Hot stamping mold release agent and preparation method and application of hot stamping mold release agent

A release agent and release force technology, which is applied in textiles and papermaking, fiber raw material processing, paper coating, etc., can solve the problems of poor compatibility and release stability, and achieve good adhesion, easy peeling, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

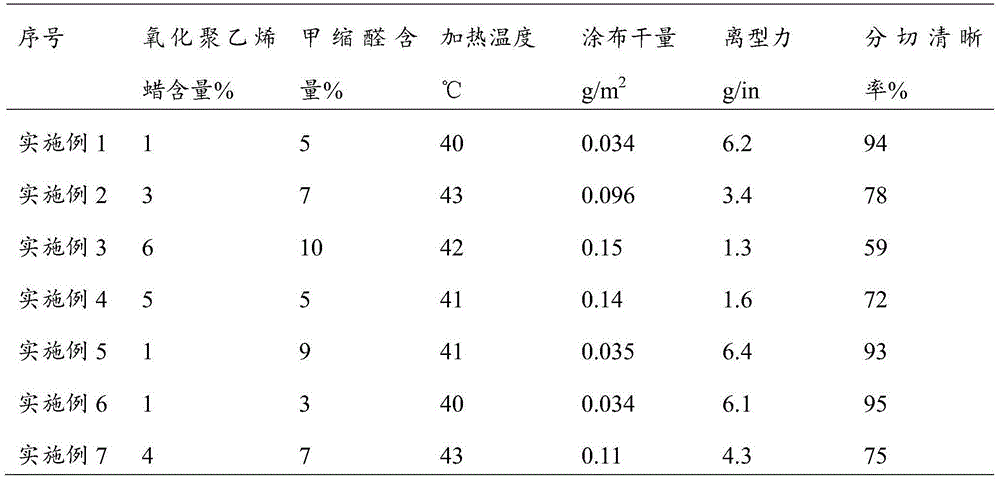

Embodiment 1

[0017] Mix 44% toluene, 10% xylene and 40% methyl ethyl ketone, add 5% methylal, add 1% oxidized polyethylene wax while stirring at 300rpm / min, heat to 40°C, and continue stirring for 15min to obtain hot water. Printing release agent; taking 1000g of hot stamping release agent as 100%, the percentages described are all mass percentages.

[0018] The release force of the hot stamping release agent is 6.2g / in, the cutting clarity rate is 94%, and its coating dry weight is 0.034g / m 2 .

Embodiment 2

[0020] Mix 40% toluene, 20% xylene and 30% methyl ethyl ketone, add 7% methylal, add 3% oxidized polyethylene wax while stirring at 340rpm / min, heat to 43°C, and continue stirring for 15min to obtain hot iron Printing release agent; taking 1000g of hot stamping release agent as 100%, the percentages described are all mass percentages.

[0021] The release force of the hot stamping release agent is 3.4g / in, the cutting clarity rate is 78%, and its coating dry weight is 0.096g / m 2 .

Embodiment 3

[0023] Mix 50% toluene, 18% xylene and 16% methyl ethyl ketone, add 10% methylal, add 6% oxidized polyethylene wax while stirring at 330rpm / min, heat to 42°C, and continue stirring for 15min to obtain hot iron Printing release agent; taking 1000g of hot stamping release agent as 100%, the percentages described are all mass percentages.

[0024] The release force of the hot stamping release agent is 1.3g / in, the cut is clear as 59%, and its coating dry weight is 0.15g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com