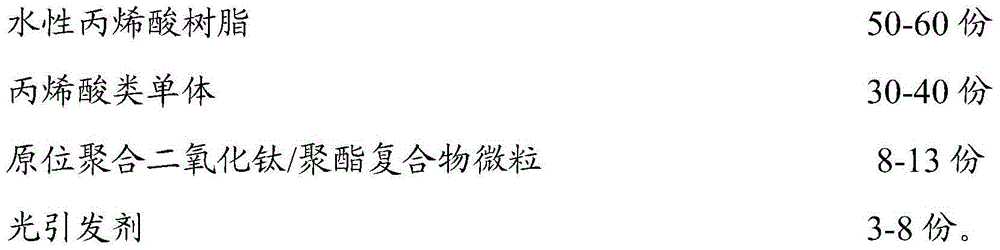

Anti-dazzling thin film and preparing method thereof

InactiveCN104133257AGood compatibilityExcellent anti-glareCoatingsOptical elementsWater basedPolyester

The invention belongs to the field of high molecular materials, and particularly relates to an anti-dazzling thin film and a preparing method of the anti-dazzling thin film. The anti-dazzling thin film comprises a base material and an anti-dazzling layer arranged on the base material in a coating mode. The anti-dazzling layer comprises, by weight, 50-60 parts of water-based acrylic resin, 30-40 parts of acrylic acid monomer, 8-13 parts of in situ polymerization titanium dioxide / polyester compound particle and 3-8 parts of photoinitiator. The preparing method comprises the following steps of preparing the in situ polymerization titanium dioxide / polyester compound particle, preparing ultraviolet light polymerization coating liquor and coating a film through a spinning coating mode. According to the technical scheme, the anti-dazzling layer is formed by coating of the water-based ultraviolet light polymerization coating liquor with the in situ polymerization titanium dioxide / polyester compound particles with the anti-dazzling function, the compatibility of the anti-dazzling layer and the base material is good, the anti-dazzling effect is obvious, and the anti-dazzling thin film has wide market prospects.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Anti-glare PC board and preparation process thereof

The invention discloses an anti-glare PC board and a preparation process thereof. The anti-glare PC board is prepared from the following raw materials in parts by weight: 50-60 parts of silicate, 80-100 parts of polycarbonate resin, 0.5-0.7 parts of polymethyl methacrylate, 2-6 parts of glass fibers, 0.1-0.3 parts of polystyrene, 0.1-0.2 parts of a silane coupling agent and 2-3 parts of metal oxide. Because silicate is added, strong absorption performance is realized on ultraviolet light and blue light, the transmittance of visible light in other wavelength ranges is relatively high, the anti-dazzle performance is better, there is no impact on viewing, the cost is lower, and the chemical performance is stable. Polystyrene is added and has good acid and alkali resistance, so that the corrosion resistance of the PC board is enhanced, the service life of the PC board is prolonged, and the transparency of the PC board is not influenced. By adding the silane coupling agent, the compatibility of all components in the PC board is enhanced, and the stability of the PC board is improved.

Owner:江苏迪迈新材料有限公司

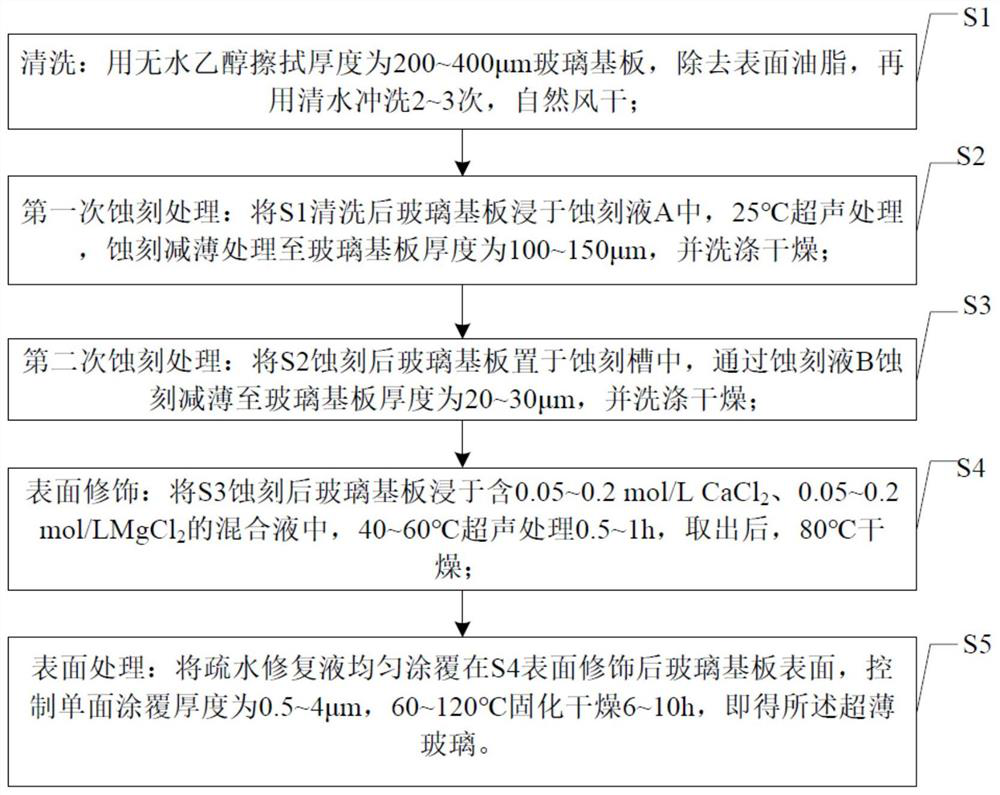

Method for manufacturing ultrathin glass by etching

PendingCN112551909AIncreased structural stability and mechanical strengthAvoid chippingCoatingsGlass productionFluorocarbon EmulsionsSodium silicate

The invention discloses a method for manufacturing ultrathin glass by etching. The method comprises the following steps: respectively etching by using an etching solution A and an etching solution B,carrying out surface modification by using Ca < 2 + > and Mg < 2 + >, and carrying out surface treatment by using a hydrophobic repair solution, wherein the etching solution A takes water as a solventand comprises the following components in molar concentration: 1.5-3mol / L of hydrofluoric acid, 0.5-1.5 mol / L of hydrochloric acid, 1.0-1.5 mol / L of sodium fluosilicate and 0.1-0.2 mol / L of lauryl sodium sulfate; the etching solution B takes water as a solvent and is prepared from the following components in molar concentration: 0.5-1.5 mol / L of hydrofluoric acid, 0.3-0.8 mol / L of hydrochloric acid, 0.5-0.8 mol / L of sodium fluosilicate and 0.1-0.2 mol / L of lauryl sodium sulfate; the hydrophobic repair liquid comprises the following components in parts by mass: 40-50 parts of water-based fluorocarbon emulsion, 1-3 parts of a hydrophobic agent, 5-7 parts of sodium silicate, 2-3 parts of sodium fluoride, 10-15 parts of nano titanium oxide sol, 15-20 parts of nano silicon oxide sol, 3-5 partsof a structure directing agent, 1-2 parts of an amino silane coupling agent and 0.5-2 parts of an emulsifier. According to the method, the defect position on the surface of the etched glass substrateis repaired, and the structural stability and the mechanical strength are improved; and the glass is endowed with flexibility to prevent the ultrathin glass from being broken.

Owner:凯盛科技股份有限公司

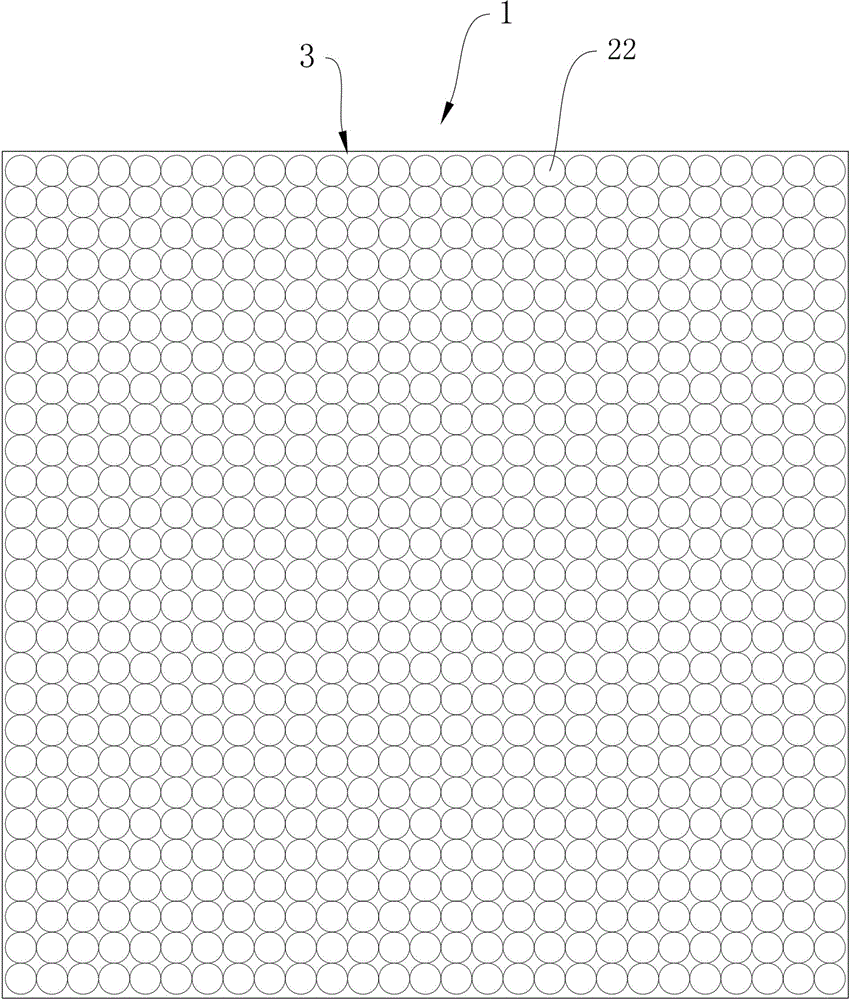

Table lamp

PendingCN107166219AGood anti-glareAvoid plating easy to fall offElectrical apparatusElectric light circuit arrangementPhysicsChemical plating

The invention discloses a table lamp which comprises a light emitting potion and a light emitting portion installation foundation. The light emitting portion installation foundation comprises a shell and a honeycomb light-transmitting plate arranged on the opening side of the shell. The honeycomb light-transmitting plate and the shell are connected to form a light source containing cavity which contains the light emitting portion. The light emitting portion comprises a light emitting body. The honeycomb light-transmitting plate is provided with a honeycomb through hole opposite to the light emitting body. In the table lamp, the honeycomb through hole in the honeycomb light-transmitting plate can achieve the effect of shielding part of light, and thus achieves the good ant-dazzle purpose, and meanwhile the problem that a plating layer is likely to fall off when a chemical plating layer is adopted for preventing dazzle can be avoided.

Owner:OPPLE LIGHTING

Touch screen tempered glass film and preparation method thereof

ActiveCN106010327AReduce waste of resourcesProduction economyFilm/foil adhesivesFurnace temperatureNitrate

A preparation method of a touch screen tempered glass film belongs to the technical field of tempered glass films of electronic products. The preparation method comprises the steps that a glass substrate and sticking glue are prepared, the lower surface of the glass substrate is stuck with the sticking glue to obtain the touch screen tempered glass film, and the preparation method further comprises the following steps that A, the prepared glass substrate is placed into a reactor filled with SOCl2 liquid after cleaned and dried, the reactor is stood for 3-5 h, the glass substrate is taken out and placed into a resistance furnace, the temperature of the glass substrate is raised to 450 DEG C to 550 DEG C with the furnace temperature, the temperature is kept for 1-3 h, and a pretreatment layer is formed on the surface of the glass substrate; B, the glass substrate treated by the step A is soaked in nitrate with the temperature of 330 DEG C to 550 DEG C, insulation treatment is performed for 2-10 h, and an ion exchange layer is obtained; C, the glass substrate treated by the step B and the sticking glue are combined so that the touch screen tempered glass film is obtained. The invention further discloses the touch screen tempered glass film prepared with the method, and the antibacterial effect of an antibacterial layer gathered on the surface of the tempered glass is better.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com