Spraying device for box of electric hoist

A technology of electric hoist and spraying device, which is applied to the device for coating liquid on the surface, mixer with rotating stirring device, coating, etc., which can solve the problems of difficult cleaning, paint scattering, paint waste, etc., and achieve easy recycling, The effect of reducing waste and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

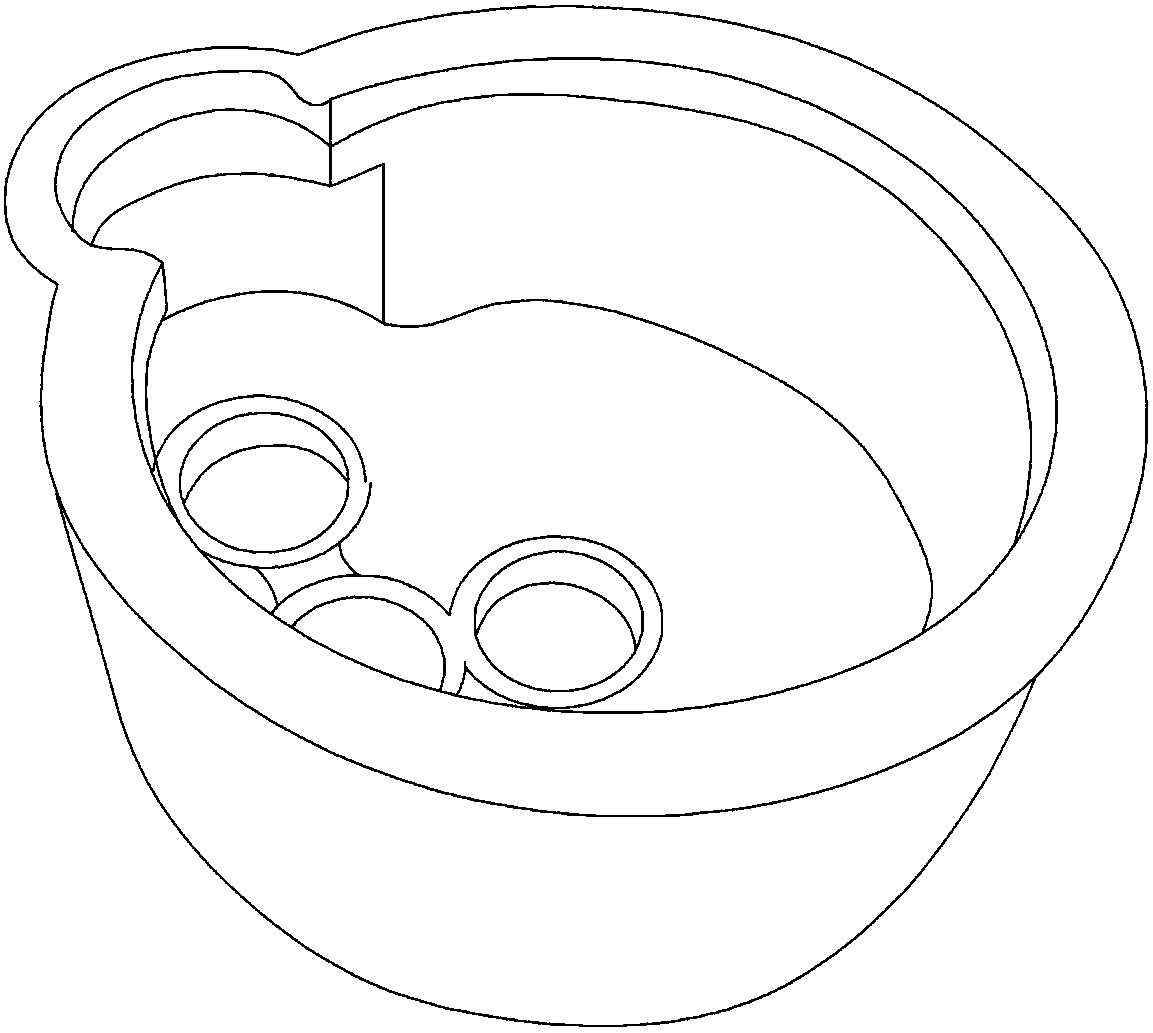

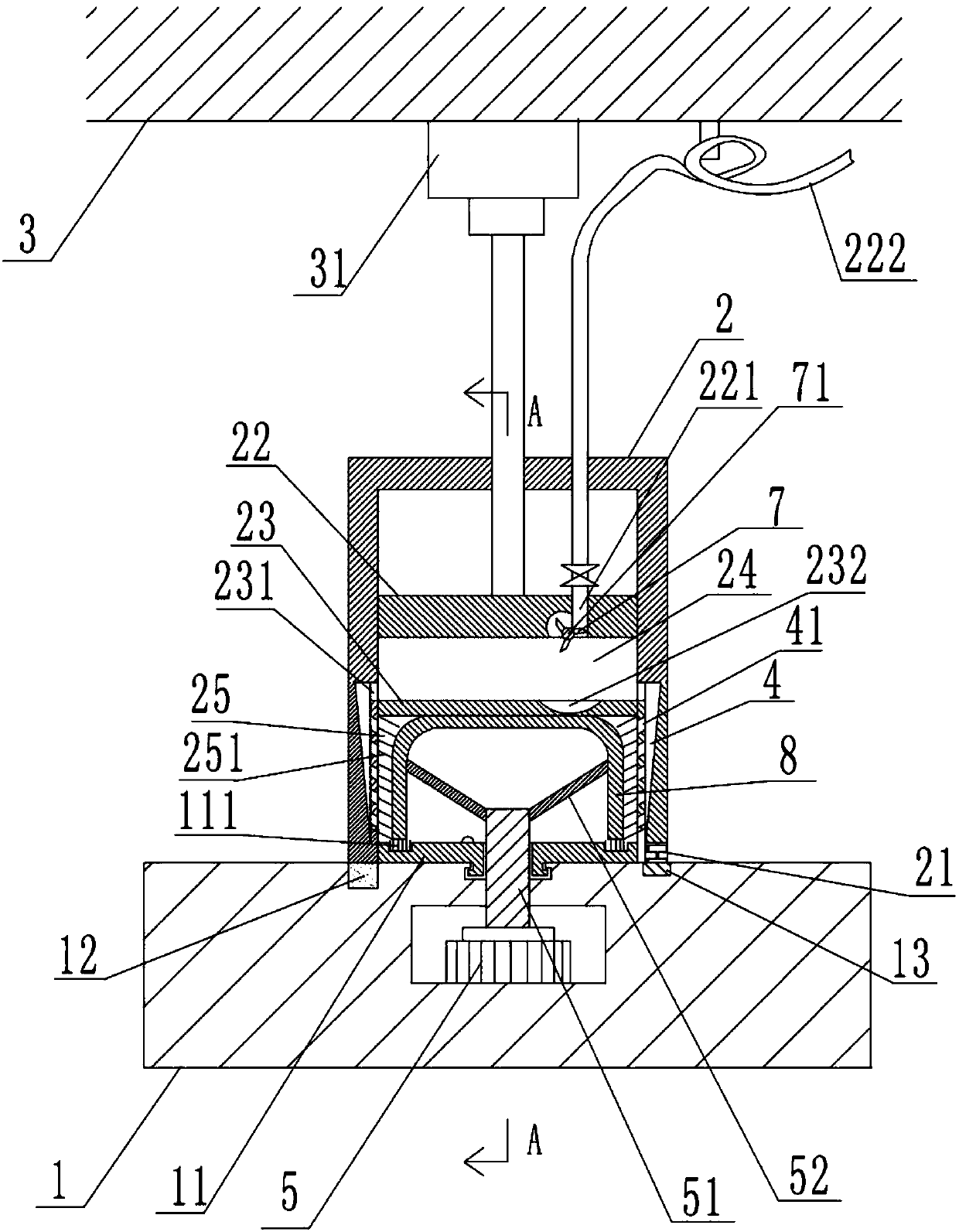

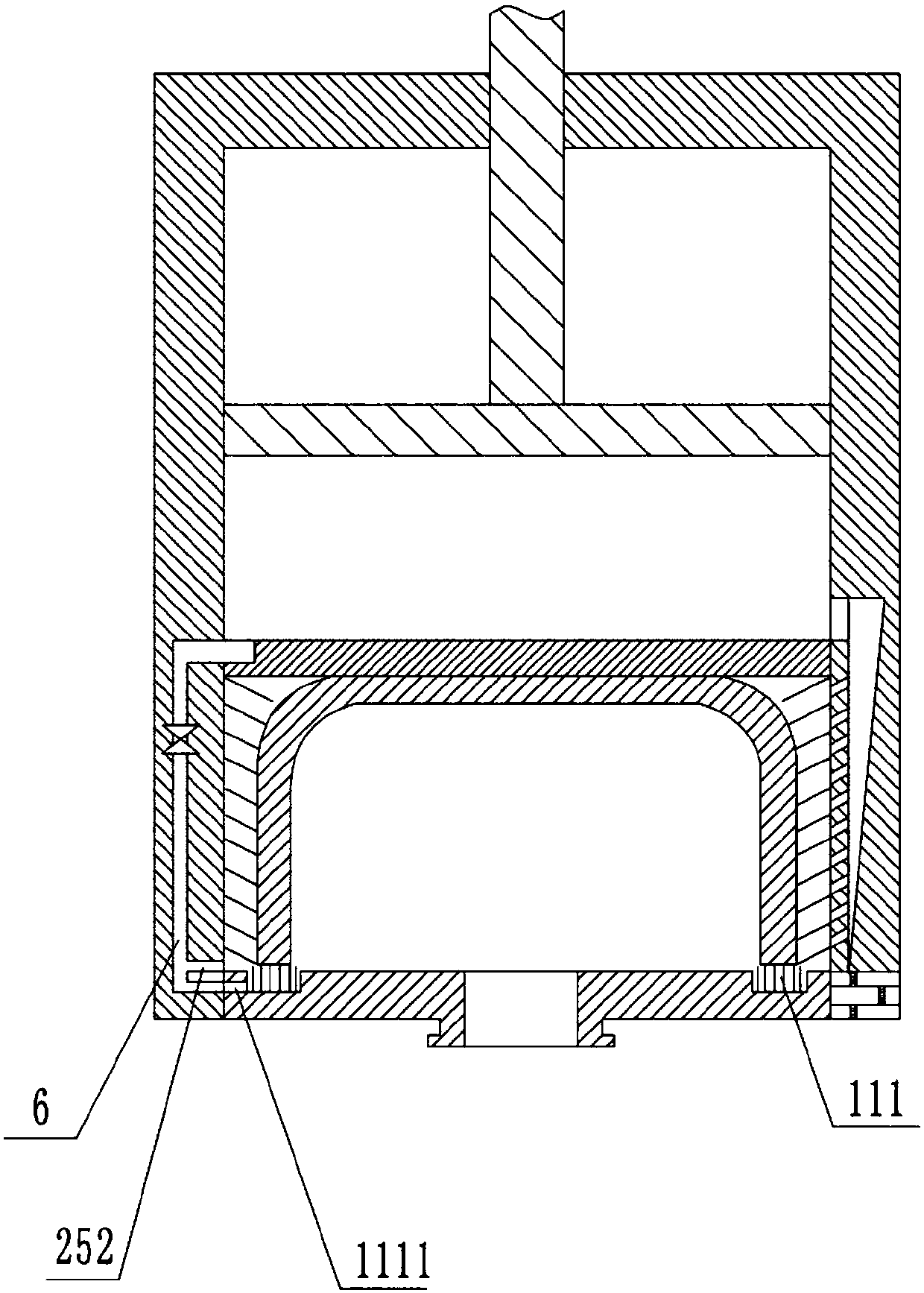

[0024] The reference signs in the accompanying drawings of the description include: spraying station 1, baffle plate 11, second paint brush 111, material return hole 1111, pressure sensor 12, second magnet 13, spraying cover 2, first magnet 21, piston 22 , feed channel 221, feed hose 222, partition 23, suction hole 231, isolation chamber 232, material chamber 24, paint spray chamber 25, first paint brush 251, feed return hole 252, fixed part 3, hydraulic pressure Cylinder 31, paint channel 4, paint spray hole 41, motor 5, rotating shaft 51, support bar 52, return material channel 6, stirring blade 7, stirring rotating shaft 71, electric hoist casing 8.

[0025] Such as figure 1 , figure 2 and image 3 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0026] The electric hoist box spraying device includes a spraying ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com