Polyester release film for optics

A release film, polyester technology, used in applications, household appliances, other household appliances, etc., can solve the problems of affecting personal health, low coating accuracy, easy to pollute the environment, etc., to reduce the phenomenon of rainbow patterns and ensure coating. The effect of flatness and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

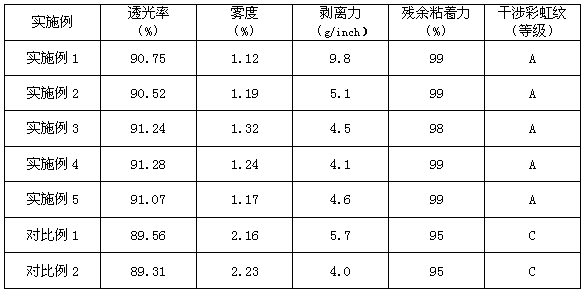

Examples

Embodiment 1

[0018] Take 18 parts of water-based silicone elastomer emulsion DC 7935 (DOW CORNING); 2 parts of crosslinking agent DC 7975 (DOW CORNING); 110 parts of deionized water; the above materials are uniformly dispersed by a high-shear emulsifier to obtain a solid content of 5 % waterborne silicone elastomer coating.

[0019] The pre-crystallization and drying temperature of polyethylene terephthalate slices is about 160-180°C, the crystallization time is 10-20 minutes, and the drying time is 4-6 hours. After drying, the polyethylene terephthalate chip has a pre-crystallinity of 35% to 42%; the moisture content is W(H 2 O) <30ppm. The crystallized and dried polyethylene terephthalate chips enter the twin-screw extruder for heating, melting and plasticization, and the temperature of the extruder is 210°C-280°C. Directly determining the uniformity of the shape and thickness of cast slabs is the key to casting cast slabs. The temperature of the die head is controlled at 260 ° C to 28...

Embodiment 2

[0021] Take 27 parts of water-based silicone elastomer emulsion DC 7950 (DOW CORNING); 3 parts of crosslinking agent DC 7975 (DOW CORNING); 116 parts of deionized water; the above materials are uniformly dispersed by a high-shear emulsifier to obtain a solid content of 8 % waterborne silicone elastomer coating.

[0022] The pre-crystallization and drying temperature of polyethylene terephthalate slices is about 160-180°C, the crystallization time is 10-20 minutes, and the drying time is 4-6 hours. After drying, the polyethylene terephthalate chip has a pre-crystallinity of 35% to 42%; the moisture content is W(H 2 O) <30ppm. The crystallized and dried polyethylene terephthalate chips enter the twin-screw extruder for heating, melting and plasticization, and the temperature of the extruder is 210°C-280°C. Directly determining the uniformity of the shape and thickness of cast slabs is the key to casting cast slabs. The temperature of the die head is controlled at 260 ° C to 28...

Embodiment 3

[0024] Take 36 parts of water-based silicone elastomer emulsion DC 7980 (DOW CORNING); 4 parts of crosslinking agent DC 7975 (DOW CORNING); 116 parts of deionized water; the above materials are uniformly dispersed by a high-shear emulsifier, and the solid content is 10% waterborne silicone elastomer coatings.

[0025] The pre-crystallization and drying temperature of polyethylene terephthalate slices is about 160-180°C, the crystallization time is 10-20 minutes, and the drying time is 4-6 hours. After drying, the polyethylene terephthalate chip has a pre-crystallinity of 35% to 42%; the moisture content is W(H 2O) <30ppm. The crystallized and dried polyethylene terephthalate chips enter the twin-screw extruder for heating, melting and plasticization, and the temperature of the extruder is 210°C-280°C. Directly determining the uniformity of the shape and thickness of cast slabs is the key to casting cast slabs. The temperature of the die head is controlled at 260 ° C to 280 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com