Cracking quality-separation utilization production system of briquette prepared from coal with small particle size

A production system and small particle size technology, which is applied in the field of coal cracking, can solve the problems of slow cracking rate and insufficient cracking of raw coal, and achieve good effect, purification quality and increased product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

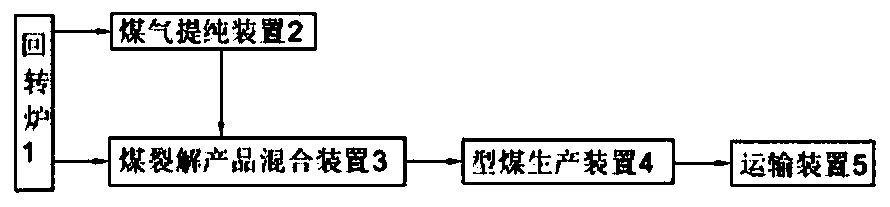

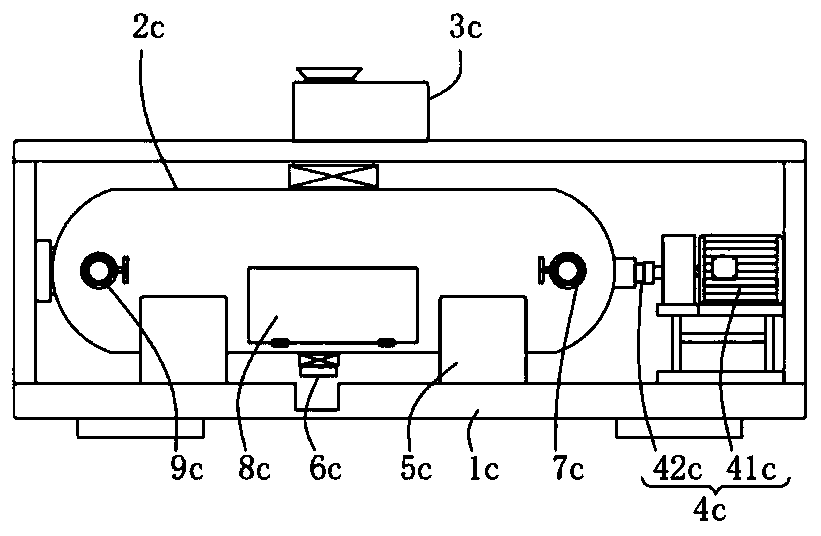

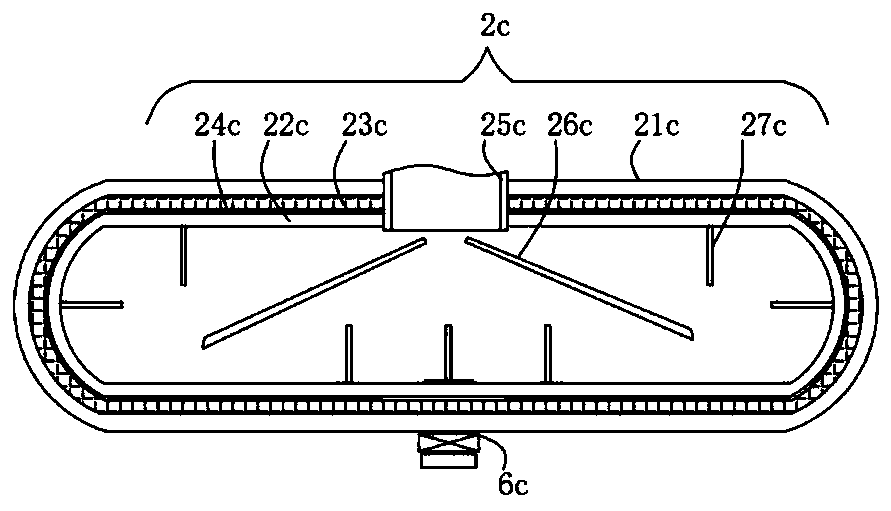

[0044] Please refer to Figure 1-Figure 33 . The pyrolysis, quality, and utilization production system for preparing briquettes from small particle size coal includes: rotary furnace 1, gas purification device 2, coal cracking product mixing device 3, briquette production device 4 and conveying device 5, and the cracked products in rotary furnace 1 The gas in the rotary furnace 1 is purified by the coal gas purification device, and then sent to the cracking product mixing device 3, and the gas purification device 2 is mixed with the coal cracking product through the pipeline The device 3 is connected, and the product in the coal cracking product mixing device 3 is transported to the briquette production device 4, mainly semi-coal is transported to the briquette production device 4 as the main raw material for briquette production, and the product in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com