Anti-glare film, polarizing plate, liquid crystal panel, and image display device

An anti-glare film and anti-glare layer technology, which is applied in the fields of liquid crystal panels and image display devices, polarizers, and anti-glare films, can solve the problems of reduced contrast and glare, and achieve good black color sense and good anti-glare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0044] Hereinafter, an antiglare film and the like according to a first embodiment of the present invention will be described with reference to the drawings. First of all, in this specification, terms such as "film", "sheet", and "plate" cannot be distinguished from each other only based on the difference in names. Therefore, for example, a "film" is a concept that also includes a member that can also be called a sheet or a plate. As a specific example, the "anti-glare film" also includes members called "anti-glare sheet" or "anti-glare plate". In addition, in this specification, a "weight average molecular weight" is the value obtained by dissolving in solvents, such as tetrahydrofuran (THF), and carrying out polystyrene conversion by the conventionally well-known gel permeation chromatography (GPC) method.

[0045] >>

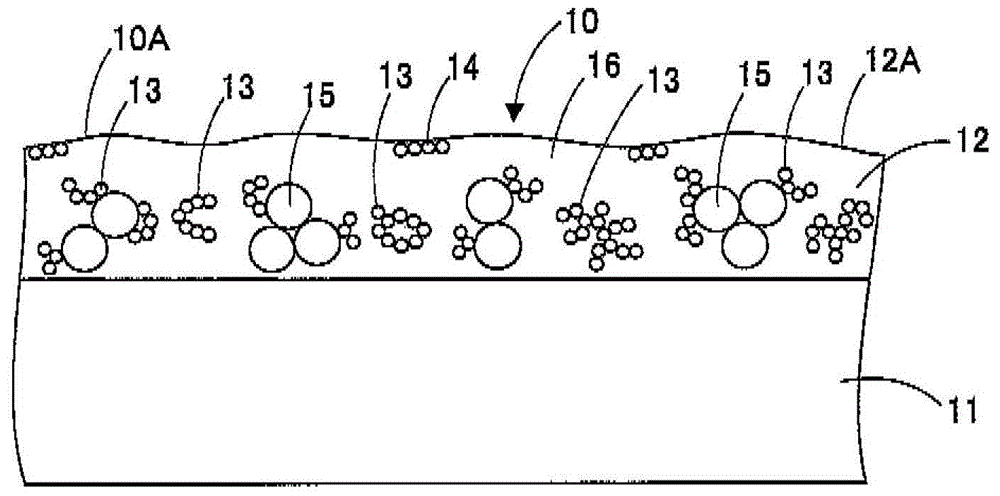

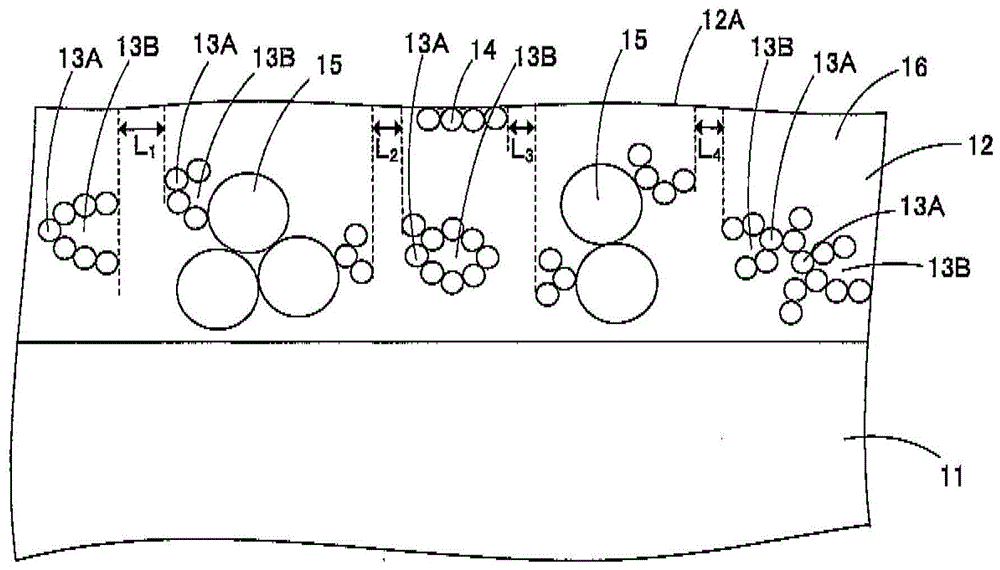

[0046] figure 1 It is a schematic structural diagram of the anti-glare film of this embodiment, figure 2 for figure 1Enlarged view of part of . Such a...

no. 2 approach

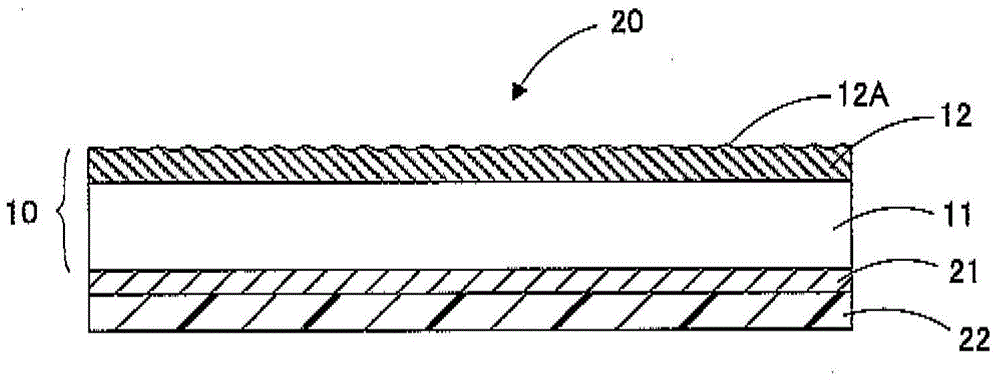

[0175] Next, an antiglare film according to a second embodiment of the present invention will be described with reference to the drawings. It should be noted that, unless otherwise specified, the content overlapping with the first embodiment will be omitted. Image 6 is a schematic configuration diagram of another anti-glare film according to this embodiment, Figure 7 for Image 6 Enlarged view of part of .

[0176] >>

[0177] Such as Image 6 As shown, the antiglare film 50 includes at least a translucent substrate 51 and an antiglare layer 52 provided on the translucent substrate 51 . Since the translucent base material 51 is the same as the translucent base material 11 described in the first embodiment, description thereof will be omitted in this embodiment.

[0178] >

[0179] The antiglare layer 52 includes a first inorganic fine particle aggregate 53 formed by aggregating three or more inorganic fine particles, a second inorganic fine particle aggregate 54 formed...

no. 3 approach

[0201] Next, an antiglare film according to a third embodiment of the present invention will be described with reference to the drawings.

[0202] >>

[0203] Figure 8 It is a schematic structural diagram of the anti-glare film of this embodiment, Figure 9 for Figure 8 Partial enlarged view of Figure 10 for Figure 9 Partial enlarged view of Figure 11 It is a schematic diagram showing the mode of measuring the clarity of the transmitted image of the anti-glare film according to the present embodiment with a transmission image clarity measuring device.

[0204] Such as Figure 8 As shown, the anti-glare film 60 includes a light-transmitting base material 61 and an anti-glare layer 62 provided on the light-transmitting base material 61 and having a concave-convex surface 62A.

[0205] The surface 60A of the anti-glare film 60 forms an uneven surface. In this embodiment, since no functional layer such as a low-refractive index layer is provided on the anti-glare laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com