Preparation method of anti-dazzle glass

An anti-glare and glass technology, applied in the field of advanced photo frames, can solve problems such as poor performance, low glass transmittance, environmental pollution, etc., and achieve the effects of excellent anti-glare performance, uniform concave-convex structure, and high etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

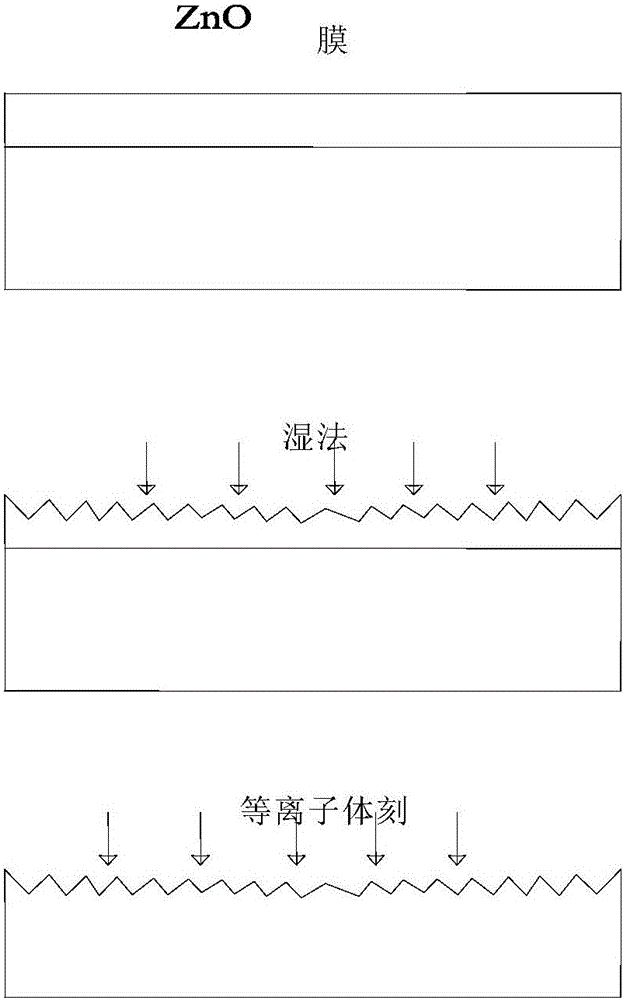

Embodiment 1

[0026] After the electronic display glass is ultrasonically cleaned, it is placed on the substrate holder of the DC magnetron sputtering equipment, and the ZnO ceramic target is used as the target material. The base distance of the target is about 7cm, and the background vacuum is 8.0×10 -4 Above Pa, fill with high-purity Ar gas, and pre-sputter for 10 minutes to remove oxides and other impurities on the target surface. After pre-sputtering, fill it with high-purity Ar gas, the flow rate of Ar gas is 30sccm, the working pressure is 0.5Pa, and the sputtering power density is 6W / cm 2 , the substrate temperature is 300 degrees Celsius, the deposition is 10 minutes, and the film thickness is about 800nm. After the coating is completed, the ZnO-coated glass is taken out, soaked in dilute HCl with a mass fraction of 0.5% for etching, and taken out after etching for 45 seconds. After drying, put it into a plasma etching machine. The etching gas is Ar gas, the flow rate is 30sccm, an...

Embodiment 2

[0028] After the electronic display glass is ultrasonically cleaned, it is placed on the substrate holder of the DC magnetron sputtering equipment, and the ZnO ceramic target is used as the target material. The base distance of the target is about 7cm, and the background vacuum is 8.0×10 - Above 4Pa, fill with high-purity Ar gas, and pre-sputter for 10 minutes to remove oxides and other impurities on the target surface. After pre-sputtering, fill with high-purity Ar gas, the flow rate of Ar gas is 30 sccm, the working pressure is 0.5Pa, and the sputtering power density is 6W / cm 2 , the substrate temperature is 300 degrees Celsius, the deposition is 10 minutes, and the film thickness is about 800nm. After the film coating is completed, the ZnO film glass is taken out, soaked and etched in KOH with a mass fraction of 33%, and taken out after etching for 135s. After drying, put it into a plasma etching machine, the etching gas is Ar gas, the flow rate is 30 sccm, and the dischar...

Embodiment 3

[0030] After the electronic display glass is ultrasonically cleaned, it is placed on the substrate holder of the DC magnetron sputtering equipment, and the ZnO ceramic target is used as the target material. The base distance of the target is about 7cm, and the background vacuum is 8.0×10 -4 Above Pa, fill with high-purity Ar gas, and pre-sputter for 10 minutes to remove oxides and other impurities on the target surface. After pre-sputtering, fill with high-purity Ar gas, the flow rate of Ar gas is 30 sccm, the working pressure is 0.5Pa, and the sputtering power density is 6W / cm 2 , the substrate temperature is 300 degrees Celsius, the deposition is 10 minutes, and the film thickness is about 800nm. After the coating is completed, the ZnO-coated glass is taken out, soaked in dilute HCl with a mass fraction of 0.5% for etching, and taken out after etching for 45 seconds. After drying, put it into a plasma etching machine. The etching gas is CF4 gas, the flow rate is 10sccm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com