Anti-dazzling thin film and preparing method thereof

An anti-glare, thin-film technology, used in optics, instruments, optical components, etc., to achieve good compatibility, broad market prospects, and obvious anti-glare effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

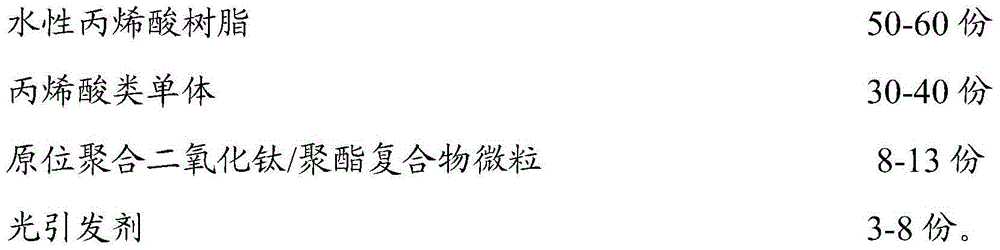

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of in-situ polymerized titanium dioxide / polyester composite particles:

[0023] Add ethylene glycol into the reaction kettle, add terephthalic acid and various additives while stirring to prepare a slurry, pressurize to 0.2MPa under nitrogen protection; control the internal temperature of the reaction kettle to 230-250°C, and the esterification reaction At the end, the pressure is reduced to normal pressure, the temperature is lowered to 230°C, and then nano-titanium dioxide is added to disperse evenly in ethylene glycol, and then added to the reaction kettle, and the temperature is raised to 260°C. After low vacuum and high vacuum stages, the temperature in the polycondensation kettle is controlled to 275 -285°C, the vacuum degree is less than 30Pa, after reaching the required viscosity, inject nitrogen gas to pressurize and discharge, and granulate to obtain composite particles. The average particle size of the particles is controlled at 5 μm, and the co...

Embodiment 2

[0031] 1) Preparation of in-situ polymerized titanium dioxide / polyester composite particles:

[0032] Add ethylene glycol into the reaction kettle, add terephthalic acid and various additives while stirring to prepare a slurry, pressurize to 0.2MPa under nitrogen protection; control the internal temperature of the reaction kettle to 230-250°C, and the esterification reaction At the end, the pressure is reduced to normal pressure, the temperature is lowered to 230°C, and then nano-titanium dioxide is added to disperse evenly in ethylene glycol, and then added to the reaction kettle, and the temperature is raised to 260°C. After low vacuum and high vacuum stages, the temperature in the polycondensation kettle is controlled to 275 -285°C, the vacuum degree is less than 30Pa, after reaching the required viscosity, nitrogen gas is injected to pressurize the material, and the composite particles are obtained by granulation. The average particle size of the particles is controlled at ...

Embodiment 3

[0040] 1) Preparation of in-situ polymerized titanium dioxide / polyester composite particles:

[0041] Add ethylene glycol into the reaction kettle, add terephthalic acid and various additives while stirring to prepare a slurry, pressurize to 0.2MPa under nitrogen protection; control the internal temperature of the reaction kettle to 230-250°C, and the esterification reaction At the end, the pressure is reduced to normal pressure, the temperature is lowered to 230°C, and then nano-titanium dioxide is added to disperse evenly in ethylene glycol, added to the reaction kettle, and the temperature is raised to 260°C. After low vacuum and high vacuum stages, the temperature in the polycondensation kettle is controlled to 275 -285°C, the vacuum degree is less than 30Pa, after reaching the required viscosity, nitrogen gas is injected to pressurize and discharge, and granulate to obtain composite particles. The average particle size of the particles is controlled at 8 μm, and the conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com