Optical laminates, polarizing paltes and image display devices

一种图像显示装置、光学叠层体的技术,应用在光学、光学元件、辨认装置等方向,能够解决防炫层光学特性低、分散稳定性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

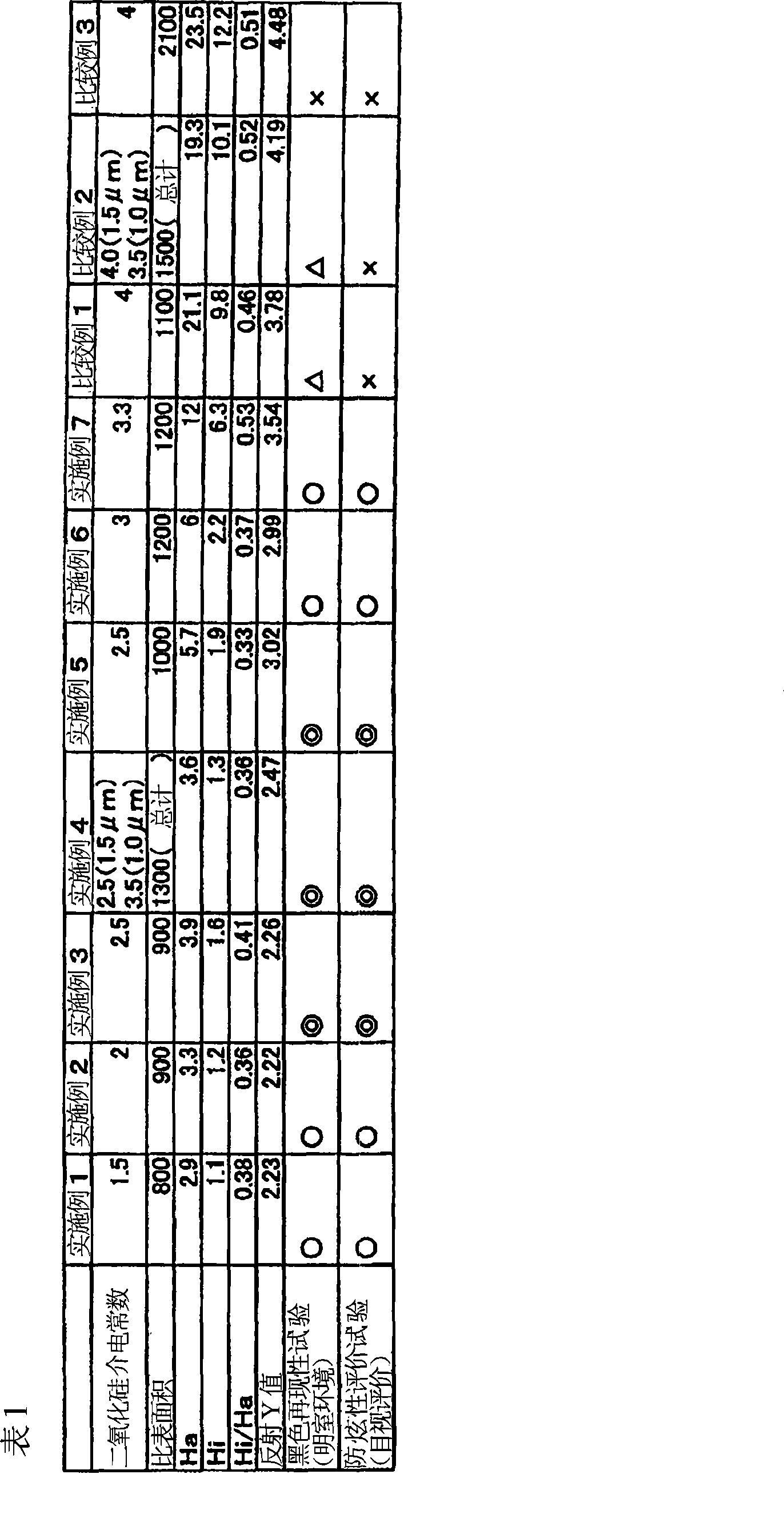

Examples

preparation example 1

[0148] Preparation of resin composition 1 for anti-glare layer formation

[0149] UV curable resin:

[0150] Pentaerythritol triacrylate (PETA) (refractive index 1.51) 20 parts by mass

[0151] Cellulose acetate propionate (molecular weight 50000) 0.25 parts by mass

[0152] Photocuring Initiator:

[0153] Ilgakyyua 184 (manufactured by Chiba Specialty Chemicals Co., Ltd.) 1.2 parts by mass

[0154] Irugakuyua 907 (manufactured by Chiba Specialty Chemical Co., Ltd.) 0.2 parts by mass

[0155] Amorphous silica particles (dielectric constant 2.5) 1.24 parts by mass

[0156] (average particle size 1.0μm, surface hydrophobic treatment with silane coupling agent)

[0157] Silicone leveling agent 0.013 parts by mass

[0158] 34.0 parts by mass of toluene

[0159] 8.5 parts by mass of methyl isobutyl ketone

[0160] Mix the above materials thoroughly to make a composition. This composition was filtered through a filter made of polypropylene with a pore size of 30 μm to prep...

preparation example 2

[0162] Preparation of resin composition 2 for anti-glare layer formation

[0163] UV curable resin

[0164] Pentaerythritol triacrylate (PETA) (refractive index 1.51) 38 parts by mass

[0165] Cellulose acetate propionate (molecular weight 50000) 0.76 parts by mass

[0166] Photocuring Initiator:

[0167] Irugakuyua 184 (manufactured by Chiba Specialty Chemical Co., Ltd.) 2.3 parts by mass

[0168] Irugakuyua 907 (manufactured by Chiba Specialty Chemicals Co., Ltd.) 0.4 parts by mass

[0169] Amorphous silica particles (average particle diameter 1.5 μm, dielectric constant 2.5) 1.16 parts by mass

[0170] Amorphous silica particles (average particle diameter 1.0 μm, dielectric constant 3.0) 7.27 parts by mass

[0171] Silicone leveling agent 0.079 parts by mass

[0172] 60.2 parts by mass of toluene

[0173] 14.1 parts by mass of methyl isobutyl ketone

[0174] Mix the above materials thoroughly to make a composition. This composition was filtered through a filter m...

preparation example 3

[0176] Preparation of resin composition 3 for anti-glare layer formation

[0177] UV curable resin

[0178] Pentaerythritol triacrylate (PETA) (refractive index 1.51) 2.20 parts by mass

[0179] Isocyanuric acid-modified diacrylate M215 (manufactured by Nippon Kayaku Co., Ltd., refractive index 1.51)

[0180] 1.21 parts by mass

[0181] Polymethyl methacrylate (molecular weight 75000) 0.34 parts by mass

[0182] Photocuring Initiator:

[0183] Irugakuya 184 (manufactured by Chiba Specialty Chemicals Co., Ltd.) 0.22 parts by mass

[0184] Irugakuyua 907 (manufactured by Chiba Specialty Chemical Co., Ltd.) 0.04 parts by mass

[0185] Translucent first particle:

[0186] Monodisperse acrylic beads (particle size 9.5 μm, refractive index 1.535) 0.82 parts by mass

[0187] Translucent second particle: 1.73 parts by mass

[0188] Amorphous Silica Ink (Amorphous Silica Ink)

[0189] (average particle size 1.5μm, sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com