Touch screen tempered glass film and preparation method thereof

A tempered glass and touch screen technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve problems such as glass film coloring and other problems, reduce resource waste, prevent harm to the human body, and transmit visible light high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

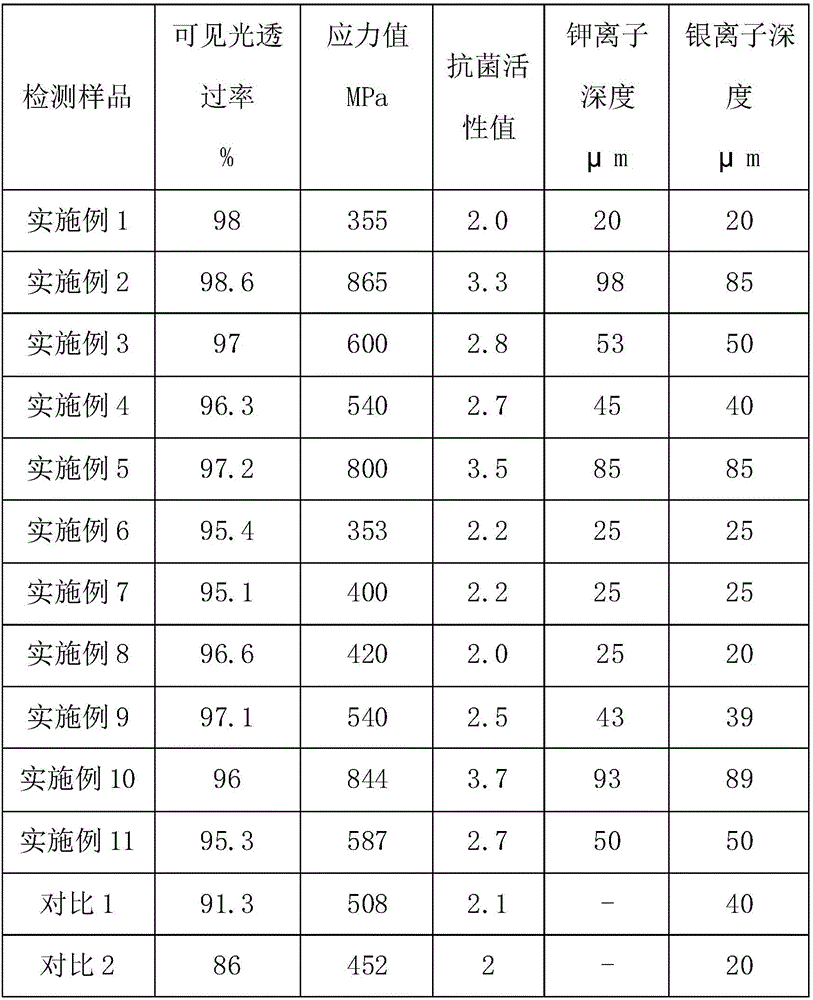

Examples

Embodiment 1

[0029] First, take a 0.05mm thick soda-calcium-silicon ultra-clear float glass substrate without defects and mildew, cut it into a certain size, clean and dry it, and then do the following:

[0030] A. Preparation of the pretreatment layer: After cleaning and drying the prepared glass substrate, place it in a 2 In the liquid reactor, let it stand still for 3 hours, then take it out, put it in a resistance furnace, heat it up to 450°C with the furnace, keep it warm for 1 hour, and form a pretreatment layer on the surface of the glass substrate; during this process, the temperature rise mainly has two functions. SOCl 2 Before the boiling point, appropriately raising the ambient temperature can improve the reactivity; in SOCl 2 Unreacted SOCl remaining on the glass surface after the boiling point 2 The decomposition is complete, and the traditional washing process is replaced by the method of decomposition. The heating up with the furnace is to prevent defects such as glass br...

Embodiment 2

[0034] First, take a 0.2mm thick soda-calcium-silicon ultra-clear float glass substrate without defects and mildew, cut it into a certain size, clean and dry it, and then do the following treatment:

[0035] A. Preparation of the pretreatment layer: After cleaning and drying the prepared glass substrate, place it in a 2 In the liquid reactor, let it stand for 5 hours, then take it out, put it in a resistance furnace, raise the temperature to 500°C with the furnace, keep it warm for 3 hours, and form a pretreatment layer on the surface of the glass substrate;

[0036] B. Preparation of ion-exchange layer: dry silver nitrate and potassium nitrate, mix evenly at a ratio of 10% silver nitrate and 90% potassium nitrate to obtain mixed nitrate, and then heat in an atmosphere furnace filled with dry nitrogen or air to 450°C, and then immerse the glass substrate treated in step A in the mixed nitrate at 450°C, and keep it warm for 10 hours to obtain the ion exchange layer;

[0037] C...

Embodiment 3

[0039]First, take a 0.15mm thick soda-calcium-silicon ultra-clear float glass substrate without defects and mildew, cut it into a certain size, clean and dry it, and then do the following treatment:

[0040] A. Preparation of the pretreatment layer: After cleaning and drying the prepared glass substrate, place it in a 2 In the liquid reactor, let it stand for 4 hours, then take it out, put it in a resistance furnace, raise the temperature to 550°C with the furnace, keep it warm for 2 hours, and form a pretreatment layer on the surface of the glass substrate;

[0041] B. Preparation of ion-exchange layer: dry silver nitrate and potassium nitrate, mix uniformly at a ratio of 0.5% silver nitrate and 99.5% potassium nitrate to obtain mixed nitrate, and then heat in an atmosphere furnace filled with dry nitrogen or air to 400°C, and then immerse the glass substrate treated in step A in the mixed nitrate at 400°C, and keep it warm for 6 hours to obtain the ion exchange layer;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com